2

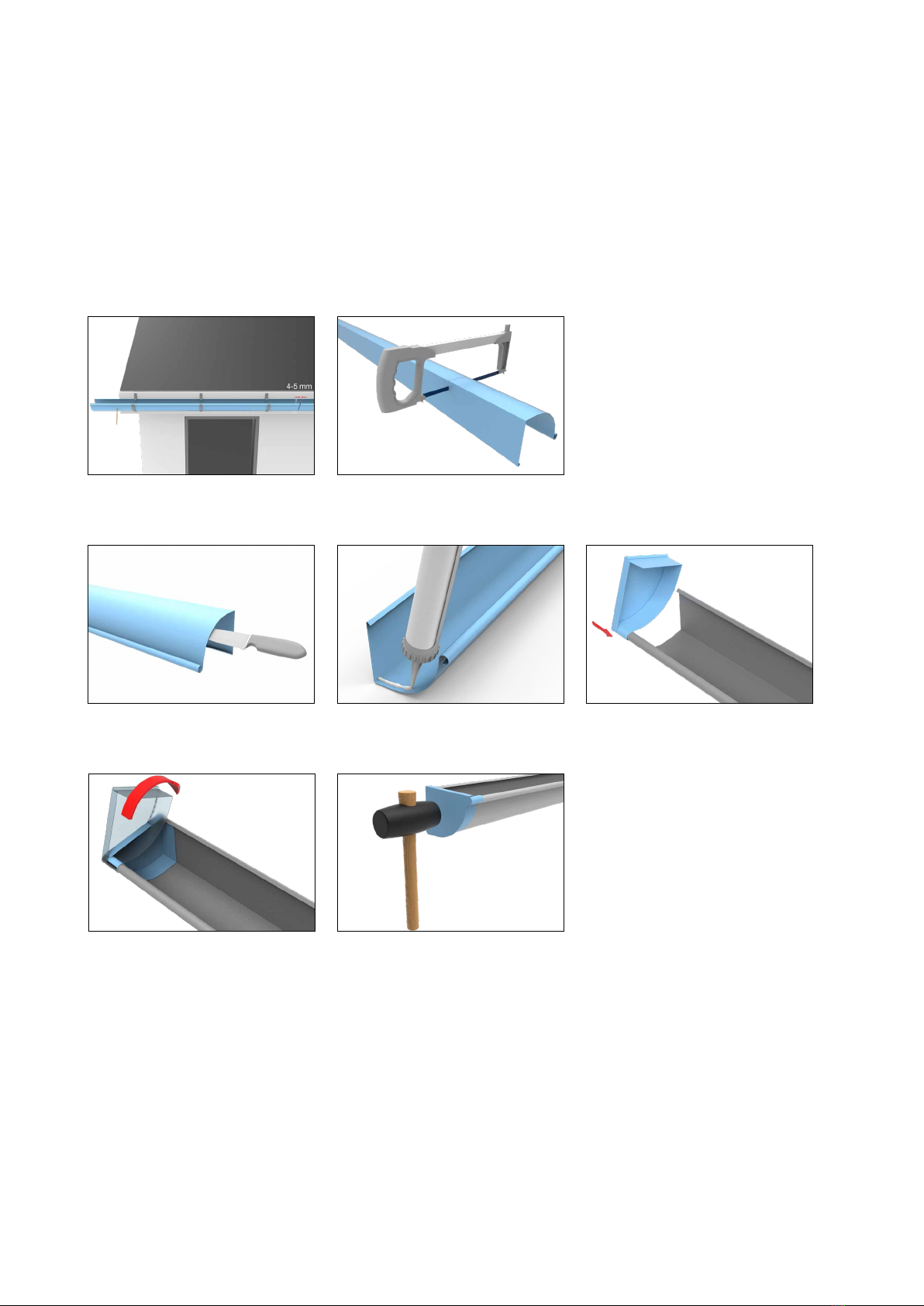

Before you start

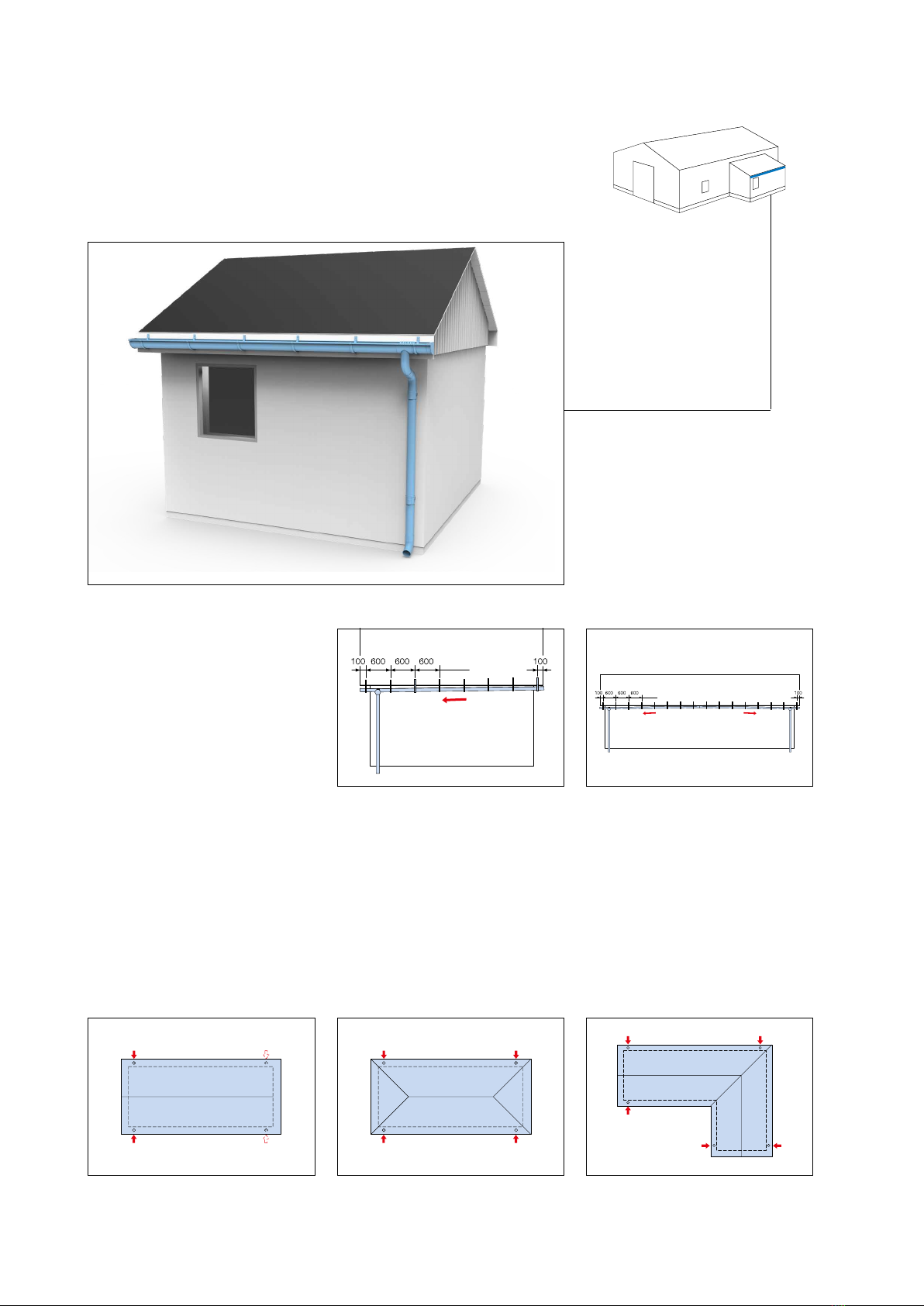

It is the total area of the roof that

decides the dimensions of the roof

drainage system. The bigger the roof,

the more water the system must take

care of. It will pay in the long run to be

careful when you measure your roof

and calculate dimensions. Take your

calculation to your local dealer, who will

help you to pick out all the components

you need. Please, also visit our web

site for dimensioning help.

Measure the roof area

There are various types of roofs but

measure each roof part by multiplying

the roof length with the roof width. If

the area is less than 50 m² use

gutters with 100 mm width and pipes

with 75 mm diameter. If the area is

between 50-100 m² use gutters with

125 mm width and pipes with 87 mm

diameter. If the area is larger than

100 m² there are gutters with

150 mm width and pipes with

100 mm diameter or 190 mm gutters

and 111/120 mm pipes. If there are

different roof sizes on the same

building the largest roof part is dimen-

sional.

Transport, storage, unpacking

Make sure that the roof drainage

components are handled with care

during transport, storage and

unpacking. If not, the coating may be

damaged or the pipes and gutters

dented. Store pipes and gutters on a

plane and stable surface. Non coated

components must be unpacked and

stored in a dry and ventilated place.

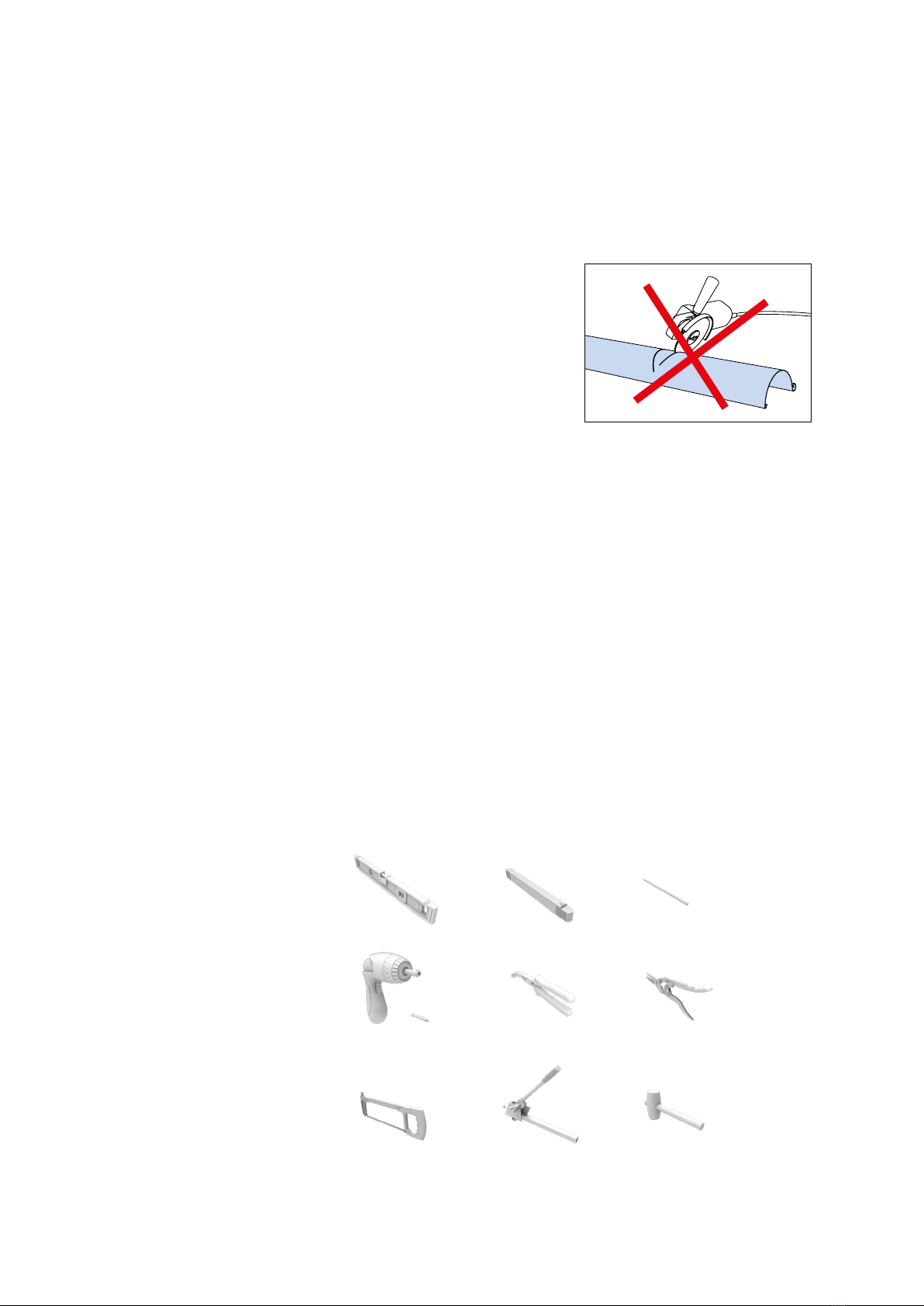

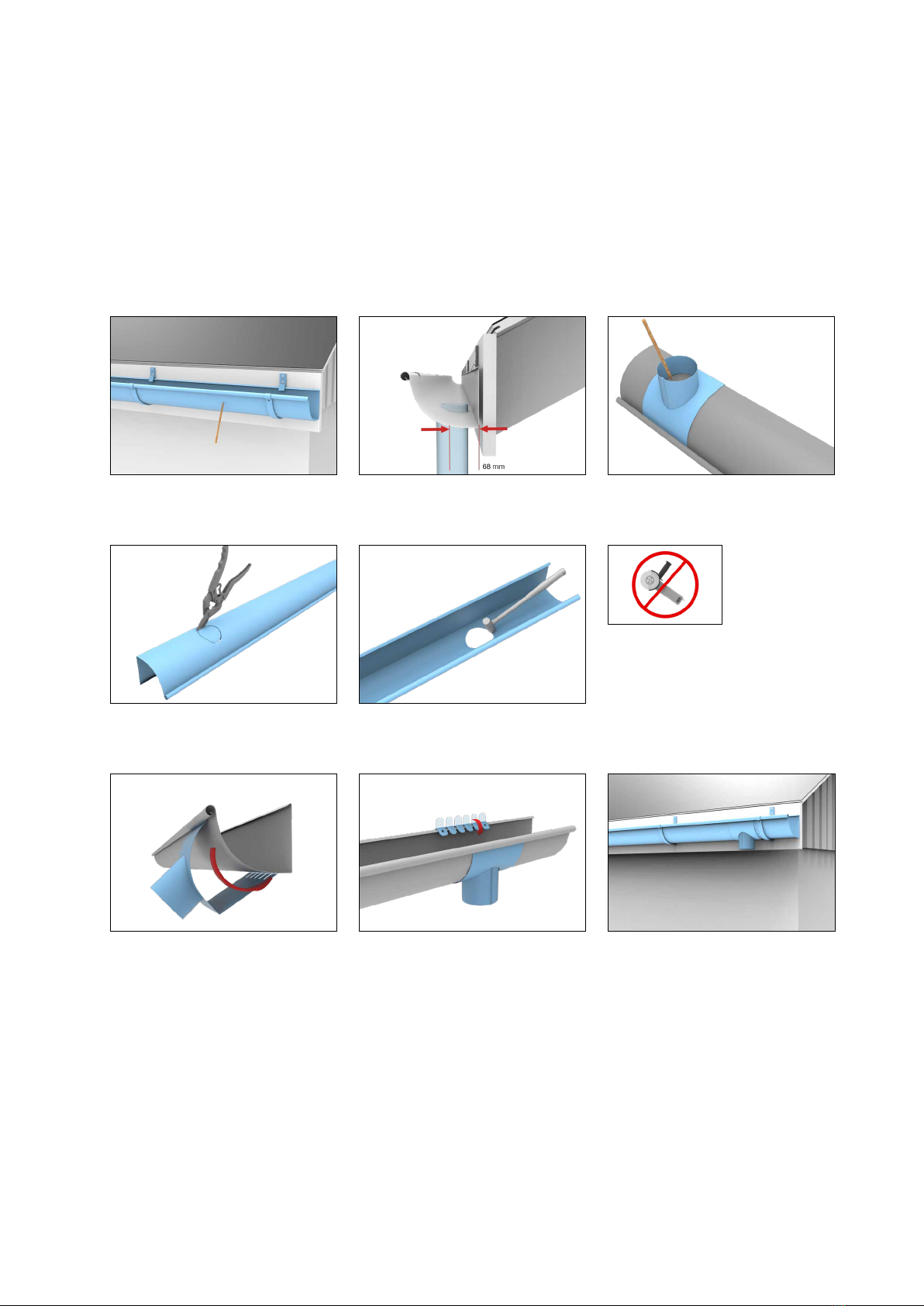

Cutting

Cut the gutters and pipes with plate

shears or a hacksaw on a firm

underlay on the ground. Never use an

angle grinder. It heats the steel up up

and thus destroyes the galvanization.

The coating may also be scorched by

hot chips or filings.

After-treatment

If the coating has been damaged,

paint it with Lindab’s repair paint to

prolong the lifespan of the roof

drainage system.

Maintenance

If you want to keep the roof drainage

system in mint condition, give the

system an overhaul a couple of times

a year. Clean the gutter and pipes

from leaves and twigs. Wash with

water and a mild detergent. Don’t use

a high pressure washing appliance.

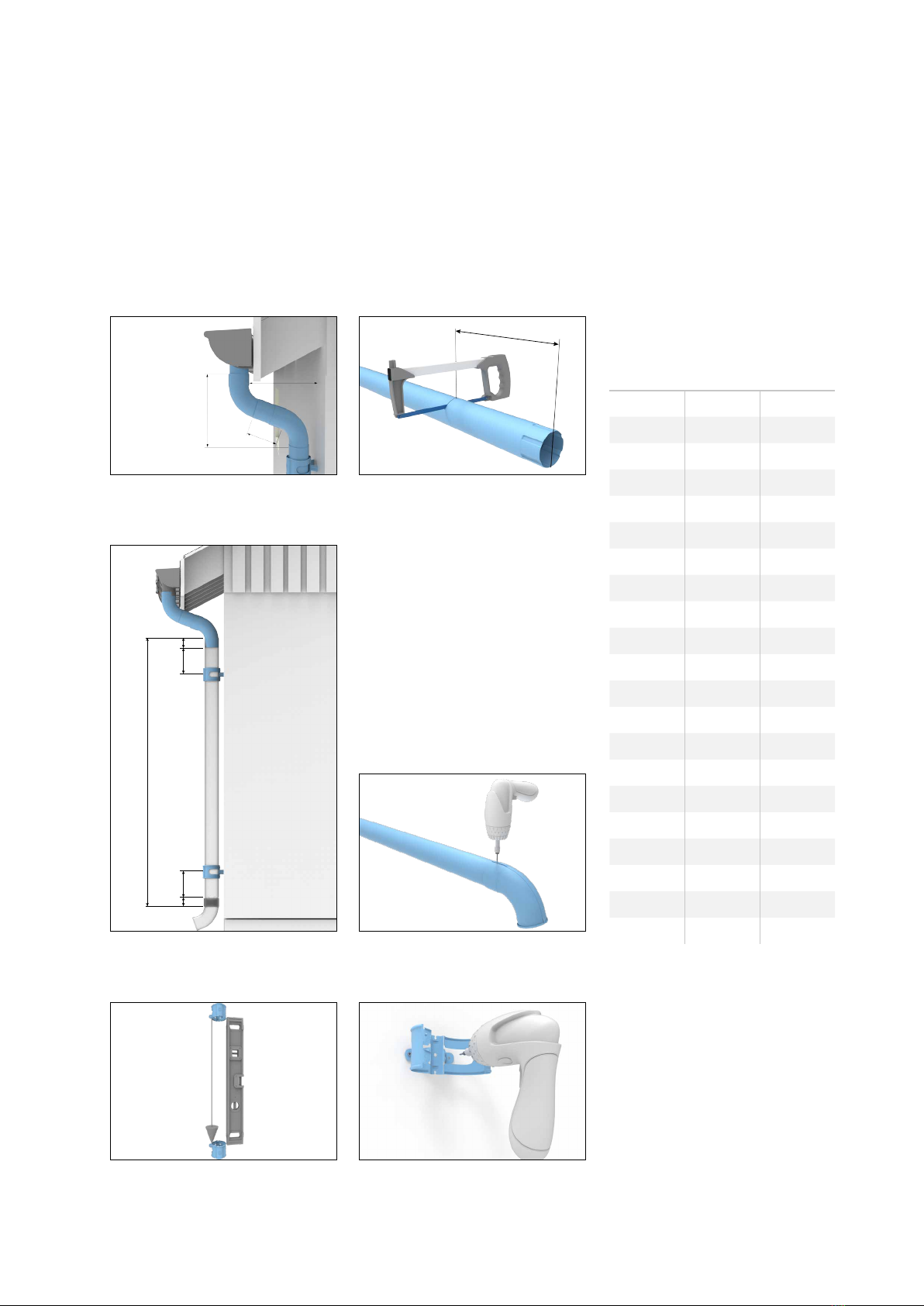

Preparation

Tools

Lindab’s roof drainage system can be

mounted with ordinary hand tools like

pliers, hammer, hacksaw, screwdriver,

folding rule and string. For bending

brackets, you need a bracket bender.

Contact your local dealer and they

will lend you one.

Fastening

The fasteners you need are for

fastening the brackets and the pipe

holders. We always recommend that

you use stainless screws and use the

right screws intended for each

material. The pipe holders are

mounted on the house façade. Check

if it´s wood, concrete or bricks.

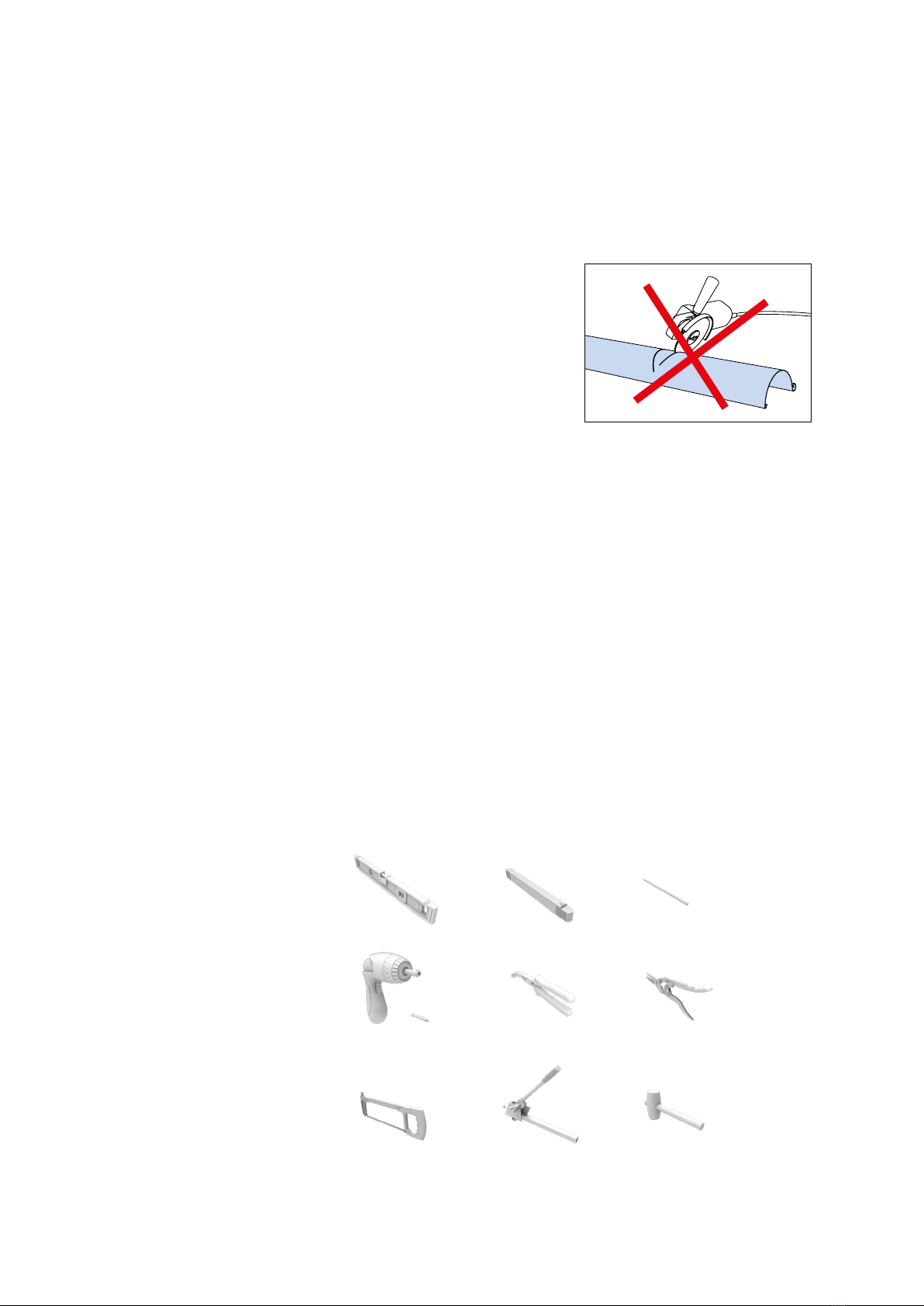

Never use an angle grinder

Spirit level

Screw driver

Hack saw

Folding rule

Seam plier

Bracket bender

Pencil

Steel scissors

Rubber hammer