Linea DH-360 Specification sheet

Product instruction manual

Linea DH-360, DH-460 and DH-650

The Linea has been designed to be user friendly,

however we strongly recommend you take a few minutes

to read through this manual to ensure correct operation.

Keep this manual safe for future reference.

Thank you for purchasing the Linea. Please read through this instruction booklet carefully and keep it safe in case

needed for future reference.

Contents

Safety Precautions

Do not use the machine if the power cord is damaged in anyway. Do not use a power supply

that is not in accordance with the rated voltage.

Do not try to disassemble, modify or repair the machine yourself. If you encounter a problem you

must call a qualied engineer.

Keep long hair, loose clothing and items such as ties and jewellery away from the rollers of the

machine at all times to avoid danger of entanglement. If entanglement occurs, press the REVERSE

button or cut o the power immediately.

Keep water and liquids away from the machine at all times. Do not operate the machine with wet

hands. Do not cut o the power to the machine whilst in operation (except if entanglement occurs).

Use the safety guard at all times.

The Linea works at a high temperature, therefore ensure you do not touch the rollers or any

part of the machine which states ‘HOT’ or ‘CAUTION’ whilst it is in operation. Do not cover the

machine if it is still cooling down. Do not laminate any material other than what is stated in this

manual and do not use any lamination lm other than what is recommended for this system.

Operate the machine in a well ventilated, clean, dry place with a large enough working space at the front and rear

of the machine.

Ensure the power cable is not dragging on the oor or causing a hazard to operators.

For producing the top quality results that this machine is designed to do, you must use high quality lamination

lm. Pro life lm is the suggested brand by the manufacturer.

Further advice

Page 2 - Safety precautions

Page 3 - Machine parts and stand (options extra) assembly

Page 4 - Control panel and functions of digital display

Page 5 - Operating instructions

Page 6-8 - Loading/threading the lm

Page 9 - Cleaning and maintenance

Page 9 - Troubleshooting

Page 9 - Specication chart

Page 10 - Warranty and incorrect use

Do not use the machine if the power cord is damaged in anyway. Do not use a power supply

that is not in accordance with the rated voltage.

Do not try to disassemble, modify or repair the machine yourself. If you encounter a problem you

must call a qualied engineer.

Keep long hair, loose clothing and items such as ties and jewellery away from the rollers of the

machine at all times to avoid danger of entanglement. If entanglement occurs, press the REVERSE

button or cut o the power immediately.

Keep water and liquids away from the machine at all times. Do not operate the machine with wet

hands. Do not cut o the power to the machine whilst in operation (except if entanglement occurs).

Use the safety guard at all times.

Machine parts and stand assembly

Stand assembly

(Optional with DH-650)

Core adapter Top roll shaft

Heating roller

Top stabilizer bar

Roller pressure

knob

Control panel

Right side cover

Feed table

Feed guide

Left side cover

Active bolt

Safety shield

Supply roll

tension knob

Control panel and functions of the digital display

Temperature control

The temperature setting you require for laminating can vary and can be eected by many dierent factors, these

include thickness of media, thickness and construction of laminating lm, speed of the machine and temperature

and humidity of the room you are working in. For this reason, we do not provide a precise chart detailing the exact

temperature required for operation. Please refer to the guide at the bottom of this page if you need help. Always

use a test print to send through the machine before starting to laminate your work.

The temperature control knob will increase or decrease the set temperature as it is turned and the set temperature

will show on the LCD display. The current temperature of the rollers will also be displayed on the LCD display. The

temperature ranges from 0oC-140oC. If the temperature reaches 140oC, the over heating protection function will

automatically activate to prevent the machine getting any hotter.

Approximate temperature guide

This chart is a rough guide only and should NOT be taken as an exact indication of the settings for your laminating

job. As previously stated, many dierent factors can eect the temperature and speed required. The supplier does

not accept responsibility for incorrect settings being applied.

Encapsulating

Example lm Approx temperature Approx speed

75 Micron 100°-110° 0.5 m per min

125 Micron 110°-120° 1.0 m per min (decrease speed for thicker documents

and increase the temperature slightly)

Error messages

Should the LCD display panel show the words

OPN fault or CLS fault, there maybe a problem

with your machine. This very rarely occurs but

if it does contact your supplier immediately and

turn o the power.

Familiarise yourself with the control panel

before commencing operation of the machine

Set Temperature

Current Temperature

Speed control

The speed control function allows adjustment of the speed of the machine. This can be manually

adjusted by turning the knob anti clockwise to increase the speed and clockwise to decrease the

speed. The speed can range from 0M per min to 1.4M per min

Hot and cold settings

To change the function of the machine to either hot or cold press the HOT/COLD switch. When it is

switched to hot the set temperature will show on the LCD display. When it is switched to cold, COLD

will show on the LCD display.

Forward and reverse switch

The FWD/REV switch changes the working direction of the motor. When it is switched to forward

the motor will run forward and will show on the LCD display. This function is used for

laminating and encapsulating.

When it is switched to reverse the motor will run backwards and REVERSE will show on the

LCD display. This function is used to remove items fed in incorrectly or by mistake - please note

removed items will not be reuasable

Operating instructions

Ensure the laminator is placed on a at, sturdy work surface or on the assembled stand (optional extra). Check the

power voltage for the machine to ensure this meets your own supply. Plug the power cord into the back of the

machine and into your power supply. Contact your supplier if you do not have a power cord with the machine.

Turn on the power switch, the control panel display will

light, this indicates the power is connected.

Motor overload circuit breaker

If the machine should jam in a way that the motor could be eected, the circuit breaker will cut o the power

to avoid damage. Once the overload has been cleared, press the circuit breaker button and the motor will start

again. The circuit breaker button is located at the rear of the machine next to the power switch. The button is red

in colour.

Run and stop switch

The RUN/STOP switch enables you to start and stop the motor. When it is switched to RUN the

machine will

Loading/threading the lm - Encapsulating

Please follow the step by step guide below to correctly load your lm;

Remove the feed tray by retracting the bolt

Remove the top mandrel

Remove the safety guard

Completely unscrew the mandrel

and cap

Load the lm onto the mandrel and

make sure it is loaded with the lm

coming o the bottom of the roll with

the adhesive side up. Tighten the screw

back up with screwdriver provided

Ret the mandrel complete with

the loaded lm

Thread lm from top mandrel down

under top idler bar and over top

laminating roller surface as shown

(ensure lm is loaded with

adhesive side up)

6

Load lm onto bottom mandrel in

the same fashion as with the top

mandrel, remove bottom mandrel as

shown

NOTE: Indents are drilled in the

mandrels to locate core holder so

top and bottom lms line up

Core holder located on mandrel

Move bottom stabilizer bar forward

to assist lm loading

Film threading diagram -

Lift top roller by turning roller

pressure handle anti-clockwise

Re-t the feed tray

Re-t the plastic safety guard - With the

guard and/or tray not in position you can

put the drive switch to run and then by

pressing the load button the machine

will run forward when the load button is

released the machine will stop

Please note: There is a trip safety

switch which means that the

machine will not work if the feed

tray and safety guard are not

correctly in place.

NOTE: SAFETY TRIP SWITCH

Ensure the roller pressure is in the

‘LOCK’ position when running the

machine

Auto memory function

The linea has an auto memory function, that

means if you work on the same roll of lm,

the temperature and speed will be set to the

smae settings as the last time the machine

was used.

Load bottom lm around roller bar

as shown

Bring top lm down under idler bar

and web the lms together as shown

overlapping the top & bottom lm by

several inches

Take a piece of cardboard insert it in

between the rollers (in the nip)

Re-t the feed tray

NOTE: Ensure stabilizer bar is

relocated in the back position when

loaded

Cleaning and maintenance of your machine

The most expensive part of a laminator is usually the rollers, if these become

damaged they are costly to repair. Always ensure you look after the rollers and

clean them regularly to avoid a build up of glue (see advice below). Never hold

a sharp object such as a knife close to the rollers in case of catching the rubber

as this could cause permanent damage that will effect the result of your work.

When your laminator is cooling down, always seperate the rollers using the roller

pressure knob, this will ensure that your rollers do not touch when still hot as

this could leave a ‘at spot’.

Cleaning the rollers

It is easier to remove adhesive from the rollers when they are warm, do not

attempt this if the machine is hot (above 40oC). For easy access, remove the

safety shield and feed tray. Always use a clean cloth and a mild anti-static foam

cleaner such as Amberclens by Ambersil or similar, do not use a heavy duty

solvent or anything abrasive.

If the lm becomes jammed in the machine in any way and there is a large build

up of adhesive, do not try and remove this yourself, contact your supplier for

advice.

Troubleshooting

My laminator has no power

Make sure that the electrical outlet being used is not damaged and that it is supplying power. Ensure the power cord

is rmly tted in the back of the machine and not straining in any way. If all of this seems correct, there are three

fuses to check, one is located next to the power switch, the other two are located underneath the laminator.

Contact your supplier if none of these solutions resolve the problem.

My lamination is coming out cloudy

This means that the temperature is not hot enough, try and increase by 5oC and wait until the laminator has reached

the new temperature before putting through another print.

My lamination has come out wrinkled/creased

This means that the temperature is too hot. You should also put a test document through rst to avoid ruining your

work. Reduce the temperature by 5oC and wait until the laminator has cooled before trying again.

The lm is wrapping around the rollers when I try to laminate

The lm may be threaded incorrectly, refer to the threading diagram on page 6 or 8 (depending on if you are doing

single sided or encapsulating. The adhesive side of the lm may be facing the roller. Stop the operation, wait until

the laminator has cooled down and thread the lm again in the correct manner.

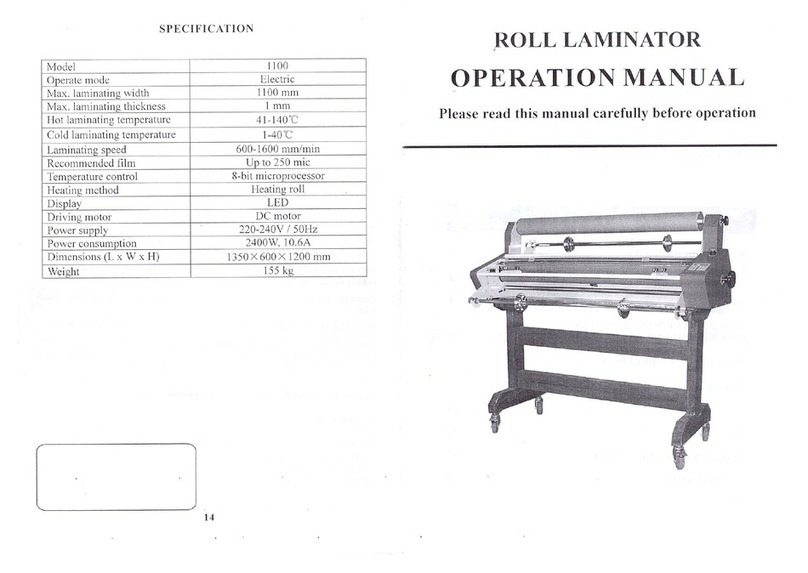

Specication chart

MODEL DH-360 DH-460 DH-650

MAX LAMINATING WIDTH 340mm 460mm 650mm

MAX LAMINATING THICKNESS 5mm 5mm 5mm

MAX LAMINATING TEMPERATURE 140C 140C 140C

MAX LAMINATING SPEED 1.4m/min 1.4m metres/minute 1.4 metres/minute

RECOMMENDED FILM Prolife lm, up to 250 micron Prolife lm, up to 250 micron Prolife lm, up to 250 micron

DIAMETER OF HEATING ROLLER 44mm 55mm 55mm

DIAMETER OF PULL ROLLER 30mm 45mm 45mm

POWER SUPPLY 100, 110, 220-240V, 50, 60Hz

POWER 700W 950W 1600W

DIMENSIONS 620 x 420 x 310mm 720 x 520 x 400mm 910 x 520 x 400mm

WEIGHT 30kg 45kg 58kg

STAND N/A N/A Optional Extra

Warranty & Incorrect Use

IMPORTANT INFORMATION

Your laminator should reach you in perfect condition, however please retain all original packaging once you have unpacked your

laminator in case you need to return it to us. If your laminator arrives damaged or faulty in anyway, this must be reported to your

supplier immediately. If you send your laminator back for repair under warranty at any time, then the warranty may be void if the

laminator is not packaged correctly and as a result is damaged in transit. The laminator you have purchased comes with a 1 year

warranty on defective parts. THIS DOES NOT COVER any jams, misfeeds or wrap arounds caused by operator error and you will be

liable for the repair costs (including delivery charges) if the damage is caused by operator error.

E&O.E

10

Other manuals for DH-360

1

This manual suits for next models

2

Table of contents

Other Linea Laminator manuals

Popular Laminator manuals by other brands

Rebel

Rebel URZ0987 user manual

GBC

GBC Ultima 65 Installation & operation manual

CWT

CWT EXPRESS Use and maintenance manual

Titanium

Titanium HomeOffice PL 250 operating manual

BEIJING YC DIGITTECH

BEIJING YC DIGITTECH YCY-215D user manual

Professional Laminating Systems

Professional Laminating Systems II Series Operator's manual