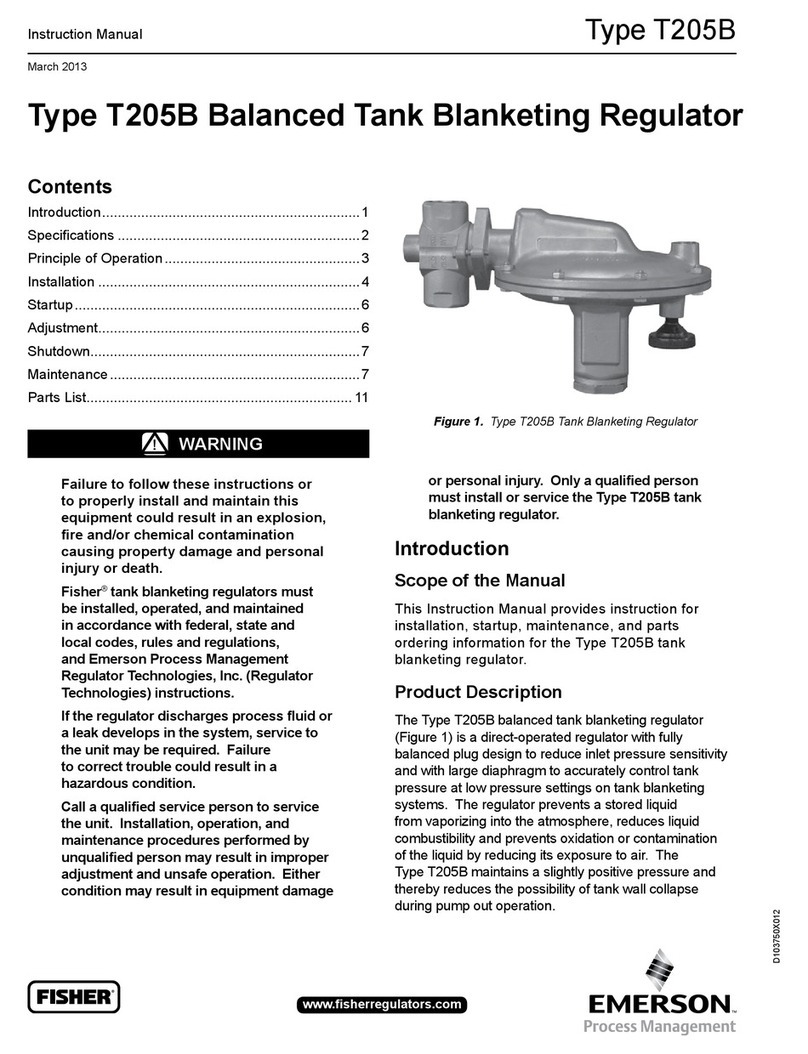

Linkam Scientific Instruments MDS600 User manual

MDS600

Motorised Temperature Controlled Stage

Linkam Scientific Instruments

USER GUIDE

2

Contents

Before Setting Up Your Equipment……………………………………………………………………………………...3

Important Notice...................................................................................................................4

Warranty..............................................................................................................................4

Technical Support…………………………………………………………………………………………………………..….4

Equipment Maintenance........................................................................................................4

Handling Liquid Nitrogen.......................................................................................................4

Feedback..............................................................................................................................4

Safety Precautions................................................................................................................5

Symbol Reference.............................................................................................................5

Introduction..........................................................................................................................6

MDS600 Stage Specification..............................................................................................6

MDS600 System....................................................................................................................6

Stage Anatomy.....................................................................................................................7

Stage Assembly................................................................................................................7

Lid Assembly....................................................................................................................7

Mounting Stage to Microscope with Dovetail Substage.............................................................8

Setting up the Condenser For Koehler Illumination..............................................................7

Vacuum Tweezers.................................................................................................................9

Connecting the Instruments.................................................................................................10

T95 System Controller Cable Connections.........................................................................10

LNP95 Cooling Pump Connection.....................................................................................11

Remove Transit Screws............................................................................................11

Back Panel Cable Connection....................................................................................11

Setting Up ECP Water Circulator Pump.............................................................................12

Sample preparation.............................................................................................................13

MDS/CC Crucible Carrier and Quartz Crucible....................................................................13

MDS/CC Crucible carrier and Stainless Steel Ring…………………………………………………………...14

Cooling Connections............................................................................................................16

Purging Procedure...............................................................................................................17

Use LinkPad to set the LNP95 to Manual Mode..................................................................17

Filling the Liquid Nitrogen Dewar.....................................................................................17

Purging the Stage Method 1............................................................................................18

Purging the Stage Method 2............................................................................................19

Using Linksys32 Software with MDS600 Stage…………………..……………………………………………….20

Motorised XY Control……………………………………………….……………………………………………...….20

MDS Setup Menu……………………………………………………………………………………..………………...21

Using LinkPad with MDS600 Stage…………………………………………………………………..………………..22

Appendix............................................................................................................................23

Replacing MDS/CC Crucible Carrier………………………….…………………………………………………..…...23

G10MT Sample Holder and Sample Mapping……………………………………………………………………...25

G10MT Sample Holder and Quartz Sample Window……………….……………………………………...25

Sample Preparation Using G10MT Sample Holder……………….………………………………………...26

Sample Mapping Using Linksys32 Software……………………………………………….………………….27

Window Assembly...............................................................................................................30

Lid Window Assembly....................................................................................................30

Bottom Window Assembly..............................................................................................30

Spares and Accessories........................................................................................................31

Troubleshooting..................................................................................................................33

Contact Details....................................................................................................................36

3

Before Setting Up Your Equipment

Please register your products by going to www.linkam.co.uk and click on the

product/software registration button.

You will need to register your equipment with us to:

Activate your warranty and technical support

Access the online setup videos

Permanently unlock the Linksys32 software (if purchased)

If you have purchased Linksys32 software, please install the software first. This pro-

cess will guide to register all of your products.

See Linksys32 manual for further installation instructions.

A CD with a setup videos is supplied with your system.

4

Important Notice

Please check that your Linkam equipment has not been damaged during transit. If there is any evidence of

external damage DO NOT SWITCH ON ANY ELECTRICAL ITEMS.

Contact LINKAM SCIENTIFIC or their appointed distributor immediately. Your warranty may be im-

paired if Linkam is not informed of any transport damage within 7 working days of delivery.

NO attempt should be made to repair or modify the equipment in any way, as there are no user replaceable

parts.

No attempt should be made to open the case except by qualified personnel as hazardous voltages are pre-

sent.

In order to use this equipment successfully, please take time to read this manual all the way through before

using it.

Warranty

This equipment has a warranty against defects in material and workmanship for a period of 12 months.

Linkam will either repair or replace products that prove to be defective. For warranty service or repair,

this product must be returned to Linkam or a designated service facility.

The warranty shall not apply to defects resulting from interfacing, unauthorized modification or misuse,

operation outside of the environmental specifications for the product, or improper site preparation or

maintenance.

Technical Support

Any technical questions or queries should be addressed to the Technical Support Department at the ad-

dress shown on the back of this manual.

Equipment Maintenance

Use a small quantity of isopropyl alcohol with a soft cloth and gently wipe the surface. To clean the hot-

stage, use isopropyl alcohol (IPA) and cotton swabs. Take great care not to touch the platinum tempera-

ture sensor protruding from the side of the heating element. The sensor is very fragile.

Handling Liquid Nitrogen

To cool samples below room temperature a LNP95 liquid nitrogen pump is required. Please refer to your

health and safety manual for instructions on how to handle liquid nitrogen safely. The Dewar supplied

with the LNP95 has a safety release valve built into the siphon assembly. Always use in a well ventilated

room.

Feedback

Your feedback will be greatly appreciated, please go to www.linkam.co.uk to fill in the Feedback form.

5

Safety Precautions

1) Read this guide before using the equipment. Save these instructions for later use.

2) Follow all warnings and instructions which may be placed on the programmer or stage.

3) If for any reason the mains fuse needs to be replaced then it must be replaced by one of the same

type and rating as shown in the equipment ratings.

4) To prevent electric shock, do not remove the cover of the controller or associated electronics.

5) Never use the equipment if a power cable has been damaged. Do not allow any heavy objects to

rest on the power cables. Never lay the power cables on the floor.

6) Do not obstruct any ventilation holes. Do not attempt to insert anything into these openings.

Provide adequate ventilation of at least 75mm all around the equipment.

7) Do not expose the equipment to water. If for any reason it gets wet then unplug it from the mains

and contact Linkam Scientific Technical Support.

8) The equipment is not intended to be used outdoors.

9) Each product is equipped with a 3-wire grounded (earth) mains plug or a free-end 3 wire

mains lead. The plug only fits into a grounded-type outlet. The free-end mains lead should be

connected to a correctly grounded 3-wire mains outlet. Do not defeat the purpose of the grounded

(earth) type plug.

Free - end mains leads are colour coded as follows :

Colour Function

Brown Live

Blue Neutral

Green/Yellow Earth (Ground)

10) If any problems occur then unplug the equipment from the mains outlet and contact Linkam Sci-

entific Technical Support.

11) Do not remove the cover from the equipment unless the mains inlet has been removed. Any

servicing should be carried out by qualified service personnel.

Symbol Reference

Caution:

This safety symbol is on the back panel of the equipment and warns:-

The user must not make or remove any connections while the unit is powered on.

To avoid electric shock do not remove the cover. Refer servicing to qualified service personnel.

Caution:

This warning symbol indicates that the surface labelled with this symbol may be hot.

6

Introduction

Thank you for purchasing the MDS600 motorised

temperature controlled stage system. Please take

the time to read through the manual as it will help

you to make the most out of the equipment.

Visit our website (www.linkam.co.uk) to register

your equipment, this will ensure that we can

update you if there are any firmware updates

available to your System Controller and/or

Linksys32 software

MDS600 Stage Specifications

Maximum temperature: 600°C

Minimum temperature: -196°C

Maximum heating rate: 150°C/min

Objective Lens WD: 4.6mm

Condenser lens WD: 12.5mm

XY travel distance: 15mm

Maximum Speed: 6000µm/s

Minimum speed: 0.1µm/s

Aperture hole: 2mm

Weight: 1.2Kg

MDS600 System

The system consists of a MDS600 stage, a T95-

LinkPad System Controller, a LNP95 liquid nitro-

gen cooling pump system and Linksys32 soft-

ware.

Linksys32-DV (digital video) or Linksys32-AV

(analogue video) video capture software can be

added as an option.

Please install the Linksys32 software first and

activate the licence key. See Linksys32 manual

for more information.

The MDS600 stage is mounted onto the micro-

scope by using either specific stage clamps or an

adaptor plate.

MDS600 System

7

Stage Anatomy

Stage Assembly

1. Stage body water connector

2. XY Motor cables

3. Gas purge valve

4. Liquid nitrogen cooling connector

5. Manual X-Manipulator thumbscrew

6. X– manipulator motor

7. Y-manipulator motor

8. Manual Y-Manipulator thumbscrew

9. Stage body

10. Lemo connector for stage lead

11. Gas purge valve

12. Stage body plate cover screw

13. Stage chamber

14. Seeding post. Only available for MDBCS196

15. Stainless steel cooling tube

16. Warm post. Only available for MDBCS196

17. Sample carrier (MDS/CC)

18. Heating element wire

19. Platinum temperature sensor

20. Aperture hole

21. 22mm diameter pure silver heating block

Lid Assembly

The Stage Lid is removed from the stage by un-

screwing anti-clockwise.

22. Stage Lid

23. Lid Insert

24. Viewing Window (22 x 0.17mm glass)

25. Holes for Tube Clip Holder or window

removal tool

22

23

25

24

1

2

3

4

5

7

6

8

9

11

10

12

13

14

15

16

17

18

19

20

21

8

Mounting Stage to Microscope

with Dovetail Substage

The following description is for mounting the

stage on to microscopes which have a circular

dovetail substage assembly (1).

Attach the curved stage clamps (part no. 9541) to

the base of the stage using the supplied hex

screws and the outer most holes in the base plate.

Adjust the two positioning thumbscrews (2) and

locking thumbscrew (3) so that approximately

5mm of thread is exposed on the inside edge of

the clamp. This will roughly position the stage in

the centre of the dovetail.

Place the stage onto the dovetail, then focus a

10X objective lens on the aperture of the silver

block. Using the two positioning screws (2)

ensure that the aperture is in the centre of the field

of view and lock the stage in place by tightening

the Locking Thumbscrew (3).

For other types of microscope substage, refer to

the diagram included with the stage adaptor.

Setting up the Condenser for Koehler

Illumination.

Place a small sample on a cover slip and place

onto the surface of the silver block. Use a 5X or a

10X lens to focus on the sample. Now close

down the microscope field diaphragm and adjust

the condenser focus so that the edges of the dia-

phragm are in focus. Now use the condenser

positioning screws to centre the condenser in your

field of view. Open the diaphragm so that it just

fills the field of view.

For more information about Koehler illumination

see the extremely informative ‘Microscopy Pri-

mer’ on the Molecular Expressions website.

http://micro.magnet.fsu.edu/primer/

index.html

9541 curved clamps set

1

2

2

3

Linkam Imaging Station

with dovetail substage

1

9

Vacuum Tweezers

The vacuum tweezers are used to manipulate the

sample windows onto the silver block to prevent

fingerprints on the glass and scratching the sur-

face of the silver block when using standard fine

tip metal tweezers.

The System is supplied with a Vacuum Tweezers

Kit which consists of a Vacuum Pump (1) and

tweezers (2).

Connect the tubing at the end of the tweezers to

the Regulator Valve (3) connection.

Use the dial on the valve to adjust the vacuum for

the tweezers.

Use a finger to block the hole of the tweezers to

pick up a sample cover slip with the suction cup.

Release the finger to drop the sample cover slip.

1

2

To vacuum pumpTo tweezers

3

10

Connecting the Instruments

T95 System Controller

Cable Connections

For more details on the T95 System Controller

please refer to the T95 System Controller manual.

Connect the Stage Cable to the Lemo Connector

on the stage and connect the other end to the

Stage Connection Socket (1).

Connect the cable from the stage labelled ‘MOT

X’ to Slot 1of the T95; labelled ‘MOT X’ (2).

Connect the cable from the stage labelled ‘MOT

Y’ to Slot 2 of the T95; labelled ‘MOT Y’ (3).

T95 back panel

1

23

11

LNP95 Cooling Pump Connection

Remove Transit Screws

Before using the LNP95 Liquid Nitrogen Pump

System, remove the 4 transit screws, marked by

small yellow labels, from the base of the LNP95.

Transit screws shown by arrows in the adjacent

image. These screws hold the pumps in place for

shipping.

Keep the screws safe by screwing them into the

holes on the back panel as shown by the arrows.

The screws must be replaced back into the transit

holes on the base, when shipping back to Linkam

for service or repair.

Back Panel Cable Connection

Connect the Instrument Bus Cable (2) between

the LNP95 and T95 as shown.

Note: either of the purple coloured Instrument

Bus Sockets on the LNP95 can be used.

Important: THE LNP95 MUST BE

SWITCHED ON BEFORE T95 SYSTEM

CONTROLLER

T95

LNP95

2

12

Setting Up ECP

Water Circulator Pump

If you have purchased the ECP with the system,

read the following to set up the ECP with the

MDS600 stage. Refer to the ECP manual for

more details.

When heating the stage above 300°C for a pro-

longed period of time, the metal casing body of

the stage can get quite hot. Connect the tubing

from the ECP as shown in the opposite picture to

cool the stage.

Note: the performance of the stage is not affected

whether the ECP is in use or not.

Note: If you have an LNP95 Liquid Nitr ogen

Cooling system, the tubing from the Dewar must

not be connected to the MDS600 stage when

heating above 300°C. The thin black capillary

tube will melt inside the heater and damage it.

ECP Inlet ECP Outlet

13

Sample Preparation

For accurate results it is most important that the

surface of the block, window and carrier are ex-

tremely clean, since air gaps between the silver

block and the sample window will result in tem-

perature errors.

The block is made of silver and since it is a soft

metal it can get scratched easily especially by

using sharp fine tweezers. This can cause a ridge

to form which prevents the sample window from

sitting flat on the block with the resulting air gap

causing significant temperature errors.

For this reason we recommend that the sample

and windows are always handled using the

Linkam Vacuum Tweezers.

MDS/CC Crucible Carrier

and Quartz Crucible

The MDS/CC sample holder (1) is used to load

larger volume liquid samples using the Quartz

Crucible.

The MDS/CC is fitted on to the MDS600 stage

and hovers a few millimetres above the silver

heating block.

Place the quartz crucible (2) into the MDS/CC

sample holder by placing the crucible into the

aperture at the end of the holder. Tap the edge of

the crucible and make sure the crucible sits flat on

top of the silver block.

1

2

14

Pipette the sample into the Quartz Crucible. Use

as little sample as possible to ensure a small ther-

mal load and therefore better temperature sensi-

tivity.

Place a W13G (13 x 0.17mm) (1) glass cover slip

on top to flatten the sample.

Microscope objectives require a flat surface to

give maximum field of view.

MDS/CC Crucible Carrier

and Stainless Steel Ring

This sample loading method is likely to be more

routinely used than the Quartz Crucible as the

16mm glass sample cover slips can be discarded

after each experiment.

Place the Stainless Steel Ring (2) within the

MDS/CC.

Tap the edge of the ring lightly to ensure that it

has dropped through the aperture of the MDS/CC

and sits properly on the surface of the silver

block.

It is critical that the ring is able to move freely

inside the aperture of the sample holder and sits

flat against the surface of the silver block.

The Stainless Steel Ring is used to push the

16mm cover slip around the surface of the block

when using the motorised XY manipulators.

1

2

15

Use the vacuum tweezers or a pair of tweezers as

shown and place a W16G (16 x 0.17mm) (1) glass

cover slip (1) into the stainless steel ring.

Tap the edges lightly to ensure that it sits flat

against the surface of the block. If the cover slip

does not sit perfectly flat against the temperature

controlled surface the heat flow will be compro-

mised and the sample temperature will be signifi-

cantly different to the displayed temperature. The

Stainless Steel Ring is used to push the 16mm

cover slip around the surface of the block when

using the motorised XY manipulators.

Using a pipette or tweezers or spatula place the

sample on the 16mm cover slip. Ensure that the

sample is as small as possible and that it is as flat

as possible. Heat flow into or out of the sample is

affected by the amount of sample area in contact

with the temperature controlled cover slip.

Place a second 16mm cover slip on top of the

sample and gently tap the top with the back of the

vacuum tweezers to disperse powder samples to

ensure good thermal contact of irregularly shaped

samples and to create a flat surface for the micro-

scope lens to focus on.

Accurate temperatures can be obtained by keep-

ing the sample as small and flat as possible.

1

16

Cooling Connections

These connections need only be made if the

experiments are to be carried out below room

temperature.

The Dewar siphon (1) is the thick white foam

tubing and is attached to the liquid nitrogen Dew-

ar. The thin black capillary tube inside the white

foam tube must be inserted into the liquid nitro-

gen cooling connectors on the stage.

The white tubing slides on to the outside of the

connector. Twist the siphon whilst sliding it on

and push until it comes to a stop. It does not need

to go all the way to the base of the connector.

The thicker silicon tube from the LNP95 cooling

pump ends in a white PTFE connector (2), this is

pushed over the end of the other stainless steel

connector as seen in the image.

The short tube branching from the side of this

white connector is the Gas Purging Tube (3).

There is a valve opening Insert connector (4)

inserted into the end of this tube. During the

purging procedure, insert this connector into the

Gas Purge Valve (5) on the side of the stage to

open it.

The Gas Purge Valve (5) is opened when the Gas

Insert (6) is pushed firmly into the connector, a

“click” is heard when the two parts are connected

properly. To remove the Gas Insert, push the

outer sleeve of Gas Purge Valve toward the stage

and the Gas Insert (6) should drop out.

There is a second Gas Purge Valve on the oppo-

site side of the stage to allow the gas to leave the

stage. A Gas Insert must also be inserted into this

Gas Purge Valve (7) when purging.

The smaller tube from the outlet on the LNP95

should be placed in position on the top of the lid

using the Tube Clip Holder (8). This tube blows

warm recycled nitrogen gas across the lid window

to prevent condensation on the viewing window

surface.

8

1

2

3

4

7

5

6

8

17

Use LinkPad to set the LNP95 to

Manual Mode

Touch the active area (1) under ‘Lnp speed’ to

change to the LNP Screen Menu. Touch

’Man’ (2) to switch the LNP95 to manual mode.

The word ‘auto’ is changed to ’speed’ to indicate

the LNP95 is functioning in manual mode.

Using the Keypad type in 100 (max pump speed)

and touch the ’Enter’ button (4) to start the

LNP95 at the programmed speed (5).

Filling the Liquid Nitrogen Dewar

Please follow your health and safety manual for

directions on how to handle liquid nitrogen and

ensure that you have the correct safety equipment

including gloves and safety goggles.

Fill the Dewar until approximately 2/3 full and

replace the lid with siphon attached.

DO NOT FASTEN THE CATCHES.

Wait for the nitrogen to stop bubbling before

fastening the catches.

Take care when placing lid on a table to always

have the black capillary pointing upwards. It is

easily damaged which will impair N2 flow.

1

2

4

5

Purging Procedure

Before starting a cooling experiment, you will need to purge air from the stage chamber with dry nitro-

gen . This will remove the water in the air which would otherwise condense and freeze on the sample

disrupting your image quality.

Before you can start purging, the LNP95 must be set to manual mode.

You can either use the LinkPad touch screen or Linksys32 software.

18

Purging the Stage Method 1

There are two methods for purging the stage. Method 1 uses recycled nitrogen gas produced by the

LNP95 from the 2L Dewar.

1. Make sure the stage lid is in place and the stage door is closed.

2. Switch on the temperature programmer and set the limit to 40°C. Press the START button and

wait until the temperature limit is reached. Press HOLD to hold the temperature at 40°C.

3. Switch on the LNP95 cooling system and set it to manual mode, (see page 17) and set the speed to

maximum of 100.

4. Check that the Gas Inserts are locked into place

5. Using a finger on the left hand, block the hole in the white plastic pump connector found on the

perpendicular side to the purging tube. Still working with the left hand, pinch the narrow window

tube to block it. This action will divert all of the nitrogen gas to the Purging Tube and through the

Stage Chamber.

6. With the nitrogen gas flowing through the Sample Chamber, use a finger on the right hand to

block the gas outlet for a few seconds to allow pressure build, then release the gas . Do this for a

few minutes to purge the stage.

7. Look at the change of reflection in the stage window as the stage is pressurised and released to

check that the stage is properly sealed. If there is no change, there may be a leak due to incorrect

placing of the silicon o-rings in either the bottom or lid window or the window (top/bottom may

be broken).

8. The purging procedure allows mixing of nitrogen gas with the residual air inside the Sample

Chamber. By pressurising the chamber with nitrogen gas and releasing it, the air inside the

Chamber is being diluted with the nitrogen gas.

9. Remove the two Gas Inserts and unblock the pump connector and window tube.

10. Change the LNP95 to AUTOMATIC mode so that the T95 automatically controls pump speed

during your cooling experiment

11. Go to www.linkam.co.uk and register your equipment to see videos of how to purge and more.

Pinch window tube

with right hand

Block hole in

Connector with finger

Purging

tube

Block and release outlet

valve with finger

19

Purging the Stage Method 2

This method uses an inert gas from a gas cylinder

to purge the stage at temperatures above ambient

when the LNP95 is not required.

1. Make sure the Stage Lid is in place and the

Stage Door is closed.

2. From a gas cylinder connect the Gas Insert

with a tubing 3mm inner diameter and 6mm

outer diameter to the Gas Purge Valve (1).

3. Connect a Gas Insert to the opposite side Gas

Purge Valve (2).

4. Use the gas regulator to set a gas flow rate of

1.5L/min.

5. With the gas flowing through the Sample

Chamber, block the gas outlet for a few sec-

onds and releasing the gas outlet valve with a

finger. Do this for a few minutes to purge the

stage.

Reduce the gas flow rate to 20cc/min to continu-

ously purge the stage or remove the two Gas

Inserts to keep the chamber under closed inert

atmosphere.

Note: Helium gas is not recommended for contin-

uous purging. This gas has a very high thermal

conductivity and will cool the silver heating block

too much during an experiment and may cause the

temperature to fluctuate.

1

2

1

To gas

cylinder

Block and release

outlet valve with

finger

20

Using Linksys32 Software with MDS600 Stage

Please refer to Linksys32 manual to control the temperature of the MDS600. With Linksys32-DV/AV for

digital video/analogue video capture. The following chapter will provide extra information to control the

motorised XY manipulators using Linksys32 software and automatically map a sample using Linksys32-

DV/AV software with a camera.

Motorised XY Control

When connected there is an additional Motorised Tool Bar (1) in the main screen of Linksys32.

1. Goto Position, continue a paused step move or stor ed position move

2. Pause Motion, pause a step move or stor ed position move

3. Stop Motion, stop a step move or stor ed position move

4. Goto Reference, move to the reference position

5. Goto Stored Position, move to the displayed Stored Position

6. Goto Post, move to the War m Post when using G7MTB Sample Holder. Only available for

MDBCS196

7. Save the Current Position, saves the cur rent XY values into the displayed Stor ed Position

8. Delete the Current Stored Position, deletes the XYZ values stored in the displayed Stored Position

9. Change Motion to Step Move / Change Motion to Freely Move, Used to change to joystick opera

-tion between step and free movement (step size is setup in the MDS setup table)

10. Joystick, hold the mouse left button down and move the mouse ar ound to move in X and Y

11. X Possition, display the cur r ent X position

12. Y Possition, display the cur rent Y position

13. Z Possition, inactive with MDS600

14. Motor Status, Status of XY Motor, Stopped or Moving

15. XY Velocity, speed selection for XY motor s. Use the up or down ar row / Nudge Control to se-

lect a preset Speed (Fine, Medium or Rapid), see MDS Setup Menu, page 20

16. Z Velocity, inactive with MDS600

17. Stored Position, stor ed position number selected (1-150), use the up or down arrow / Nudge Con-

trol to select the stored position number

123456789

10

11 12 13 14

15 16 17

Table of contents

Other Linkam Scientific Instruments Controllers manuals