The device MUST NOT be used or stored

at ambient temperature lower than 0 °C.

The device is designed for use in a normal

environment, always indoors, protected from

rain or sunlight. Climate class N.

WARNING: Protect the cooler and

electrical connection from rain and spraying

water!

WARNING: Do not under any

circumstances lay the cooler on its side, not

even during transport.

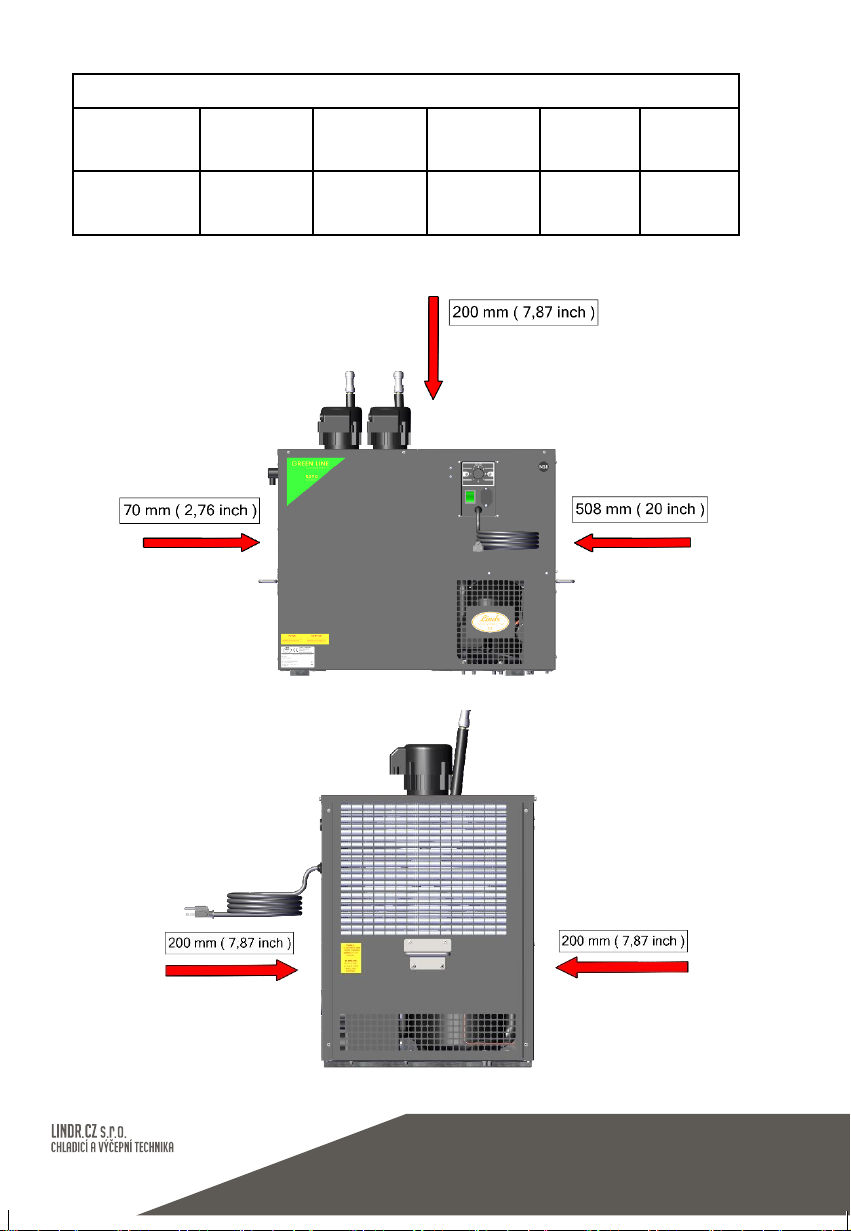

NOTE: In order for the device to

work correctly and at maximum output, it is

important to not cover up any of the device's

vents and ensure sufficient air circulation.

6. Electrical Connection:

Connect the device to a power socket in

accordance with specifications on the

product label of the device. Electrical wiring

is subject to local regulations. If the power

lead (cable) is damaged, it must be replaced

by the manufacturer, the manufacturer's

service technician or a similarly

qualified person to prevent risk of hazardous

situations.

WARNING: Do not use or turn on

the device if the power lead (cable) is

damaged!

7. Testing:

The product is delivered ready for immediate

use.

8. Warranty:

The device comes with a warranty in

accordance with general legal regulations of

the Czech Republic or in accordance with

the trade agreement. During the validity

period of the warranty, we will remove any

defects on the product free of charge,

provided these defects were not caused by

excess wear, improper handling, incorrect

storage or by using the product in a way that

is counter to the instruction manual or the

product's design as defined by the

manufacturer. Materials replaced during the

validity period of the warranty are our

property. The legitimacy of the warranty

claim is always decided by an authorised

service centre. Warranty provided by a

retailer outside of the territory of the Czech

Republic is governed by the agreement

between the retailer and the buyer in their

mutual relationship; this agreement is not

directly linked to the manufacturer. The

agreement does not give the buyer the right

to submit warranty claims to the

manufacturer. Transport expenses or other

costs are not covered by the warranty.

Attention:

Electrical devices and appliances must be

checked/inspected at a time stipulated by

valid legislation of the country the device is

operated in. Inspection of wiring may only be

done by a person with valid authorisation for

this activity. Service work, provision of spare

parts and inspection is done by the

manufacturer or an authorised service

centre.