LINKRICH TSP520B User manual

- 1 -

TSP520B

Thanks for choosing LINKRICH products:

We mainly produce food processing equipment, baking equipment, professional kitchen

equipment, steel kitchen ware, commercial refrigeration equipment and ice cream machine, more than

6 series, 127 kinds of products for you to choose. They are environment-friendly with excellent designs.

High technique to save power, complete functions, easy to operate, LINKRICH products are more

competitive than those of the same line in the international market.

ATTENTION

New user or repairing this product must be performed by the experts or qualified person or those

who have gotten the license of installation, or those who are authorized by the manufacturer.

When installation or maintenance, please obey the following instructions carefully to ensure the

safety use of this appliance.

Please keep this instruction Manual for future reference, or hand it to next user.

Put off the package to make sure none of the parts is missing or damaged. If there is any doubt

about the product, please do not use it, and consult it to the experts.

Keep the packing material out of reach of the children to avoid accident( Especially the plastic bag,

screw etc)

This appliance could be only operated by the person who is familiar with the unit.

When not using the appliance or the operator is absent, please turn off the unit to avoid any

accidental injury or damage.

When it needs to be repaired, please ask for expert, and use the original fitted spare part. It will be

dangerous if not following the above requirements.

This appliance is just for commercial using, not for any other use, otherwise, it may be dangerous.

Do not rinse the equipment with water directly.

Clean the surface of stainless steel periodically with appropriate method to prevent any damage

brought by oxidization or any other chemical interference.

Installation

This is a new machine at a level and long table, dry place , ordinary temperature environment.

Pull conveyor straight, put down table and then both safety guards

Start level or pedal switch, press left-hand side, the conveyors move left, press right-hand side, the

conveyors move right .if the movement is opposite, change any two wires of the power supply and

re-lest the machine

Please look this machine remark about electrical before you operate this machine

Operation

- 2 -

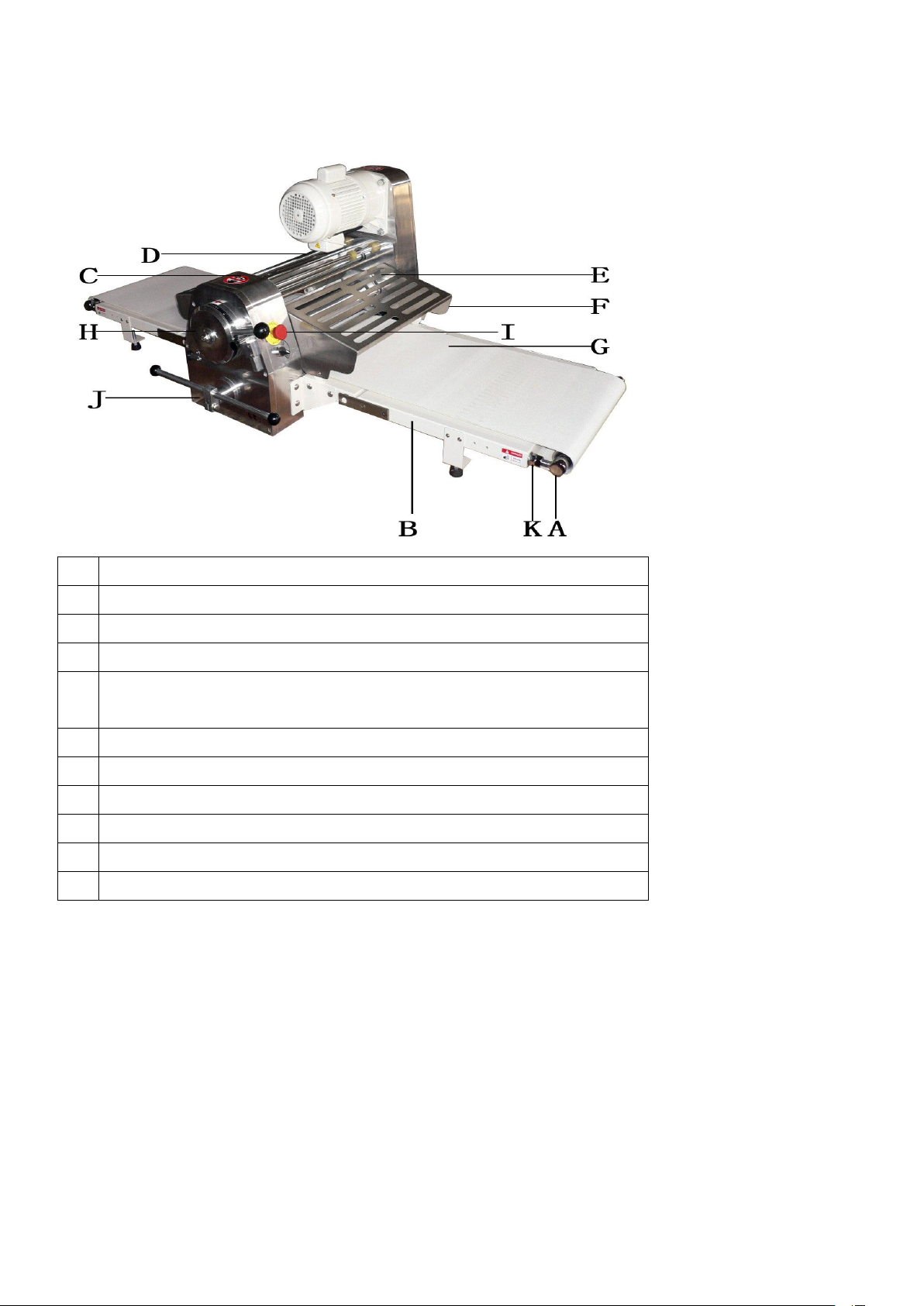

A

Roller(Active X2,Passive X2)

B

Table(Small X2.Big X2)

C

Upper Machine Body

D

Flour Tray

E

Upper pressing Roller ,Upper scraper X2

Lower pressing Roller ,Upper scraper X2

F

Safety Guard:Left&Right

G

Conveyor:2pcs

H

Thickness Handle

I

Power switch

J

Start Level

K

Conveyor Adjusting Nut:4pcs

1. When using machine, set up the thickness handle ( H ) to the most left position.

2. Note : do not put hands into safety guard.

3. Switch off power when cleaning.

4. Lift up safety guards ( F ) after operation and then turn off power switch (I ).

Safety guards

All the safety devices must be checked before operation .Maintenance should be made immediately

when defects or malfunction found.

- 3 -

1. Check the warning sings on the machine.

2. Clean up the water, oil and resin on the machine and its foundation immediately. it avoid slide and

injury.

3. Keep your body away from any moving part of the machine.

4. Beware of foreign objects fall into the machine while operating.

5. Do not climb onto the machine while it is running.

6. In case any fault occurs in the process of operation, press Emergency Stop button

Trouble shooting

1. Machine can not work :

a. power supply is on ?

b. power switch is on ?

c. Safety guard ( F ) has put down ?

d. Lift safety guard if hear click from limit switch.

e. Lift up safety guard, start level ( J ) and check if hear click from limit switch.

2. Electrical cabinet vibrates continuously:

a. Belt loose ?

b. Wires do not connect well ?

c. Something inside the electrical cabinet ?

3. Machine only works in one side :

a. Breaker failed ?

b. The wiring of Level ( J ) or limit switch failed ?

c. The wiring of motor is not good ?

d. Electricity is not three phase ?

4. Conveyor one side works, the other

side stop :

a. The gear wore out .

b. Conveyor belt ( G ) is not tight enough .

5. Thickness handle ( h ) can not fix and

slip downward :

If machine words smoothly when toward right-hand side but jump when toward

Left-hand side , it means the chain inside rear machine body is too loose, set the

handle at scale 15-20 ,and use screw driver to open cover. Apply spanner

- 4 -

to adjust motor plate to tighten chain. Check handle ( H ) if it can be operated smoothly.

6. Conveyor ( g ) moves toward one side

during production :

Adjusting nuts ( K ) to let the belt move straight for example , if belt moves toward rear

Side, loose the front nut, when adjusting nuts, make sure that the speed of belt is the same

as roller and no slip between roller and belt.

7. Noise from roller :

a. Bearing wore out.

b. If noise comes from pressing roller & scraper and conveyor .it means something sticks on

active roller. To clean the active roller simple lift table

can break down. Refer to assembly drawing for active roller and passive roller .

8. Conveyor ( g ) too tight :

Machine locates at a humid place may cause conveyor becomes shorter. If conveyors arc too tight,

loose nuts ( K ) during regular inspection.

If conveyors ( G ) are too tight, it may.

a. Has not sufficient horse power.

b. Damage bearing & shaft of active roller and passive roller .

c. Over load and damage driving gear .

Maintenance

1. Change gear :

Switch off power, applying screw driver to dismantle side plate of lower machine body disconnect 3

electrical wires on the connecting box. Lift up safety guards and switch off

Power switch off, then set the thickness handle to scale “o” apply alan-key M5 to open cover take

out gear housing ,then replace the gears, after replacement, reverse the procedures and set the

thickness handle to scale “ o “.

2. REPLACE DRIVING ROLLER AND BEARING :

Switch off power , lift up safety guards and switch off power switch off. Then apply alan-key

To open cover, loose the nuts of bearing , use a cress type screw driver to move bearing through the

joint or roller and bearing ,replace the roller and assembly by

Reversing procedures.

3. Charge conveyors :

a. Remove the roller by following the procedures mentioned above.

b. Apply spanner M 12 to take the belts on roller and remove product tray .

c. Apply spanner M 23 to loose the nuts of roller.

d. Use spanner M 19 to loose the belts of support and separate the table.

- 5 -

e. Use spanner M 14 to take away the belts of table holder and separate them.

f. Dismantle the table and belts for replacement .

g. Assembly by reversing the processes .

h. The tightness of belts should be properly , when machine is running , press the belts slightly

and check if slip happened between belts and roller.

4. Cleaning:

Wash the conveyor belt by clean water when working is finished everytime.the machine can not use

until the conveyor belt become dry.

5. Daily maintenance:

Pls fill with oil when working is over everyday.

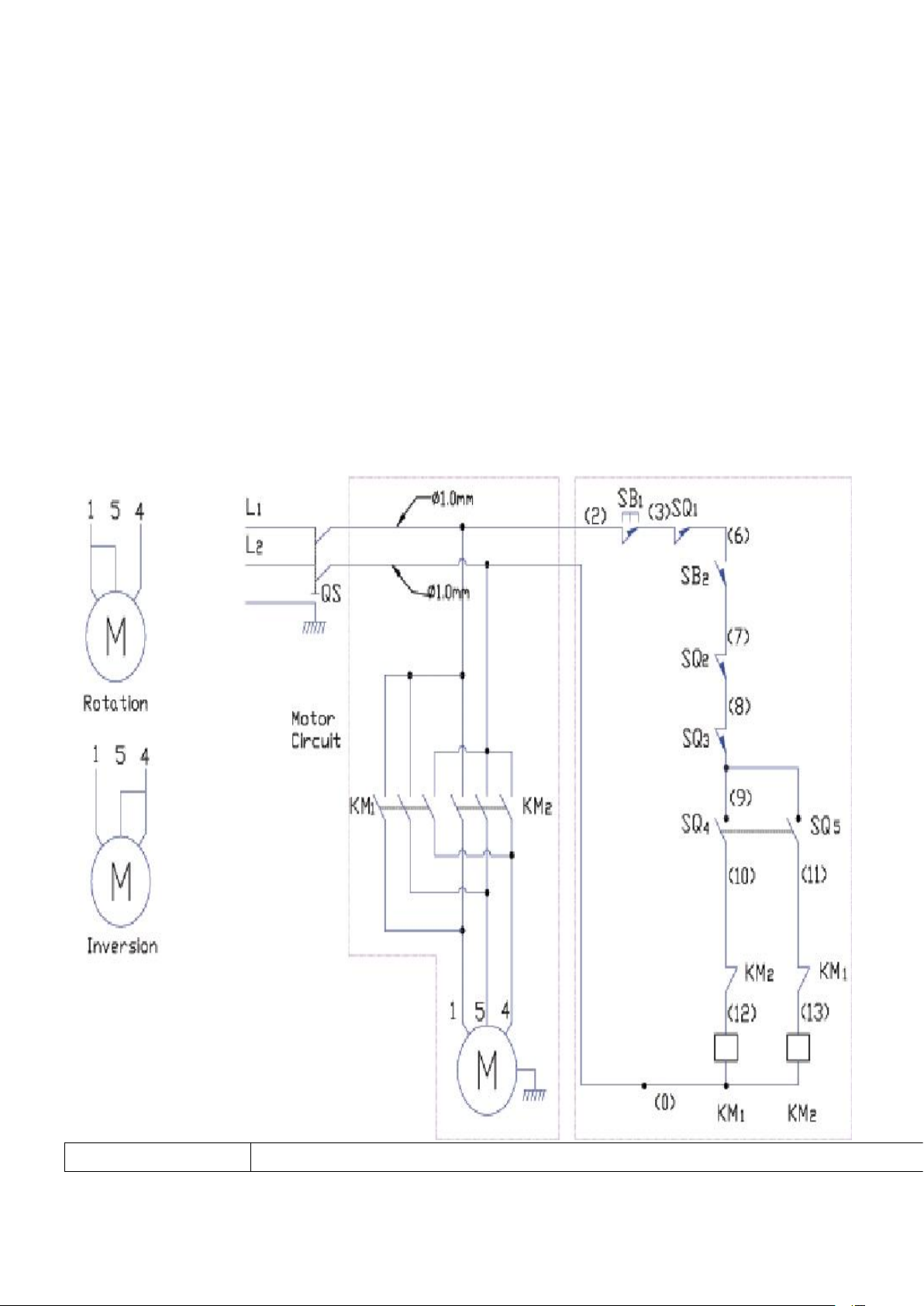

Sybol

Part name

- 6 -

SB1

Emergency Stop

SB2

Green Rotary Switch

SQ1

Stop Button

SQ2、SQ3

Protect Cap Travel Switch

SQ4、SQ5

Postive Inversion Travel Switch

KM1、KM2

Contactor

M

Slow Speed Motor

P

Indlcated Light

Parameter of Motor

HP

HZ

P

Speed

Pole Number

Insulation

Class

PH

V

I

Wire Diameter

1

50

0.75

1660

4

F

1

220

3.8

4x1.0

1

50/60

0.75

1380/1680

4

F

1

110/220

12/6

4x1.5

Machine Illustration

Part list

1. JDR520350 Plastic ball

2. JDR520340 Adjusting lever

3. 6205 ZZ Bearing

4. JDR520050 Adjusting plate

5. JDR520330 Washer

6. M 10X20L Screw

7. JDR520400 Fixed lever

8. JDR520900 Plastic screw

9. JDR520390 Permanent seat

10. M 6X18L Screw

11. JDR520060 Fixed plate

12. M 10X12L Screw

13. M 6X20L Screw

14. JDR520140 Shaft

15. JDR520070 Permanent seat

16. M 8X12L Screw

17. 16X30X1.5t Washer

18. S 16 O ring for shaft use

- 7 -

19. M 6X6L Screw

20. JDR520360 Adjusting seat

21. M10 Soft hat

22. M10X40L Screw

23. JDR520370 Adjusting lever

24. JDR520380 Plastic ball

25. JDR520200 Gear(M2 27T)

26. 6X6X12 Pin

27. 6X6X14 Pin

28. JDR520030 Cover

29. M6X13.1LX7L Screw

30. JDR520910 Spring

31. 5X5X12 Pin

32. JDR520190 Gear(M2 21T)

33. S 22 O ring for shaft use

34. JDR520180 Gear shaft

35. S 25 O ring for shaft use

36. JDR520170 Gear

37. JDR520780 Washer

38. JDR520160 Gear rack

39. JDR520920 Spring

40. JDR520150 Gear rack

41. M 6X40L Screw

42. JDR520080 Adjusting sheet

43. JDR520770 Washer

44. JDR520210 Eccentric mounting

45. JDR520100 Roller adjusting block

46. Ø6 Washer

47. 6205 ZZ Bearing

48. M 8X 8L Screw

49. M 6X12L Screw

50. S 13 O ring for shaft use

51. JDR520250 Gear(M3 15T)

52. JDR520230 Upper plastic gear shaft

- 8 -

53. JDR520090 Adjusting block

54. Ø10 Lockwasher

55. M 10 Nut

56. 6005 ZZ Bearing

57. R 47 O ring for hole use

58. 10X30X1.5t Washer

59. M 10X 20L Screw

60. JDR520300 Washer

61. 51108 (TP1) Bearing

62. JDR520280 Gear(M3 27T)

63. JDR520290 Gear(M3 15T)

64. 8X22X2.0t Washer

65. M 8X18L Screw

66. JDR520270 Gear(M3 24T)

67. JDR520260 Gear(M3 10T)

68. JDR520240 Lower plastic gear shaft

69. JDR520710 Fixed lever

70. JDR520720 Rubber sleeve

71. Ø12 Lockwasher

72. M 12 Nut

73. 6X6X18 Pin

74. JDR520450 Shaft

75. 6X6X30 Pin

76. JDR520110 Roller adjusting block

77. JDR520500 Gear(12T)

78. R 52 O ring for hole use

79. JDR520490 Washer

80. JDR520480 Washer

81. JDR450020 Base

82. JDR520700 Screw

83. M6X15L Screw

84. JDR520440 Upper roller

85. 6206 ZZ Bearing

86. 6X6X25 Pin

- 9 -

87. JDR520430 Lower roller

88. 6X6X35 Pin

89. JDR520470 Screw

90. 6203 ZZ Bearing

91. JDR520420 Conveyor roller

92. 30203 Bearing

93. JDR520410 Bearing sleeve

94. JDR520310 Shaft

95. 6004 ZZ Bearing

96. JDR520320 Bearing sleeve

97. 5X5X30 Pin

98. JDR520540 Bracket support plate

99. JDR520010 Base

100. Ø10 Lockwasher

101. M10X15L Screw

102. M8X15L Screw

103. JDR520560 Link block

104. JDR450960 Holder

105. M16 Nut

106. JDR520580 Adjusting lever

107. S20 O ring for shaft use

108. JDR520510 Gear (18T)

109. JDR520520 Gear (24T)

110. Motor

111. M12X35L Screw

112. JDR450040 Cover

113. M6X20L Screw

114. M24X10H Nut

115. Ø24 Washer

116. Ø24XØ62X3.0t Washer

117. JDR520730 Flour tray

118. JDR520740 Safety guard

119. JDR520760 Microswitch sleeve

120. JDR520750 Safety guard rubber roller

- 10 -

121. M6 Soft hat

122. M5X12L Screw

123. JDR520650 Upper knife sleeve

124. JDR520660 Knife sleeve pin

125. JDR520670 Upper knife

126. JDR520680 Lower knife sleeve

127. JDR520690 Lower knife

128. JDR520550 Shaft

129. JDR520570 Bracket board

130. JDR520600 Conveyor roller

131. JDR520610 Active shaft

132. Spring

133. 8X22X2 Washer

134. M8 Nut

135. Ø8 Washer

136. M8X70 Screw

137. JDR520530 Fixed plate

ONE YEAR PARTS WARRANTY

LINKRICH warrants to the original purchaser of every new LINKRICH product, under normal and proper

use and maintenance service as specified by LINKRICH and upon proper installation and start-up in

accordance with the instruction packet supplied with each LINKRICH unit. LINKRICH’s obligation under

this warranty is limited to a period of one (1) year from the date of original installation.

WARRANTY CLAIMS

All claims for parts must be made directly through LINKRICH. All claims should include:

Personal Details: Products Details:

Your name Model number

Your company Serial number of the product

Address Date of purchase

Email Proof of purchase

Phone

Pertinent information supporting the existence of the alleged defect.(Such as picture etc.)

Our warranty departments will according to the actual situation and reply you within

24hours.

What is not conered by this Warranty

Linkrich’s sole obligation under this warranty is limited to replacement of parts, Subject to the additional

- 11 -

limitations below.

This warranty neither assumes nor authorizes any person to assume obligations other than those

expressly covered by this warranty.This warranty is limited to replacement of parts, and the shipment

charge is not included.

No consequential damages. Linkrich is not responsible for Economic loss; or special, indirect, or

consequential damages, including without limiyayion, losses or damages arising from food or product

spoilage claims whether or not account of refrigeration failure.

Warranty is not transferable. This warranty is not assignable and applies only in favor the original

purchaser/user to whom delivered. Any such assignment or transfer shall vold the warranties herein

made and shall vold all waanties, express or implied, including any warranty of merchantability or fitness

for a particular purpose.

Improper usage. Linkrich assumes no liability for parts or labor coverage for component failure or other

damages resulting from improper usage or installation or failure to clean and/or maintain peoduct as set

forth in the warranty packet provided with the unit.

Residential applications: linkrich assumes no liability for parts or labor coverage for component failure or

other damages resulting from installation in non-commercial or residential applications.

Alteration, neglect, buse, isuse, accident, damage during transit or installation, fire, flood, acts of god.

Linkrich is not responsible for the repair or replacement of any parts that linkrich determines have been

subjected after the date of manufacture to alteration, neglect, abuse, accident, damage during transit or

installation, fire, flood, or act of god.

Improper electrical connections. Linkrich is not responsible for the repair or erplacement of failed or

damaged components resulting from electrical power failure, the use of extension cords, low voltage, or

voltage drops to the unit.

No implied warranty of merchantability or fitness for a particular purpose: there are no otner warranties,

expressed, implied or statutory, except the one (1) year parts warranty as described above. These

warranties are exclusive and in lieu of all other warranties, including implied warranty and

merchantability or fitness for a particular purpose. These are no warranty which extend beyond the

description on the face hereof.

- 12 -

Table of contents

Other LINKRICH Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use