9BOC Smootharc Advance II MIG 250R Operating manual

DO

Always

DON‘T Example of BOC rating plate

How important is the correct input cable and plug on a welding machine?

The size of the plug depends on a formula that

not only uses the maximum current draw but

also the duty cycle of the power source. Theuse

of any welding power source will not only cause

the machine itself to heat up, but the input

cable, plug and mains power circuit will increase

in temperature as well. That’s why it’s important

to understand input and output currents and to

make sure that the input circuit is correctly rated

to supply the required input draw. Thisallows

the machine to operate at or near maximum

output and protects the circuit board from

tripping, overheating and/or catchingfire.

For your safety, BOC meets AS/NZS Standards for safe electricalcompliance.

All BOC welding machines undergo an

independent certification process to meet

Australian and New Zealand regulations

regarding electrical safety. The triangle-

circle-tick (RCM) symbol signifies that BOC

has taken the necessary steps to have the

product comply with the electrical safety

and/or electromagnetic compatibility (EMC)

legislative requirements as specified by the

Electrical Regulatory Authorities Council

(ERAC). Depending on the machine, BOC may

be required to have a 32A single phase plug

to ensure that when the machine runs at its

maximum output, the input supply plug and

lead will not overheat. For your safety, please

check for this symbol before buying any welding

machine in Australia and NewZealand.

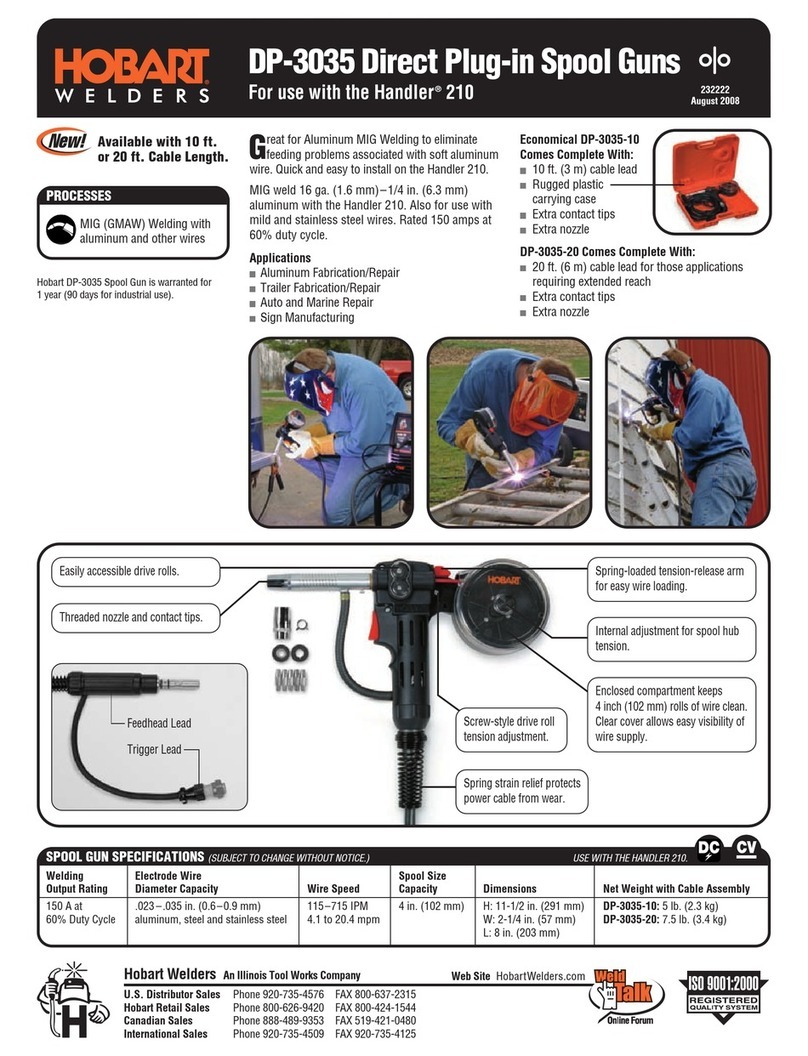

Check the rating plate onyourmachine.

All welding machines that comply with IEC 60974

or AS 60974 must have a rating plate similar to

the one shown. Welding machines draw some

current when idle (not welding) and a higher

current when welding. Effective rated primary

current (I1eff ) combines the conductor heating

due to these two levels of current. I1eff is the

maximum rated effective supply current that

determines the minimum plug and input cable

rating as well as the minimum capacity of the

input circuit that the machine gets plugged

into to safely operate the machine. Look for the

I1eff on the welding machine’s rating plate and

ensure that you have the correct input circuit to

support this powerdraw.

What if I don’t have a 240 volt 15 amp or 32 ampoutlet?

If you don’t have a suitable power outlet, you

should contact a qualified electrician to advise

whether the wiring in your building will cater for

a 15 amp or 32 amp outlet. You mayalso need

to upgrade your circuit breakers and possibly

switchboard to suit. Failure to do this may cause

an electrical fire in the building which may

voidinsurances.

Regulatory Compliance Mark (RCM)

andnumber

✓Use the correct input current,

✓cable and ✓ plug in accordance

with AS60974-1 for your safety and

to get the maximum performance

from your welding machine.

Example

If the I1eff rating on your

machine is 27A then you must

use a 32A plug as a 15A is

undersized for the welding

current being used and may

cause the cable to overheat.

✖Don’t risk damage to your

machine or cause tripping and/

or fire by using the wrong input

current, cable orplug.

✖Don’t tamper with plugs or

filedown earth pins. Doing so

willvoidwarranty.

✓ Inspect cables and plugs

regularly. ✓Contact a qualified

electrician for advice and/or

upgrade and, if needed, to replace

any damaged plugs orcables.

00$

/LIW7,*

0,*

0,*

3XOVH

6PRRWKDUF

0XOWLSURFHVV

Before operating your welding machine, follow the instructions in the operating manual provided.

For more information refer to WTIA TN 22 – Welding Electrical Safety (Revised 2003) and WTIA TN 07 Health

&Safety in Welding. If you have any queries please contact BOC 131 262 (AU), 1800 111 333 (NZ).