Linea DH-1100 User manual

OPERATION MANUAL

on

ROLL LAMINATOR

Product instruction manual

Linea DH-1100

The Linea has been designed to be user friendly,

however we strongly recommend you take a few minutes

to read through this manual to ensure correct operation.

Keep this manual safe for future reference.

Warranty & Incorrect Use

IMPORTANT INFORMATION

Your Linea Roll Fed Laminator should reach you in perfect condition, however please retain all original packaging once you have

unpacked your Laminator as this system is covered by a return to manufacturers warranty. If your Laminator arrives damaged or

faulty in anyway this must be reported to your supplier immediately. If you send your Laminator back for repair at any time , then

the warranty may be void if the Laminator is not packaged correctly and as a result is damaged in transit. The laminator you have

misfeeds or Film wrapped around the rollers caused by operator error and you will be liable for the repair costs (including any

delivery charges).

The Laminator rollers are covered against manufacturing defects, they are not covered against any damages caused by misuse

ie. being cut with a knife or damage from non Laminating incidences.

E&O.E

1

WARNING

Please do not use broken, aging or self-made electrical wire and damaged supply cord.

Please do not immoderately draw, twist or enlace the electrical wire, to avoid the fire or

electric shock.

Please do not use the power supply that is not in accordance with the rated voltage, to

avoid the fire or electric shock.

NO DISJOINT

ENTANGLEMENT

CAUTION

ELECTRIC SHOCK

CAUTION

HIGH

TEMPERATURE

CAUTION

Don't disjoint, modify and repair the machine yourself.

If there are any problems on the machine, please do not

use it, send it to the dealer for repairing.

If the supply cord is damaged, it must be replaced by

the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

Keep hands, long hair, loose clothing and articles such

as ties or necklaces away from the front of the heating

roller and pull roller to avoid entanglement.

In case some articles entangled, press the FWD / REV

switch to REV right away; if not workable, cut off the

power supply at once, and contact your dealer for

settlement.

Do not put articles on the laminator while it is working,

so that to disperse the heat.

Do not insert the easy-burnt or easy-softened material

into the machine, in case they are melt and give rise to

smoke.

Do not touch the cover, heating roller and heating parts

while the machine is working, in case heat injury.

SAFETY PRECAUTIONS

Do not make the electrical wire or plug or the machine

bedewed by water or other liquids.

Do not operate the machine with wet hand.

Do not make the machine pressing on the electrical

wire.

Do cut off the power supply while moving the machine.

Do not operate the machine with the cover open.

The power socket must be properly grounded.

SAFETY PRECAUTIONS

2

CAUTION

WORKING

PLACE

This machine should be put at the dry and clean place, do not put it

at the damp place or near the exit of cooling appliances.

This machine should be put on the horizontal and firm place. In

front and rear of the machine, there should be sufficient place for

the document in and out.

Do not put any articles on the machine.

LAMINATING

FILM

Please use good quality laminating film, in order to show the

lamination effect, and avoid the entanglement.

OBJECT

The laminating machine use the hot press technology, do not use the

following objects in case laminating failure or laminating film

entangle.

1.Easy-burnt material, easy-softened material

2.The document printed by heat-sensitive paper, or any articles

that can be faded or transformed after heating.

3.Any articles that have drape, breakage, dampness or

deformation before laminating.

4.Coin or any other hard articles.

means exception while cold laminating operation.

Do not attempt to laminate articles that exceed total recommend

material thickness.

MACHINE

OPERATION

Do not turn to other usages except the usage range stated in this

operation manual.

Do not use the machine outside the room. Before leaving, please cut

off the power supply if the operation is over.

If there are any problems on the machine, please do not use it,send

it to the dealer for repairing.

While operating the machine, mind the children nearby, in case any suddenness.

Do not suspend the electrical wire on the table or cabinet or any other places

that the children can touch, or place easy stumble persons.

Using the accessory that not recommended or sold by the manufacturer, might

cause damage on the machine.

The photo or document once is laminated, it will become permanent and will

not be taken apart.

Please do not laminate the collected rare articles, or some articles might be

taken out in the future.

ADVICES

LCD

Speed control knob Temp. control knob

Load button

FWD / REV switch

RUN / STOP switch

STRUCTURE AND CONTROL PANEL

3

m m

HOT / COLD switch

Top roll shaft

Right side cover

Feed table

Roller pressure

knob

Top supply roll

tension knob

Safety shield

Control panel

Core adapter

Top stabilizer

bar

Feed guide

Bottom supply

roll tension knob

Bottom roll

shaft

Active bolt

Stand

Take-up bobbin

tension knob

Take-up bobbin

Heating roller

Emergency stop

Left side cover

Bottom stabilizer bar

Base plate (optional)

1. LCD display and Function

When the sensor is in open circuit,

OPN FAULT displays on the LCD.

When the sensor is in short circuit,

CLS FAULT displays on the LCD.

2. Function of control panel

1) Temperature control knob

Protecting function of temp sensor's open circuit and shot circuit

Note: No matter what problems happened, the machine will cut off the

heating power supply automatically, and the motor will stop running.

FUNCTIONS OF LCD DISPLAY

AND CONTROLPANEL

-

4. 2 155

FAULT

4. 2 1

-

INSTALLATION

1.Upon receipt of the laminator, inspect of box, the machine and all other

contents of the box for shipping damage. Shipping damage should be brought

to the immediate attention of the delivering carrier.

2.The laminator comes fully assembled on a stand .

3.Screw the wheel on the stand, put the stand upright. Place the tie bar

horizontally, connect the bar and stand with the bolt which has spring washer

on it, then fasten it.

4.Put the laminator on the assembled stand.

5.Start operation after turning the wheel stop switch to "OFF".

4

4) HOT / COLD switch

5) RUN / STOP switch

6) LOAD button

Press HOT / COLD switch can change the function of machine between

hot and cold lamination.

A)While set the HOT / COLD switch to HOT, the machine is on hot

laminating, the set temperature will display on the LCD.

B)While set the HOT / COLD switch to COLD, the machine is on cold

laminating, COLD will display on the LCD.

Press RUN / STOP switch can change the working condition of the

motor.

A)While set the RUN / STOP switch to RUN, the motor of the machine

works.

B)While set the RUN / STOP switch to STOP, the motor of the machine

stops, STOP will display on the LCD.

When the safety shield or feeding table are taken out, the machine will

not run. Set the speed at minimum speed, press the LOAD button

continuously, the machine can run at minimum speed, you can either

load the film or clean the roller.

FUNCTIONS OF LCD DISPLAY

AND CONTROL PANEL

5

A)Turn the temperature control knob can increase or decrease the set

temperature. The set temperature will display on the LCD.

B)The range of temperature that can be adjusted manually is 0 -140 .

C)The true temperature of the roller will display on the LCD.

D)When the true temperature reach 140 , the over-heat protecting

system will run automatically.

2) Speed control knob

A)Turn the speed control knob can increase or decrease the laminating

speed. The set laminating speed will display on the LCD.

B)The max. laminating speed is 1.4 m/min.

3) FWD / REV switch

Press FWD / REV switch can change the working direction of the motor.

A)While set the FWD / REV switch to FWD, the motor runs forward,

Will display on the LCD. The laminating film in, the machine works.

B)While set the FWD / REV switch to REV, the motor runs reverse,

REVERSE will display on the LCD. The laminating film out. This

function is used for remove the object inserted by mistake.

2) Insert the plug into the power socket that is grounding correct.

3) Turnon thepowerswitch, the LCD light, it indicates the power is connected.

2. Motor overload circuit breaker

This machine is equipped with motor overload circuit breaker (it is located next

to the power switch), in order to protect the motor working normally. When the

motor is overload, the circuit breaker will jump and cut off the motor power. One

minute later, when the overload is clear, press the circuit breaker button, the

motor will start again.

3.Film threading

HOT FILM

Step 1: Raising the safety shield.

Remove the active bolt on the shield, raise the safety shield.

Step 2: Taking out the feed table.

Remove the active bolt under the feed table, take out the feed table.

Remark: the machine will power off when the safety shield and the feed

table are not in their proper positions.

OPERATION INSTRUCTIONS

OPERATION INSTRUCTIONS

PREPARATION

1. Connecting the power source

1) Checking the rated voltage on the machine, to insure it conform to the power

source. Also, checking the plug to insure it conform to the socket.

3. Emergency Stop

There is a emergency stop button on the front of

the laminator. In emergency situation pressing the

button will stop the rollers and stop heating. Rotate

the button to the direction of arrow to turn on the

power supply.

POWER

SWITCH

WIRE CIRCUIT

BREAKER

FAN

SWITCH

FAN

ON

OFF

POWER

ON

OFF

6

CAUTION: For hot laminating, the top and bottom roll film must have same

width, besides, the top film and bottom film must be aligned. (If the film is not

in alignment, loose the bolt on core adapter and align it.)

Step 4: With both roll films threaded and installed in their respective brackets,

unwind the top and bottom supply rolls about half-turn each. This will provide

enough slack in the web to allow the feed table to slide on easily.

Step 5: Slide the feed table into position and lock the active bolt.

OPERATION INSTRUCTIONS

7

Step 3: Follow the diagram to thread the film

Remark: Usually the shiny side is the polyester side, it contact the roller.

The dull side is coated with adhesive. For the matte film, the two sides have

minor difference, please especially be careful. Heat the film with lighter can

easily tell the polyester side and adhesive side. The adhesive side must face

away against to the roller.

Slide the roll film onto the roll shaft (follow the above instruction, do not load

the film in wrong side). Hold the roll film on the core adapter, the core adapter

can hold the core of the roll film, to prevent it rotating. Screwing the bolt on the

core adapter. Put the rolls on the brackets. Make sure it is fully seated.

Top roll film

Bottom roll film

Top stabilizer bar

Bottom stabilizer bar

Top heating roller

Bottom heating roller

Top pull roller

Bottom pull roller

Film ou tsid e top

stabilizer bar

Top roll film

Top stabilizer bar

Top heating roller

Film inside top

sta bilizer bar

Bottom roll film

Bottom stabilizer bar

Bottom heating roller

Top pull roller

Bottom pull roller

Film Threading Diagram

Tension knob

Spring

Bracket

Friction plate

Bushing

Core adapter

Roll film Bolt Bracket

Bushing

Core adapter

Bolt

Tension knob

Friction plate

Step 6: Position the safety shield forward toward the roller and lock the active

bolt.

Remark: The machine will not power on without the feed table and the safety

shield in the proper positions.

Step 7: Make sure there is still enough slack in the web. Close the rollers with

the knob on the right side of the laminator. With the film draped over the two

heating rollers, and melted or taped together, push one edge of the threading card

between the heating rollers so that the film is firmly positioned. Make sure the

rollers are in closed position. If a threading card is not available, any piece of

card stock or poster board will work.

Step 8: Set the FWD / REV switch to FWD and set the RUN / STOP switch to

RUN. If the film and the card are in the nip (the point where the top and bottom

roller meet), the film and the threading card will start into the laminator and will

pass through both sets of rubber rollers. When the threading card has cleared the

back of the machine, set the RUN / STOP switch to STOP.

CAUTION:For operator safety, the safety shield must be in position over the

upper heating roller when the machine is ON.

COLD FILM

Step 1: Raising the safety shield.

Remove the active bolt on the shield, raise the safety shield.

Step 2: Follow the diagram to thread the film

Slide the roll film onto the roll shaft (follow the above instruction, do not load

the film in wrong side). Hold the roll film on the core adapter, the core adapter

can hold the core of the roll film, to prevent it rotating. Screwing the bolt on the

core adapter. Put the rolls on the brackets. Make sure it is fully seated.

OPERATION INSTRUCTIONS

8

Top heating roller

Bottom heating roller

Cold film

Top stabilizer bar

Top pull roller

Bottom pull roller

Take-up bobbin

Back paper

Step 3: Insert a piece of wide cardboard (guiding paper) between the rollers. the

width of cardboard should be larger than the width of cold film. Pull the film

from the top roller passing over the top stabilizer bar to the top roller.

Step 4: Put the paper back of the cold film to the bobbin at take-up bar to rewind

the paper back. Allow some of the cold film with melted resin to stick the wide

cardboard (guiding paper).

Step 5: Position the safety shield forward toward the roller and lock the active

bolt.

Step 6: Close the rollers with the knob on the right side of the laminator. Set the

FWD / REV switch to FWD and set the RUN / STOP switch to RUN. The films

will be fed into the machine. Check the status of lamination.

Remark: The machine will not power on without the safety shield in the

proper positions.

HOT LAMINATING

1.Turn on the machine, set the RUN / STOP switch to STOP, set the HOT /

COLD switch to HOT. The machine begin heating. Turn the temperature knob to

the temperature for whatever film is being used.

2.The laminator will be ready to operation in about 10 minutes.

1) Trial lamination

If the roll film is the first time to be used, the trial lamination is required for

perfect result. After the true temperature of the roller reach to the set temperature,

close the rollers with the knob on the right side of the laminator, set the FWD /

REV switch to FWD and set the RUN / STOP switch to RUN, let at least 250mm

of film go through the rollers before inserting the items to be laminated.

Examine the film coming out the back of machine.

Adjust the machine according to the above instructions until you have the

perfect lamination result.

2) After the trial lamination has a satisfied result, position the feed guides

according to the width of the item to be laminated, entering the item in the web

of film.

Remind: keep clear and enough space behind the machine, so that the

laminated item can come out easily, it will not wind onto the rubber roller. If

the machine is stopped for a long period, set the temperature decreased by

5-10this will prolong the work-life of the machine.

Stop the machine after the item to be laminated pass through the roller

completely, otherwise there will be an imprint on the item.

OPERATION INSTRUCTIONS

9

Temperature setting

Normally, your film supplier should provide the information about the film

application temperatures and operating characteristics. If you do not know the

source of your film, or if the supplier cannot provide the information, please try

the temperature and speed until you have the best result.

COLD LAMINATING

1.Set the HOT / COLD switch to COLD.

2.Set the speed to the required speed.

3.Put the document on the feed table.

4.Set the FWD / REV switch to FWD and set the RUN / STOP switch to RUN.

5.Stop the machine after the document to be laminated pass through the roller

completely, otherwise there will be an imprint on the document.

CAUTION:The adhesive side must face away from the roller.

GENERAL MAINTENANCE

Do not laminate the metal or other hard items in case the damage of the rubber

rollers.

While stop the laminating, lift the top rubber roller with the knob on the right

side of the machine. Do not press the rubber roller in case the rubber become

stiff and thus shorten its work-life.

Cleaning the machine timely will help prevent dirt or adhesive build-up on the

rubber rollers and will improve the performance of the unit.

CLEANING THE RUBBER ROLLERS

During the normal lamination, excess adhesives from the film will often cling to

the rubber rollers.

To clean the rubber rollers, lift the rubber roller, remove the film from the

machine first, heat up the machine to 30-40 . The warm roller enable it

easier to remove the adhesive built-up on the rollers. Raise the safety shield

and take out the feed table. Using a clean, soft, ethanol dampened cloth,

gently rub the adhesive off the rollers.

CAUTION:Never use any abrasive or sharp metal material or rub too hard

on the roller, because you may damage the rubber surface.

MAINTENANCE AND SERVICE

10

Set the speed at minimum speed, press the LOAD button, the roller will run,

cleans the roller. After cleaning, position the feed table and slide on the

safety shield.

CAUTION:If the film gets wrapped around the roller, set the RUN/STOP

switch to STOP immediately, set the HOT / COLD switch to COLD.

WARNING:Do not use any cleaning solution to clean the roller, because

some solutions may burn on the hot roller. After the roller cool down, cut

the film on the top and bottom, just in front of the stabilizer bars. Reverse

the roller at a very low speed and allow the machine to back out the film that

is wrapped around the rolls, pull the film off the roller. Clean the adhesive

on the roller.

PROBLEM SOLUTION

Please read this section before you have a problem

PROBLEM:No power is getting to the machine.

SOLUTION:Make sure there is power at the electrical outlet being used, and

make sure both ends of the power cord are firmly engaged.

The laminator equipped with three fuses (one is located next to the power switch,

the other two are located under the bottom of laminator). Please check these

fuses.

PROBLEM:Wrinkling of the film around the material being laminated.

SOLUTION:This is normal and inevitable on any laminator, especially with

thicker material. These wrinkles will be trimmed away with the scrap, so they do

not affect appearance. Because the rollers are being held apart by the paper, they

cannot pull equally on the plastic around the paper. This creates wrinkles that

tend to look like the bow waves of a boat, radiating out through the clear part of

the web from the sheet of material.

PROBLEM:When two pieces of material are laminated side by side, the plastic

adhesive to one piece but not the other.

SOLUTION:To get maximum efficiency from the film rolls, you can feed

several items into the laminator side by side. However, wrinkling can occur if

these items are of unequal thickness, because the laminating rollers are lifted off

the thinner items by the thicker items. When laminating items side by side, it is

important to arrange them so that the thickness is the same.

MAINTENANCE AND SERVICE

11

12

MAINTENANCE AND SERVICE

PROBLEM: Film gets wrapped around the laminating rollers while hot

laminating.

SOLUTION:The film is threaded improperly. If the adhesive side face to the

roller, the film will be wrapped around the rollers. Thread the film in proper

position.

The laminating temperature is too high, the film will be melted and wrapped

around the roller. Decrease the laminating temperature.

Set the RUN / STOP switch to STOP immediately, set the HOT / COLD switch

to COLD. After the roller cool down, cut the film on the top and bottom, just in

front of the stabilizer bars Reverse the roller at a very low speed and allow the

machine to back out the film that is wrapped around the rolls, pull the film off

the roller.PROBLEM: Wrinkling of the plastic on a laminated material.

SOLUTION:Check the tension of the film, make sure the film is threaded

properly (see film threading).

PROBLEM:Film is not properly adhered.

SOLUTION: The laminating temperature is too low, there is not enough

heat for melting the adhesive. Increase the laminating temperature.

PROBLEM: The laminated material seems to have a irregular surface that

does not match the texture of the paper being coated.

SOLUTION:This is usually caused by adhesive build-up or dirt on the

rubber rollers. Inspect the rubber rollers and clean it.

Damages to the rubbers can also cause irregularities in the surface of the

film.

PROBLEM:General haziness or cloudiness in the film after lamination.

SOLUTION:Increase the temperature or decrease the speed. That

cloudiness is a function of incomplete adhesion. On a variable speed

machine loaded with thicker film, it may be that the film is being run too

fast.

.

SERVICE

If the service is required, please provide the following information:

The detail of the problem

Installation Date

Serial number

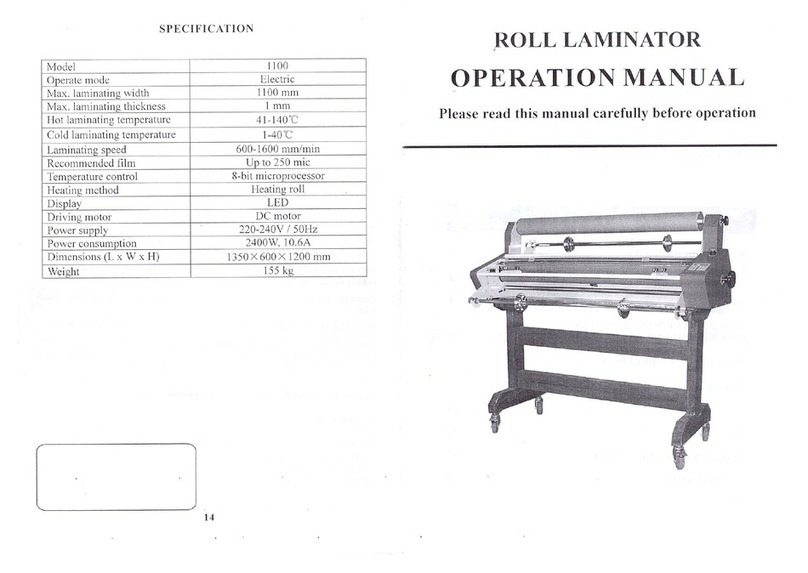

Model 1100

Operate modeElectric

Max. laminating width 1050 mm

Max. laminating thickness 5 mm

Max. laminating temperature140

Max. Laminating speed 1.8M/min

Recommended film Up to 250 mic

Temperature control 8-bit microprocessor

Heating method Heating roll

Power supply AC100,110,220-240V/50,60Hz

Power consumption 2700W

Dimensions (L x W x H) 1350 600 1170 mm

Weight 155 kg

SPECIFICATION

13

Other manuals for DH-1100

1

Table of contents

Other Linea Laminator manuals