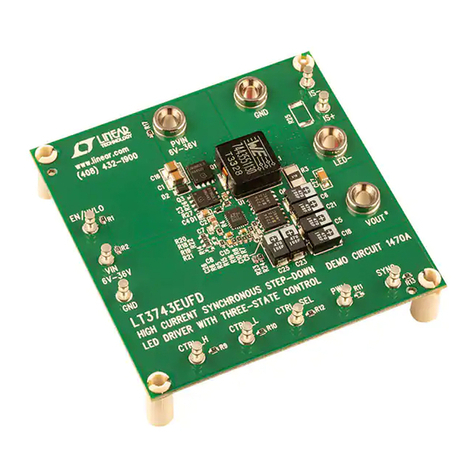

QUICK START GUIDE FOR DEMONSTRATION CIRCUIT

DC1296A

HIGH EFFICIENCY USB POWER MANAGER + DUAL BUCK + BUCK-BOOST

LTC3556EUFD

4

This form allows the feedback resistor divider net-

work on each regulator to be changed. The informa-

tion changed here, is saved, and is durable from

session to session. However, the factory values can

be recovered by pressing the “Restore defaults” but-

ton

QUICK START PROCEDURE

Complete the Quick Start Procedure outlined in the

Quick Start Guide for Demo Circuit 590 available

from the Linear Technology Web Site, prior to pro-

ceeding.

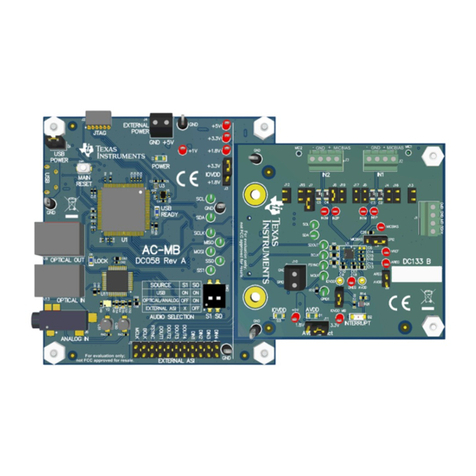

Refer to Figure 2 for the proper measurement

equipment setup and jumper settings and follow the

procedure below.

NOTE.

When measuring the input or output voltage ripple, care

must be taken to avoid a long ground lead on the oscilloscope

probe. Measure the input or output voltage ripple by touching the

probe tip directly across the VBUS or VOUT(x) and GND terminals.

See Figure 2 for proper scope probe technique.

1.

Set PS1 to 5.0V, and PS2 to 3.6V. Using the

LTC3556 GUI click on “5X Mode(500mA)”. In-

crease Ld2 to 200mA. Measure VOUT (VM6) ≈

3.68V, and I(VBUS) (AM1) ≈ 454mA.

VBUS is 5V, and can supply up to 500mA, or

2.5W. VOUT is being loaded at 200mA +

≈454mA (battery charge current) ≈654mA, so

VOUT will be 2.5W/0.654A ≈ 3.80V.

2.

Using the LTC3556 GUI click on “10X Mode(1A)”

under Average Input Current Limit Setting.

Measure VOUT (VM6) and IBAT. Measure VOUT

(VM6) ≈ 3.97V, and I(VBUS) (AM1) ≈ 510mA.

The input power limit is now higher than the

power load at VOUT, so VOUT rises to 3.97V ≈

(V(

BAT)

+ 0.35V).

3.

Set V(BAT) (PS2) to 2.5 V. Measure the battery

Current IBAT in trickle charge mode. Remove

the NTC jumper (JP1) and observe the CHRG

LED slow blinking rate (1.5Hz at 50% Duty Cy-

cle). Reinstall the NTC jumper (JP1). When

V(BAT) is below 2.85V (Typ.), the battery

charger attempts to trickle charge the battery up

above this threshold at ≈ I

CHARGE

/10 = 50mA.

When the battery charger detects a fault such as

the NTC pin signaling the battery is too cold or

too hot, it signals this by pulsing the

CHRG

pin at

a frequency and duty cycle that identifies the re-

ported fault.

4. Set the voltage on the BAT pin (PS2) to 4.21V.

Once the battery reaches the float voltage, the

battery charger switches from Constant Current

(CC) mode to Constant Voltage (CV) mode. The

purpose of Constant Voltage mode is keep the

battery “topped off” at the float voltage. If the

battery is unloaded, this current should be very

small.

5. With PS1 set at 5V, set the voltage on BAT (PS2)

to 3.6V. Set Ld1 to zero current and set ENALL

jumper (JP2) to “LO. Verify that the GOODALL

LED is lit. The GOODALL LED lights red when

one or all of the regulators is out of regulation, or

when all the regulators are off.

6.

Set the ENALL jumper (JP2) to “Hi” to turn on

VOUT1-VOUT3. Observe the start-up sequence

with an oscilloscope, measure VOUT1, VOUT2

and VOUT3 and observe the state of the

POWERGOOD ALL LED. The sequencing of

regulators VOUT1, 2, & 3 is controlled by the

state of the SEQ pin. The SEQ pin is a three state

input to the LTC3556, and three sequences are

programmable. There is no equivalent to the

SEQ pin in the I

2

C channel. SEQ is grounded so

the power supply sequence should be VOUT1

then VOUT2, then VOUT3.

7. Move the SEQ jumper (JP3) to “3->1->2”.

8. Set ENALL jumper (JP2) to “LO.

9.

Set the ENALL jumper (JP2) to “Hi” to turn on

VOUT1-VOUT3. Observe the start-up sequence

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.