Lincoln Electric SAE-400 SEVERE DUTY IM727 User manual

Other Lincoln Electric Welding System manuals

Lincoln Electric

Lincoln Electric Precision TIG 375 User manual

Lincoln Electric

Lincoln Electric FlexCool 35 User manual

Lincoln Electric

Lincoln Electric Power Wave AC/DC 1000 User manual

Lincoln Electric

Lincoln Electric power wave ac/dc 1000 sd User manual

Lincoln Electric

Lincoln Electric SPEEDTEC 405S User manual

Lincoln Electric

Lincoln Electric FineLine 170HD User manual

Lincoln Electric

Lincoln Electric IM788 User manual

Lincoln Electric

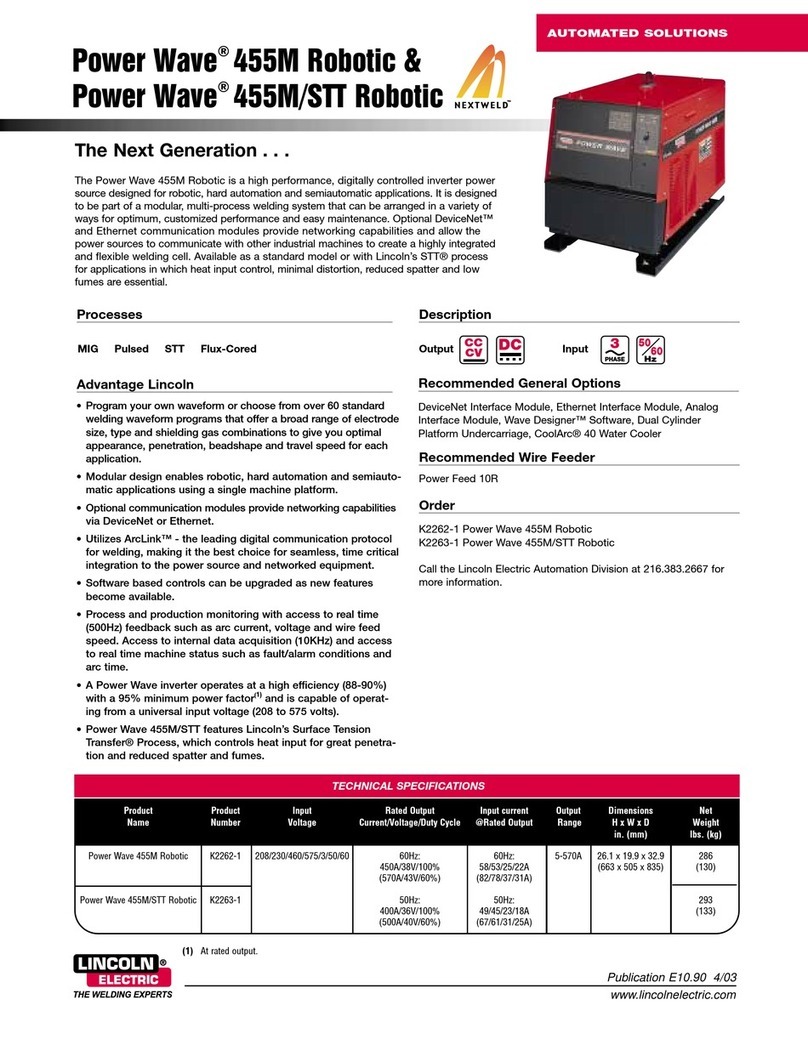

Lincoln Electric Power Wave 455M/STT Robotic User manual

Lincoln Electric

Lincoln Electric PRO-CORE 125 User manual

Lincoln Electric

Lincoln Electric SP20/MP2 Series Mounting instructions

Lincoln Electric

Lincoln Electric K1757-2 User manual

Lincoln Electric

Lincoln Electric IM536-D User manual

Lincoln Electric

Lincoln Electric FLEXCUT 200 CE User manual

Lincoln Electric

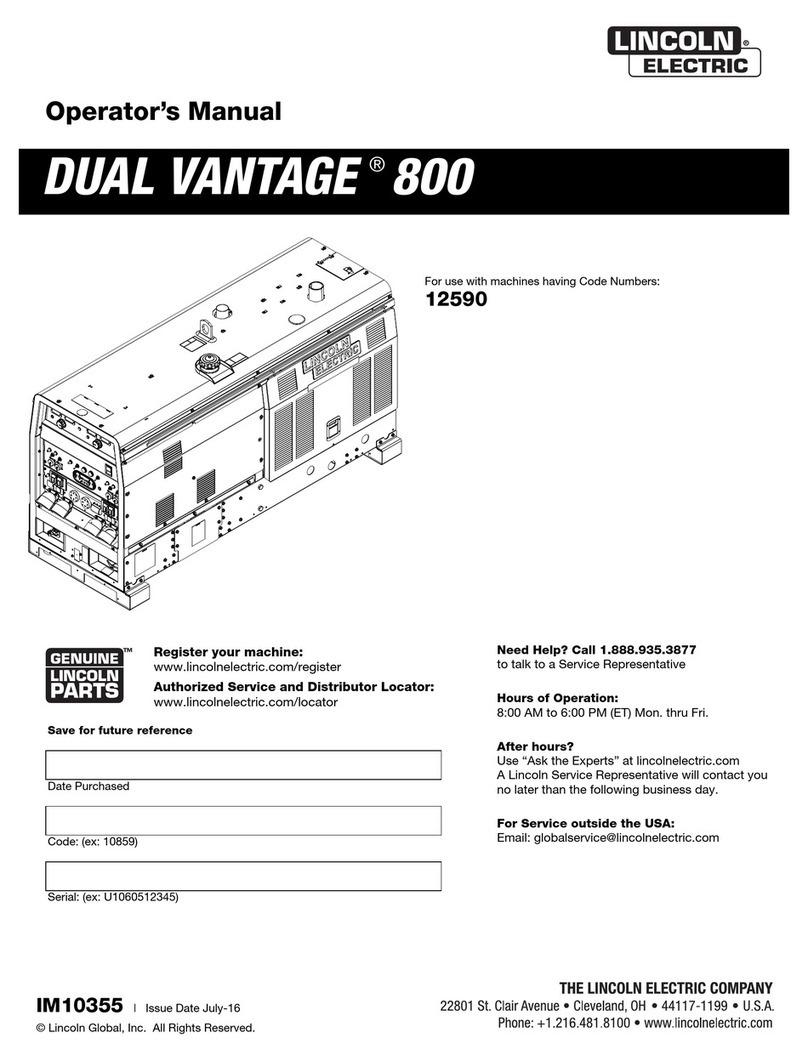

Lincoln Electric DUAL VANTAGE 800 User manual

Lincoln Electric

Lincoln Electric SP-135T IM724 User manual

Lincoln Electric

Lincoln Electric POWERFEED IM827-D User manual

Lincoln Electric

Lincoln Electric LF 56D User manual

Lincoln Electric

Lincoln Electric Precision TIG 225 User manual

Lincoln Electric

Lincoln Electric PF 56D User manual

Lincoln Electric

Lincoln Electric SAM400 User manual