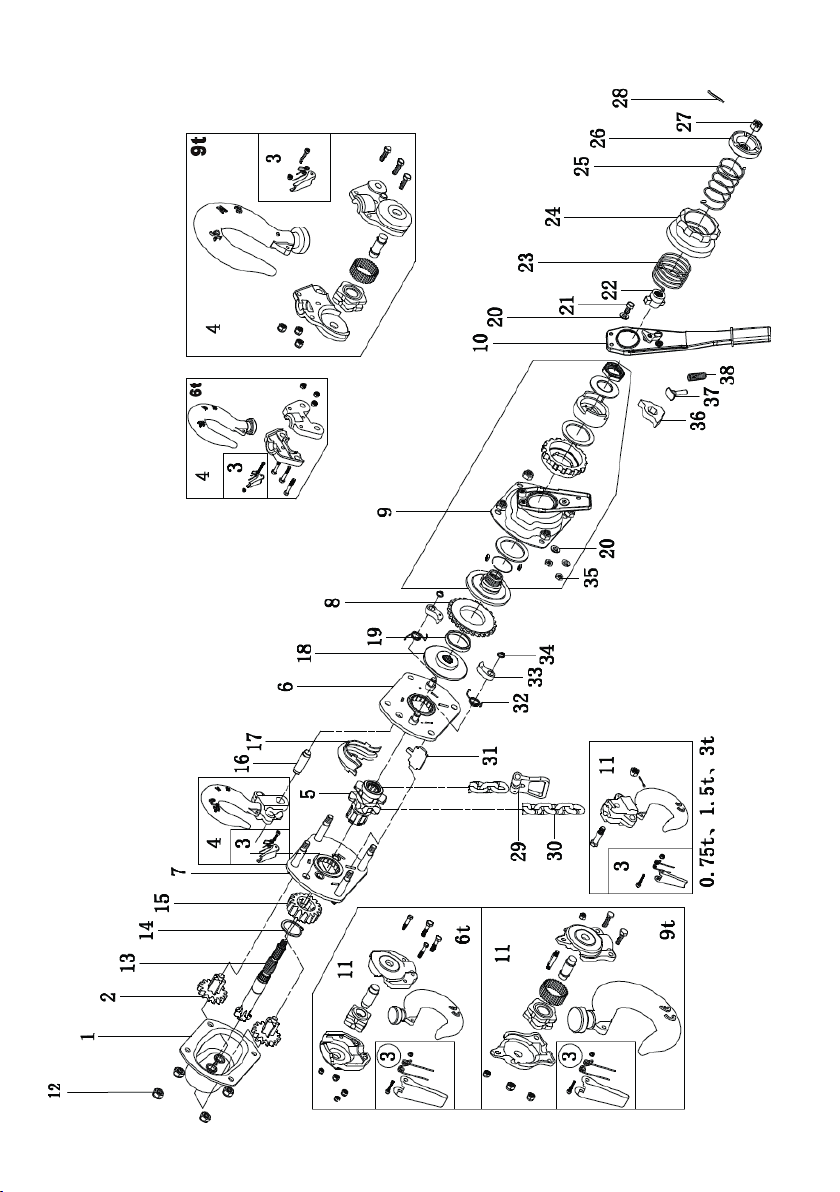

LINX-LIFT LINX-LIFT PZ Series User manual

This manual suits for next models

5

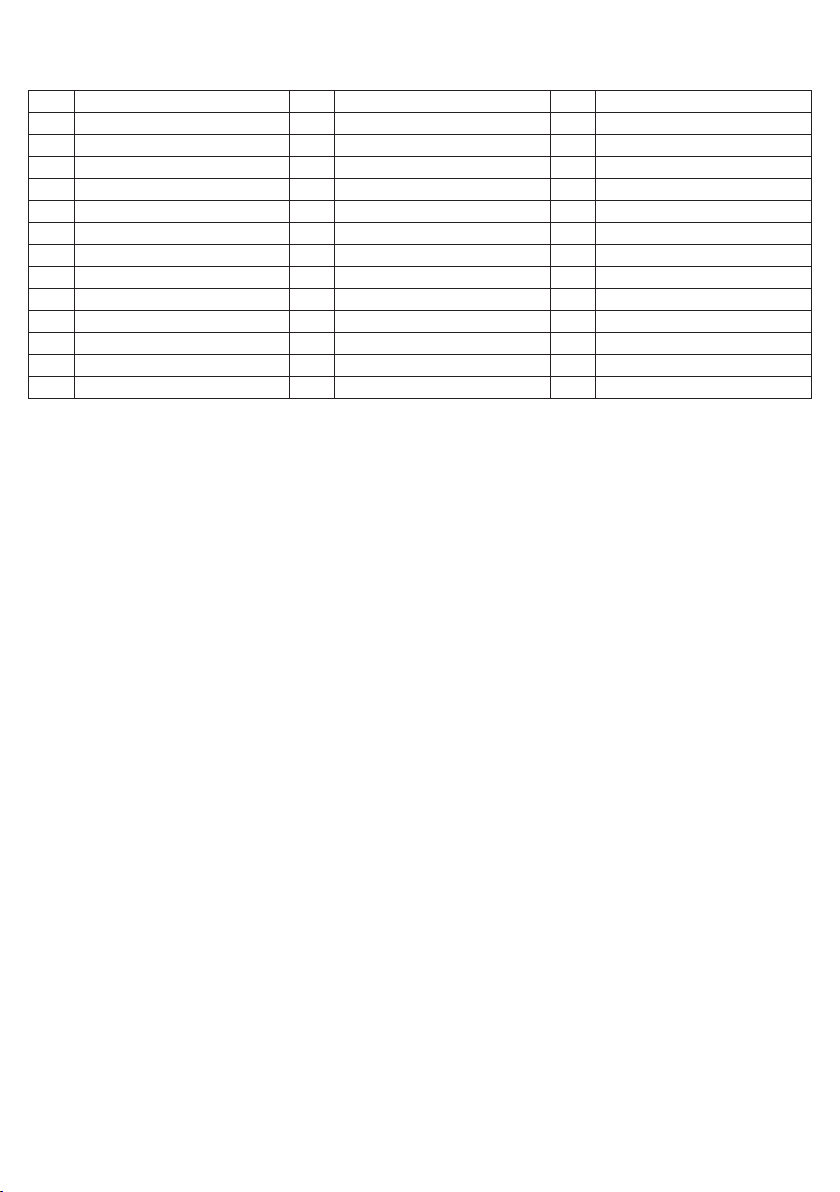

Table of contents

Other LINX-LIFT Chain Hoist manuals

Popular Chain Hoist manuals by other brands

R&M

R&M LOADMATE LM 16 Installation and maintenance manual

EINHELL

EINHELL TC-EH 250-18 operating instructions

Yale

Yale CPV Series Operating, Maintenance, Spare Parts and Wirind Diagrams

Feider Machines

Feider Machines F2TPA-A instruction manual

POWERTEX

POWERTEX PLC user manual

Paccar Winch

Paccar Winch Gearmatic GH30B Service and maintenance manual

Tractel

Tractel corso 0,25 t Operation and maintenance manual

little mule

little mule Lineman's 322C Operating, Maintenance & Parts Manual

CM

CM 5623A Operating, Maintenance & Parts Manual

Ingersoll-Rand

Ingersoll-Rand PAL250K-E Installation and operation manual

Grizzly

Grizzly G8703 instruction sheet

Endo

Endo EHL-05TS, EHL-1TW instruction manual

Cequent

Cequent Reese 7067300 instruction sheet

Ingersoll-Rand

Ingersoll-Rand LCA015 Parts, operation and maintenance manual

Surtek

Surtek POLEC1 manual

Ingersoll-Rand

Ingersoll-Rand Hercu-Link HA1-005 Parts, operation and maintenance manual

EINHELL

EINHELL TC-EH 600 operating instructions

Thiele

Thiele OCTA STAR Mounting instructions