Page Number - 3

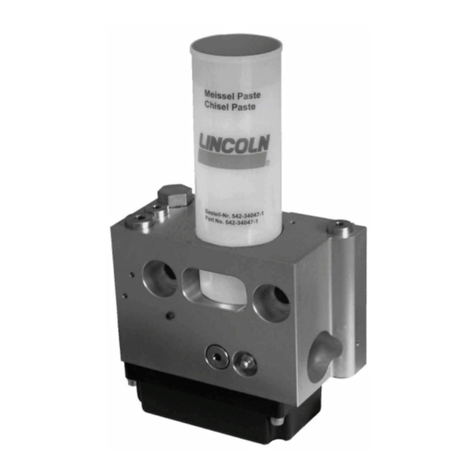

MODEL 4475 & 4480

1:1 AIR OPERATED PUMP

Form 422824

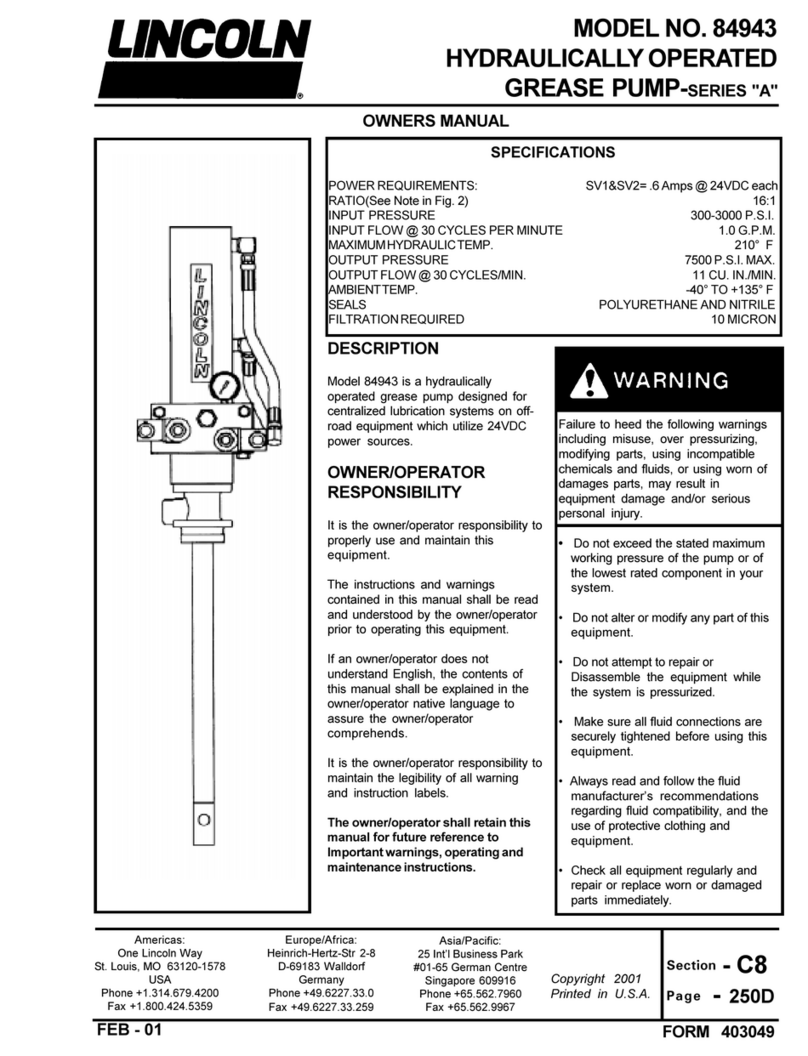

FAILURE TO HEED THE FOLLOWING WARNINGS INCLUDING MISUSE, OVER PRESSURIZING, MODIFYING PARTS, USING

INCOMPATIBLE CHEMICALS AND FLUIDS, OR USING WORN OR DAMAGED PARTS, MAY RESULT IN EQUIPMENT DAM-

AGE AND/OR SERIOUS PERSONAL INJURY, FIRE, EXPLOSION, OR PROPERTY DAMAGE.

Do not exceed the stated maximum working pressure of the pump or of the lowest rated component in your system.

Do not alter or modify any part of this equipment.

Do not operate this equipment with combustible gas or fuel, gasoline, diesel fuel, kerosene, etc.

Do not attempt to repair or disassemble the equipment while the system is pressurized.

Make sure all fluid connections are securely tightened before using this equipment.

Always read and follow the fluid manufacturers recommendations regarding fluid compatibility, and the use of

protecti e clothing and equipment.

Check all equipment regularly and repair or replace worn or damaged parts immediately.

Ne er point the dispensing al e at any part of the body or at another person.

Ne er try to stop or deflect material from dispensing al e or leading connection or component with your hand or body.

Always check equipment for proper operation before each use, making sure safety de ices are in place and operating

properly.

Always follow the pressure relief procedure after shutting off the pump, when checking or ser icing any part of the

system, and when installing, cleaning or changing any part of the system.

Annual inspection by a factory authorized ser ice center is

recommended.

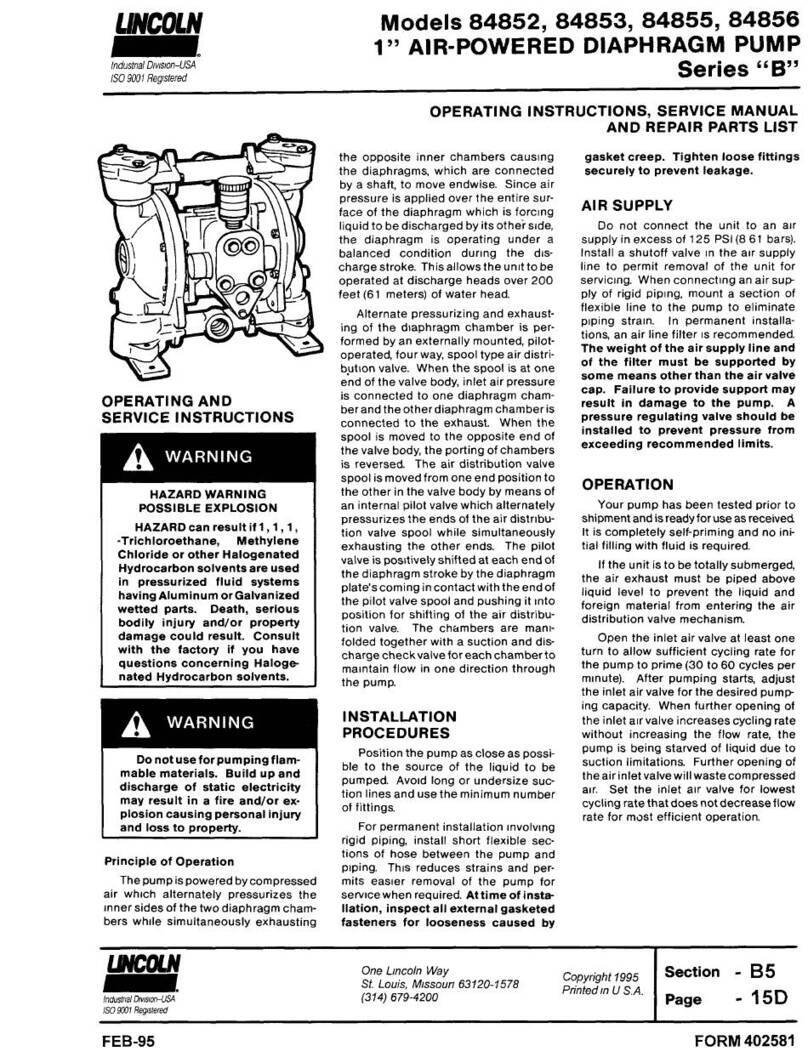

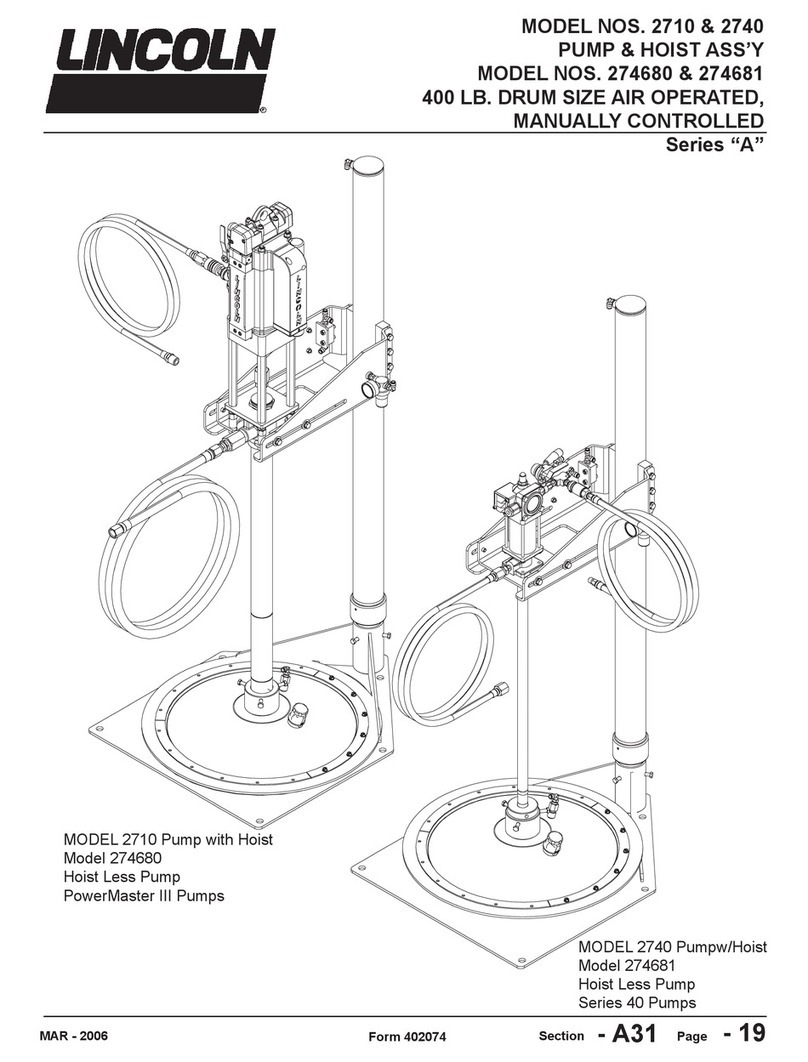

INSTALLATION

Typical bulk tank and drum system hookups are shown and

described as follows only as a guide in selecting and

installing a system. Contact a Lincoln factory representati e

for assistance in designing a system for a specific require-

ment.

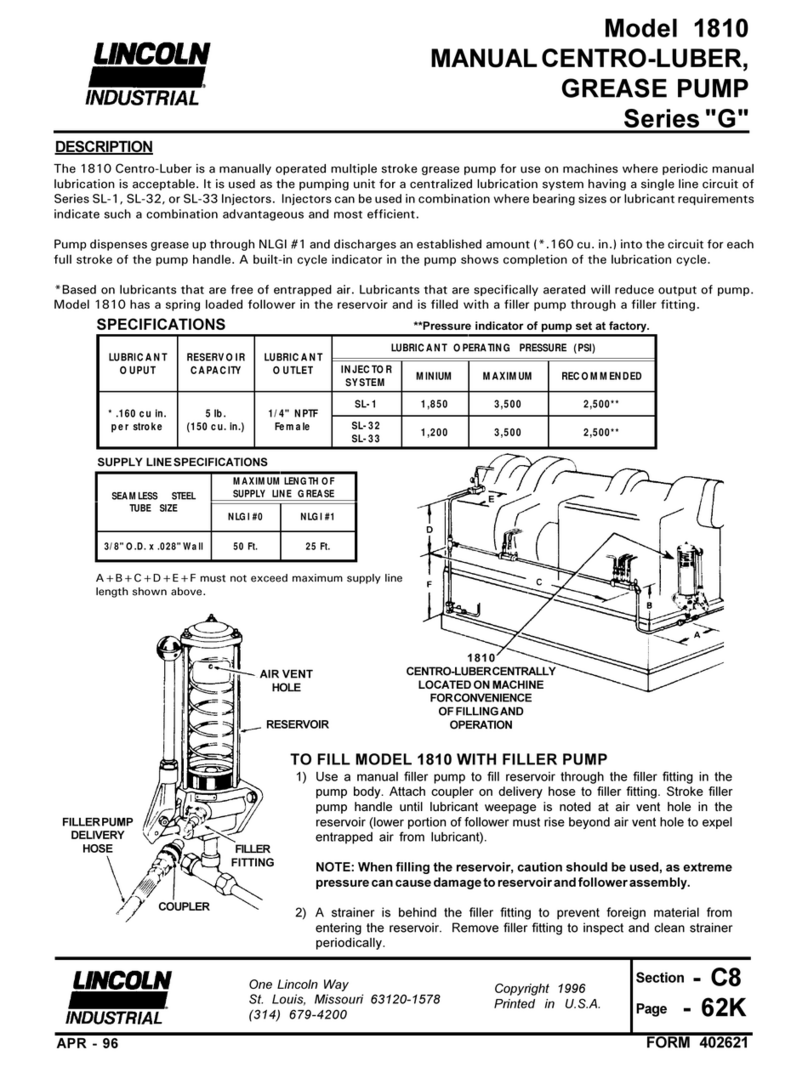

Lincoln recommends using Mini-regulator 602003 (1/4 port

size) with Gage 247843 and 1/4 I.D. Air line supply. See

Figure 3.

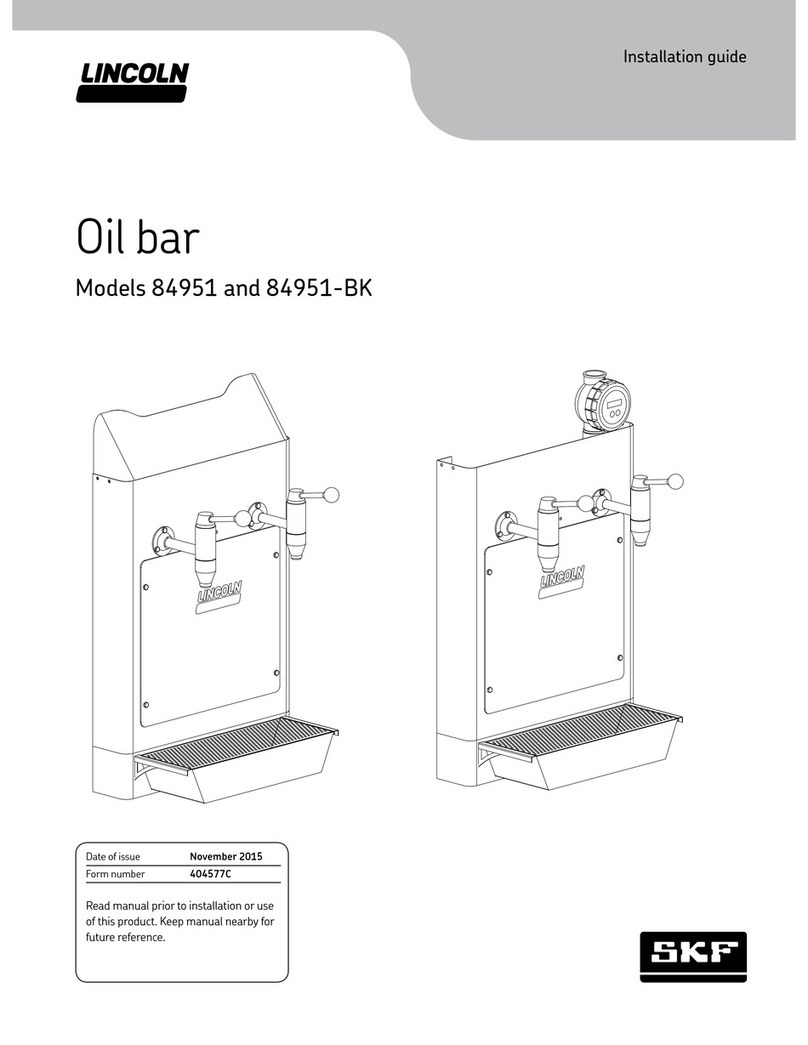

SPIGOT APPLICATIONS

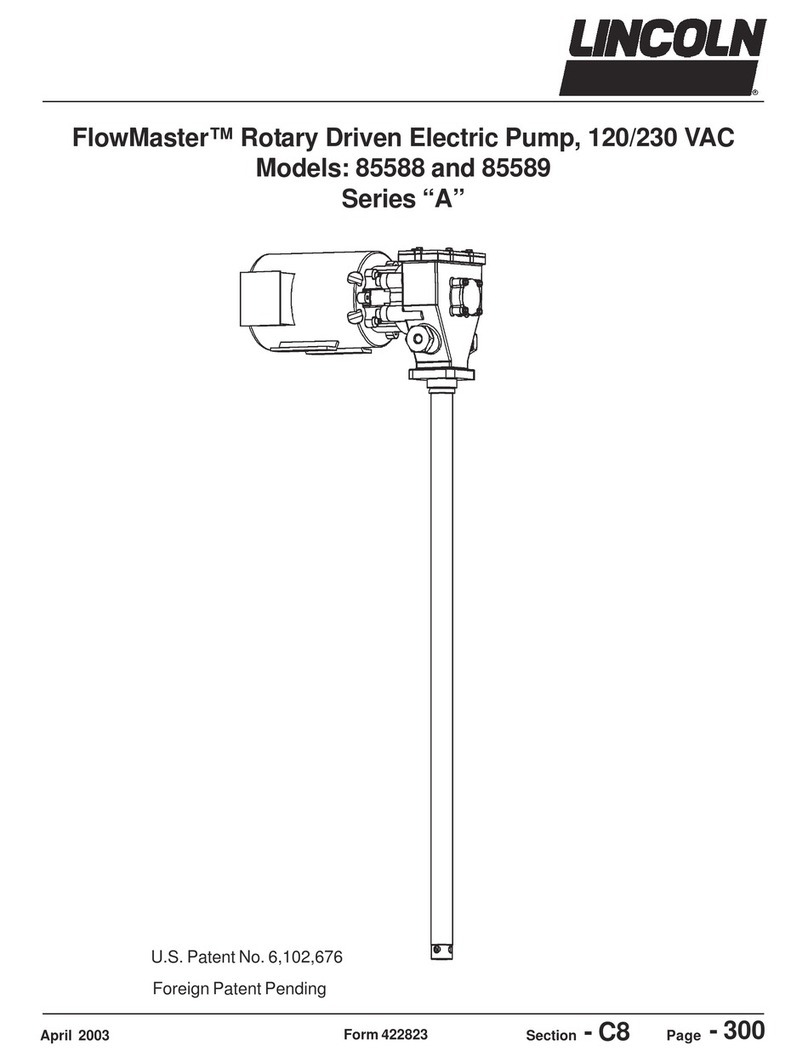

Make sure all connections are tight. Thread the pump tube

into the 3/4 NPT material inlet of the pump as shown in

Figure 1.

Loosen the bung collet and install the bung bushing into the

2 NPT fitting of your drum or tank. Slide the pump and

pump tube into the bung collet and adjust to desired height.

Make sure all connections are securely tightened.

To start pump in spigot applications, turn on the main air

supply. Slowly open the air regulator. Regulate air pressure

from 20-40 psig. Open the dispensing al e 1/4 turn to allow

air to be purged from the system. Allow pump to cycle until

fluid without air pockets flows from dispensing al e, then

close dispensing al e.

In a direct supply system, with adequate air pressure

supplied to the motor, the pump starts when the 1/4 turn

dispensing al e is opened and stalls against pressure

when it is closed.

The pump was tested in lightweight oil which was left in

to protect the pump from corrosion. Flushing the pump

before connecting it to the system might be desired to

pre ent possible contamination of the fluid you are

pumping.

Clean/flush the supply lines, hoses, reducers, connectors

and accessories with mineral spirits or oil based sol ent to

purge any contaminants such as dirt, moisture, or metal

sha ings that could damage the pump or system

components. Blow dry with air.

To reduce the risk of injury from splashing or static

sparking when flushing the pump with sol ents, always

hold a metal part of the dis-pensing al e firmly to the

side of a grounded metal pail and operate at lowest

possible fluid pressure.