Page Number - 4

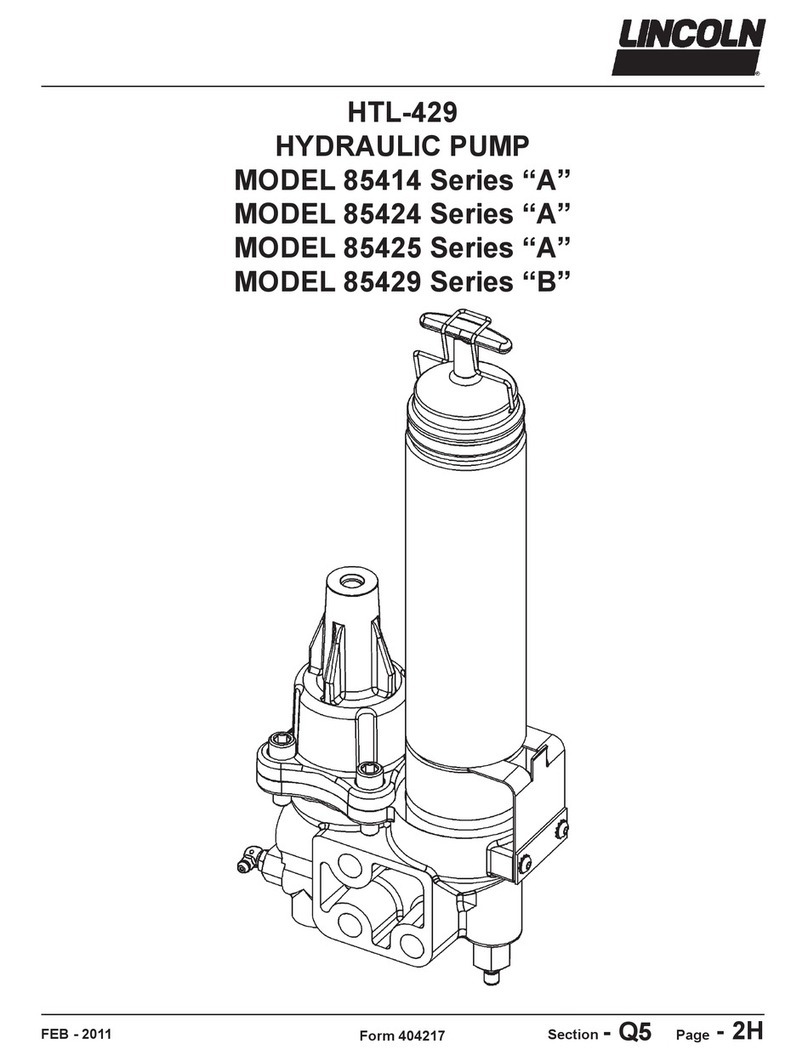

HYDRAULIC HAMMER PUMP

MODEL 85429

Series B

Form 402361

INSTA ING THE PUMP

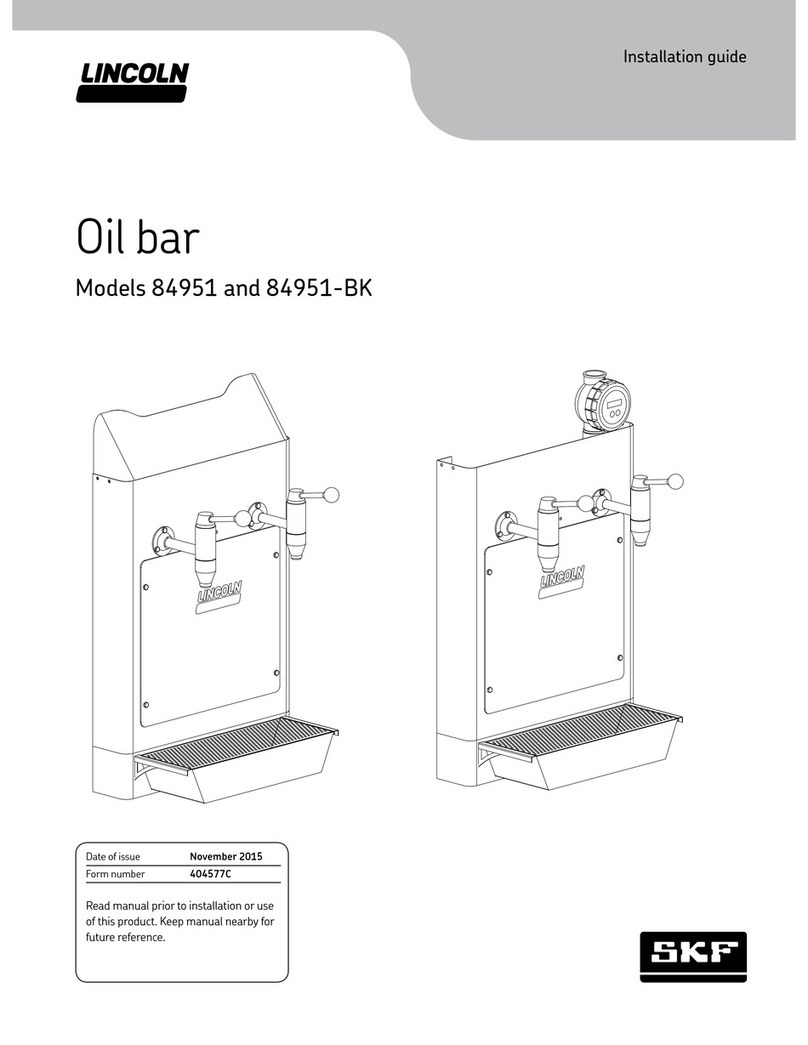

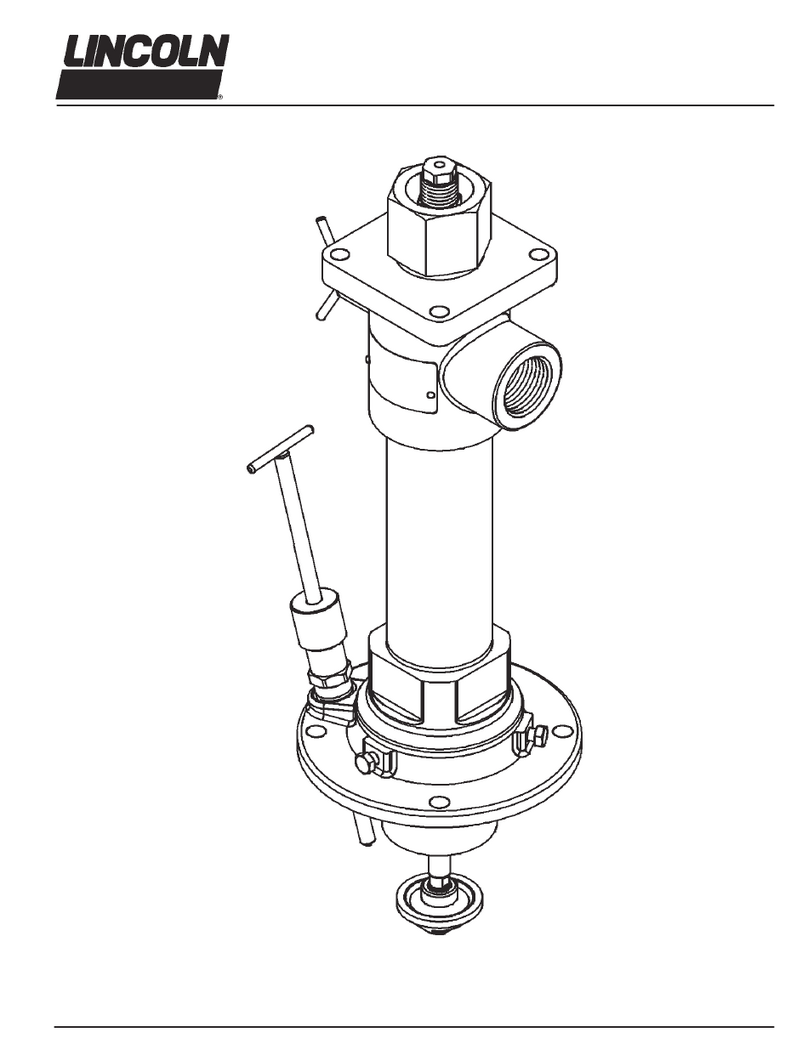

The pump should be installed directly on the hammer or the

carrier adapter for the hammer or attachment. It is prefera-

ble to mount the pump so that the cartridge housing (28) is

in the upright position (as shown on the front page), but

horizontal positioning is acceptable. Allow sufficient space

for cartridge changing and service. (See Fig. #2 for dimen-

sions). The red low-level indicator (18) should be readily

visible. mount the pump in a position that it will be protect-

ed from damage by any debris which may be encountered

when the hammer or attachment is in operation.

IMPORTANT: The feed line to the lube point must also be

protected from damage by armoring the line or other

suitable method of protection.

1. Lincoln recommends using Grade 8 fasteners, or

equivalent, for mounting the pump to the hammer or

adapter. It is important that two flat washer are used

between the bolt head or nut and the pump body of each

fastener. 1/2 grade 8 bolts, nuts and flat washer are

recommended. Apply 120 ft.-lbs. torque to the fasteners.

Fabricate a mounting bracket if necessary.

2. Using appropriate high-pressure hose, connect the

pump hydraulic inlet to the source of hydraulic power.

This may be either the supply or return lines to the

hammer. See above.

3. Fill the pump with lubricant. (See FILLING PUMP WITH

LU RICANT AND AIR PURGING INSTRUCTIONS.)

4. Attach the lubricant feed line to the lube outlet on the

pump.

5. Prime the lubricant feed line with lubricant.

6. Connect the lubricant feed line to the lube point. This

should be a direct connection, avoiding any grease fitting

couplers of possible.

7. Protect the lubricant feed line from damage by covering

with steel channel or angle iron if necessary.

IMPORTANT: The Low Level Indicator Rod (14) will extend

from the bottom of the pump when the grease cartridge

housing is empty. See (Fig. # 3, View D) Replace empty

cartridge or fill cartridge housing promptly with fresh lubri-

cant.

Adjusting the Spring Clip

For the Spring Clip (32) to properly retain the grease car-

tridge housing (28), it must be properly adjusted for either

bulk or cartridge filling. If the pump is to be used with

grease cartridges, the spring clip (32) must be adjusted to

fit tightly in the groove when a grease cartridge installed is

in the grease cartridge housing (28). If the pump is to be

bulk filled or filled with a pump, the spring clip should be

adjusted to fit into the groove tightly with no grease cartridge

installed in the cartridge housing (28). See Illus. #3, View A.

Refer to appropriate section for details on adjustment.

1. 271924 - 0.031 in³ (0.5 cm³)

2. 271925 - 0.018 in³ (0.3 cm³)

3. 271926 - 0.012 in³ (0.2 cm³)

4. 271927 - 0.006 in³ (0.1 cm³)

Always use Lincoln Industrial parts for service and repair.

Maintenance and Repair

Relieve pressure from the pump and supply lines before

servicing or repairing the pump, to reduce the risk of an

injury from injection, splashing fluid or moving parts.

Filling Pump with Grease

Removing Empty Cartridge

1. Disengage the retaining clip from

the follower handle as shown in

the illustration, below.

2. Pull the spring clip of the reservoir

retainer by grasping the finger tab

on the clip and disengage the clip

fingers from the housing groove.

Loosen the Grease Cartridge

Housing a couple of turns to break

the seal.

3. Pull back the follower handle until the follower rod is fully

extended and latch the follower rod groove into the slot in

the tube cap.

4. Unscrew the grease cartridge housing (28) from the pump

head (11).

5. Carefully release the follower handle to eject the empty

cartridge from the container tube.

Installing Grease Cartridge

1. Visually check follower seal lip direction before loading a

new cartridge. The follower seal lip must be directed

toward the follower handle for cartridge loading. See

illustration below. To change the direction of the follower

seal, unscrew the tube cap from the container tube and

pull on handle to remove the follower seal from the tube.

Flip the follower seal over and re-assemble.

2. Pull back on the follower handle and latch the follower

rod groove into the slot on the tube cap.

3. Remove the plastic cap from the grease cartridge and

insert the cartridge into the container tube.

4. Remove the pull-tab from the grease cartridge. Pull the

finger tab on the spring retainer (31) back to clear the

grease cartridge housing (28) as the housing is placed

into the opening in the pump head (11). Screw grease

cartridge-housing (28) into the pump head (11) and

tighten.

5. Release follower rod from slot. Purge air from pump.

See air-purging instructions.

6. Latch the retaining clip over the top of the follower handle

to prevent the follower rod from protruding from the

grease cartridge housing.