Premum

2

We reserve the right to make changes

1.0 Installation

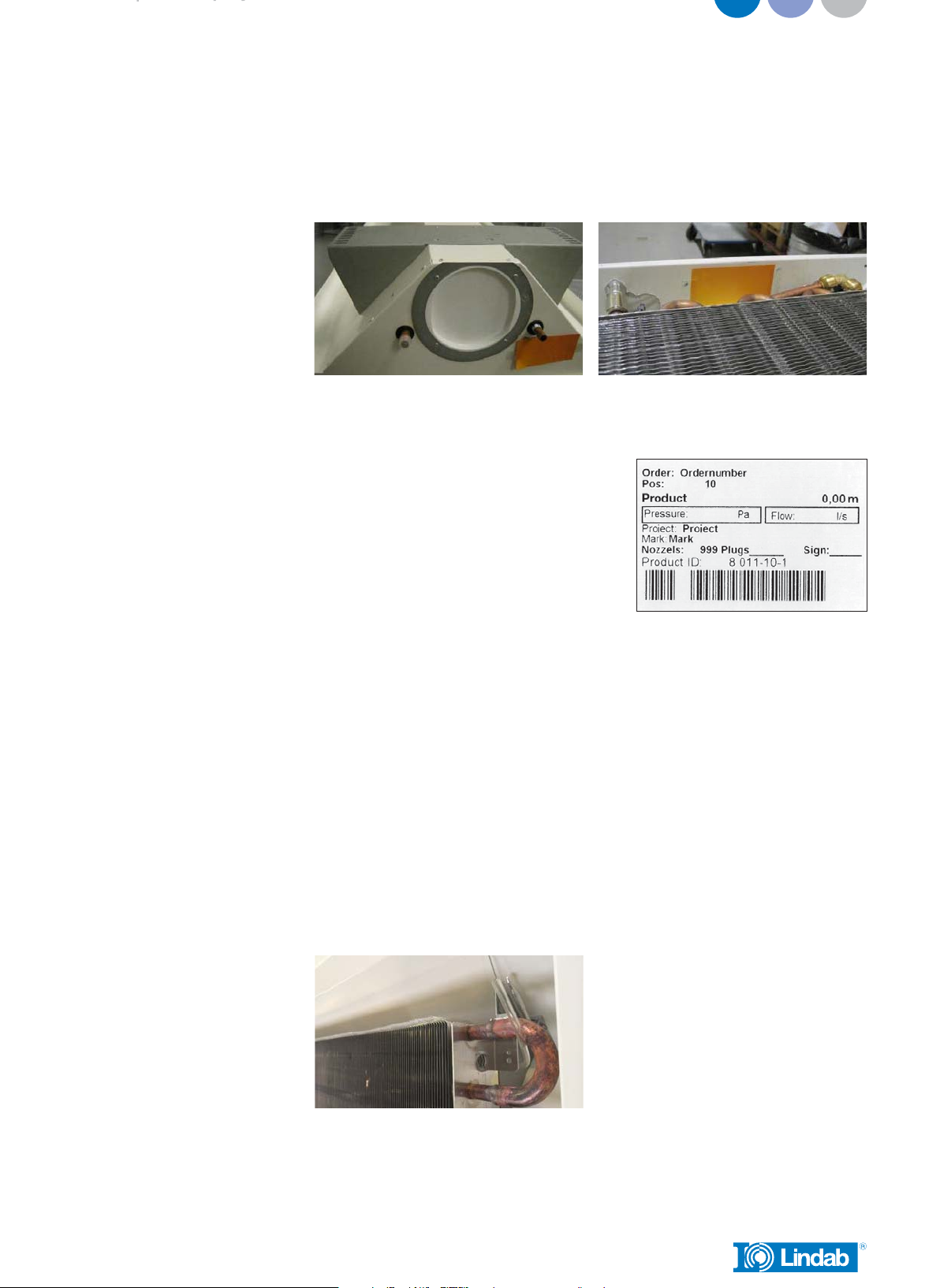

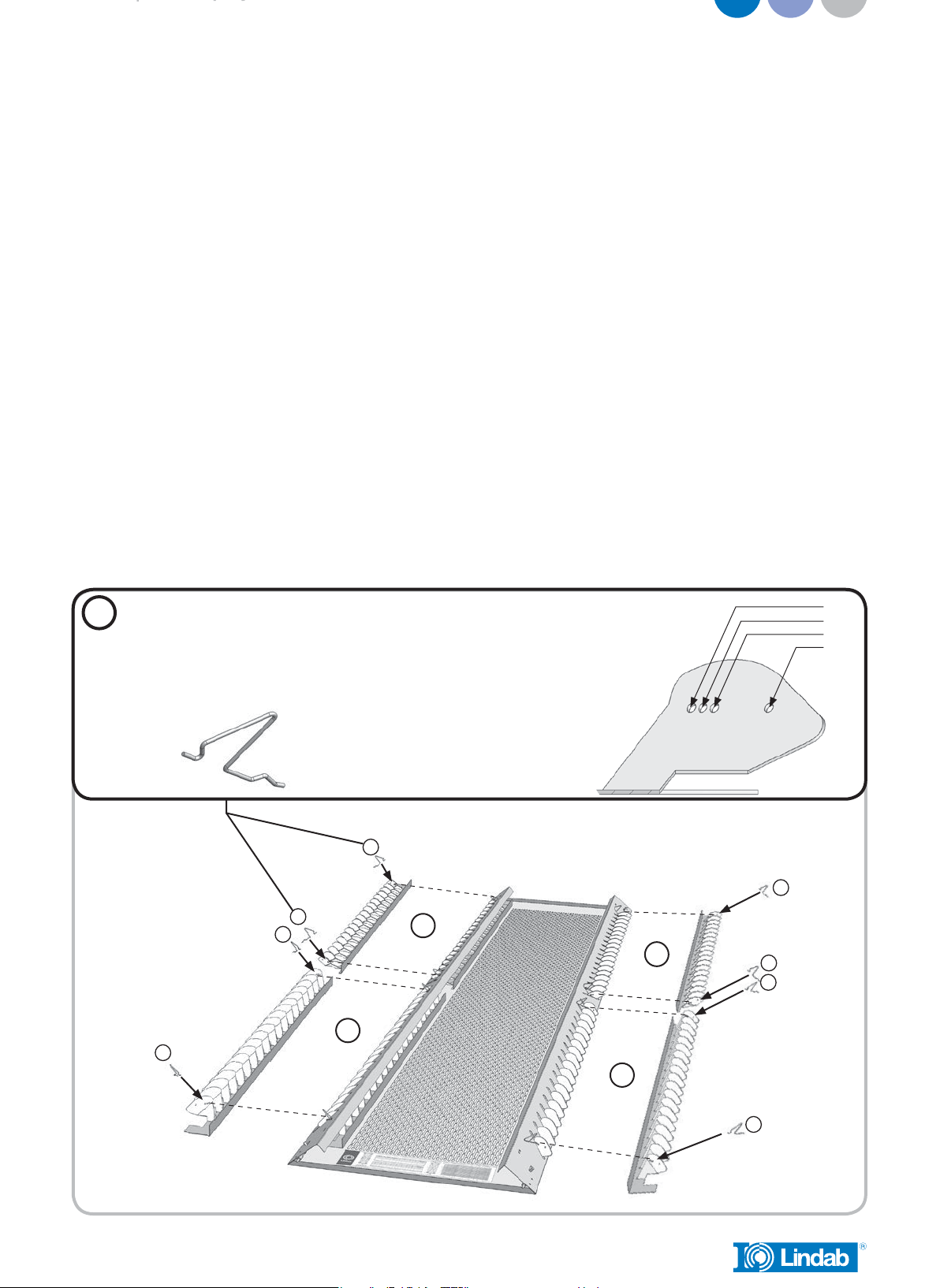

1.1 Product description

Lindab’s supply air beam Premum can be used for cooling, heating and ventilation.

Water valves, actuators, Regula Secura, Regula Combi and Regula Connect can all

be built into the Premum beam.

Premum feature the Lindab JetCone, a innovative way of regulating air volume. The

air volume can easily be adjusted without having to worry about pressure and noise

issues. And with the new adjustable AirGuide system, altering the flow pattern is

simpler than ever.

The Premum chilled beam is fully integratable with the Lindab eHybrid solution and

together they provide an optimal energy efficient ventilation and cooling solution

1.2 Handling

The beam must be handled with care, ensuring that the beam does not sustain dents,

scratches or bends during installation.

Always seek to lift the beam at multiple points.

– Do not lift in pipes

– Do not lift in edges

– Each beam is equipped with protective film to avoid any damage during transport

and handling at building site. The film needs to be removed before commissioning

the products.

1.3 Mounting instruction

– Please visit www.lindqst.com

• Select Documentation Finder

• Select “Premum”

• Select “Mounting”

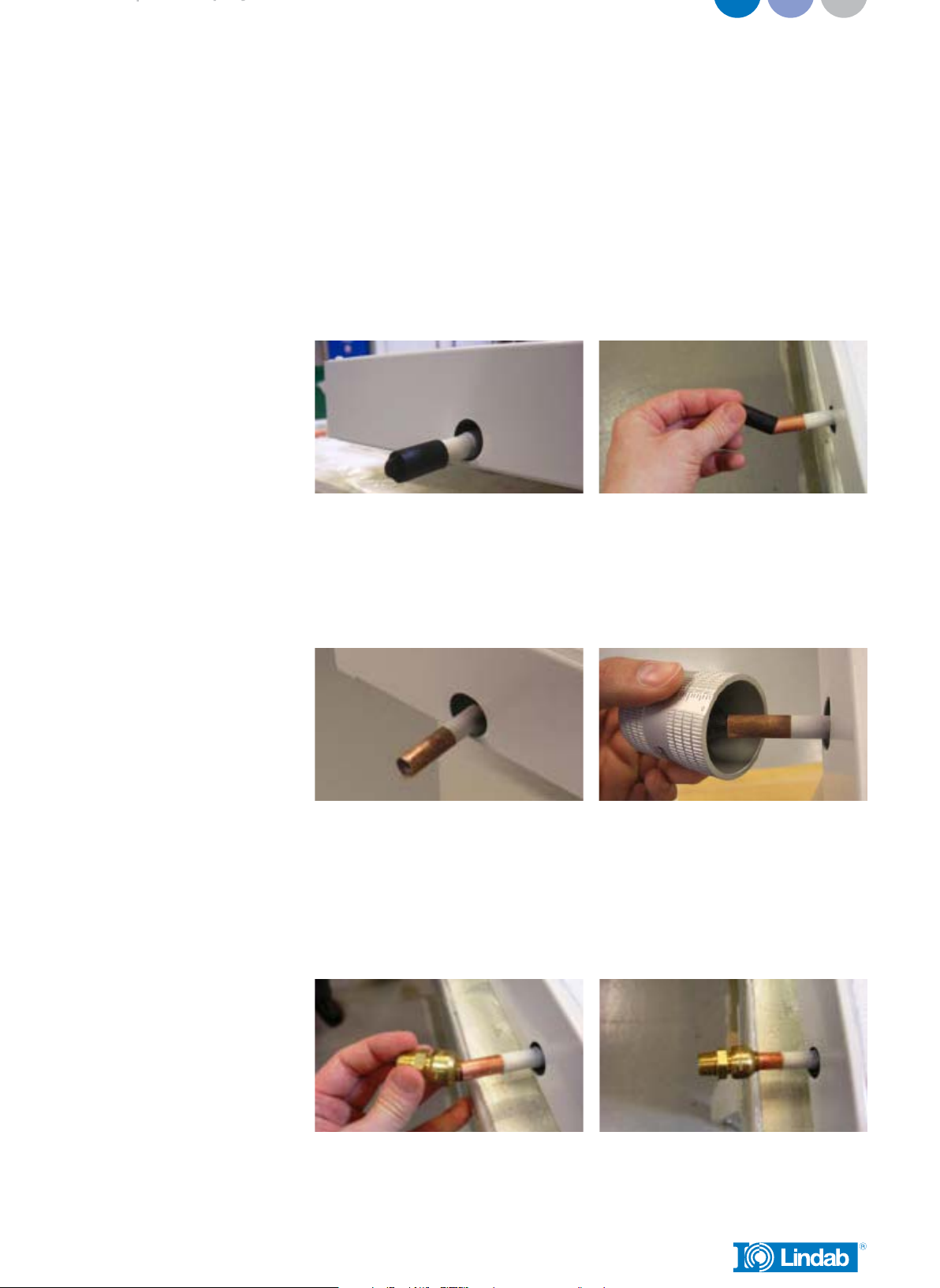

1.4 Air connection installation

The primary air supply should be connected with instructions from a ventilation spe-

cialist. Lindab’s chilled beams can beneficially be used together with Lindab’s Safe®

duct systems.

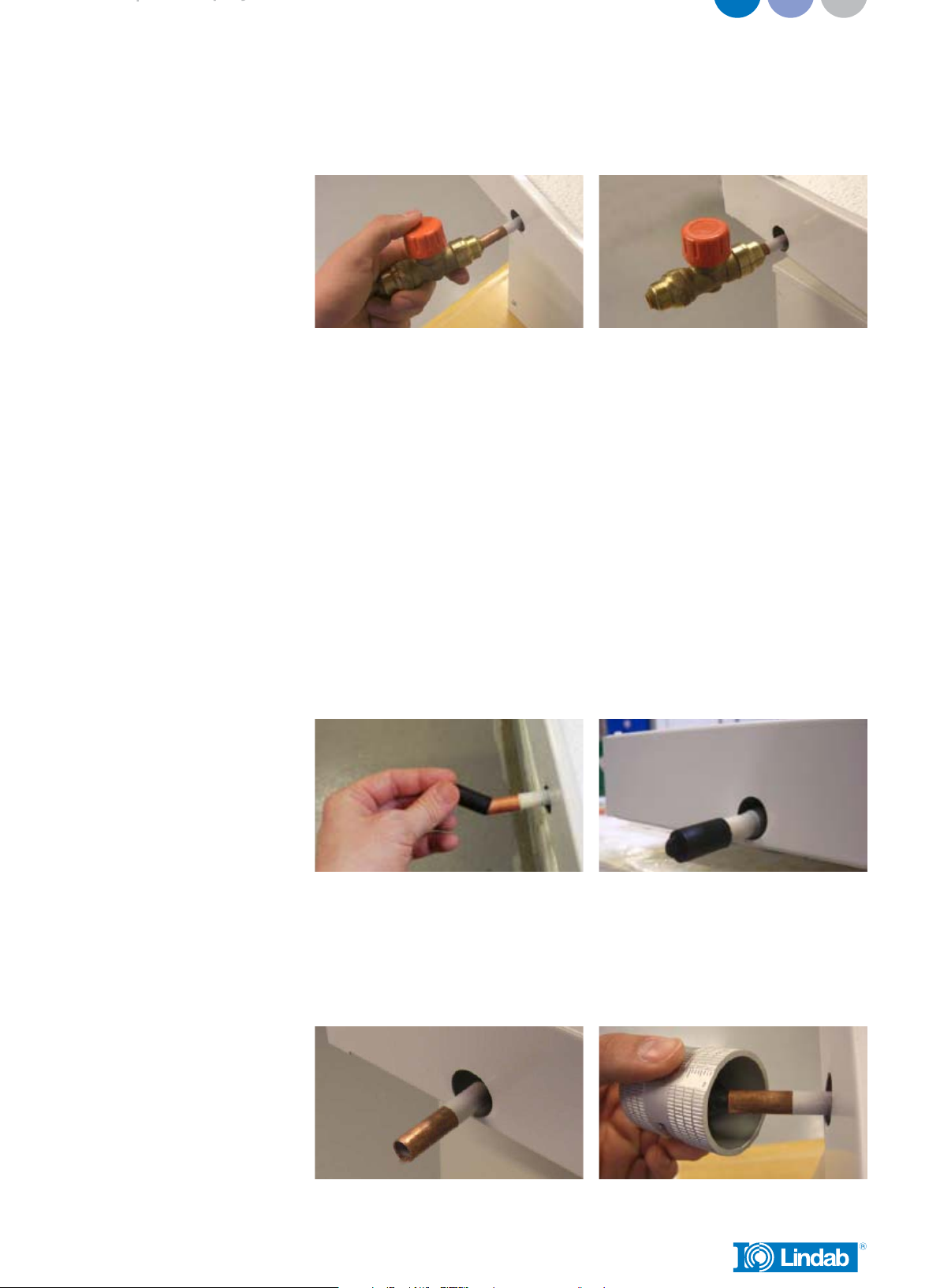

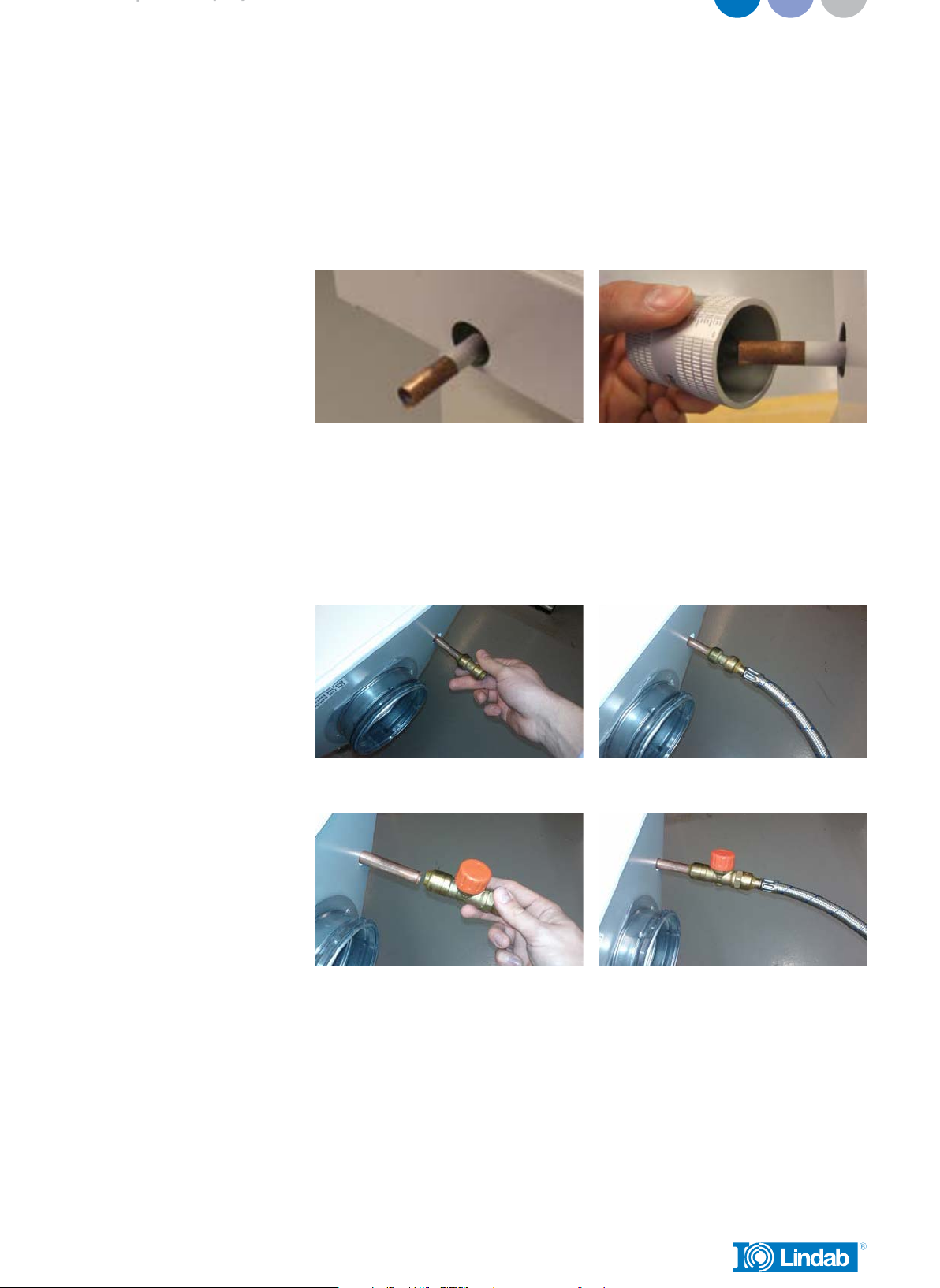

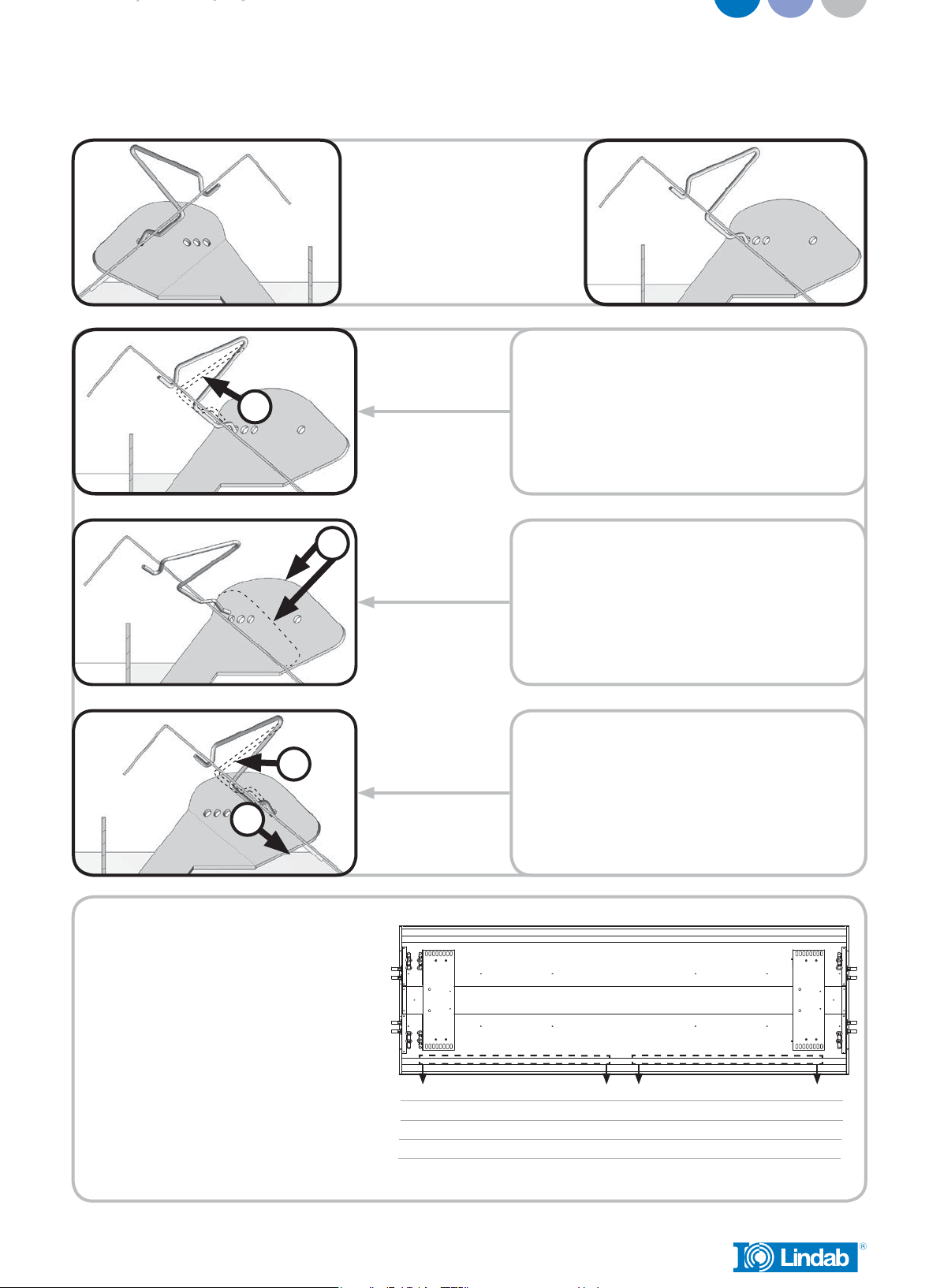

1.5 Connection description water

Flow indication arrows are shown on the inlet and return pipes in order to assist the

installer. If the beam has been ordered with integrated valves, a special direction

of the flow must be upheld to ensure correct flow through the thermostatic valve. If

the beam has been delivered without integrated valves, the flow can be reversed,

depending on the location of the retrofitted valve. Please note the flow direction indi-

cator on the valve to insure correct installation in relation to the desired flow.