QUICK START GUIDE FOR DEMONSTRATION CIRCUIT 909

MULTI-LED CAMERA LIGHT CHARGE PUMP

LTC3217

WARNING: The LEDs on this demo board produce very bright light. Do not look directly at LEDs when power is

applied. Serious eye damage may occur.

1

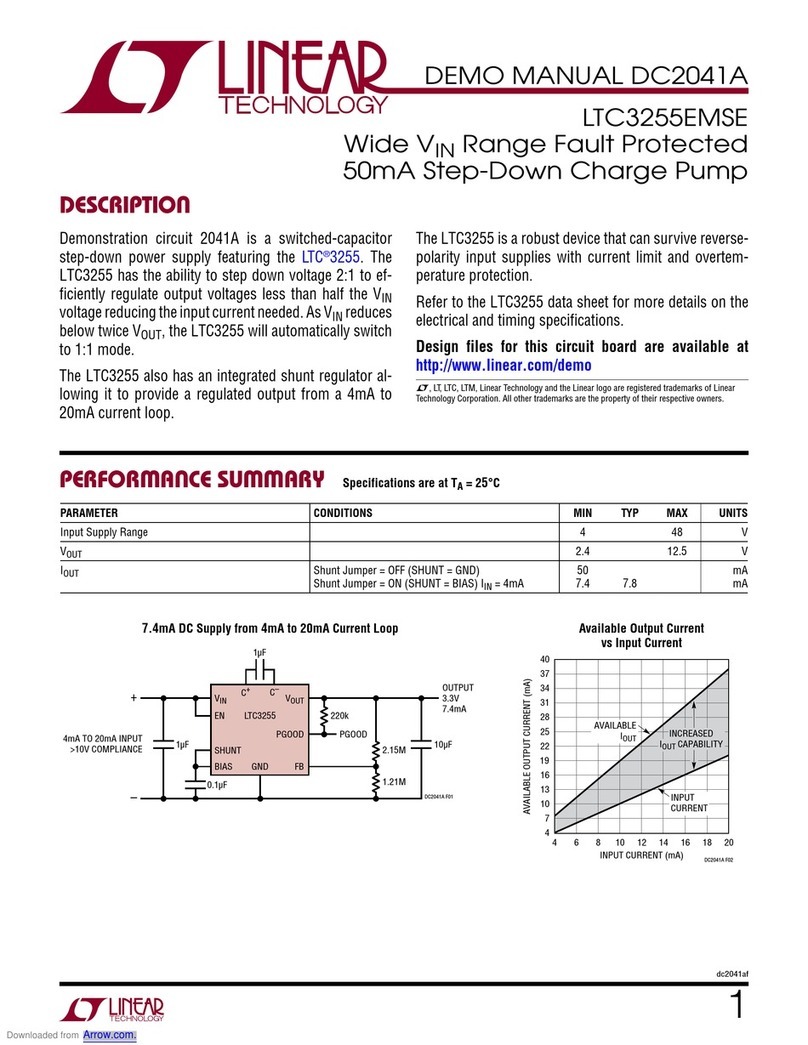

DESCRIPTION

Demonstration Circuit 909 is a Multi-LED Camera

Light Charge Pump featuring the LTC3217.

The LTC3217 is a low noise charge pump designed to

power four high current LEDs. The LTC3217 requires

only four small ceramic capacitors plus two resistors

to form a complete LED power supply and a current

controller.

Built-in soft-start circuitry prevents excessive inrush

current during start-up and mode changes. High

switching frequency enables the use of small external

capacitors. Independent high and low current set-

tings are programmed by two external resistors.

Shutdown mode and current output levels are se-

lected via two logic inputs. The intensity of the dis-

play may be adjusted by pressing the EN1, EN2, or

both buttons. The intensity may be further controlled

by pulse width modulating EN2.

An ultra-low dropout current source maintains accu-

rate LED current at very low I

LED

voltages. Automatic

mode switching optimizes efficiency by monitoring

the voltage across the LED current source and

switching modes only when ILED dropout is detected.

Design files for this circuit board are available. Call

the LTC factory.

, LTC and LT are registered trademarks of Linear Technology Corporation.

QUICK START PROCEDURE

The DC909 is only intended for continuous operation at a current level of 300mA or less. As a result, the higher

current settings should only be used for periods less than 10 seconds.

The use of the Demo Circuit 909 requires a DC

power supply capable of supplying at least 1A of

current.

1. Connect the DC power supply across the Vin

and GND terminals of the board as shown in

Figure 1. For best stability and noise perform-

ance, use the shortest leads possible between

the board and the supply. Capacitor C5 has

been placed on the board to assist in offsetting

the effects of long power supply leads.

2. Set the output of the supply to a voltage be-

tween 2.9V and 4.5V.

3. Pressing either EN1, EN2, or both of the enable

buttons will enable the part and illuminate the

LED. The individual LED current settings for the

set enable pins are shown in the table 1.

TABLE 1. Enable Pin Truth Table

EN2 EN1 I

The ISET resistors (R1 and R2) may be re-

placed with different values to achieve other

current levels. The resistance required

(RSET [Ω]) to achieve a desired LED current

(I

LED

[A]) may be approximately determined by

the following equation:

RSET=488/I

LED

Pulse width modulation may be performed on

demo circuit 909 by connecting a pulse genera-