Linear Technology DC2247A Quick setup guide

1

dc2247af

DEMO MANUAL DC2247A

Description

LT3922

36V 2A Synchronous

2MHz Boost LED Driver

Demonstration circuit DC2247A is a 36V 2A synchronous

2MHz boost LED driver featuring the LT

®

3922. It drives

a single string of LEDs at 330mA up to 34V when VIN is

between 7V and 28V. It runs down to 4VIN with reduced

ILED and can withstand VIN as high as 36V, but has over-

voltage lockout (OVLO) set for 28V for this application.

DC2247A runs at 2MHz switching frequency. Spread

spectrum frequency modulation (SSFM) can be turned

on with a simple jumper, reducing EMI. DC2247A comes

with low EMI features including optimized layout, SSFM,

and input and output filters. It passes CISPR 25 class 5

conducted and radiated EMI. It is protected against both

open and short LED conditions and reports the faults.

The LT3922 has an input voltage range from 2.8V to 36V.

Its internal synchronous 2A 40V switches allow up to 34V

of LEDs on the output with room for overvoltage protection

and overshoot during an open LED event. It has adjustable

switching frequency between 200kHz and 2.5MHz. It can

be synchronized to an external source or programmed with

SSFM for low EMI. The PWMTG high side PWM MOSFET

driver assists with short-circuit protection and versatility.

LT3922 can be configured as boost, boost-buck, or buck

mode LED driver and maintain all of its low-EMI, PWM

dimming and fault diagnostic features.

The LT3922 can be PWM dimmed with an external PWM

signal or an internally-generated PWM signal. DC2247A

has a jumper that can be set to switch between internally-

generated PWM signal, externally-generated PWM signal,

and no PWM signal (100% on). It can be analog dimmed

with a control voltage on its CTRL pin.

When run with both PWM dimming and SSFM, the spread

spectrum aligns itself with the PWM signal for flicker-free

operation.

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks of Linear

Technology Corporation. All other trademarks are the property of their respective owners.

Small ceramic input and output capacitors are used to

save space and cost. The board is designed with tiny, high

frequency capacitors on both sides of the VOUT pins for

a reduction in radiated EMI. The open LED overvoltage

protection uses the IC’s constant voltage regulation loop

to regulate the output to approximately 37.5V if the LED

string is opened although it may reach almost 40V peak

during transient from running LEDs to open. There is a

protection diode from LED+to GND to prevent negative

ringing during a short circuit. The output current can be

monitored through the ISMON output pin.

Undervoltage and overvoltage lockout can be adjusted on

the circuit with a few simple resistor choices.

There is an EMI filter on the input of DC2247A. There is also

a small ferrite bead output filter. These filters, combined

with proper board layout and SSFM are effective to help

the PCB pass CISPR 25 class 5 conducted and radiated

EMI. Please follow the recommended layout and four-layer

thickness of DC2247A for low EMI applications.

The LT3922 data sheet gives a complete description of

the part, operation and applications information. The

data sheet must be read in conjunction with this Demo

Manual for DC2247A. The LT3922EUFD is assembled in a

28-lead plastic 4mm x 5mm QFN package with a thermally

enhanced ground pad. Proper board layout is essential

for maximum thermal performance. See the data sheet

section Layout Considerations.

Design files for this circuit board are available at

http://www.linear.com/demo/DC2247A

2

dc2247af

DEMO MANUAL DC2247A

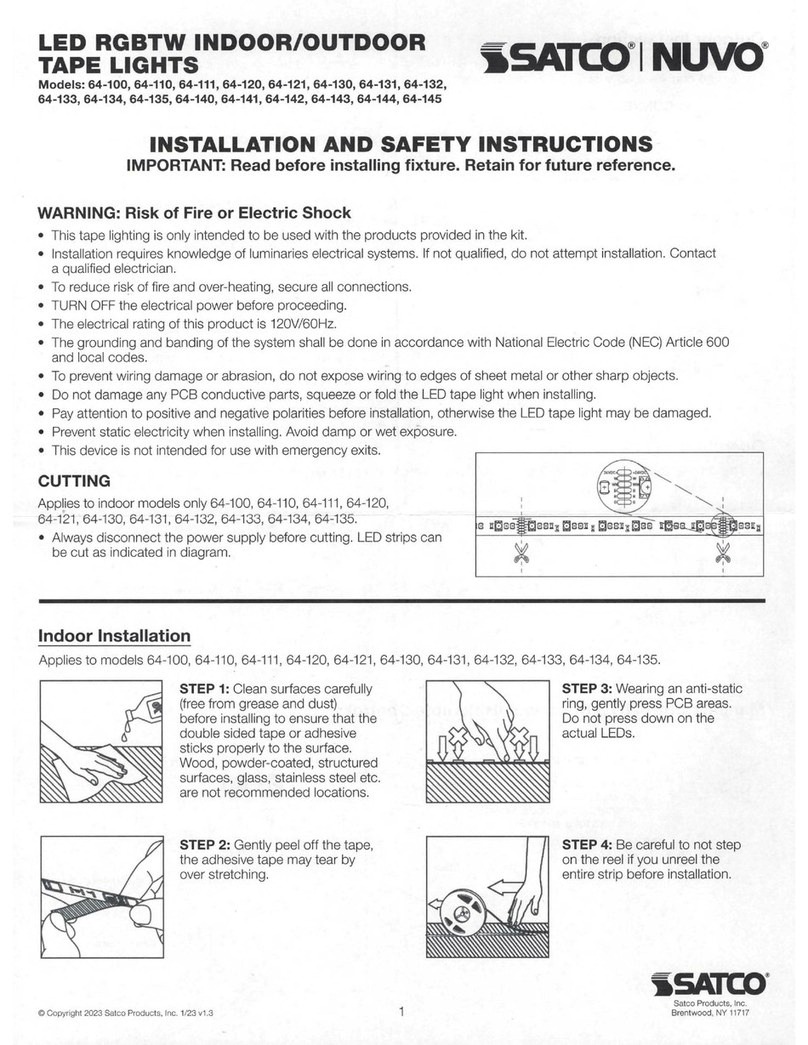

Quick start proceDure

Demonstration circuit DC2247A is easyto set upto evaluate

theperformanceof the LT3922Follow theprocedurebelow:

1. With power off, connect a string of LEDs that will run

with forward voltage less than or equal to 34V(at

330mA) to the LED+and LED–terminals on the PCB

as shown in Figure 1.

2. Connect the EN/UVLO terminal to GND.

3. Set JP1 to ON and JP2 to EXT/ON for 100% always-on

LED operation. Set JP3 to NO SSFM to run without

SSFM or external synchronization.

4. With power off, connect the input power supply to the

LOW EMI VIN and GND terminals. Make sure that the

input voltage will not exceed 36V.

5. Turn the input power supply on and make sure the

voltage is between 5V and 36V to start operation.

6. Release the EN/UVLO-to-GND connection.

7. Observe the LED string running at the programmed

LED current.

8. To change the brightness with analog dimming, simply

attach a voltage source to the CTRL terminal and set

the voltage between 0V and 1.5V. See data sheet for

details.

9. To change brightness with external PWM dimming, set

JP1 to EXT and JP2 to EXT/ON. Attach a 3V rectangular

waveform with varying duty cycle to the PWM terminal.

10. To change brightness with internally-generated PWM

dimming, set JP1 to INT and JP2 to INT. Adjust the

setting of the VR1 variable resistor with a small flat-

head screwdriver to toggle between 0% and 100%

PWM dimming duty cycle in 1/128 steps.

11. To enable spread spectrum frequency modulation, set

JP3 to SSFM ON.

performance summary

Specifications are at TA= 25°C

PARAMETER CONDITIONS MIN TYP MAX UNITS

Input Voltage Low EMI VIN Range Operating ILED > 0mA 4 28 V

Input Voltage Low EMI VIN Range Operating VLED = 34V, ILED = 330mA 7 28 V

Safe Input Voltage Low EMI VIN Range 0 36 V

Switching Frequency R2 = 45.3k, SSFM = OFF 2 MHz

Switching Frequency R2 = 45.3k, SSFM = ON 2 to 2.5 MHz

ILED R1 = 0.3Ω, 7.0V < Low EMI VIN < 28V, VLED = 34V 330 mA

VLED Range R4 = 1M, R5 = 33.2k VIN 34 V

Open LED Voltage VOUT R4 = 1M, R5 = 33.2k, OPEN LOAD 37.5 V

Efficiency (100% PWM DC) PVIN = 12V, VLED = 34V, ILED = 330mA 90 %

Efficiency with EMI Filters Removed PVIN = 12V, VLED = 34V, ILED = 330mA 91 %

Internally-Generated PWM Dimming Range Operating JP1 = INT, JP2 = INT 1/128 100%

Internally-Generated PWM Dimming Frequency Operating JP1 = INT, JP2 = INT R10 = 332k 122 Hz

3

dc2247af

DEMO MANUAL DC2247A

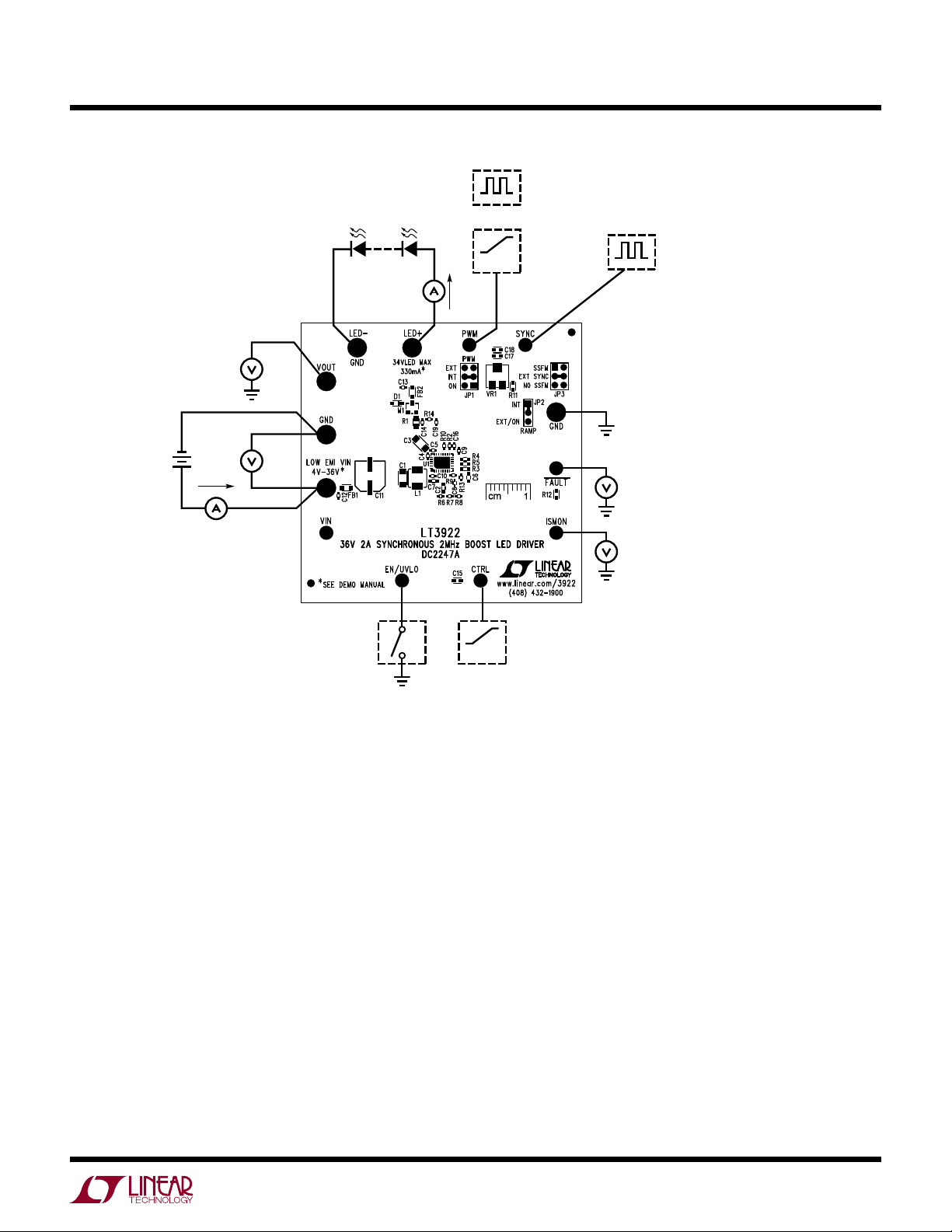

Figure 1. Test Procedure Setup Drawing for DC2247A

Quick start proceDure

DC2247 F01

MONITOR

FAULT FLAG

MONITOR

LED CURRENT

–

+

–

+

VIN

+

–

VOUT

IIN

INPUT

SUPPLY

+–

ILED

–

+

UP TO

34V LEDS SET JP3 FOR SYNC AND SSFM.

CONNECT EXTERNAL SYNC

SIGNAL TO SYNC TERMINAL WHEN

“EXT SYNC” OPTION IS SELECTED.

SET JP1 AND JP2 TO MATCH

EXT: EXTERNAL PWM DIMMING

INT: INTERNAL PWM DIMMING

ON: 100% ON, NO PWM DIMMING

ADJUST VR1 WITH SCREWDRIVER

FOR INTERNAL PWM DIMMING

DUTY CYCLE CONTROL

1V 2V

OR

EXTERNAL

PWM DIMMING

OPTIONAL

SYNC

INTERNAL

PWM DIMMING

0V 2V

OPTIONAL

ANALOG DIMMING

FOR LED CURRENT

REDUCTION

OPTIONAL

CONNECT

EN/UVLO TO GND

FOR SHUTDOWN

4

dc2247af

DEMO MANUAL DC2247A

Quick start proceDure

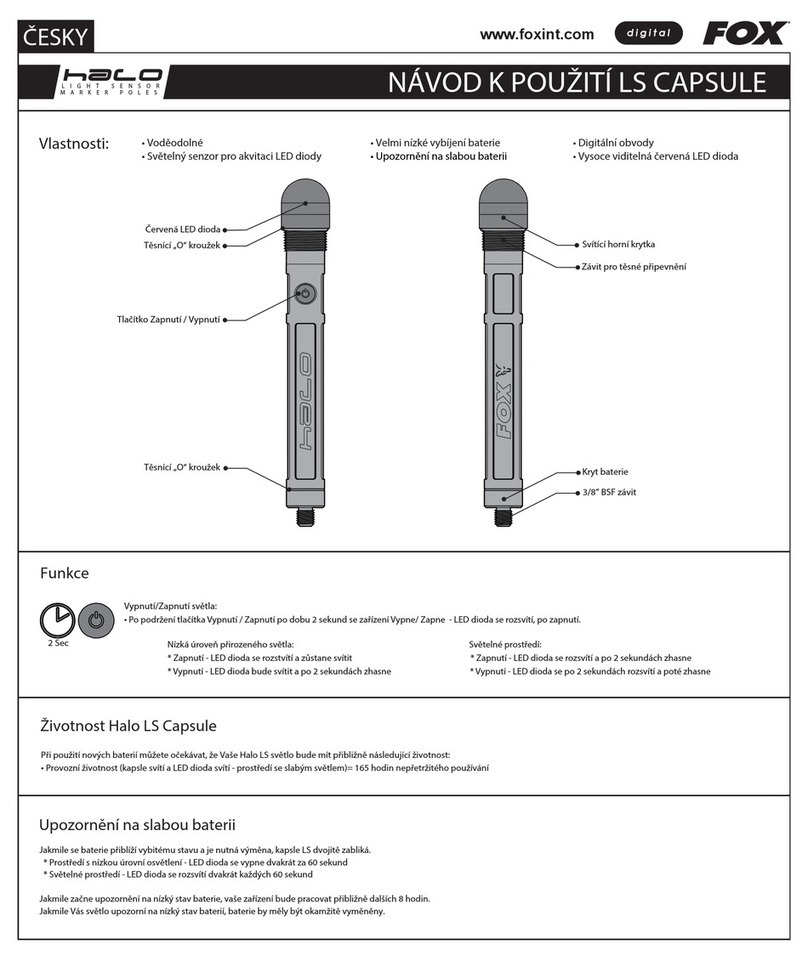

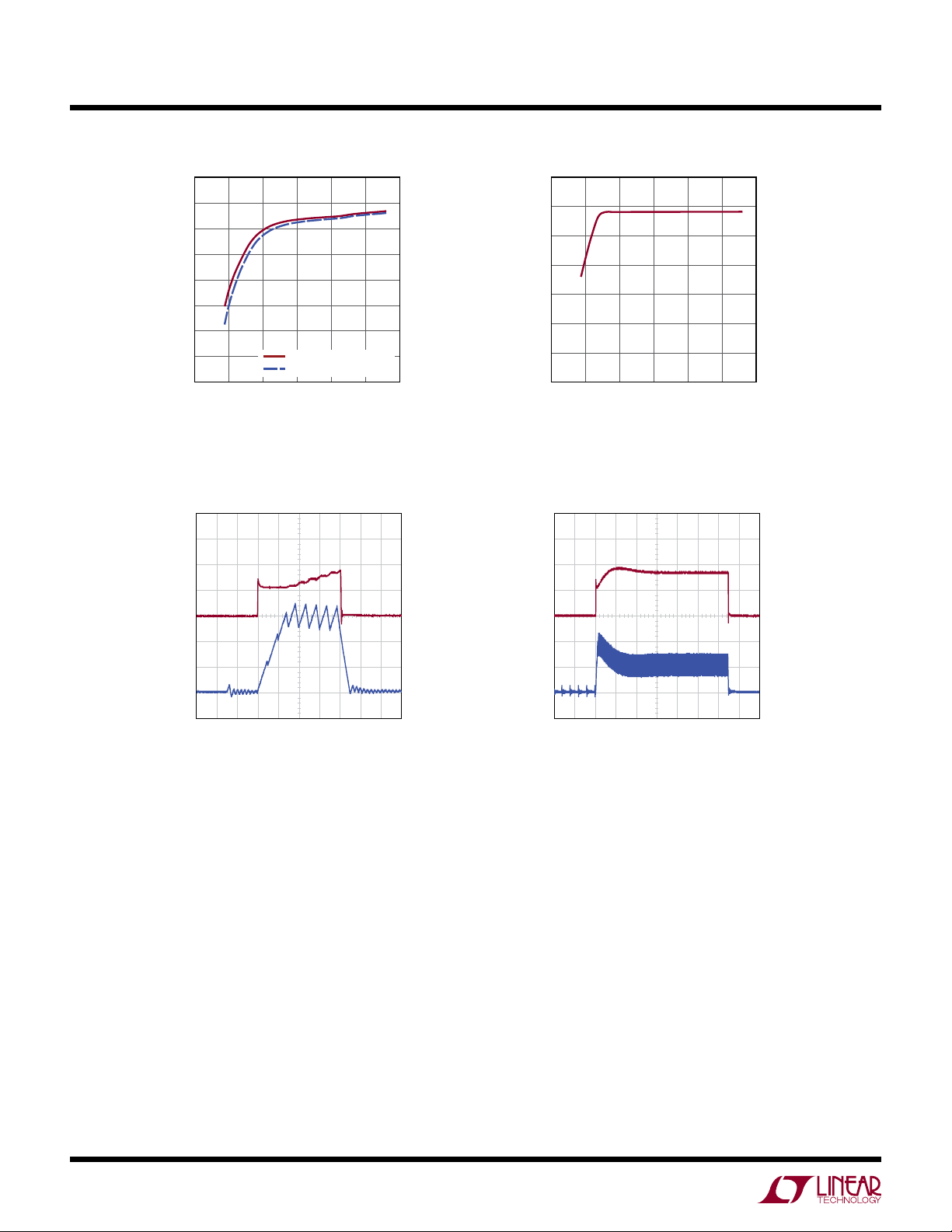

Figure 2. DC2247A Efficiency and LED Current Versus Input Voltage for 34V 330mA LED Load. Efficiency Remains High

Through the Range Due to Synchronous Switching. At Low VIN, ILED Can Be Reduced Due to Peak Switch Current Limit

Figure 3. Infinite-Persist Scope Traces Show PWM Dimming and SSFM Working Together for Flicker-Free

Brightness Control with both a) Externally and b) Internally Generated PWM Dimming

a) b)

VIN (V)

EFFICIENCY (%)

DC2247 F02a

60

65

70

75

80

85

90

95

100

0

30

252015105

WITHOUT EMI FILTERS

WITH EMI FILTER

VIN (V)

LED CURRENT

DC2247 F02b

0.00

0.05

0.10

0.15

0.20

0.30

0.35

0.40

0

30

252015105

1µs/DIV

ILED

200mA/DIV

IL

1A/DIV

VIN = 12V, VLED = 34V, ILED = 330mA

fSW = 2MHz, SSFM ON

2000:1, 120Hz EXTERNAL PWM DIMMING

DC2247 F03a 10µs/DIV

ILED

200mA/DIV

IL

1A/DIV

VIN = 12V, VLED = 34V, ILED = 330mA

fSW = 2MHz, SSFM ON

128:1, 122Hz INTERNAL PWM DIMMING

V

PWM

= 1.01V

DC2247 F03b

5

dc2247af

DEMO MANUAL DC2247A

Quick start proceDure

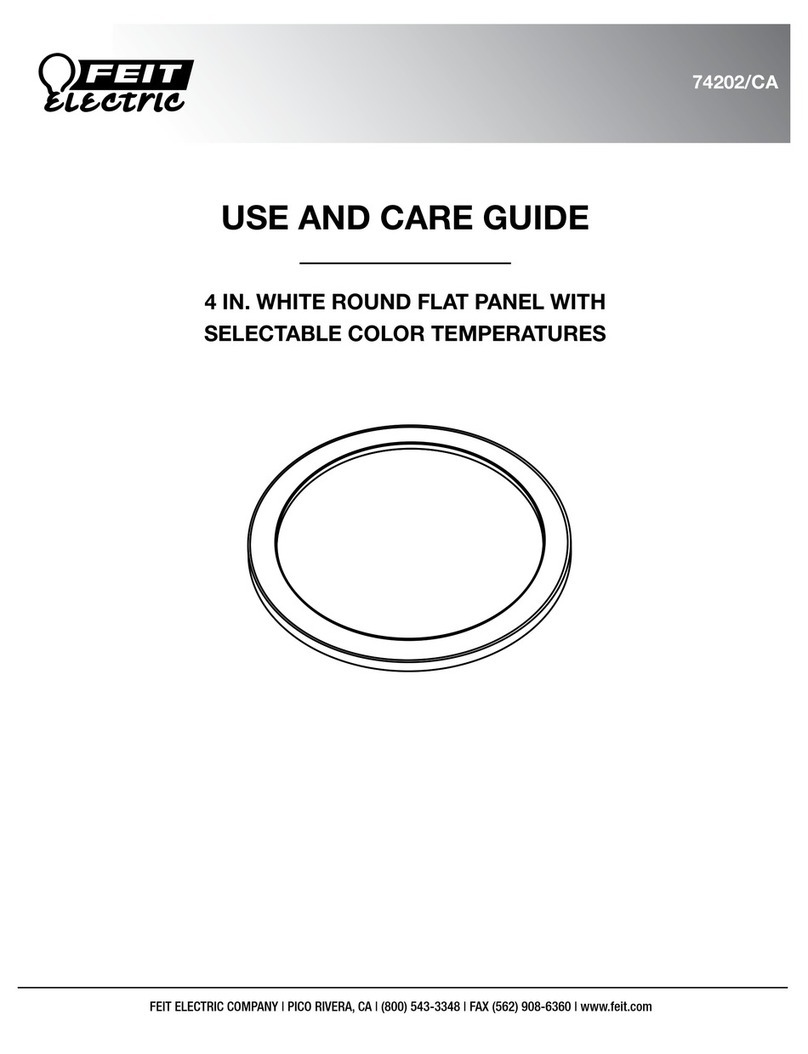

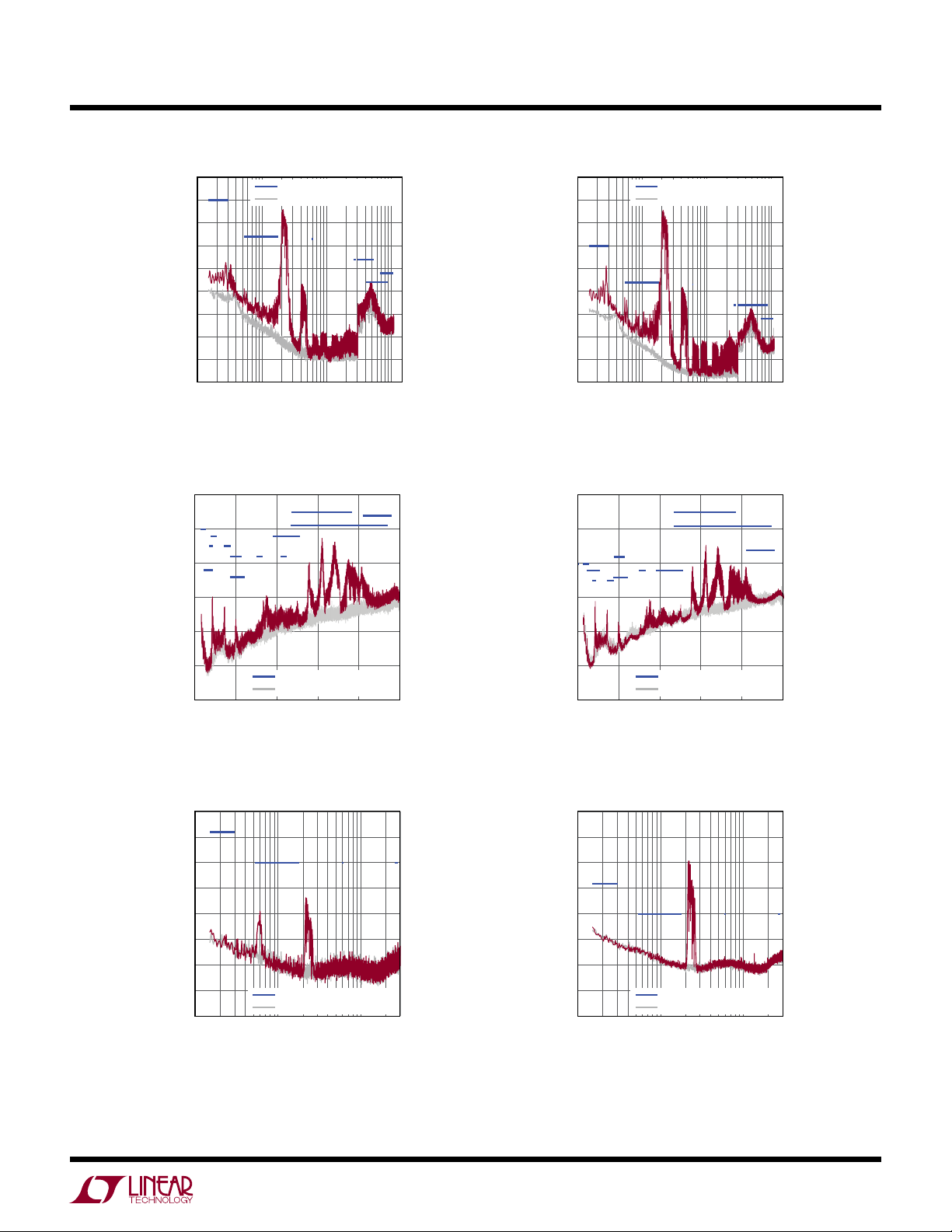

Figure 4. DC2247A Conducted Peak and Average EMI—Passes CISPR 25 Class 5 Limits.

Figure 5. DC2247A Radiated Peak and Average EMI—30MHz to 1GHz—Passes CISPR 25 Class 5 Limits

MHz

PEAK CONDUCTED EMI (dBµV)

DC2247 F04a

–10

0

10

20

30

50

40

60

80

70

0.1 10 1001

CISPR 25

CLASS 5 LIMITS

CISPR 25 CLASS 5 LIMITS

NOISE FLOOR

MHz

PEAK RADIATED EMI (dBµV/m)

DC2247 F05a

–10

0

10

20

30

40

50

0

1000

800600400200

CISPR 25 CLASS 5 LIMITS

NOISE FLOOR

MHz

AVERAGE CONDUCTED EMI (dBµV)

DC2247 F04b

–10

0

10

20

30

50

40

60

80

70

0.1 10 1001

CISPR 25

CLASS 5 LIMITS

CISPR 25 CLASS 5 LIMITS

NOISE FLOOR

MHz

AVERAGE RADIATED EMI (dBµV/m)

DC2247 F05b

–20

0

10

20

30

–10

40

0

1000

800600400200

CISPR 25 CLASS 5 LIMITS

NOISE FLOOR

Figure 6. DC2247A Radiated Peak and Average EMI—150kHz to 30MHz—Passes CISPR 25 Class 5 Limits

MHz

PEAK RADIATED EMI (dBµV/m)

DC2247 F06a

10

15

20

25

30

40

35

45

50

0.1 101

CISPR 25 CLASS 5 LIMITS

NOISE FLOOR

MHz

AVERAGE RADIATED EMI (dBµV/m)

DC2247 F06b

0

5

10

20

15

25

30

35

40

0.1 101

CISPR 25 CLASS 5 LIMITS

NOISE FLOOR

6

dc2247af

DEMO MANUAL DC2247A

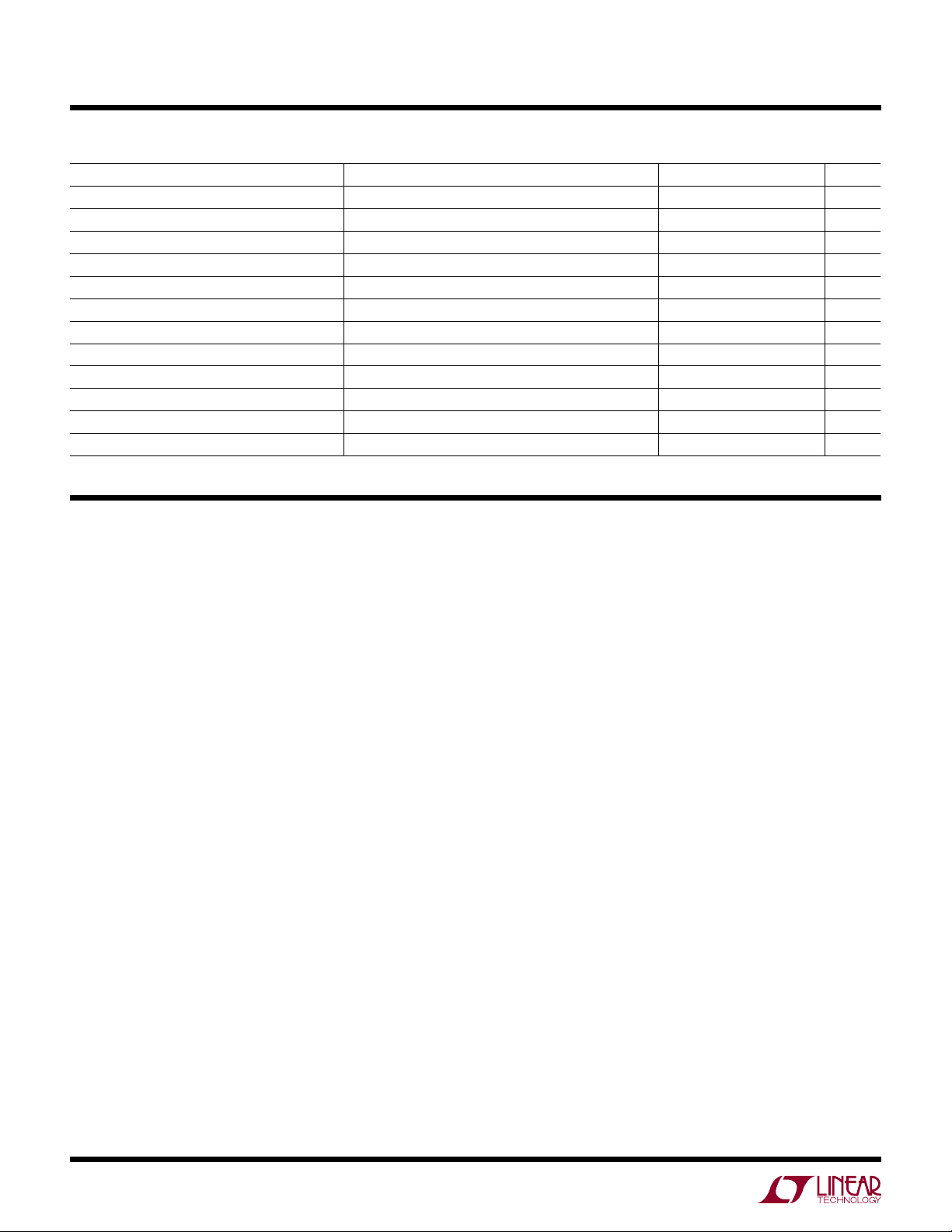

parts List

ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER

Required Circuit Components

1 1 C1 CAP., X5R, 4.7µF, 50V, 10%, 1206 MURATA, GRM31CR71H475KA12L

2 1 C2 CAP., X5R, 1µF, 50V, 10%, 0603 TDK, C1608X5R1H105K080AB

3 1 C3 CAP., X7R, 2.2µF, 50V, 10%, 1206 MURATA, GRM31CR71H225KA88K

4 2 C4, C5 CAP., X5R, 0.47µF, 50V, 10%, 0402 TAIYO YUDEN, UMK105ABJ474KV-F

5 1 C6 CAP., X7R, 220pF, 50V, 10%, 0603 MURATA, GRM188R71H221KA01D

6 1 C7 CAP., X7R, 2.2µF, 6.3V 10%, 0603 AVX, 06036C225KAT2A

7 1 C8 CAP., X5R, 1µF, 6.3V, 10%, 0402 MURATA, GRM155R60J105KE19D

8 2 C9, C10 CAP., X7R, 100nF, 6.3V, 10%, 0402 AVX, 04026C104KAT2A

21 1 L1 INDUCTOR, 4.7µH, 4.45mm x 4.06mm WURTH ELEKTRONIK, 74437324047

22 1 M1 P-MOSFET, Si2319CDS, SOT23 VISHAY, SI2319CDS-T1-GE3

23 1 R1 RES, CHIP, 0.3, 1/3W, 1%, 0805 SUSUMU, RL1220S-R30-F

24 1 R2 RES, CHIP, 45.3k, 1/16W, 1%, 0402 VISHAY, CRCW040245K3FKED

25 1 R3 RES, CHIP, 24k, 1/10W, 1%, 0603 VISHAY, CRCW060324K0FKEA

26 1 R4 RES, CHIP, 1M, 1/10W, 1%, 0603 VISHAY, CRCW06031M00FKEA

27 1 R5 RES, CHIP, 33.2k, 1/10W, 1%, 0603 VISHAY, CRCW060333K2FKEA

28 1 R6 RES, CHIP, 499k, 1/16W, 1%, 0402 VISHAY, CRCW0402499KFKED

29 1 R7 RES, CHIP, 221k, 1/16W, 1%, 0402 VISHAY, CRCW0402221KFKED

30 1 R8 RES, CHIP, 31.6k, 1/16W, 1%, 0402 VISHAY, CRCW040231K6FKED

31 1 R9 RES, CHIP, 100k, 1/16W, 1%, 0402 VISHAY, CRCW0402100KFKED

32 1 R10 RES, CHIP, 332k, 1/16W, 1%, 0402 VISHAY, CRCW0402332KFKED

36 1 U1 I.C., LED DRIVER, 28QFN 4X5 LINEAR TECH., LT3922EUFD#PBF

Optional Demo Board Circuit Components

9 1 C11 CAP., ALUM., 33µF, 50V, 20%, 6.3mm x 7.7mm SUN ELECTRONIC INDUSTRIES CORPORATION, 50CE33BS

10 2 C12, C13 CAP., X7R, 0.1µF, 50V, 10%, 0402 MURATA, GRM155R71H104KE14D

11 1 C14 CAP., X5R, 2.2µF, 6.3V, 10%, 0402 MURATA, GRM155R60J225ME15D

12 0 C15, C17, C18 (OPT) CAP., OPTION, 0603

13 0 C16, C19 (OPT) CAP., OPTION, 0402

14 1 D1 DIODE, SCHOTTKY, 40V, 1A, SOD323F NXP, PMEG4010CEJ, 115

17 1 FB1 CHIP, BEAD, 600Ω, 0805 WURTH ELEKTRONIK, 742792040

18 1 FB2 CHIP, BEAD, 1.5k, 0805 WURTH ELEKTRONIK, 742792097

33 1 R11 RES, CHIP, 91k, 1/10W, 5%, 0603 VISHAY, CRCW060391K0JNEA

34 1 R12 RES, CHIP, 51k, 1/10W, 1%, 0603 VISHAY, CRCW060351K0FKEA

35 0 R13, R14 (OPT) RES, OPTION, 0402

37 1 VR1 TRIMMER., 100k, 0.25W, SMD BOURNS, 3314J-1-104E

Hardware: For Demo Board Only

15 6 E1, E3, E8, E11-E13 TEST POINT, TURRET, 0.094" MTG. HOLE MILL-MAX, 2501-2-00-80-00-00-07-0

16 7 E2, E4-E7, E9, E10 TEST POINT, TURRET, 0.061" MTG. HOLE MILL-MAX, 2308-2-00-80-00-00-07-0

19 2 JP1, JP3 HEADER 3 PIN 0.079 DOUBLE ROW WURTH ELEKTRONIK, 62000621121

20 1 JP2 HEADER 3 PIN 0.079 SINGLE ROW WURTH ELEKTRONIK, 62000311121

38 3 XJP1, XJP2, XJP3 SHUNT, 0.079" CENTER WURTH ELEKTRONIK, 60800213421

7

dc2247af

DEMO MANUAL DC2247A

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representa-

tion that the interconnection of its circuits as described herein will not infringe on existing patent rights.

schematic Diagram

8

dc2247af

DEMO MANUAL DC2247A

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ●FAX: (408) 434-0507 ●www.linear.com

© LINEAR TECHNOLOGY CORPORATION 2016

LT 0816 • PRINTED IN USA

DEMONSTRATION BOARD IMPORTANT NOTICE

Linear Technology Corporation (LTC) provides the enclosed product(s) under the following AS IS conditions:

This demonstration board (DEMO BOARD) kit being sold or provided by Linear Technology is intended for use for ENGINEERING DEVELOPMENT

OR EVALUATION PURPOSES ONLY and is not provided by LTC for commercial use. As such, the DEMO BOARD herein may not be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including but not limited to product safety

measures typically found in finished commercial goods. As a prototype, this product does not fall within the scope of the European Union

directive on electromagnetic compatibility and therefore may or may not meet the technical requirements of the directive, or other regulations.

If this evaluation kit does not meet the specifications recited in the DEMO BOARD manual the kit may be returned within 30 days from the date

of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY THE SELLER TO BUYER AND IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE. EXCEPT TO THE EXTENT OF THIS INDEMNITY, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR

ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user releases LTC from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge. Also be aware that the products herein may not be regulatory compliant or

agency certified (FCC, UL, CE, etc.).

No License is granted under any patent right or other intellectual property whatsoever. LTC assumes no liability for applications assistance,

customer product design, software performance, or infringement of patents or any other intellectual property rights of any kind.

LTC currently services a variety of customers for products around the world, and therefore this transaction is not exclusive.

Please read the DEMO BOARD manual prior to handling the product. Persons handling this product must have electronics training and

observe good laboratory practice standards. Common sense is encouraged.

This notice contains important safety information about temperatures and voltages. For further safety concerns, please contact a LTC application

engineer.

Mailing Address:

Linear Technology

1630 McCarthy Blvd.

Milpitas, CA 95035

Copyright © 2004, Linear Technology Corporation

Table of contents

Popular Lighting Equipment manuals by other brands

Precision Lighting

Precision Lighting Domino Basis Track Series instruction manual

LED Technologies

LED Technologies VR1000 user manual

Luminar Outdoor

Luminar Outdoor 56423 Owner's manual & safety instructions

GTV

GTV CAMINO AE-BPW2FCAM-20 manual

Ansorg

Ansorg Simpless SNM 06SNM Series installation manual

PROEL

PROEL PLLEDMLBG user manual

Orphek

Orphek Amazonas 500 Operational & Safety Guide

Twinkly

Twinkly TWFL200STW-WEU Instruction guide

Cooper Lighting Solutions

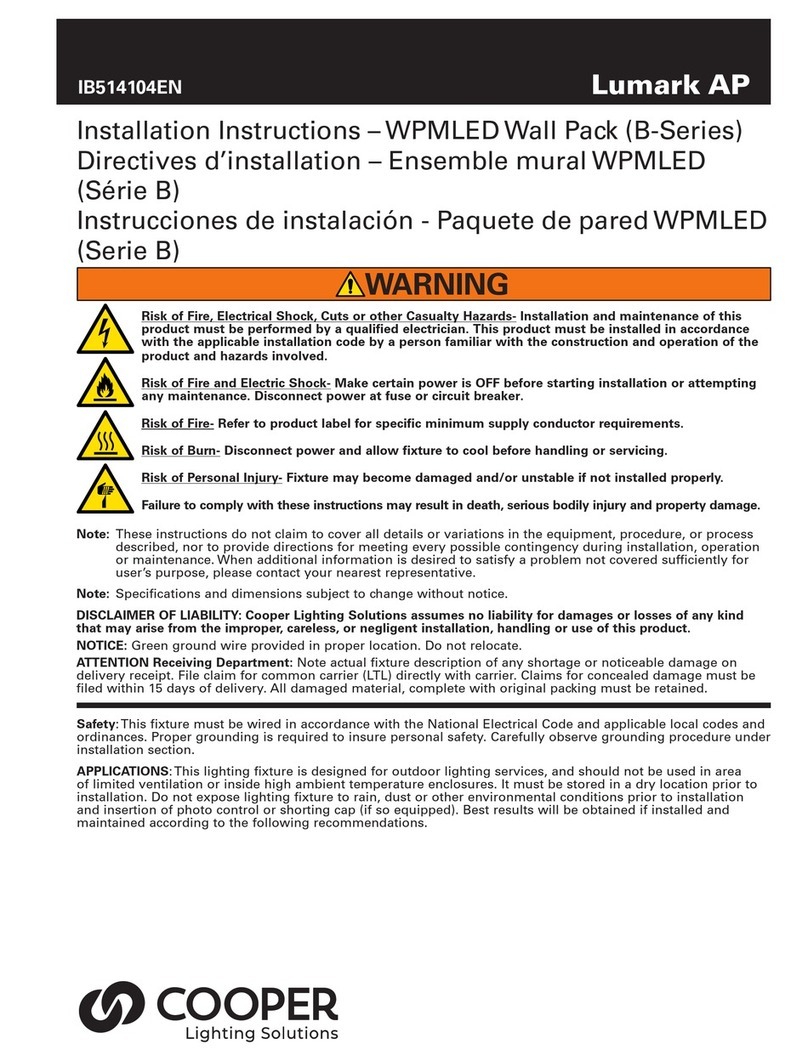

Cooper Lighting Solutions B Series installation instructions

DAEHAN

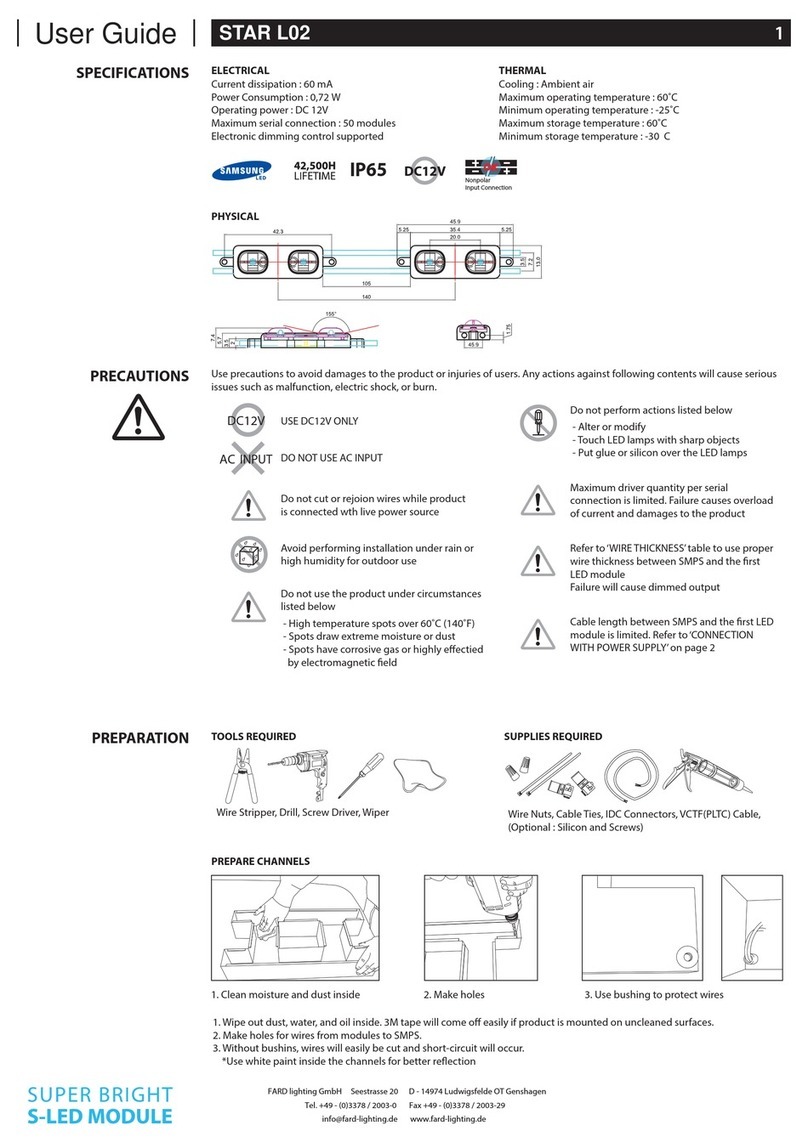

DAEHAN STAR L02 user guide

Federal Signal Corporation

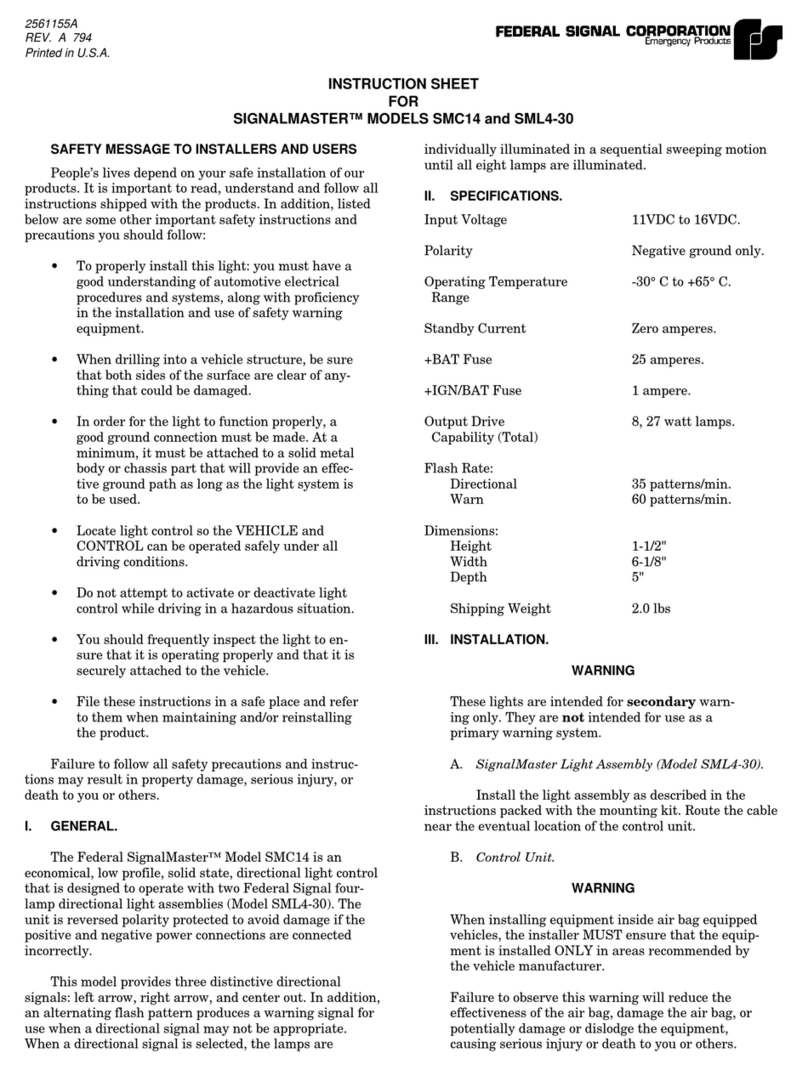

Federal Signal Corporation Signalmaster SMC14 instruction sheet

Original BTC

Original BTC Alma US-FF701N instruction manual