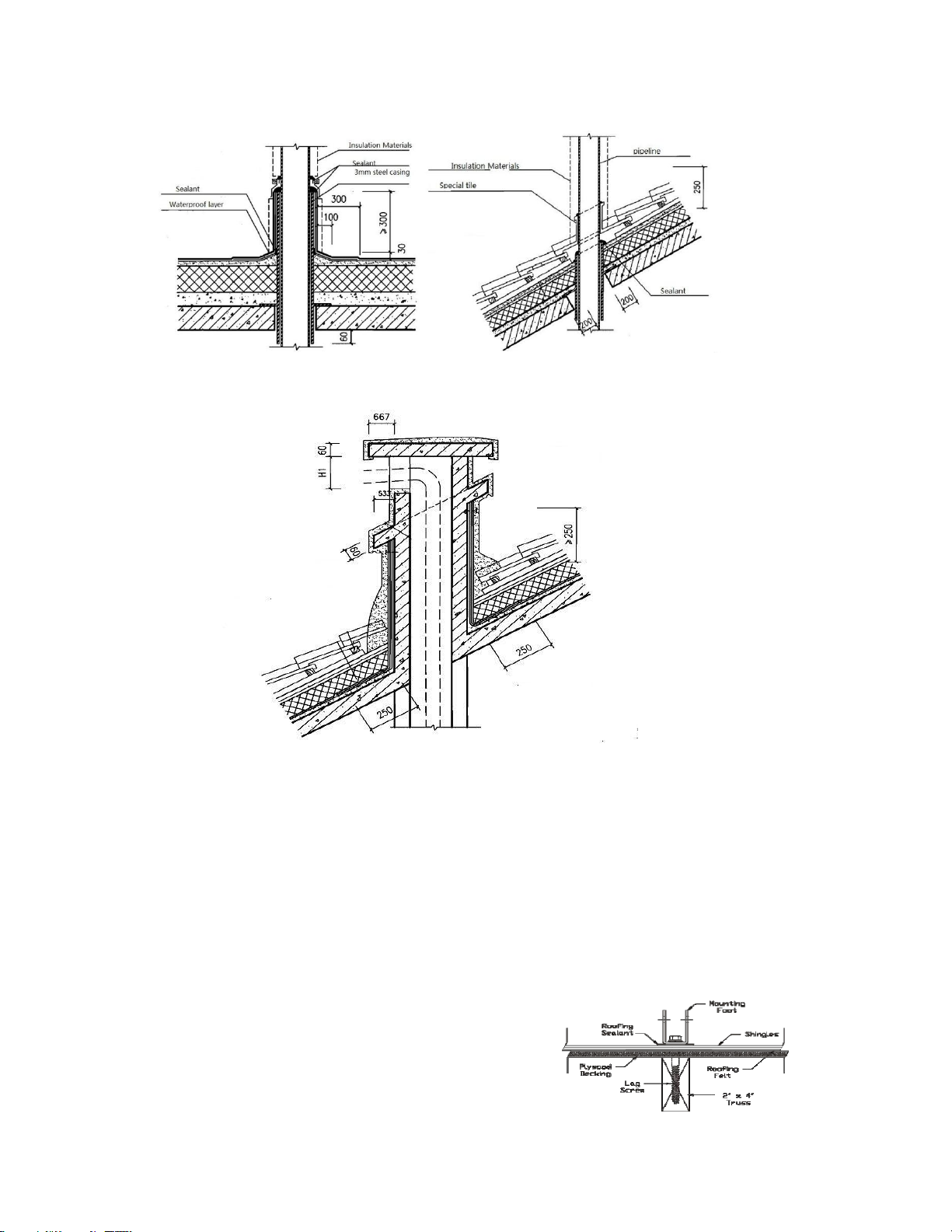

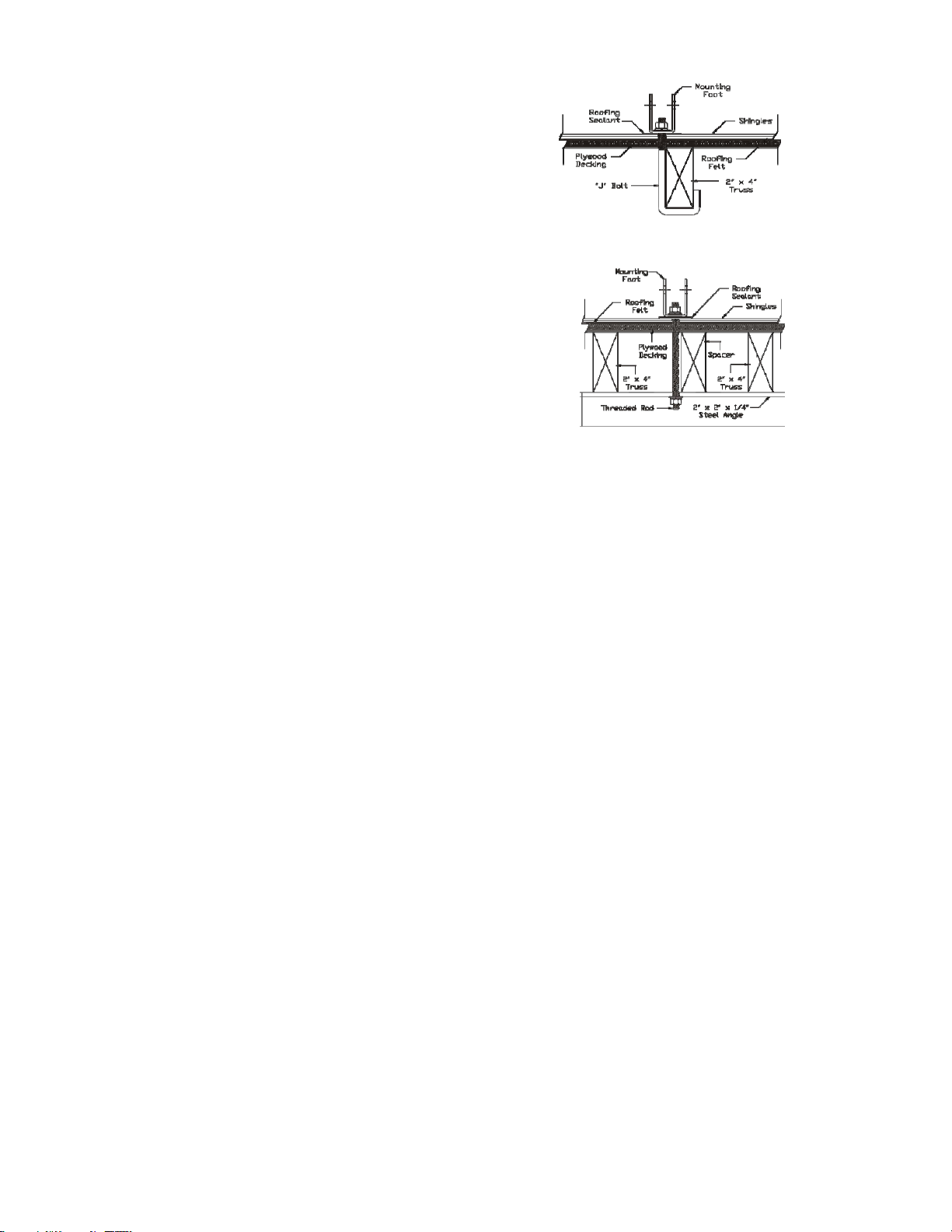

Plumbing Connections

Assemble the hot/cold interface plumbing to the collector as shown in the detail on page 5. Various lengths of ¾”

copper tubing is required and should be soldered together using lead-free solder. Service connections to the

Thermosiphon system should include isolation, mixing and drain valves (provided by installer) internal to the

residence. All hot water pipe and cold water pipe should be insulated and coated or covered to protect from UV

radiation and moisture where exposed to sunlight. Refer to the insulation manufacturer’s installation instructions for

approved methods.

“All components shall be accessible for maintenance and servicing. Components exposed to public traffic

are to be maintained below 140°F or insulated / isolated. The location of components should not impair

accessibility needed to maintain the building or site.”

Drain Valves shall be installed at readily accessible locations as to allow for filling, draining and flushing the solar

system. Ensure that the drain line from the Temperature and Pressure relief is plumbed to a safe location.

Remember this pipe can discharge very hot water carefully consider its location. In-roof piping hangers shall provide

adequate support and correct pitch of pipes. All pipe work connecting the Thermosiphon system to the ER3 system

should be sloped toward drain ports with a drainage slope of no less than 2cm vertical drop for each meter of

horizontal length (1/4” per ft) to allow for gravity draining of the Thermosiphon system. Supports for insulated pipes

should avoid compressing or damaging the insulation material.

For ER3 tanks requiring electricity, an electrician is required to install a domestic electrical outlet socket adjacent the

auxiliary water heater location. The auxiliary electric heating element typically requires a 220-240 volt 60 Hz 1500w

power supply. Be sure to check the electric heating element specification prior to the installation of the electrical

circuit.

NOTE: Use only lead-free solder. Use of 50/50 lead solder is expressly prohibited. Use of galvanized steel, CPVC,

PVC, PEX or any other type of plastic pipe is prohibited. Service connections to the Thermosiphon tank are to be

made using dielectric nipples. WARNING: Dielectric unions are expressly prohibited in these system installations.

ELECTRIC (ER3) INSTALLATION INSTRUCTIONS

Note:

1.

All electrical work must comply with local regulations

2.

All electrical work must be conducted by a suitability licensed electrician.

3.

Installation of the Electric Heating Element must be installed in accordance with the Installation

supplied with the Electric Heating Element.

4.

Overload or over-current protection of electrically operated components shall be consistent with

the maximum current rating of the device and with the provisions of article 240, Chapter 2 of the

National Electrical Code

Important

Do not turn on the power supply until the water heater has been filled with water and pressurized.

Commissioning

When all connections have been completed the solar water heater can be filled with water. Before turning on the cold

water supply open one hot tap within the household to release air from the system during the filling process. Do not

leave the open tap unattended during the filling process.

Turn on the cold water supply and wait for the system to fill. When water flows without air bursts from the open hot

tap it can be closed which will pressurize the solar water heater system. Once the system is pressurized all

connections on the water heater must be checked for leaks and repaired if necessary.

When the system is proven water tight, power can be applied to the ER3 system. To test that the element is

operational turn the circuit breaker in the switch board on and off, you should see the power meters speed change

during this action. The solar water heater is now fully operational.

Customer Hand Over

Once the solar water heater is commissioned and you are confident it is operating correctly, complete the installation

details in the Owners Instructions section of this manual .

Before leaving the installation, insure that the customer is fully aware of the systems operation and whom to contact

should there be any questions in the future.

9