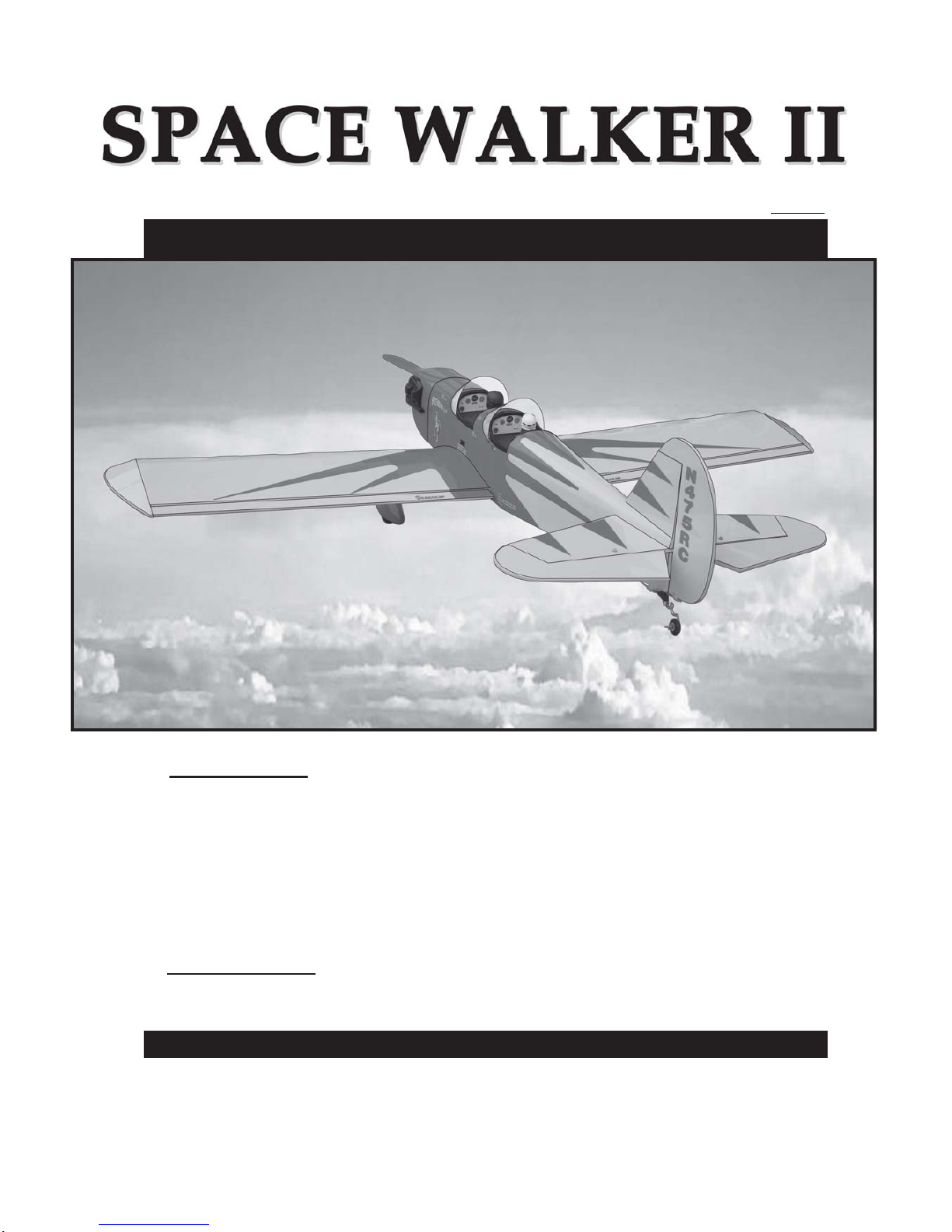

SPACE WALKER II Instruction Manual

4

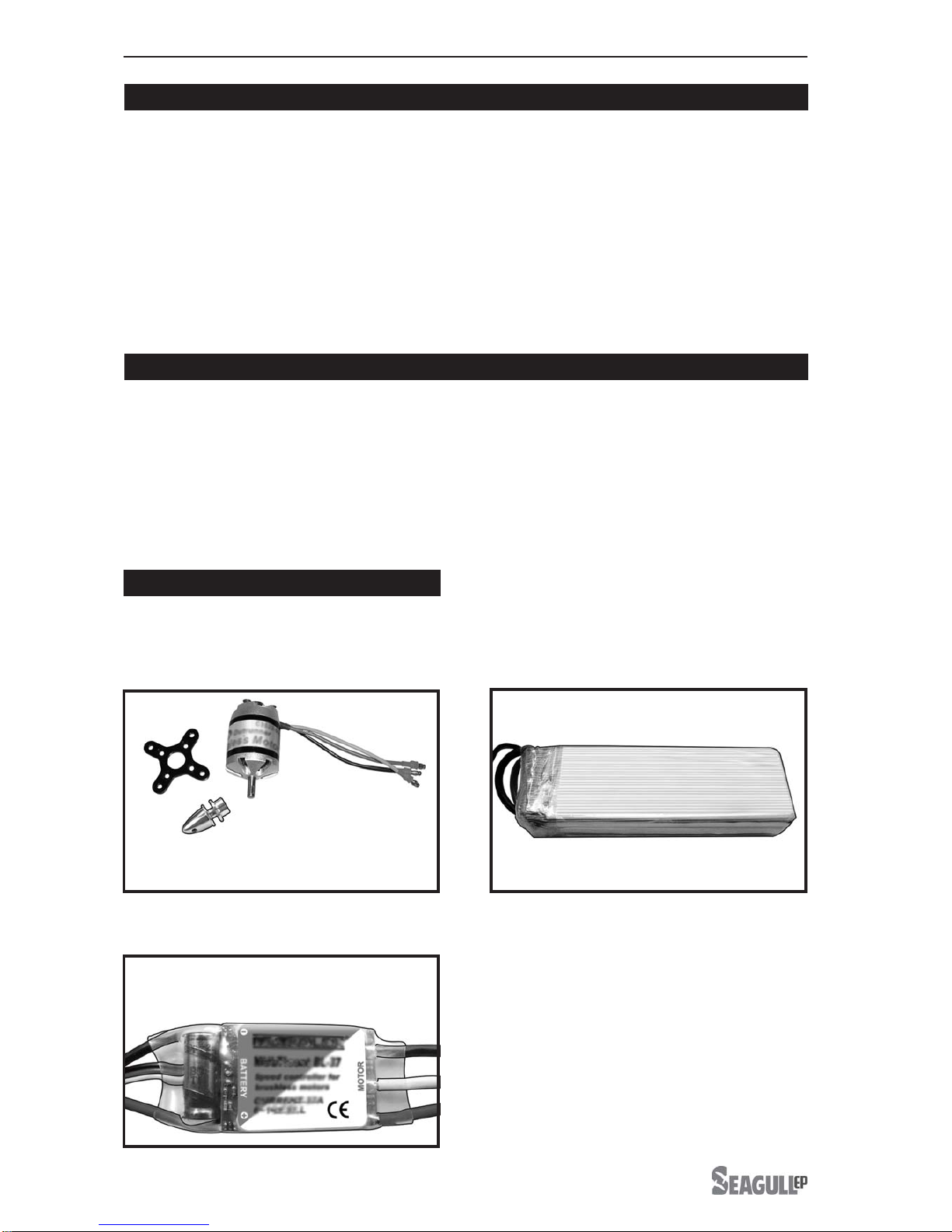

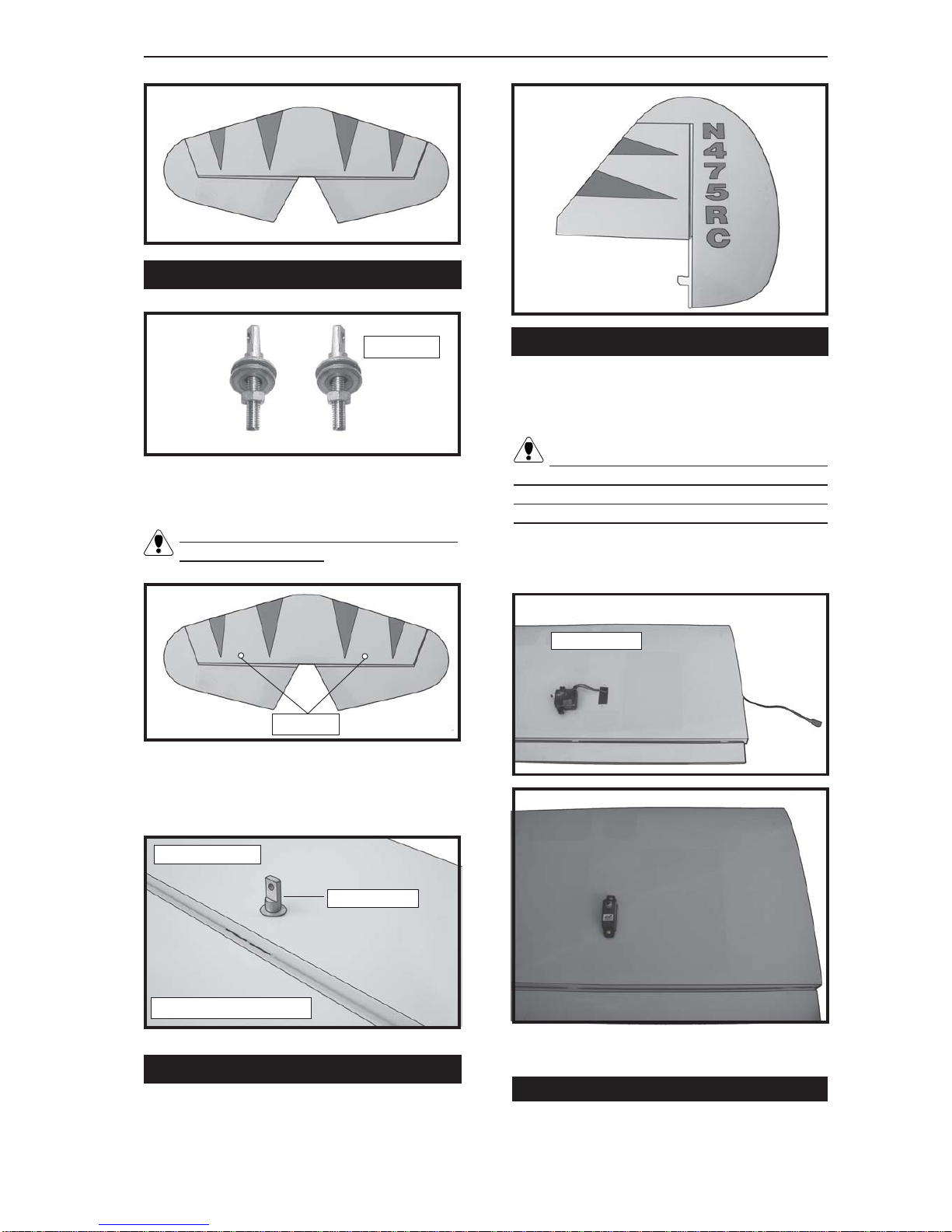

1)Carefullyremove the aileronfromone of

thewingpanels.Notethepositionofthehinges.

2)Removeeach hingefromthe wingpanel

and aileron and place a T-pin in the center of

each hinge. Slide each hinge into the wing

panel until the T-pin is snug against the wing

panel. This will help ensure an equal amount

ofhingeisoneithersideofthehingelinewhen

the aileron is mounted to the aileron.

HINGING THE AILERONS.

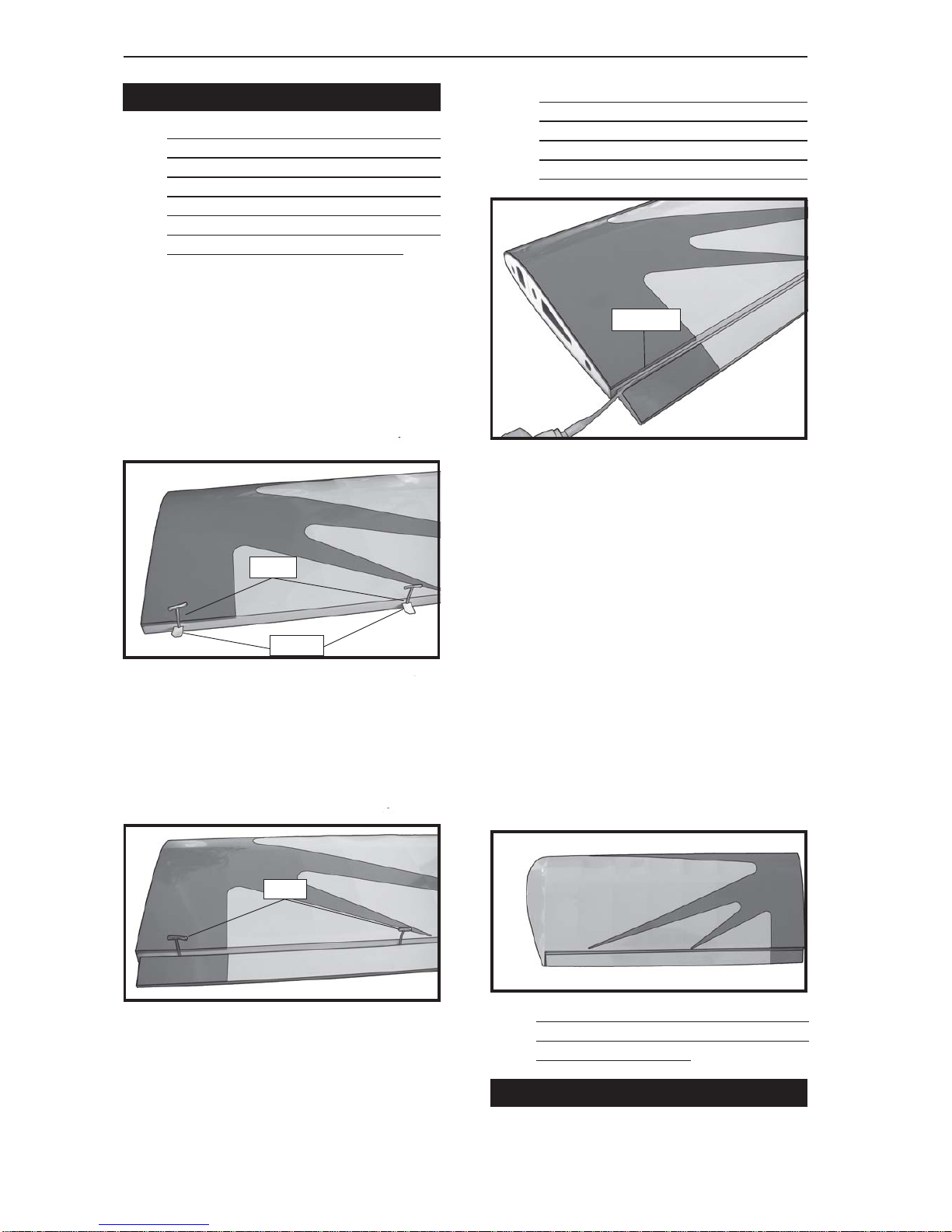

3) Slide the wing panel on the aileron until

there is only a slight gap. The hinge is now

centered on the wing panel and aileron.

Remove the T-pins and snug the aileron

against the wing panel.A gap of 1/64” or less

shouldbemaintained betweenthewing panel

andaileron.

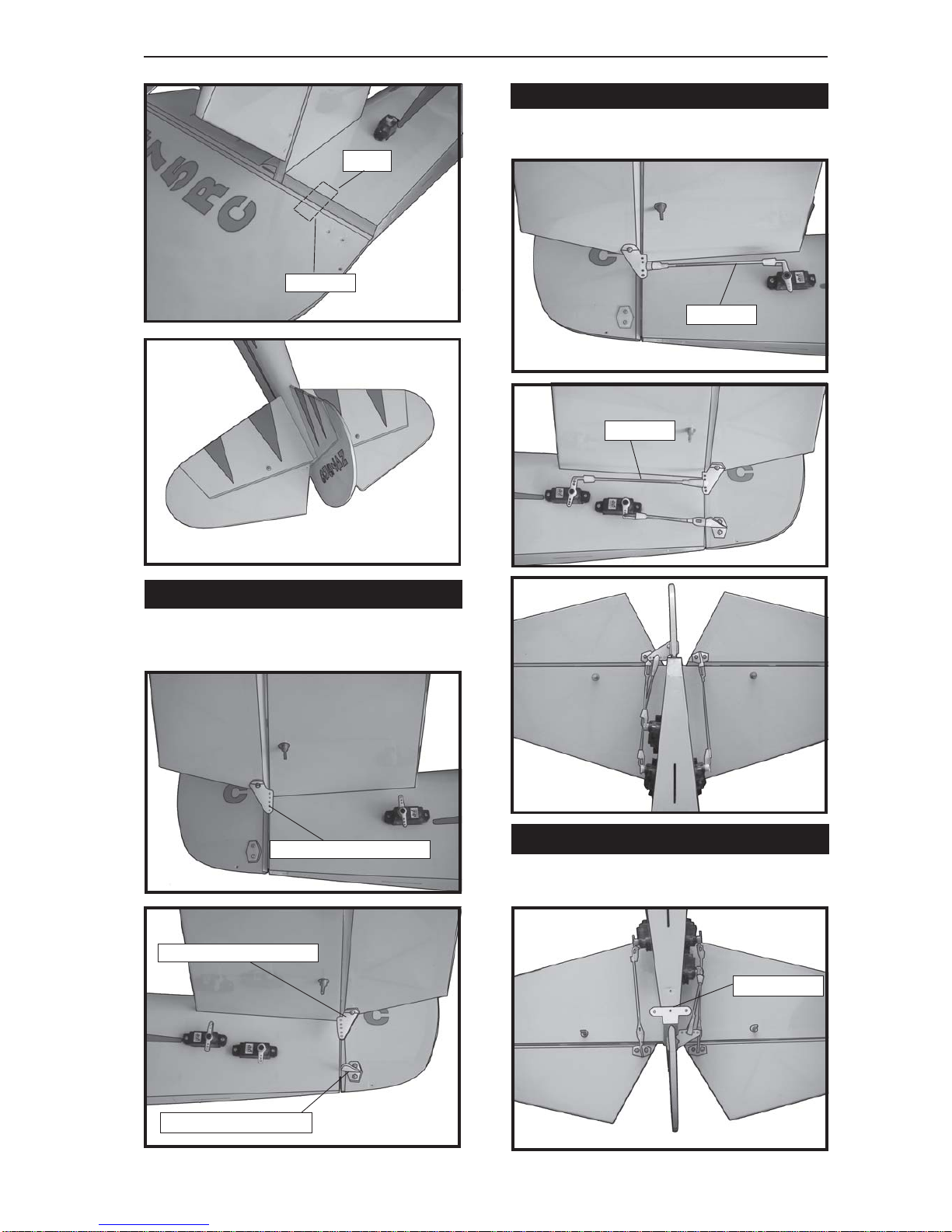

HINGING THE ELEVATOR.

4)Deflect the aileron and completely

saturate each hinge with thin C/A glue. The

aileronsfrontsurfaceshouldlightlycontactthe

wing during this procedure. Ideally, when the

8)After both ailerons are securely hinged,

firmly grasp the wing panel and aileron to

make sure the hinges are securely glued and

cannot be pulled out. Do this by carefully

applying medium pressure, trying to separate

the aileron from the wing panel. Use caution

not to crush the wing structure.

7) Repeat this process with the other wing

panel, securely hinging the aileron in place.

5) Turn the wing panel over and deflect the

aileron in the opposite direction from the

opposite side. Apply thin C/A glue to each

hinge,makingsurethattheC/Apenetratesinto

both the aileron and wing panel.

6) Using C/A remover/debonder and a

papertowel,remove anyexcess C/Agluethat

may have accumulated on the wing or in the

aileronhingearea.

The hinge is constructed of a special

material that allows the C/A to wick or

penetrateanddistributethroughoutthe

hinge, securely bonding it to the wood

structureofthe wingpanel andaileron.

hinges are glued in place, a 1/64” gap or less

will be maintained throughout the lengh of the

aileron to the wing panel hinge line. Glue the elevator hinges in place using the

same tectniques used to hinge the ailerons.

Hinge.

T-pin.

T-pin.

C/Aglue.

Work the aileron up and down several

times to “work in” the hinges and check

for proper movement.

Note:

The control surfaces, including the

ailerons, elevators, and rudder, are

prehinged with hinges installed, but the

hinges are not glued in place. It is

imperativethatyou properlyadherethe

hingesinplace perthesteps thatfollow

using a high-quality thin C/A glue.

Note:

Note: