Link Controls CS 320 User manual

EN

Control CS 320 / Rev.D 1.01 – 1

Assembly Instructions

Control CS 320

2 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 3

1. Contents

1. Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Information in this document . . . . . . . . . . . . 3

3. General safety instructions . . . . . . . . . . . . . . 3

4. Product overview. . . . . . . . . . . . . . . . . . . . . . 4

4.1 Product description...................4

4.2 Variants ...........................4

4.3 MotherboardCS320 .................5

5. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.1 Safety instructions for installation ........6

5.2 Mains connection ....................6

5.3 Internal fuse protection................7

5.4 Mains voltage selection ...............8

5.5 Supply to external devices

(only with 400 V / 3-phase connection) ....8

5.6 Connection of electronic limit position

system absolute value encoder (AWG).....9

5.7 Mechanical limit switch (MEC) connection..9

5.8 Connection of command devices........12

5.9 Light grid connection ................14

5.10 Connection of closing edge protective

device 1 . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.11 Connection light barrier 1 .............16

5.12 Terminal assignment, relay outputs ......17

5.13 Connection of programmable inputs . . . . . 17

5.14 Safety input per EN 12453 ............20

5.15 Radio receiver, pluggable .............21

5.16 CS radio ..........................22

5.17 Digital 991 ........................22

5.18 Connection of external radio receiver ....23

5.19 Connection of frequency converter ......23

5.20 Connection of LCD monitor............24

5.21 Connection of MS BUS components .....24

5.22 Transmission system radio.............25

6. Initialisation. . . . . . . . . . . . . . . . . . . . . . . . . 25

7. Setting the limit positions . . . . . . . . . . . . . . 26

7.1 Checking the drive / travel direction .....26

7.2 Setting the mechanical limit switches ....26

7.3 Setting the electronic end position system

using the setting buttons on the circuit

board ............................26

7.4 Setting the electronic limit position system

via the LCD monitor .................27

7.5 Setting the intermediate positions of the

electronic limit position system via the

LCD monitor.......................27

8. Programming . . . . . . . . . . . . . . . . . . . . . . . . .28

8.1 Overview of the LCD monitor ..........28

8.2 LCD monitor operating modes..........28

8.3 Expert menu.......................29

8.4 RESET............................29

8.5 RESETTING the controller with

LCDmonitor.......................30

8.6 RESETTING the controller without

LCDmonitor.......................30

9. Navigator (only LCD monitor) . . . . . . . . . . . .32

10. Functional overviews . . . . . . . . . . . . . . . . . . .34

10.1 Automatic mode....................34

10.2 Input operating mode ................35

10.3 Explanations of the relay modes:........43

10.4 Explanations of the inputs: ............46

10.5 Diagnosis operating mode / error memory. 50

11. Fault display and remedial measures. . . . . . .53

11.1 Fault display on the LCD monitor........53

11.2 Fault display via LED .................55

12. Technical data . . . . . . . . . . . . . . . . . . . . . . . .57

12.1 Mechanical and electrical data .........57

12.2 Category and performance level of the

safety function per EN ISO 13849-1 .....58

13. Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

14. Manufacturer’s declaration . . . . . . . . . . . . . .60

15. Annex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

15.1 Safety circuit measuring points .........61

15.2 Overview of the connections ...........62

Control CS 320 / Rev.D 1.01 – 3

EN

2 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 3

3. General safety instructions

WARNING!

Failure to comply with the documentation could

result in life-threatening danger!

Be sure to follow all the safety instructions in this

Be sure to follow all the safety instructions in this

document.

document.

Warranty

The function and safety of the equipment is only guaranteed

if the warning and safety instructions included in these

assembly instructions are adhered to.

The manufacturer is not liable for personal injury or damage

to property if these occur as a result of the warnings and

safety advice being disregarded.

The manufacturer does not accept any liability or warranty

for damage due to the use of non-approved spare parts and

accessories.

Intended use

ThecontrollerCS320isdesignedexclusivelyforcontrolling

door systems through drives with mechanical limit switches

(MEC) or an electronic limit position system (AWG).

Target group

Onlyqualiedandtrainedelectriciansmayconnect,

programme and service the control.

Qualiedandtrainedelectriciansmustmeetthefollowing

requirements:

− Knowledgeofthegeneralandspecicsafetyandaccident

prevention regulations,

−Knowledge of the relevant electrical regulations,

−Training in the use and care of appropriate safety

equipment,

−Capable of recognising the dangers associated with

electricity.

Original assembly instructions

−Copyright.

−No part of these instructions may be reproduced without

our prior approval.

−Subject to alterations in the interest of technical progress.

−All dimensions given in mm.

−The diagrams in this manual are not to scale.

Key to symbols

WARNING!

Indicates a hazard with a medium level of risk which, if not

avoided, could result in death or serious injury.

CAUTION!

Indicates a hazard with a low level of risk which, if not

avoided, could result in minor or moderate injury.

ATTENTION!

Indicates an imminent danger of damage or destruction.

CHECK

Indicates a check to be performed.

REFERENCE

Reference to separate documents which must be complied

with.

Action requestAction request

−List, itemisation

ÔReference to other sections of this document

2. Information in this document

4 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 5

4 – Control CS 320 / Rev.D 1.01

Instructions regarding installation and connection

−The control is designed with X type terminals.

−The system must be disconnected from the electricity supply

before carrying out any electrical work. It must be ensured

that the electricity supply remains disconnected for the

duration of the work.

−Local protective regulations must be complied with.

− Consultthemanufacturerbeforecarryingoutmodications

or replacing the mains connection cable.

−In general, an original wiring harness from Marantec

LegdenGmbH&Co.KGshouldbeusedforestablishingthe

connection between the door drive and controller. Changes

or replacements shall only take place following consultation

with the manufacturer and approval by the same.

Information concerning operation

−Unauthorised persons (particularly children) should not be

allowed to play with permanently installed adjusting or

control devices.

−Keep remote controls beyond the reach of children.

Observe the valid standards and regulations!

4. Product overview

4.14.1 Product descriptionProduct description

ThecontrollerCS320isdesignedforuseinindustrialareas

and can be used with all door types in these areas. It is

possible to connect drives with mechanical limit switches

(MEC) or an electronic limit position system (AWG).

All the necessary command devices and safety elements can

be connected, set and evaluated.

Programming takes place via a pluggable LCD monitor.

Alternatively, a service tool is available as an accessory.

The service tool consists of a stick and an app.

ThefollowingsuppliervariantsofthecontrollerCS320are

possible:

4.24.2 VariantsVariants

Housing variants:

− ControllerCS320inthe“standard”housing

− ControllerCS320inthe“combination”housingwith

integrated mounting rail for additional components

Variants of the pluggable LCD monitor:

−LCD monitor on the circuit board

−LCD monitor in the housing cover

− Hard-wiredLCDmonitor,pluggable(MSBUS)

−Without LCD monitor (monitor is required for all settings

apart from the limit position setting)

Command device variants:

−3-fold button CS integrated in the housing

Optional:

− Housingwithout3-foldbutton

− HousingwithON/OFFkeyswitch

− Housingwithmainswitch

− Housingwithemergencystop

−Pluggable components (circuit board)

−Brake monitoring module

−Week timer

−Radio receiver

−Radio transmission system for closing edge protective

device and/or a safety element.

The operating instructions describe the connection

andprogrammingoptionsandvariantsoftheCS320

controller with connected LCD monitor and from software

versionV1.01a.

General safety instructions

4 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 5

EN

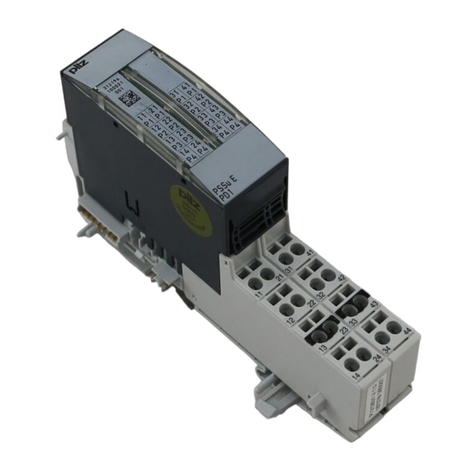

4.34.3 Motherboard CS320 Motherboard CS320

Explanation:

X1: Mains connection terminal strip

X2: Motor terminal strip

X3: Terminal strip for command devices

X4: Terminal strip for safety elements

X5: Terminal strip for relays

X6: Connector strip for internal ON/OFF switch

X7: Connector strip for internal 3-fold button KDT

X8: Connector strip for LCD monitor

(Beneath the LCD monitor)

X9: Connector strip for radio receiver

X10: Connector strip for week timer / brake monitoring

module

X11: Connector strip for electronic limit position system

(AWG)

X12: Connector strip for external radio receiver

X13: Connector strip for internal 3-fold button CS

X15: Terminal strip for mechanical limit switches (MEC)

X16: Connector strip for BUS system (MS BUS)

X17: Plug-in connector RJ for BUS system (MS BUS)

X18: Connector strip for frequency converter (interface)

X19: Terminal strip for supplying external devices

230V/50Hz

X20: Connector strip for transmission system

X21: Mains voltage selection

H1: Readyforoperation(green)

Lights up with power supply.

H2: Statusindicator(red)

Lights up with faults or with actuation of the safety

equipment

S1: Programming button (+)

(Beneath the LCD monitor)

S2: Programming button (–)

(Beneath the LCD monitor)

S3: Programming button (P)

(Beneath the LCD monitor)

F1: Fuseprotectionforexternaldevices230V/50Hz

(max. 1A slow-blow)

F2.1: Fuse protection for controller and drive L1 (max. 10 A)

F2.2: Fuse protection for controller and drive L2 (max. 10 A)

F2.3: Fuse protection for controller and drive L3 (max. 10 A)

Terminal strip for protective conductor (PE)

X10

B2

B1

W

V

U

1

2

3

4

5

6

7

8

X5

1

2

3

4

5

6

7

8

X15

1

2

3

4

5

6

7

8

9

10

X4

X7

X6

X12

N

L3

L2

L1

X1

X21

F2.1

F2.2

F2.3

F1

1

2

3

4

5

6

7

8

9

12

11

10

X9

X8

X20

S1

X13

X19

X3

X16

H1

H2

X11

X18

S2

S3

X2

X17

4.3 / 1

6 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 7

5. Installation

5.15.1 Safety instructions for installationSafety instructions for installation

WARNING!

Life-threatening danger due to electric shock!

Before performing wiring work, always disconnect the

Before performing wiring work, always disconnect the

system from the power supply. Make sure that the power

system from the power supply. Make sure that the power

supply remains disconnected during wiring work.

supply remains disconnected during wiring work.

ATTENTION!

Property damage due to improper installation of

the controller!

In order to avoid damage to the controller, observe the

following points:

− Onlyqualiedandtrainedelectriciansmayworkon

electrical systems.

−Switch off the power supply to the system, check that it

is de-energised and safeguard against reconnection.

−Mains cables and control cables must be routed separa-

tely.

−The line types and cross-sections must be selected in

accordancewiththevalidspecications.

−It is essential to observe the local protective regulations.

− Observethespecicationsofthedoormanufacturerfor

installation.

The following points must be correct to guarantee

fault-free functioning:

−The door is installed, fully functional and designed for

power-driven operation.

− Thegearmotoristtedandreadyforoperation.

− Thecommandandsafetydevicesarettedandreadyfor

operation.

− ThecontrolhousingwiththeCS320controlleristted.

Observe the valid standards and regulations!

REFERENCE

The instructions from the respective manufacturer must be

observed for the installation of the door, the gear motor and

the command and safety devices.

5.25.2 Mains connectionMains connection

Prerequisites

The following points must be correct to guarantee the

function of the controller:

−The mains voltage must correspond with the information

on the type plate.

−The mains voltage must correspond with the voltage of the

drive.

−In the case of three-phase power, this must have a

clockwiserotatingeld.

− Withaxedconnection,anall-polemainswitchmustbe

used.

−With three-phase power, only triple block circuit breakers of

type C (max. 16 A) shall be used.

ATTENTION!

Malfunctions due to improper installation of the

controller!

Beforeswitchingonthecontrollerforthersttimebut

after all of the wiring has been completed, it is necessary

to check all motor connections on the motor and controller

sides. All control voltage inputs are galvanically separated

from the supply.

The control and load lines of the connected drives must be

double-insulated along their entire route.

Detailed wiring diagram of mains connection and

motor connection (400 V / 3-phase)

B2

B1

W

V

U

N

L3

L2

L1

X1

X21

F2.1

F2.2

F2.3

F1

X19

X11

X18

X2

M

3

3

400 V / 50 Hz

/ N / PE

5.2 / 1

6 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 7

EN

Detailed wiring diagram of mains connection and

motor connection (230 V / 3-phase)

B2

B1

W

V

U

N

L3

L2

L1

X1

X21

F2.1

F2.2

F2.3

F1

X19

X11

X18

X2

M

3

3

230 V / 50 Hz

/ PE

5.2 / 2

Detailed wiring diagram of mains connection and

motor connection (230 V / 1-phase)

B2

B1

AUF

ZU

NL

N

X1

X21

F2.1

F2.2

F2.3

F1

X19

X11

X18

X2

M

1

1

230 V / 50 Hz

/ N / PE

5.2 / 3

Explanation:

M1: Motor

X1: Mains connection terminal strip

X2: Motor terminal strip

X11: Connector strip for electronic limit position system

(AWG) with safety circuit

X15: Terminal strip for mechanical limit switches (MEC)

(safety circuit to X2 / B1-B2)

X19: Connection for supplying external devices

Connection:

Connect electronic limit position system (AWG) orConnect electronic limit position system (AWG) or

mechanical limit switch (MEC) to the controller.mechanical limit switch (MEC) to the controller.

Connect controller to the motor.Connect controller to the motor.

Connect controller to the mains network.Connect controller to the mains network.

Secure cable groups with a cable tie directly before theSecure cable groups with a cable tie directly before the

respective terminal.respective terminal.

Check and compare technical data.Check and compare technical data.

Ô“12.Technicaldata”

5.35.3 Internal fuse protectionInternal fuse protection

ThecontrollerCS320isequippedwithinternalfuse

protection (F2) at the mains input. The fuse elements are

equippedwithnefuses8A/T(5.2x20mm)inthefactory.

N

L3

L2

L1

X1

X21

F2.1

F2.2

F2.3

3

400 V / 50 Hz

/ N / PE

5.3 / 1

ATTENTION!

Malfunctions due to improper fuse protection of

the controller!

Internal fuse maximum 10 A / T!

The internal fuses do not replace fuse protection of the

supply cable. This shall be realised with max. 16 A and must

beconguredastripleblockcircuitbreakersoftypeC.

Ô“5.2Mainsconnection”

8 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 9

5.45.4 Mains voltage selectionMains voltage selection

The position of the bridge connector to X21 must be adjusted

to the supply voltage and motor voltage.

PE

PE

PE

N

L3

L2

L1

X1

X21

3

400 V / 50 Hz

/ N / PE

F2.3

F2.2

F2.1

PE

PE

PE

N

L3

L2

L1

X1

X21

F1

X19

3

230 V / 50 Hz

/ PE

F2.1

F2.2

F2.3

AUF

ZU

PE

PE

PE

L

N

X1

X21

F1

X19

X11

X18

1

230 V / 50 Hz

/ N / PE

F2.1

F2.2

F2.3

5.4 / 1

PE

PE

PE

N

L3

L2

L1

X1

X21

3

400 V / 50 Hz

/ N / PE

F2.3

F2.2

F2.1

PE

PE

PE

N

L3

L2

L1

X1

X21

F1

X19

3

230 V / 50 Hz

/ PE

F2.1

F2.2

F2.3

AUF

ZU

PE

PE

PE

L

N

X1

X21

F1

X19

X11

X18

1

230 V / 50 Hz

/ N / PE

F2.1

F2.2

F2.3

5.4 / 2

PE

PE

PE

N

L3

L2

L1

X1

X21

3

400 V / 50 Hz

/ N / PE

F2.3

F2.2

F2.1

PE

PE

PE

N

L3

L2

L1

X1

X21

F1

X19

3

230 V / 50 Hz

/ PE

F2.1

F2.2

F2.3

AUF

ZU

PE

PE

PE

L

N

X1

X21

F1

X19

X11

X18

1

230 V / 50 Hz

/ N / PE

F2.1

F2.2

F2.3

5.4 / 3

5.55.5 Supply to external devicesSupply to external devices

(only with 400 V / 3-phase connection)(only with 400 V / 3-phase connection)

TheCS320has2separatevoltagesuppliesforexternal

components, such as signal devices, light barriers, etc.

X19 230V/1~

X4 24V-DC

N

L3

L2

L1

X1

X21

X19

3

400 V / 50 Hz

max. 1A

230V-AC

max. 500mA

24V-DC

/ N / PE

X4

1

2

3

4

5

6

7

8

9

12

11

10

F1

-

+

L

N

5.5 / 1

NOTE:

Use of the connection X19 is only possible with a supply with

400V / N / 3~.

The connection X19 is protected by the fuse element F1

(max.1A/T).

Installation

8 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 9

EN

5.65.6 Connection of electronic limit positionConnection of electronic limit position

system absolute value encoder (AWG)system absolute value encoder (AWG)

5.6 / 1

A

B

A: Absolute value encoder plug

B: AWG plug-in terminal

Connector strip X11 (on connector A)

4 7

grey yellow

5 8

green pink

6 9

white brown

5.6 / 2 Cables with either numbered or

coloured wires are used for the AWG,

depending on the drive:

4 (grey): Safety chain input

5 (green): RS 485 B

6 (white): GND

7 (yellow): RS485 A

8 (pink): Safety circuit output

9 (brown): 12V DC

Connector strip B (only absolute value encoder)

5.6 / 3

C: Thermal element in the drive

D: Emergency manual actuation (emergency crank or

emergency chain)

NOTE:

In order to satisfy the requirements of EN 12453:2017 the

electronic end position system must comply as a minimum

withPL“c”withamin.category2perENISO13849-1.

In order to satisfy this requirement, it is only permissible to

use an absolute value encoder from Marantec Legden

(art. no. 97957) as an electronic end position system.

5.75.7 Mechanical limit switch (MEC) connectionMechanical limit switch (MEC) connection

Alternatively to the absolute value encoder as an electronic

system, it is also possible to connect a mechanical cam limit

switch and evaluate this.

WithrstcommissioningandafteraRESET,theconnected

limit position system is automatically detected. With a

subsequent change, the respective limit position system must

be selected via a parameter setting in the INPUT operating

mode.

Series STA, MDF05, MTZ05

5.7 / 1 S1 S2 S3 S4 S5 S6

10 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 11

Series MDF20+, KD, MTZ20+

S1 S2 S3 S4 S5 S6

5.7 / 2

Mechanical limit switches

1

2

3

4

5

6

7

8

X15

S2

S5

S1

S6

5.7 / 3

Safety circuit

U

V

W

B1

B2

X2

S3

S4

S7

S8

5.7 / 4

Example of connection with 7-wire solution

1

2

3

4

5

6

7

8

U

V

W

B1

B2

X2

X15

S2

S5

S1

S6

S3

S4

S7

S8

5.7 / 5

Legend:

S1 Supplementary limit switch UP

S2 Limit switch UP

S3 Safety limit switch UP

S4 Safety limit switch DOWN

S5 Limit switch DOWN

S6 Supplementary limit switch DOWN

S7 Emergency operation (NC - contact)

S8 Motor thermal protection

NOTE:

In order to satisfy the requirements of EN 12453:2017 the

mechanical limit switches must have been approved as a

“reliablecomponent”inaccordancewithENISO13849-1.

Drives with integrated safety catch device must not be

equipped with mechanical limit switches.

Installation

10 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 11

EN

ATTENTION!

Property damage due to improper installation!

Connection as a 6-wire solution is prohibited and can lead

to destruction of the CS 320 circuit board.

Reference potential on X2/B1-B2 = 24V-DC

Reference potential on X15=12V-DC

1

2

3

4

5

6

7

8

S3 S4 S7 S8

S2

S5

S1

S6

U

V

W

B1

B2

X2

X15

5.7 / 6

s

12 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 13

5.8 Connection of command devices

CAUTION!

Risk of injury due to uncontrolled door movement!

A CLOSE command in dead-man operation without a view

of the door is not permitted.

Install the command devices for the dead-man operation

Install the command devices for the dead-man operation

in direct visual contact with the door, although outside

in direct visual contact with the door, although outside

the danger zone for the operator.

the danger zone for the operator.

A CLOSE command without visual sight of the door may

only be given via input 1 / MOD32 (X4 / 9-10).

If the command device is not a key switch:

Install it at a height of at least 1.5 m.

Install it at a height of at least 1.5 m.

Install it where it is inaccessible to the public.

Install it where it is inaccessible to the public.

Command devices (standard)

X3

A

B

C

D

E

5.8 / 1

Legend:

A Button / input DOWN

B Button / input impuls

C Button / input UP

(UP inside, with active two-way control)

D STOP button

E Emergency stop command device

UP / STOP / DOWN switch (6-wire solution)

X3

A

C

D

5.8 / 2

UP / STOP / DOWN switch (4-wire solution)

X3

A

C

D

5.8 / 3

IMPULS button

Selection of the function via IMPULS parameter

Ô“10.2Inputoperatingmode”onpage35

B

X3

5.8 / 4

- UP switch

- STOP button

Installation

12 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 13

EN

Cover keypad KDT

Push-button with NO / NC contacts.

Up to year of manufacture 12 / 2009.

X7X7

5.8 / 7

J

J Jumper (bridge)

The jumper must be connected if the KDT keypad is not

connected.

Cover keypad CS

Silicone keys with NO contacts.

From year of manufacture 01 / 2010.

X13

5.8 / 8

External radio receiver

1

2

3

4

5

6

7

8

9

10

X4 1

2

3

4

5

6

7

8

9

12

11

10

X19

X3

F1

24 V-DC

230 V-AC

*

5.8 / 5

* optionally, depending on connection of the radio receiver

Key switch

A

C

X3

5.8 / 6

Legend:

A Button / input DOWN

C Button / input UP

(UP inside, with active two-way control)

14 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 15

ON/OFF key switch

NC contact for interrupting the door function (optional).

This switch is part of the safety circuit.

X6X6

5.8 / 9

J

J Jumper (bridge)

The jumper must be connected if the key switch is not

connected.

5.95.9 Light grid connectionLight grid connection

Itispossibletoconnectupto2lightgridstotheCS320.

Light grid 1 is connected to the closing edge protective device

input. Light grid 2 is connected to programmable input 2.

Light grid 1

Parameter SKS = MOD4

The connection cable (A) is pluggable.

1

2

3

4

5

6

7

8

9

10

A

BK

BU

WH

BN

X4

GN

GY

11

12

5.9 / 1

Light grid 2

Parameter INPUT 2 = MOD 12

The connection cable (A) is pluggable.

1

2

3

4

5

6

7

8

9

10

A

BK

BU

WH

BN

X4

GN

GY

11

12

5.9 / 2

Legend:

BK Black

GN Green

GY Grey

BU Blue

WH White

BN Brown

R Receiver

T Transmitter

NOTE:

The GridScan/Pro light grids from Cedes are shown on an

exemplary basis in this manual.

The GridScan/Pro light grids correspond to

−Performance Level d, category 2 per EN ISO 13849-1

−Protection level E per EN 12453:2017

Diagrams from other manufacturers on inquiry.

REFERENCE

For a precise description of the function and connection,

refer to the separate documentation for the light grid.

Installation

14 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 15

EN

5.10 Connection of closing edge protective

device 1

WithrstcommissioningandafteraRESET the system of

the closing edge protective device is automatically detected

and programmed. If no closing edge system is connected,

the input is requested every time the power is switched on

again until a closing edge system has been detected. With a

subsequent change, the respective system must be selected

via a parameter setting in the INPUT operating mode. In the

case of light barriers with a test function, this must be

set manually.

Ô“10.2Inputoperatingmode”

Optoelectronic closing edge protective device (OSE)

Parameter SKS = MOD1

+

-

1

2

3

4

5

6

7

8

9

12

11

10

X4

WH

GN

BN

5.10 / 1

Legend:

WH White

GN Green

BN Brown

Electrical closing edge protection (8.2 kOhm)

Parameter SKS = MOD2

8k2

1

2

3

4

5

6

7

8

9

12

11

10

X4

5.10 / 2

Pneumatic closing edge protection (DW)

Parameter SKS = MOD3 / testing automatically active

+

-

1

2

3

4

5

6

7

8

9

12

11

10

X4

5.10 / 3

16 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 17

5.115.11 Connection light barrier 1Connection light barrier 1

Withrstcommissioningandafteraresetthelightbarrieris

automatically detected and programmed. If no light barrier

system is connected, the input is requested every time the

power is switched on again until a light barrier system has

been detected. With a subsequent change, the respective

system must be selected via a parameter setting in the input

operating mode.

In the case of light barriers with a test function, this must be

set manually.

Ô“10.2Inputoperatingmode”

Light barrier 4-wire NC

withouttesting parameterLIGHTBARR1=MOD3

withtesting parameterLIGHTBARR1=MOD5

OUT

-

+

-

+

NC

1

2

3

4

5

6

7

8

9

12

11

10

X4

R

T

5.11 / 1

Light barrier Marantec Legden 2-wire

withtesting parameterLIGHTBARR1=MOD1

2

1

2

1

1

2

3

4

5

6

7

8

9

12

11

10

X4

R

T

5.11 / 2

Light barrier 3 wire NPN

withouttesting parameterLIGHTBARR1=MOD2

withtesting parameterLIGHTBARR1=MOD4

OUT

-

+

-

+

NPN

1

2

3

4

5

6

7

8

9

12

11

10

X4

R

T

5.11 / 3

Light barrier 3 wire PNP

withouttesting parameterLIGHTBARR1=MOD3

withtesting parameterLIGHTBARR1=MOD5

OUT

-

+

-

+

PNP

1

2

3

4

5

6

7

8

9

12

11

10

X4

R

T

5.11 / 4

Legend:

R Receiver

T Transmitter

NOTE:

All light barriers are active in the UP or DOWN direction

depending on the setting.

Ô“10.2Inputoperatingmode”(ParameterLBFUNC1)

Installation

16 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 17

EN

5.12 Terminal assignment, relay outputs

Four potential-free relay outputs are available, which can be

programmed with a variety of types of function.

Ô“10.2Inputoperatingmode”

1

2

3

4

5

6

7

8

X5

5.12 / 1

- Relay 1

- Relay 2

- Relay 3

- Relay 4

Internal

relay switch

contacts

There are four potential-free relay outputs able to take a max.

load of 4A at 230 V/1~.

The type of function depends on the parameter setting for the

respective relay output in the INPUT operating mode.

5.135.13 Connection of programmable inputsConnection of programmable inputs

ThecontrollerCS320has3programmableinputs,forwhich

different functions can be selected.

The type of wiring is determined on the basis of the

parameter settings for the individual inputs.

Ô“10.2Inputoperatingmode”(ParameterINPUT1-3)

ATTENTION!

Danger of damage to the circuit board due to

incorrect connection!

Inputs 1, 2 and 3 have different reference potentials and

must not be operated from a common potential!

Input 1

Optional wiring with NO / NC contacts.

Reference potential 24V-DC

Ô“10.2Inputoperatingmode”(ParameterINPUT1)

*

X4

5.13 / 1

* optionally

18 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 19

Installation

Input 2

Optional wiring with components on a 8.2 kOhm basis,

NO / NC contacts and photo sensors.

Reference potential 12V-DC

Ô“10.2Inputoperatingmode”(ParameterINPUT2)

* * *

1

2

3

4

5

6

7

8

9

12

GN

BN

WH

11

10

X4

8K2

5.13 / 2

* optionally

Legend:

GN Green

BN Brown

WH White

NOTE:

Programmable input 2 can also be used for the connection

of a light grid.

Ô“5.11Lightgridconnection”

Programmable input 2 is also used as a safety input in

accordance with EN 12453:2017.

Ifaresistancevalueisdetectedwithrstcommissioning

and after a reset, the MOD2 (safety input) is activated

automatically. Individually connected closing edge protective

device 8.2 kOhm must be activated manually in this case.

Ô“5.14SafetyinputperEN12453”

Input 3

Connector strip for optional wiring with pluggable week timer,

pluggable brake monitoring module BWM1 or as connection for

monitoring an external load contactor and drive brake.

Reference potential 5V-DC

Ô“10.2Inputoperatingmode”(ParameterINPUT3)

13:28

26.04.20

M

OK

20

B

X10

A

+ 5V

GND

IN

1

2

4

3

*

5.13 / 3

* optionally

A Week timer

The week timer offers a weekly program for opening the door

system and keeping it open with up to 8 switching times per day.

While the door is held open, the timer emits a continuous signal

that prevents the door system from closing.

After the set time interval has expired, this continuous signal

is switched off and the door system can be closed again, e.g.

manually via a CLOSE command.

Alternatively, automatic closing is also possible.

For this purpose the parameter OPEN TIME = 1 must be set in

the input operating mode.

B Brake monitoring module BWM1

The brake monitoring module is required for drives with a

brake connected (relay 4 / MOD 14-16). The module monitors

the brake function.

C Monitoring an external load contactor and

drive brake (optional)

Ô“5.13/5”

18 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 19

EN

REFERENCE

For a precise description of the function and connection,

refer to the separate documentation for the week timer and

brake monitoring module.

Connection of the brake monitoring module

A

C

B

D

1

2

4

3

1

2

3

4

5

6

7

8

X5

M

X10

XB1

5.13 / 4

Legend:

A Brake monitoring module BWM 1

B Brakerectier

C Drive brake

D Brake power supply (AC)

NOTE:

If MOD14-16 (brake actuation) is set on relay 4, the mode for

the brake monitoring module is automatically set at input 3. If

a timer is used, this setting must be adapted to set the MOD

for the timer at input 3.

Optionally, input 3 can also be used for monitoring an

external load contactor and the drive brake.

The parameter INPUT 3 must then be set to MOD22.

Connection for monitoring an external load contactor

and drive brake (optional)

If the power of the door drive/frequency inverter used exceeds

the maximum load capacity of the internal contactor, an

external load contactor must be used.

In this case, it is possible to monitor the external load

contactor and drive brake with input 3 and therefore

guarantee safe operation.

1

L1

3

L2

5

L3

13

NO

A1

2

T1

4

T2

6

T3

14

NO

A2

61

NO

62

NC

53

NO

54

NC

1

L1

3

L2

5

L3

13

NO

A1

2

T1

4

T2

6

T3

14

NO

A2

61

NO

62

NC

53

NO

54

NC

1

L1

3

L2

5

L3

13

NO

A1

2

T1

4

T2

6

T3

14

NO

A2

+ 5V

GND

IN

X10

61

NO

62

NC

53

NO

54

NC

➞

5.13 / 5

B

A

C

Q1Q2

Legend:

A Brakerectier

B Drive brake

C Brake power supply (AC)

Q1 Mains contactor

Q2 Load contactor

The wiring preparation is carried out in the factory.

20 – Control CS 320 / Rev.D 1.01 Control CS 320 / Rev.D 1.01 – 21

5.145.14 Safety input per EN 12453Safety input per EN 12453

Increased requirements on the fail-safety of the slip door

switch have been part of EN 12453 since 2001. With

EN12453:2017increasedsafetyrequirements(PLc,Cat.2)

also apply, for example to slack rope switches and switches

of fall protection systems, including the transmission and

processing of the signal.

With the setting MOD2 the programmable INPUT 2 allows

the evaluation of these components, which all work with an

internal resistance value of 8.2 kOhm. If a fault occurs in one

of the components, the system can no longer be operated and

the message ERROR STOP appears on the display.

1 – 4 components on a 8.2 kOhm basis can be linked

according to the following wiring diagrams. It does not matter

which of the respective switches represents the components

1 - 4 here.

* optionally

CHECK

The tolerance of the individual resistance values must not

exceed max. 1%.

Connection 4 components

1

2

3

4

5

6

7

8

9

12

11

10

X4

8,2 k Ω8,2 k Ω8,2 k Ω

8,2 k Ω

1

2

3

4

5.14 / 1

Connection 3 components

1

2

3

4

5

6

7

8

9

12

11

10

X4

8,2 k Ω8,2 k Ω8,2 k Ω

1

2

3

*

8,2 k Ω8,2 k Ω

1

2

8,2 k Ω

3

5.14 / 2

Connection 2 components

1

2

3

4

5

6

7

8

9

12

11

10

X4

8,2 k Ω8,2 k Ω

1

2

8,2 k Ω

1

*

8,2 k Ω

2

5.14 / 3

Connection 1 component

1

2

3

4

5

6

7

8

9

12

11

10

X4

8,2 k Ω

1

5.14 / 4

Installation

Table of contents

Other Link Controls Control Unit manuals