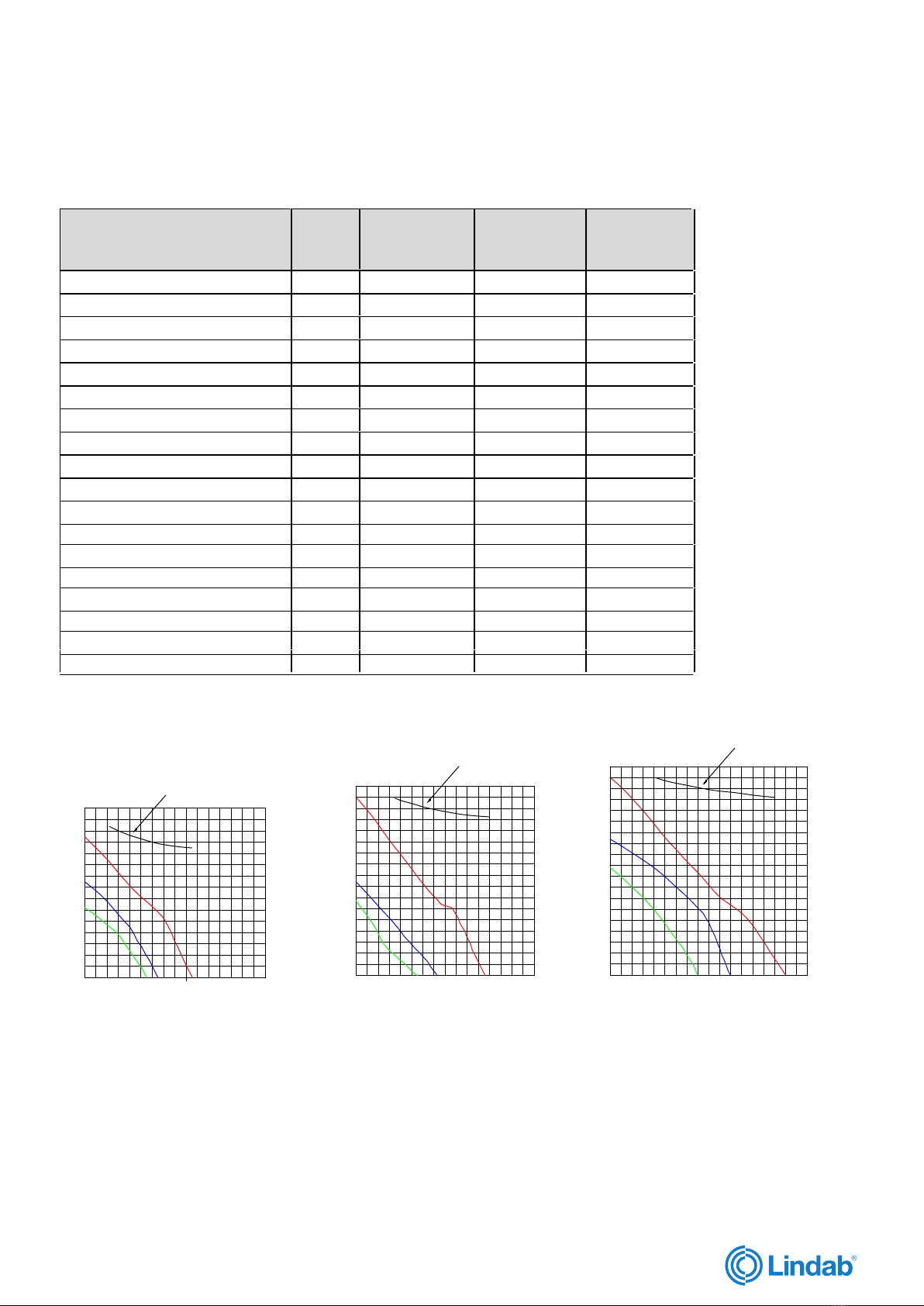

10

Lindab reserves the right to make changes without prior notice

2021-06-08

LinAir HPV

Power Cord Requirement

•It is a Class I appliance, be sure to make a reliable

grounding.

•The yellow-green wire is the grounding wire. It must

not be used for other purposes and cannot be cut. To

prevent the risk of electric shock do not use self-

tapping screws.

•Grounding resistance should be in line with the

national standard requirement of GB17790.

•User must provide a reliable grounding power supply.

Please do not connect grounding wire to places like

water pipes, gas canisters, drain outlets and other

unreliable places recognised by professionals.

•Set an appropriate indoor temperature. The indoor

temperature should not be set too high or too low.

The recommended temperature for cooling is

26-28deg.C, and 18-23deg.C for heating to make

most people feel comfortable.

•Windows and doors should be closed, otherwise, it

will affect the effectiveness of air conditioning.

•Equipment like TVs, radios etc. should be at least

one meter away from the machine, otherwise, they

will interfere with the image and make noise.

•The power of the machine should be shut down if it

is not used for a long time.

•To protect the machine, the power should be

connected for 24 hours before it is used.

•If it is shut down in winter, please clean the machine

and dry it. To protect from dust, please cover the

machine, open the outlet valve to drain out the water

in the heat exchanger and pipes, to prevent frosting.

It is recommended to inject anti-freeze into the pipes.

•Any windows should have curtains or shutters, to

avoid direct sunshine.

•Dry articles should not be put under the machine,

because when the ambient temperature is high or the

drainage is blocked, the machine may drip.

User Cautions

Specification 3 X 1.5 mm2

Model No. 60245 IEC57(YZW)

Grounding Requirements

1. If any abnormality is found (like a

scorching smell), shut down the power,

and contact Lindab, if use is continued

the machine may be damaged and

cause electric shock or fire,

maintenance can only be conducted by

a professional. The power should be

disconnected before touching the wiring

device

2. The machine can be cleaned only when

the power is disconnected, otherwise, it

may cause damage or injury. Don’t

wash the machine with water, or it may

cause electric shock, Stand on a firm

platform when cleaning ceiling air

conditioner