Linx Technologies TT Series User manual

TT Series

Master Development System

User's Guide

A large-print version of this document is available at

www.linxtechnologies.com.

Table of Contents

1 Introduction

2 Ordering Information

2 TT Series Transceiver Carrier Board

2 TT Series Transceiver Carrier Board Objects

3 TT Series Transceiver Carrier Board Pin Assignments

3 Programming Dock

3 Programming Dock Objects

4 Remote Control Demo Board

4 Remote Control Demo Board Objects

5 Prototype Board

5 Prototype Board Objects

6 Initial Setup

7 Using the Programming Dock

8 Using the Remote Control Demo Board

10 Using the Prototype Board

13 The Development Kit Demonstration Software

20 Development Kit Demonstration Software Example

28 Carrier Board Schematic

29 Remote Control Demo Board Schematic

33 Programming Dock Board Schematic

37 Prototype Board Schematic

––

1

Introduction

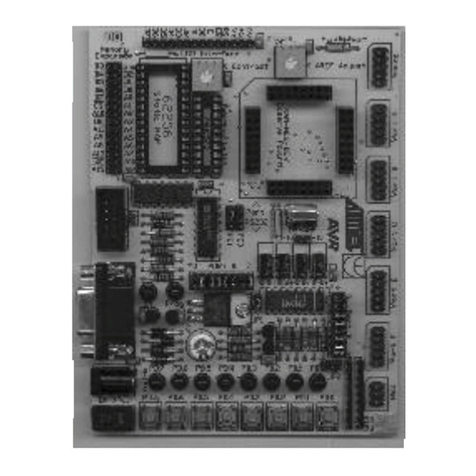

The Linx TT Series Remote Control Transceiver modules offer a simple,

efficient and cost-effective method of adding remote control capabilities to

any product. The Master Development System provides a designer with all

the tools necessary to correctly and legally incorporate the TT Series into

an end product. The boards serve several important functions:

• Rapid Module Evaluation: The boards allow the performance of the Linx

TT Series modules to be evaluated quickly in a user’s environment. The

development boards can be used to evaluate the range performance of

the modules.

• Application Development: A prototyping board allows the development

of custom circuits directly on the board. All signal lines are available on

headers for easy access.

• Software Development: A programming dock with a PC interface allows

development and testing of custom software applications for control of

the module.

• Design Benchmark: The boards provide a known benchmark against

which the performance of a custom design may be judged.

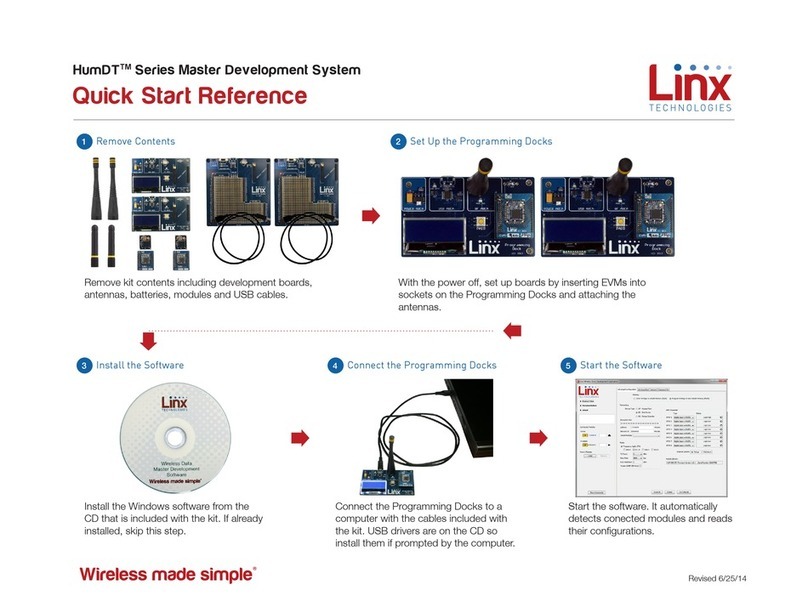

The Master Development System includes 2 Carrier Boards, 2 RC Demo

Boards, 2 Programming Dock Boards, 2 Prototype Boards, 4 TT Series

transceivers*, antennas, batteries and full documentation.

TT Series Master Development System

User's Guide

Figure 1: TT Series Master Development System

* One part is soldered to each Carrier Board

Revised 1/13/14

–– – –

23

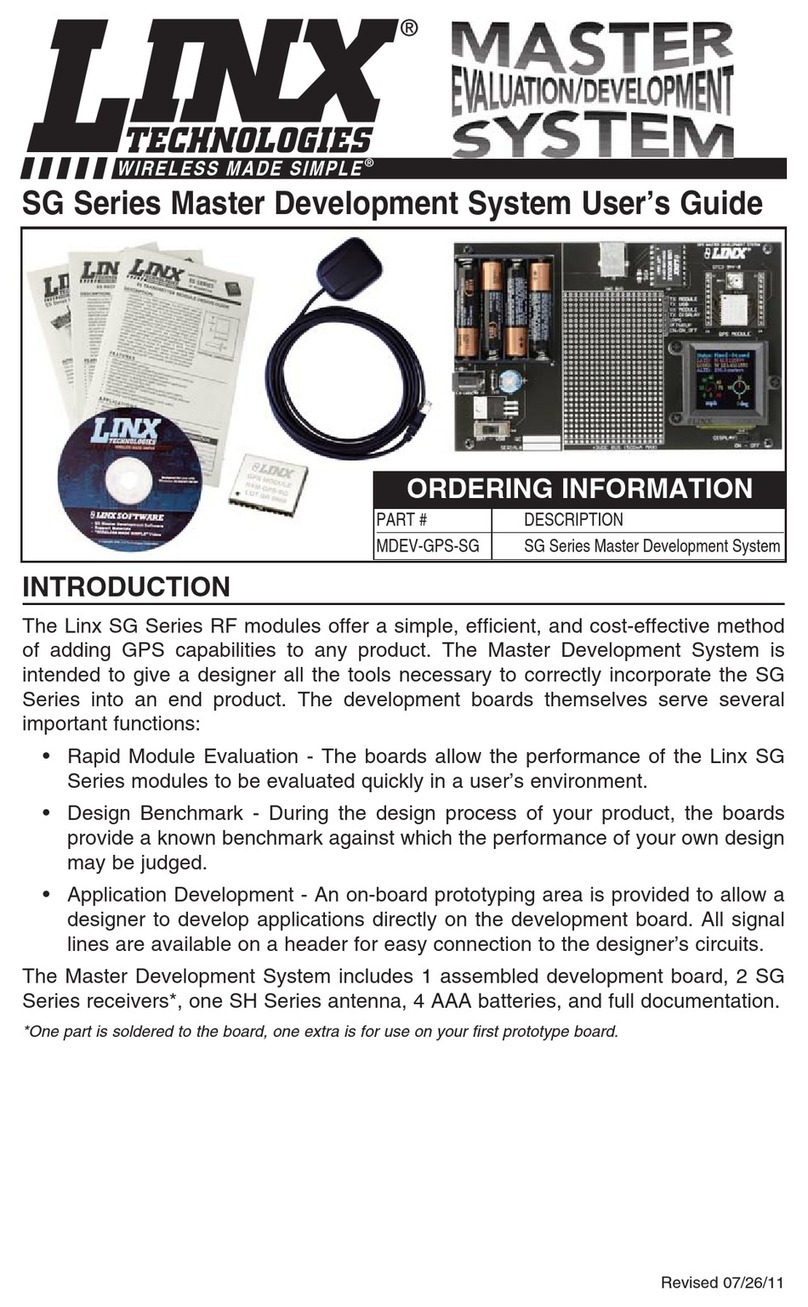

Ordering Information

Ordering Information

Part Number Description

MDEV-900-TT TT Series Master Development System

MDEV-900-TT-A Amplified TT Series Master Development System

EVAL-900-TT TT Series Basic Evaluation Kit

EVAL-900-TT-A Amplified TT Series Basic Evaluation Kit

TRM-900-TT 900MHz TT Series Remote Control Transceiver

TRM-900-TT-A 900MHz Amplified TT Series Remote Control and Sensor

Transceiver

EVM-900-TT 900MHz TT Series Carrier Board

EVM-900-TT-A 900MHz Amplified TT Series Evaluation Module

MDEV-DEMO-RC-A Development System Remote Control Demo Board, Type A

MDEV-DEMO-RC-B Development System Remote Control Demo Board, Type B

MDEV-PGDOCK Development System Programming Dock

MDEV-PROTO Development System Prototype Board

CON-SOC-EVM EVM Module Socket Kit

Figure 2: Ordering Information

TT Series Transceiver Carrier Board Objects

1. TT Series Transceiver

2. MMCX RF Connector

3. Dual Row Header

4. Single Row Header

TT Series Transceiver Carrier Board

Figure 3: TT Series Transceiver Carrier Board

1

2

2

33

4 4

BottomTop

TT Series Transceiver Carrier Board Pin Assignments

Figure 5: Programming Dock

7 MODE_IND

9 CMD_DATA_IN

11 LATCH_EN

13 ACK_EN

15 CMD_DATA_OUT

17 VCC

19 C0

21 C1

23 NC

25 RSSI

27 NC

29 NC

31 NC

33 NC

35 NC

37 NC

GND 6

RESET 8

PDN 10

NC 12

PAIR 14

NC 16

LVL_ADJ 18

NC 20

NC 22

NC 24

NC 26

NC 28

NC 30

NC 32

NC 34

NC 36

41 S3

42 S4

43 S5

44 S6

45 S7

46 ACK_OUT

47 NC

48 NC

49 NC

50 NC

51 NC

52 NC

53 NC

54 NC

55 NC

56 NC

40 S2

39 S1

38 S0

ANTENNA 1 2-5 GND (RF Connector)

Programming Dock

Programming Dock Objects

1. Carrier Board Socket

2. RP-SMA Antenna Connector

3. MODE_IND LED

4. Micro USB Connector

5. LCD Display

Figure 4: TT Series Transceiver Carrier Board Pin Assignments (Top View)

2

3

4

5

1

–– – –

45

1

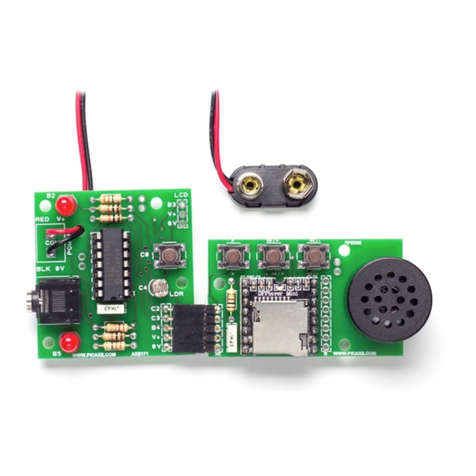

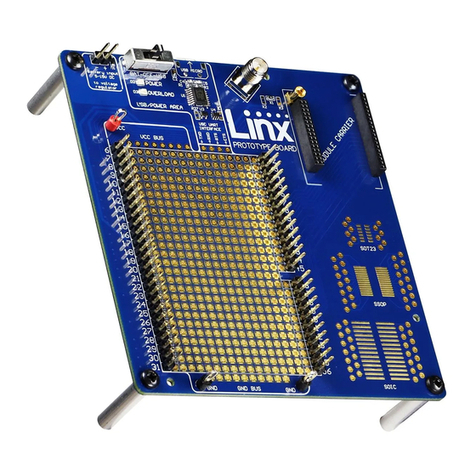

Prototype Board

Prototype Board Objects

1. Carrier Board Socket

2. RP-SMA Antenna Connector

3. Micro USB Connector

4. Power Switch

5. Power LED

6. External Battery Connection

7. Prototyping Area

8. 3.3V Supply Bus

9. Ground Bus

10. USB Interface Lines

11. Module Interface Headers

12. Command Data Interface Routing Switches (on back)

Figure 7: Prototype Board

4

1

2

3

10

6

7

8

11

5

9

11

11

Remote Control Demo Board

Board BBoard A

Remote Control Demo Board Objects

1. Carrier Board Socket

2. RP-SMA Antenna Connector

3. Power Switch

4. MODE_IND LED

5. CONFIRM LED

6. PAIR button

7. Status Line Output LEDs

8. Status Line Input Buttons

9. 4 AAA Batteries (Not shown, on the back of the boards)

Figure 6: Remote Control Demo Board

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

12

–– – –

67

Initial Setup

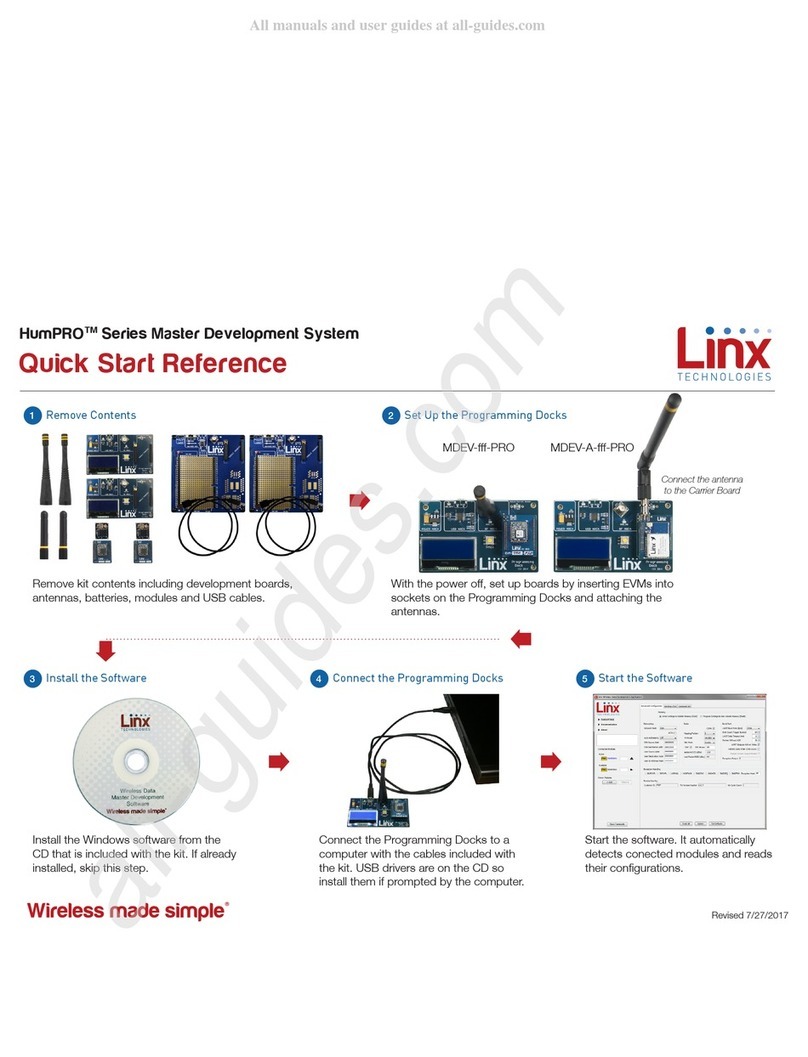

There are several boards that are included with the Basic Evaluation

Kit and the Master Development System. The Basic Evaluation Kit

includes two Carrier Boards and two Remote Control Demo Boards. The

Master Development System includes these boards but also adds two

Programming Docks and two Prototype Boards.

The Carrier Boards have a TT Series transceiver on a daughter board with

headers. These boards snap into sockets on the other boards, enabling the

modules to be easily moved among the test boards.

There are two Remote Control Demo Boards that are populated differently.

Board A has the buttons on the right column and board B has them on the

left column. These accept the Carrier Boards and are used to demonstrate

the remote control functionality of the TT Series. They can also be used for

range testing. These boards use hardware configuration, so if any changes

have been made to the modules using the software then they may not

operate correctly. A restore to default configuration can be used to reset

the modules.

The Programming Docks have a socket for a Carrier Board and a USB

interface for connection to a PC. This is used with the demonstration

software included with the kit to configure the module through its

Command Data Interface.

The Prototype Boards have a socket for a Carrier Board, a USB interface

and a large area of plated through holes that can be used to develop

custom circuitry. The board can be powered either from the USB

connection or an external battery.

Warning: Installing or removing a Carrier Board while power is

applied could cause permanent damage to the module. Either turn

off power to the board or unplug the USB cable before installing or

removing a Carrier Board

!

Using the Programming Dock

Snap a Carrier Board onto the socket on the Programming Dock as shown

in Figure 8.

Connect a micro USB cable into the connector at the top of the board.

Plug the other end into a PC. The board is powered by the USB bus.

The demonstration software included with the kit or custom application

software can be used to configure the module through its Command

Data Interface. The LCD is used to display information about the module.

This includes the module’s local address and a custom nickname. The

nickname is entered using the development kit software and can be

any name that helps distinguish the modules from one another. This is

convenient when multiple programming docks are connected to the same

computer. Please see the development kit software section for more

information on the nicknames.

The TT Series transceiver has a serial Command Data Interface that offers

the option to configure and control the transceiver through software instead

of through hardware. This interface consists of a standard UART with a

serial command set. This allows for fewer connections in applications

controlled by a microcontroller as well as for more control and advanced

features than can be offered through hardware pins alone.

Figure 8: Programming Dock with a Carrier Board

–– – –

89

Range Testing

Several complex mathematical models exist for determining path loss in

many environments. These models vary as the transmitter and receiver are

moved from indoor operation to outdoor operation. Although these models

can provide an estimation of range performance in the field, the most

reliable method is to simply perform range tests using the modules in the

intended operational environment.

Range testing can be performed with the Remote Control Demo Boards.

To prepare the board for range testing, simply turn it on by switching the

power switch to the ON position. Pressing a status line button on one

board (the IU) activates an LED on the other board (the RU). The RU then

sends an acknowledgement back to the IU, which turns on the CONFIRM

LED. This indicates good bi-directional RF communications and lets the

user set one board down and walk with the other board.

As the maximum range of the link in the test area is approached, it is not

uncommon for the signal to cut in and out as the radio moves. This is

normal and can result from other interfering sources or fluctuating signal

levels due to multipath effects. This results in cancellation of the transmitted

signal as direct and reflected signals arrive at the receiver at differing times

and phases. The areas in which this occurs are commonly called “nulls”

and simply walking a little farther usually restores the signal. If the signal is

not restored, then the maximum range of the link has been reached.

To achieve maximum range, keep objects such as your hand away from

the antenna and ensure that the antenna on the transmitter has a clear and

unobstructed line-of-sight path to the receiver board. Range performance

is determined by many interdependent factors. If the range you are able to

achieve is significantly less than specified by Linx for the products you are

testing, then there is likely a problem with either the board or the ambient

RF environment in which the board is operating. First, check the battery,

switch positions, and antenna connection. Next, measure the receiver’s

RSSI voltage with the transmitter turned off to determine if ambient

interference is present. High RSSI readings while the transmitter off indicate

there is interference. If this fails to resolve the issue, please contact Linx

technical support.

Using the Remote Control Demo Board

Snap a Carrier Board onto the socket on each Remote Control Demo

Board as shown in Figure 9.

Insert 4 AAA batteries into the holders on the back of each board, connect

antennas and turn on power.

The modules come paired out of the box, but to Pair additional modules,

press the PAIR button on both boards. The MODE_IND LEDs flash to

indicate that the modules are searching for each other and exchanging

addresses. The MODE_IND has a quick flash while searching (100ms on,

900ms off) and a longer flash once Pairing is complete (400ms on, 100ms

off). This process only takes a few seconds. The pairing process takes the

status line input / output directions into account. If these are changed then

the modules should be paired again.

Once complete, pressing a button on one board (the Initiating Unit or IU)

causes an LED to light up on the other board (the Responding Unit or RU).

The RU sends an acknowledgement message to the IU. If the message is

valid, the IU turns on the CONFIRM LED.

Figure 9: Remote Control Demo Board with a Carrier Board

Note: The Remote Control Demo boards are designed for hardware

configuration. If the modules are changed through software configuration

then the boards may not operate as expected. A restore to default

configuration can be used to reset the modules.

Note: To restore the default configuration, push the PAIR button four

times and hold it down on the fifth press. The MODE_IND LED flashes

when it has reset. Alternatively press and hold the RESTORE button on

the back of the board for 5 seconds. When the LED turns off, release the

button and the LED flashes twice to indicate a successful restore.

–– – –

10 11

Supply for the module is connected through R17. This can be removed and

replaced by another supply or used to measure the current consumption of

the module.

Figure 11 shows the bottom of the board.

SW1 and SW2 connect the USB interface to the Command Data Interface

lines on the module. This allows the prototype board to be used with the

development kit software or a custom application. When in the “USB

Connected position”, the module is connected to the USB interface. The

“Header Only” position connects the module to the header.

Footprints for 0603 size resistors are on most lines so that pull-ups or

pull-downs can easily be added to the lines. The pads are connected to

VCC or GND based on the most common configuration for the module. The

schematic at the end of this document shows how each line is connected.

Using the Prototype Board

Snap a Carrier Board onto the socket on the Prototype Board as shown in

Figure 10.

Connect a micro USB cable into the connector at the top of the board.

Plug the other end into a PC or any USB power adapter. The board is

powered by the USB bus. This board features a prototyping area to

facilitate the addition of application-specific circuitry. The prototyping area

contains a large area of plated through-holes so that external circuitry

can be placed on the board. The holes are set at 0.100" on center with

a 0.040" diameter, accommodating most industry-standard SIP and DIP

packages.

At the top of the prototyping area is a row connected to the 3.3V power

supply and at the bottom is a row connected to ground. External circuitry

can be interfaced to the transceiver through the breakout headers. The

numbers next to the headers correspond to the pin numbers on the Carrier

Board. Figure Figure 4 shows the pin assignments for the Carrier Board.

The OVERLOAD LED indicates that that too much current is being pulled

from the USB bus. This is used to prevent damage to the parts or the bus.

Figure 10: Prototype Board with a Carrier Board

Note: The onboard 3.3-volt regulator has approximately 400mA available

for additional circuitry when plugged into a PC. If more current is

required, the user must power the board from an external supply or a

USB charger with more current capabilities, up to 1A.

Figure 11: Prototype Board Bottom Side

–– – –

12 13

The Development Kit Demonstration Software

The development kit includes software that is used to configure and control

the module through the Programming Dock. The software defaults to the

Demo & EZConfiguration tab when opened (Figure 13). This window offers

basic configuration and demonstration of the module’s functionality with the

current configuration.

1. Clicking the Contact Linx, Documentation and About labels on the

left side expands them to show additional information and links to the

latest documentation. This is shown in Figure 15.

2. The Help window shows tips and comments about the software.

3. The active module is connected to the PC and being configured by the

software.

4. Available modules are connected to the PC but are not currently being

configured or controlled by the PC

5. Known Modules are not currently connected to the PC, but have either

been connected to the software in the past or have been manually

entered.

6. The Given Permissions window shows the list of modules that are

paired with the active module and the Permissions Mask for each one.

7. The demo area replicates a remote control device. The appearance

changes with the programmed configurations.

7

4

1

2

3

10

6

8

11

5

9

Figure 13: The Master Development System Software Demo and EZConfiguration Tab

Module to Prototype Board Pin Number Cross Reference

Pin Name Module Pin Number Prototype Board Pin Number

MODE_IND 35 7

RESET 16 8

CMD_DATA_IN 27 9

POWER_DOWN 24 10

LATCH_EN 15 11

ACK_EN 36 13

PAIR 33 14

CMD_DATA_OUT 29 15

VCC 25 17

LVL_ADJ 14 18

C0 30 19

C1 32 21

RSSI 21 25

S0 9 38

S1 10 39

S2 12 40

S3 13 41

S4 20 42

S5 26 43

S6 19 44

S7 18 45

ACK_OUT 31 46

Figure 12: Module to Prototype Board Pin Number Cross Reference

The overload condition is reset once the excess current draw is removed.

The LADJ line has pads for both a pull up and pull down resistor. This can

be populated based on the needs of the specific module that is connected

to the prototype board. The TT Series uses the pull-down resistor. Do

not populate both resistors at the same time as this results in a direct

connection between power and ground.

Figure 12 shows a convenient cross reference showing which lines on the

module connect to which lines on the prototype board.

–– – –

14 15

8. The Status Details section shows the module’s control line states, radio

state and RSSI level.

9. The Sent and Received Packets window shows the commands

sent to the module and the responses from the module. This aids in

debugging custom software.

10. Once a module has been configured, the configurations can be saved

into a profile that can be recalled and programmed into other modules.

The Saved Profiles list shows all of the profiles that have been saved

into the software.

11. The Show Commands button opens a larger window to view the serial

commands sent to and received from the module.

The modules are shown with three identifiers as shown in Figure 14.

1. The type of module (TT Series)

2. The module’s local address.

3. A custom name that can be given to the module. Type a name into

the box and press Enter to apply it. This name is shown on the LCD

display on the programming dock.

Figure 14: The Master Development System

Software Module Identifiers

1

2 3

Figure 15: The Master Development System

Software Additional Information

The Advanced Configuration tab (Figure 16) offers more detailed

configuration options for the active module.

1. The Local Address box shows the module’s local address in

hexadecimal format. This can be changed by typing a new hex value.

2. The Status Line Mask sets the status lines as either inputs or outputs.

If the box is checked then the line is an input.

3. The Latch Mask determines if the status line outputs are latched or

momentary. If the box is checked then the output is latched. This

setting has no effect on lines that are configured as inputs.

4. The Paired Modules Window lists all of the modules that are paired

with the active module and their Permissions Mask.

5. The Address box enables manual pairing of a module. Enter an

address into this box and press the Set Module button to add the

address to the list.

6. The Permissions Mask determines whether a specific module is

authorized to control a specific status line output. If the box is checked

then the module is authorized to control that line.

Figure 16: The Master Development System Software Advanced Configuration Tab

7

4

12

3

10

6

8

11

5

9

12

13

14

16

17 18

15

19

–– – –

16 17

7. The Set Module button adds the address and Permissions Mask to

the list. If a current module is selected, then the Permissions can be

updated. The Remove module button removes the selected module

from the list. The Remove All Modules button removes all of the

modules from the list.

8. The Interrupt Mask sets the conditions under which an interrupt is to

be generated on the CMD_DATA_OUT line. The Message Select menu

sets the type of message that triggers the interrupt when the Selected

Message Ready box is checked.

9. The TX Power Level Source configures how the transmitter output

power is set. It uses either the voltage on the LVL_ADJ line or the value

in the box. The accepted range of values is –20 to +12.

10. The Transmitter Mode selection sets whether the module transmits

command messages when a status line input is asserted or when it

receives a software command.

11. The Receiver Mode selection turns the receiver on or off for power

savings. If the module is set as an Initiating Unit only with all status lines

as inputs, then the receiver is disabled by default.

12. The Status Line Direction selection sets how the status lines are

configured as inputs and outputs. Either the C0 and C1 hardware lines

are used to set them in groups of 4 or the Status Line Mask is used to

set them individually.

13. The Latch Status Outputs selection configures how the latched or

momentary operation for each status line output is set. Either the

LATCH_EN hardware line is used to set all of the lines the same way or

the Latch Mask is used to set the lines individually.

14. The Custom Data box enables a custom 2-byte value to be loaded

into the module to be transmitted with each control message or

Acknowledge with Data packet.

15. The Duty Cycle configuration sets the interval and Keep on times for

automatically cycling power to the receiver.

16. The Module Identity box displays the module type, firmware version

and serial number of the active module.

17. The Read All button reads all of the current configurations from the

active module.

18. The Submit button writes all changes to the active module.

19. The Set Defaults button restores the active module to factory default

conditions.

The Command Set tab (Figure 17) allows specific commands to be written

to the module.

1. The Command box shows the hexadecimal values that are written to

the module. Values can be typed into the box or a command can be

selected from the Commands menu.

2. The Response box shows the hexadecimal values that are returned

from the module in response to a command.

3. The Commands drop-down menu shows all of the commands that

are available for the active module (Figure 18). Selecting one of the

commands from this menu automatically fills in the Command box. The

values can be adjusted by typing in the box.

4

1

23

6

5

Figure 17: The Master Development System Software Command Set Tab

Figure 18: The Master Development System Software

Demo Command Set Tab Commands Menu

–– – –

18 19

4. The Items drop down menu displays all of the items that are available

for the active module (Figure 19). Selecting one of the items from

this menu automatically fills in the Command box. The values can be

adjusted by typing in the box.

5. Clicking the Send button writes the values in the Command box to the

module.

6. The structure of the selected command and its response is shown

in the main window. Please see the TT Series Transceiver Command

Data Interface Reference Guide for definitions of each value.

Figure 19: The Master Development System Software

Demo Command Set Tab Items Menu

The Sandbox tab shows the interaction of all of the connected modules

on one screen. Figure 20 shows two modules on the screen, but up to 8

modules can fit at one time.

Clicking a button on one device causes the module to transmit control

messages. Paired modules with appropriate Permissions Mask settings

activate and their status is updated in the software. Paired modules that are

not connected to the PC can activate a module that is connected and the

connected module’s status is reflected in the software.

The Sandbox is a convenient place to show the interaction of multiple units

in one location, but it is a reflection of actual module operation. It is not a

simulation.

Figure 20: The Master Development System Software Sandbox Tab

–– – –

20 21

Development Kit Demonstration Software Example

This example shows how to configure two modules to work with each

other. The software defaults to the Demo & EZConfiguration tab when

opened (Figure 21).

Install Carrier Boards onto the Programming Docks and plug a USB cable

between the Programming Docks and the PC. The software automatically

detects attached devices. The first module that is identified appears

under the Active label. This is the module that is actively controlled by

the software. Subsequent modules are listed under the Available label as

shown in Figure 22.

Modules must be paired with the active device. This is accomplished by

dragging modules from the Available or Known Modules lists to the Given

Permissions window as shown in Figure 23.

Figure 21: The Master Development System Software Demo and EZConfiguration Tab

Figure 22: The Master Development System

Software Connected Modules

Once the module is dropped into the Given Permissions window it is

written to the active module’s memory. Clicking on the down arrow displays

the paired module’s Permissions Mask. This configures which output lines

the paired module is authorized to control. In Figure 24 the Permissions are

inactive since the active module only has inputs and no outputs to control.

Figure 24: The Master Development System Software Paired Modules

Figure 23: The Master Development System Software Pairing Modules

–– – –

22 23

Changing the active module is accomplished by dragging a module from

the Available list to the Active spot, as shown in Figure 25.

With the new module active, drag the original module to the Given

Permissions window. Click on the Advanced Configuration tab (Figure 26).

Figure 25: The Master Development System Software Changing the Active Module

Figure 26: The Master Development System Software Advanced Configuration

This tab shows the advanced configurations enabled by the module’s

Command Data Interface. Any changes are highlighted in red. In the

example in Figure 27 the output mask has been changed to all inputs, S0 is

latched, the Paired module is given full permissions, the status line direction

is set by the mask and the outputs are latched by the Latch Mask. Clicking

the Set Module button sets the updated Permissions Mask. Clicking the

Submit button writes all of the changes to the module’s memory.

This configuration changes the module to have all outputs. This is shown

by clicking on the Demo & EZConfiguration tab Figure 28.

Figure 27: The Master Development System Software Advanced Configuration with Changes

–– – –

24 25

The buttons have all changed to LEDs. The symbol next to each LED

indicates if it is latching or momentary (Figure 29). S0 is latching, the rest

are momentary.

Now that the modules are configured their use can be demonstrated.

Clicking a button on the transmitter module activates an LED on the

receiving module. Figure 30 shows the transmitter, Figure 31 shows the

receiver.

Figure 28: The Master Development System Software Demo and EZConfiguration Tab with Changes

Figure 29: The Master Development System Software

Latching (1) and Momentary (2) Symbols

1 2

Figure 30: The Master Development System Software Transmitting Module

Figure 31: The Master Development System Software Receiving Module

–– – –

26 27

Full system operation is demonstrated by clicking on the Sandbox tab

(Figure 32).

These configurations can be saved as a profile for recalling or programming

into other modules. The Demo & EZConfiguration tab has the profile

window (Figure 33).

Clicking the Save Current button brings up a prompt asking for a name of

the profile (Figure 34).

Figure 32: The Master Development System Software Sandbox

Figure 33: The Master Development System

Software Saved Profiles Window

Once saved, the profile appears in the window, as shown in Figure 35.

To apply a profile, select it from a list and click the Program button. Clicking

the Remove button removes it from the list.

Figure 34: The Master Development System Software Save Profile

Figure 35: The Master Development System Software with a Saved Profile

–– – –

28 29

CONFIRM

S0

S1

S2

S3

S4

S5

S6

S7

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

PAIR

MODE_IND

LATCH_EN

RSSI

ACK_EN

RESET

PDN

LVL_ADJ

CMD_DATA_IN

CMD_DATA_OUT

ANT

C0

C1

1

23

45

67

89

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 29

30 31

32 33

34 35

36 37

J1

Carrier Interconnect Male

GND

GND

GND

GND

GND

VCC

RF MODULE AREA RF MODULE CARRIER AREA

NC

2

GND

3

NC

4

NC

5

GND

6

NC

7

S0

9

S1

10

GND

11

S7

18

S6

19

RSSI

21

GND

22 GND23

POWER_DOWN 24

VCC 25

S5 26

CMD_DATA_IN 27

S2

12

GND

17

S3

13

LVL_ADJ

14

LATCH_EN

15

RESET

16

NC

8

S4

20

GND

1

GND28

CMD_DATA_OUT 29

C0 30

ACK_OUT 31

C1 32

PAIR33

GND34

MODE_IND 35

ACK_EN 36

NC 37

NC 38

GND39

NC 40

NC 41

GND42

ANTENNA 43

GND44

TR1

TRM-XXX-TT

C1

LATCH_EN

S0

S1

S2

S3

S4

D5S6

S7

RSSI

ACK_EN

RESET

PDN

LVL_ADJ

CMD_DATA_IN

CMD_DATA_OUT

MODE_IND

PAIR

CONFIRM

ANT

C0

GND

GND

GND

GND

GND

GN

DG

ND

GND

GND

GND

GND

GND

VCC

Figure 36: TT Series Transceiver Carrier Board Module Schematic

Carrier Board Schematic

Remote Control Demo Board Schematic

1

2

3

P2

Header 3

D4

D5

D6

1

2

3

4

P1

Header 4

D0

D1

D2

D3

GND

R2

330

VCC

D1

POWER GREEN

MODE_IND

GND

R3

330

D2

MODE_IND BLUE

CONFIRM

GND

R27

330

D20

CONFIRM RED

RF 1

GND

2-5

ANT1

CONREVSMA002

PAIR

MODE_IND

CONFIRM

LATCH_EN

D0

D1

D2

D3

D4

D5

ACK_EN

PDN

CMD_DATA_IN

CMD_DATA_OUT

D6

D7

SER_I/O

C0

C1

SEND

CRT_LRN

GND

GND

VCC

GNDGND

GND

GND

1

23

45

67

89

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 29

30 31

32 33

34 35

36 37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

J1

Carrier Interconnect Female

LVL_ADJ IDENTITY

GND

X2

DNP

X1

1.8nH

ED_SEL

SEL_TIMER

D8

D9

D_CFG

A_CFG_0

A_CFG_1

BAUD_0

GND

SW1

SPDT

GND

VCC

B1

GND

Vin

1

GND

2

Vout3

U1

C1

0.47uF

GND

+C2

100uF

VDD

1

RA5

2

RA4

3

MCLR

4

RC5

5

RC4

6

RC3

7RC28

RC19

RC010

RA211

ICSPCLK 12

ICSPDAT 13

GND14

U2

PIC16F1824

VCC GND

PGD

PGC

MCLR

CMD_DATA_IN

CMD_DATA_OUT

IDENTIT

YC

RT_LRN

MODE_IND

GND

SER_I/O

R14

330

GND

S9

RESTORE

D7

RESTORE COMPLETE GREEN

PIC A/B

R36

0

R33

0

VCC

GND

SW2

LVL_ADJ

ACK_EN

R32 0

VCC

R34 10K

GND

BAUD_0

IDENTITY

SEL_TIMER

SEND

LATCH_EN

PDN

R8 0

R38 10K

R37 10K

R35 10K

R9 10K

D8

D9

R41 10K

R42 10K

D_CFG

A_CGF_0

A_CFG_1

R6 10K

R5 10K

R4 10K

GND

VCC

S8

PAIR

R1

10K

PAIR CRT_LRN

REMOTE CONTROL AREA

POWER SUPPLY AREA RF MODULE AREA

MISC CIRCUITS

MICROCONTROLLER AREA

1

2

3

P3

Header 3

D7

VCC

GND1

2

3

4

J2

MCLR

PGD

5

6

PGC

VCC

GND

VCCS0

D0

SEND

D5

R12

330

D3

R10

10K

GND

GND

VCCS1

D1

SEND

R17

330

R15

10K

GND

GND

D10

D8

VCCS2

D2

SEND

R21

330

R19

10K

GND

GND

D14

D12

VCCS3

D3

SEND

R25

330

R23

10K

GND

GND

D18

D16

VCCS4

D4

SEND

R13

330

R11

10K

GND

GND

D6

D4

VCCS5

D5

SEND

R18

330

R16

10K

GND

GND

D11

D9

VCCS6

D6

SEND

R22

330

R20

10K

GND

GND

D15

D13

VCCS7

D7

SEND

R26

330

R24

10K

GND

GND

D19

D17

C0

C1 GND

VCC

R30 0 ohm

R31 0 ohm

ED_SEL R7 10K

R39 0 ohm GND

GND

PIC A/B

C0

C1

R28 0 ohm GND

VCC

R29 0 ohm

R40 0 ohm VCC

ED_SEL R43 10K VCC

PIC A/B

A Board B Board A Board

Figure 38: Remote Control Demo Board Microcontroller Area Schematic

CONFIRM

S0

S1

S2

S3

S4

S5

S6

S7

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

PAIR

MODE_IND

LATCH_EN

RSSI

ACK_EN

RESET

PDN

LVL_ADJ

CMD_DATA_IN

CMD_DATA_OUT

ANT

C0

C1

1

23

45

67

89

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 29

30 31

32 33

34 35

36 37

J1

Carrier Interconnect Male

GND

GND

GND

GND

GND

VCC

RF MODULE AREA RF MODULE CARRIER AREA

NC

2

GND

3

NC

4

NC

5

GND

6

NC

7

S0

9

S1

10

GND

11

S7

18

S6

19

RSSI

21

GND

22 GND23

POWER_DOWN 24

VCC 25

S5 26

CMD_DATA_IN 27

S2

12

GND

17

S3

13

LVL_ADJ

14

LATCH_EN

15

RESET

16

NC

8

S4

20

GND

1

GND28

CMD_DATA_OUT 29

C0 30

ACK_OUT 31

C1 32

PAIR33

GND34

MODE_IND 35

ACK_EN 36

NC 37

NC 38

GND39

NC 40

NC 41

GND42

ANTENNA 43

GND44

TR1

TRM-XXX-TT

C1

LATCH_EN

S0

S1

S2

S3

S4

D5S6

S7

RSSI

ACK_EN

RESET

PDN

LVL_ADJ

CMD_DATA_IN

CMD_DATA_OUT

MODE_IND

PAIR

CONFIRM

ANT

C0

GND

GND

GND

GND

GND

GNDGND

GND

GND

GND

GND

GND

VCC

Figure 37: TT Series Carrier Board Header Schematic

Note: The Remote Control Demo boards are designed to accept carrier

boards for multiple module families. Some circuitry is not applicable for

some modules.

–– – –

30 31

1

2

3

P2

Header 3

D4

D5

D6

1

2

3

4

P1

Header 4

D0

D1

D2

D3

GND

R2

330

VCC

D1

POWER GREEN

MODE_IND

GND

R3

330

D2

MODE_IND BLUE

CONFIRM

GND

R27

330

D20

CONFIRM RED

RF 1

GND

2-5

ANT1

CONREVSMA002

PAIR

MODE_IND

CONFIRM

LATCH_EN

D0

D1

D2

D3

D4

D5

ACK_EN

PDN

CMD_DATA_IN

CMD_DATA_OUT

D6

D7

SER_I/O

C0

C1

SEND

CRT_LRN

GND

GND

VCC

GNDGND

GND

GND

1

23

45

67

89

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 29

30 31

32 33

34 35

36 37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

J1

Carrier Interconnect Female

LVL_ADJ IDENTITY

GND

X2

DNP

X1

1.8nH

ED_SEL

SEL_TIMER

D8

D9

D_CFG

A_CFG_0

A_CFG_1

BAUD_0

GND

SW1

SPDT

GND

VCC

B1

GND

Vin

1

GND

2

Vout3

U1

C1

0.47uF

GND

+C2

100uF

VDD

1

RA5

2

RA4

3

MCLR

4

RC5

5

RC4

6

RC3

7RC28

RC19

RC010

RA211

ICSPCLK 12

ICSPDAT 13

GND14

U2

PIC16F1824

VCC GND

PGD

PGC

MCLR

CMD_DATA_IN

CMD_DATA_OUT

IDENTITYCRT_LRN

MODE_IND

GND

SER_I/O

R14

330

GND

S9

RESTORE

D7

RESTORE COMPLETE GREEN

PIC A/B

R36

0

R33

0

VCC

GND

SW2

LVL_ADJ

ACK_EN

R32 0

VCC

R34 10K

GND

BAUD_0

IDENTITY

SEL_TIMER

SEND

LATCH_EN

PDN

R8 0

R38 10K

R37 10K

R35 10K

R9 10K

D8

D9

R41 10K

R42 10K

D_CFG

A_CGF_0

A_CFG_1

R6 10K

R5 10K

R4 10K

GND

VCC

S8

PAIR

R1

10K

PAIR CRT_LRN

REMOTE CONTROL AREA

POWER SUPPLY AREA RF MODULE AREA

MISC CIRCUITS

MICROCONTROLLER AREA

1

2

3

P3

Header 3

D7

VCC

GND1

2

3

4

J2

MCLR

PGD

5

6

PGC

VCC

GND

VCCS0

D0

SEND

D5

R12

330

D3

R10

10K

GND

GND

VCCS1

D1

SEND

R17

330

R15

10K

GND

GND

D10

D8

VCCS2

D2

SEND

R21

330

R19

10K

GND

GND

D14

D12

VCCS3

D3

SEND

R25

330

R23

10K

GND

GND

D18

D16

VCCS4

D4

SEND

R13

330

R11

10K

GND

GND

D6

D4

VCCS5

D5

SEND

R18

330

R16

10K

GND

GND

D11

D9

VCCS6

D6

SEND

R22

330

R20

10K

GND

GND

D15

D13

VCCS7

D7

SEND

R26

330

R24

10K

GND

GND

D19

D17

C0

C1 GND

VCC

R30 0 ohm

R31 0 ohm

ED_SEL R7 10K

R39 0 ohm GND

GND

PIC A/B

C0

C1

R28 0 ohm GND

VCC

R29 0 ohm

R40 0 ohm VCC

ED_SEL R43 10K VCC

PIC A/B

A Board B Board A Board

Figure 40: Remote Control Demo Board Power Supply Area Schematic

1

2

3

P2

Header 3

D4

D5

D6

1

2

3

4

P1

Header 4

D0

D1

D2

D3

GND

R2

330

VCC

D1

POWER GREEN

MODE_IND

GND

R3

330

D2

MODE_IND BLUE

CONFIRM

GND

R27

330

D20

CONFIRM RED

RF 1

GND

2-5

ANT1

CONREVSMA002

PAIR

MODE_IND

CONFIRM

LATCH_EN

D0

D1

D2

D3

D4

D5

ACK_EN

PDN

CMD_DATA_IN

CMD_DATA_OUT

D6

D7

SER_I/O

C0

C1

SEND

CRT_LRN

GND

GND

VCC

GNDGND

GND

GND

1

23

45

67

89

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 29

30 31

32 33

34 35

36 37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

J1

Carrier Interconnect Female

LVL_ADJ IDENTITY

GND

X2

DNP

X1

1.8nH

ED_SEL

SEL_TIMER

D8

D9

D_CFG

A_CFG_0

A_CFG_1

BAUD_0

GND

SW1

SPDT

GND

VCC

B1

GND

Vin

1

GND

2

Vout3

U1

C1

0.47uF

GND

+C2

100uF

VDD

1

RA5

2

RA4

3

MCLR

4

RC5

5

RC4

6

RC3

7RC28

RC19

RC010

RA211

ICSPCLK 12

ICSPDAT 13

GND14

U2

PIC16F1824

VCC GND

PGD

PGC

MCLR

CMD_DATA_IN

CMD_DATA_OUT

IDENTITYCRT_LRN

MODE_IND

GND

SER_I/O

R14

330

GND

S9

RESTORE

D7

RESTORE COMPLETE GREEN

PIC A/B

R36

0

R33

0

VCC

GND

SW2

LVL_ADJ

ACK_EN

R32 0

VCC

R34 10K

GND

BAUD_0

IDENTITY

SEL_TIMER

SEND

LATCH_EN

PDN

R8 0

R38 10K

R37 10K

R35 10K

R9 10K

D8

D9

R41 10K

R42 10K

D_CFG

A_CGF_0

A_CFG_1

R6 10K

R5 10K

R4 10K

GND

VCC

S8

PAIR

R1

10K

PAIR CRT_LRN

REMOTE CONTROL AREA

POWER SUPPLY AREA RF MODULE AREA

MISC CIRCUITS

MICROCONTROLLER AREA

1

2

3

P3

Header 3

D7

VCC

GND1

2

3

4

J2

MCLR

PGD

5

6

PGC

VCC

GND

VCCS0

D0

SEND

D5

R12

330

D3

R10

10K

GND

GND

VCCS1

D1

SEND

R17

330

R15

10K

GND

GND

D10

D8

VCCS2

D2

SEND

R21

330

R19

10K

GND

GND

D14

D12

VCCS3

D3

SEND

R25

330

R23

10K

GND

GND

D18

D16

VCCS4

D4

SEND

R13

330

R11

10K

GND

GND

D6

D4

VCCS5

D5

SEND

R18

330

R16

10K

GND

GND

D11

D9

VCCS6

D6

SEND

R22

330

R20

10K

GND

GND

D15

D13

VCCS7

D7

SEND

R26

330

R24

10K

GND

GND

D19

D17

C0

C1 GND

VCC

R30 0 ohm

R31 0 ohm

ED_SEL R7 10K

R39 0 ohm GND

GND

PIC A/B

C0

C1

R28 0 ohm GND

VCC

R29 0 ohm

R40 0 ohm VCC

ED_SEL R43 10K VCC

PIC A/B

A Board B Board A Board

Figure 39: Remote Control Demo Board RF Carrier Area Schematic

1

2

3

P2

Header 3

D4

D5

D6

1

2

3

4

P1

Header 4

D0

D1

D2

D3

GND

R2

330

VCC

D1

POWER GREEN

MODE_IND

GND

R3

330

D2

MODE_IND BLUE

CONFIRM

GND

R27

330

D20

CONFIRM RED

RF 1

GND

2-5

ANT1

CONREVSMA002

PAIR

MODE_IND

CONFIRM

LATCH_EN

D0

D1

D2

D3

D4

D5

ACK_EN

PDN

CMD_DATA_IN

CMD_DATA_OUT

D6

D7

SER_I/O

C0

C1

SEND

CRT_LRN

GND

GND

VCC

GNDGND

GND

GND

1

23

45

67

89

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 29

30 31

32 33

34 35

36 37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

J1

Carrier Interconnect Female

LVL_ADJ IDENTITY

GND

X2

DNP

X1

1.8nH

ED_SEL

SEL_TIMER

D8

D9

D_CFG

A_CFG_0

A_CFG_1

BAUD_0

GND

SW1

SPDT

GND

VCC

B1

GND

Vin

1

GND

2

Vout3

U1

C1

0.47uF

GND

+C2

100uF

VDD

1

RA5

2

RA4

3

MCLR

4

RC5

5

RC4

6

RC3

7RC28

RC19

RC010

RA211

ICSPCLK 12

ICSPDAT 13

GND14

U2

PIC16F1824

VCC GND

PGD

PGC

MCLR

CMD_DATA_IN

CMD_DATA_OUT

IDENTITYCRT_LRN

MODE_IND

GND

SER_I/O

R14

330

GND

S9

RESTORE

D7

RESTORE COMPLETE GREEN

PIC A/B

R36

0

R33

0

VCC

GND

SW2

LVL_ADJ

ACK_EN

R32 0

VCC

R34 10K

GND

BAUD_0

IDENTITY

SEL_TIMER

SEND

LATCH_EN

PDN

R8 0

R38 10K

R37 10K

R35 10K

R9 10K

D8

D9

R41 10K

R42 10K

D_CFG

A_CGF_0

A_CFG_1

R6 10K

R5 10K

R4 10K

GND

VCC

S8

PAIR

R1

10K

PAIR CRT_LRN

REMOTE CONTROL AREA

POWER SUPPLY AREA RF MODULE AREA

MISC CIRCUITS

MICROCONTROLLER AREA

1

2

3

P3

Header 3

D7

VCC

GND1

2

3

4

J2

MCLR

PGD

5

6

PGC

VCC

GND

VCCS0

D0

SEND

D5

R12

330

D3

R10

10K

GND

GND

VCCS1

D1

SEND

R17

330

R15

10K

GND

GND

D10

D8

VCCS2

D2

SEND

R21

330

R19

10K

GND

GND

D14

D12

VCCS3

D3

SEND

R25

330

R23

10K

GND

GND

D18

D16

VCCS4

D4

SEND

R13

330

R11

10K

GND

GND

D6

D4

VCCS5

D5

SEND

R18

330

R16

10K

GND

GND

D11

D9

VCCS6

D6

SEND

R22

330

R20

10K

GND

GND

D15

D13

VCCS7

D7

SEND

R26

330

R24

10K

GND

GND

D19

D17

C0

C1 GND

VCC

R30 0 ohm

R31 0 ohm

ED_SEL R7 10K

R39 0 ohm GND

GND

PIC A/B

C0

C1

R28 0 ohm GND

VCC

R29 0 ohm

R40 0 ohm VCC

ED_SEL R43 10K VCC

PIC A/B

A Board B Board A Board

Figure 41: Remote Control Demo Board Remote Control Area Schematic

–– – –

32 33

1

2

3

P2

Header 3

D4

D5

D6

1

2

3

4

P1

Header 4

D0

D1

D2

D3

GND

R2

330

VCC

D1

POWER GREEN

MODE_IND

GND

R3

330

D2

MODE_IND BLUE

CONFIRM

GND

R27

330

D20

CONFIRM RED

RF 1

GND

2-5

ANT1

CONREVSMA002

PAIR

MODE_IND

CONFIRM

LATCH_EN

D0

D1

D2

D3

D4

D5

ACK_EN

PDN

CMD_DATA_IN

CMD_DATA_OUT

D6

D7

SER_I/O

C0

C1

SEND

CRT_LRN

GND

GND

VCC

GNDGND

GND

GND

1

23

45

67

89

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 29

30 31

32 33

34 35

36 37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

J1

Carrier Interconnect Female

LVL_ADJ IDENTITY

GND

X2

DNP

X1

1.8nH

ED_SEL

SEL_TIMER

D8

D9

D_CFG

A_CFG_0

A_CFG_1

BAUD_0

GND

SW1

SPDT

GND

VCC

B1

GND

Vin

1

GND

2

Vout3

U1

C1

0.47uF

GND

+C2

100uF

VDD

1

RA5

2

RA4

3

MCLR

4

RC5

5

RC4

6

RC3

7RC28

RC19

RC010

RA211

ICSPCLK 12

ICSPDAT 13

GND14

U2

PIC16F1824

VCC GND

PGD

PGC

MCLR

CMD_DATA_IN

CMD_DATA_OUT

IDENTITYCRT_LRN

MODE_IND

GND

SER_I/O

R14

330

GND

S9

RESTORE

D7

RESTORE COMPLETE GREEN

PIC A/B

R36

0

R33

0

VCC

GND

SW2

LVL_ADJ

ACK_EN

R32 0

VCC

R34 10K

GND

BAUD_0

IDENTITY

SEL_TIMER

SEND

LATCH_EN

PDN

R8 0

R38 10K

R37 10K

R35 10K

R9 10K

D8

D9

R41 10K

R42 10K

D_CFG

A_CGF_0

A_CFG_1

R6 10K

R5 10K

R4 10K

GND

VCC

S8

PAIR

R1

10K

PAIR CRT_LRN

REMOTE CONTROL AREA

POWER SUPPLY AREA RF MODULE AREA

MISC CIRCUITS

MICROCONTROLLER AREA

1

2

3

P3

Header 3

D7

VCC

GND1

2

3

4

J2

MCLR

PGD

5

6

PGC

VCC

GND

VCCS0

D0

SEND

D5

R12

330

D3

R10

10K

GND

GND

VCCS1

D1

SEND

R17

330

R15

10K

GND

GND

D10

D8

VCCS2

D2

SEND

R21

330

R19

10K

GND

GND

D14

D12

VCCS3

D3

SEND

R25

330

R23

10K

GND

GND

D18

D16

VCCS4

D4

SEND

R13

330

R11

10K

GND

GND

D6

D4

VCCS5

D5

SEND

R18

330

R16

10K

GND

GND

D11

D9

VCCS6

D6

SEND

R22

330

R20

10K

GND

GND

D15

D13

VCCS7

D7

SEND

R26

330

R24

10K

GND

GND

D19

D17

C0

C1 GND

VCC

R30 0 ohm

R31 0 ohm

ED_SEL R7 10K

R39 0 ohm GND

GND

PIC A/B

C0

C1

R28 0 ohm GND

VCC

R29 0 ohm

R40 0 ohm VCC

ED_SEL R43 10K VCC

PIC A/B

A Board B Board A Board

Figure 42: Remote Control Demo Board Miscellaneous Circuits Schematic

C12

0.1uF

VCC

GND

GND

MODE_IND

R8

330

D4

MODE_IND BLUE

IN 1

VCC2

GND3

NC

4

COM

5

NO

6

U5

MAX4544EUT

MODE_IND_MT

GND

C10

0.1uF

//IDENTITY

VCC

GND

IDENTITY

GND

VCC

A

1

GND

2

B

3/B 4

VCC5

/A 6

U7

NC7WZ04

GND

C11

0.1uF

/IDENTITY

/IDENTITY //IDENTITY

R24

10k

S2

VCC

PAIR

PAIR CRT_LRN

GND

GND

+C8

100uF

VCC

GND

Vin

1

GND

2

Vout 3

U4

LM3940IMP 3.3V

C9

0.47uF

GND

IN

1

GND

2

EN

3FAULT 4

ILIM 5

OUT 6

U3

TPS2552

GND

5VUSB VCCU

GND

R11

53.6k

PWREN#

CMD_DATA_OUT

CMD_DATA_IN

GND

GND

+

C1

4.7uF

C4

0.01uF

L1

600R/1.3A

GND

C6

47pF

R4

0

C2

0.1uF

VCC 12

VCCIO 3

3V3OUT

10

GND

5

GND

13

USBDM

9

USBDP

8

RESET#

11

TXD 1

RXD 4

RTS# 2

CTS# 6

CBUS0 15

CBUS1 14

CBUS2 7

CBUS3 16

U2

FT230X

C5

47pF

PWREN#

C7

0.1uF

GND

5V 1

DAT- 2

DAT+ 3

NC 4

GSHD

6GSHD

7

GND 5

J1

Micro USB

5VUSB

5VUSB

D1

TX/RX_IND ORANGE

RTS

CTS

R2 27

R3 27

R5

330

USB AREA POWER SUPPLY AREA RF MODULE CARRIER AREA

SIGNAL ROUTING

GND

CRT_LRNIN 1

VCC 2

GND 3

NC

4

COM

5

NO

6

U1

MAX4544EUT

GND

C3

0.1uF

SER_I

SER_O

VCC

SER_I/O

U8

VDC

1

RA5

2

RA4

3

MCLR

4

RC5

5

RC4

6

RC3

7RC2 8

RC1 9

RC0 10

RA2 11

ICSPCLK 12

ICSPDAT 13

GND 14

PIC16F1825-I/ST

VCC GND

PGM

CMD_DATA_IN

CMD_DATA_OUT

CSB RS

SI

SCL

RST

PGC

PGD

R42

DNP

VCCP

R46

0 Ohm

VCC

RS

SI

SCL

RST

CSB

VCC

GND

GND

C13

1uF

GND

C14

1uF C1-

2

C1+

3

VOUT

4

VCC

5

GND

6

SI

7

SCL

8

CSB

9

RS

10

LED+

1

LED-

12

RST

11

LCD1

2x16 LCD

R6

0 Ohm

CRT_LRN

CMD_DATA_IN

CMD_DATA_OUT

MODE_IND_MT

SER_ISER_O

RTS

CTS

DIR

1

A1

2

A2

3

A3

4

A4

5

A5

6

A6

7

A7

8

A8

9

GND

10 B8 11

B7 12

B6 13

B5 14

B4 15

B3 16

B2 17

B1 18

OE 19

VCC 20

U6

SN74AHC245

VCCVCC

/IDENTITY

GND

CRT_LRN

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

IDENTITY R9 10k GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

R35 10k

R34 10k

R33 10k

R32 10k

R30 10k

R28 10k

R22 10k

R21 10k

R18 10k

R15 10k

R14 10k

R13 10k

R12 10k

R10 10k

R36 1k

GND

R38 10k VCC

R41

0 Ohm

R40

0 Ohm

VCC

GND

SW1

VCC

R1

1 Ohm

MODE_IND

CMD_DATA_IN

CMD_DATA_OUT

GND

GND

GND GND

GND

VCC

1

23

45

67

89

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 29

30 31

32 33

34 35

36 37

J2

Carrier Interconnect

SER_I/O

R29 10k

GND

GND

VCC

GND

VCC

VCC

R27 10k

R25 10k

R20 10k

R17 10kR1610k

R1910k

R3110k

VCC

PAIR

GND R7 10k

GND R2310k

GND R2610k

GND R3710k

GND R3910k

GND R4310k

R44 10k GND

R45 10k GND

RF 1

GND

2-5

ANT1

GND

GND

X1

1nH X3

DNP

GND

X2

DNP

MICROCONTROLLER AREA

Figure 43: Programming Dock Board RF Carrier Area Schematic

Programming Dock Board Schematic

–– – –

34 35

C12

0.1uF

VCC

GND

GND

MODE_IND

R8

330

D4

MODE_IND BLUE

IN 1

VCC2

GND3

NC

4

COM

5

NO

6

U5

MAX4544EUT

MODE_IND_MT

GND

C10

0.1uF

//IDENTITY

VCC

GND

IDENTITY

GND

VCC

A

1

GND

2

B

3/B 4

VCC5

/A 6

U7

NC7WZ04

GND

C11

0.1uF

/IDENTITY

/IDENTITY //IDENTITY

R24

10k

S2

VCC

PAIR

PAIR CRT_LRN

GND

GND

+C8

100uF

VCC

GND

Vin

1

GND

2

Vout 3

U4

LM3940IMP 3.3V

C9

0.47uF

GND

IN

1

GND

2

EN

3FAULT 4

ILIM 5

OUT 6

U3

TPS2552

GND

5VUSB VCCU

GND

R11

53.6k

PWREN#

CMD_DATA_OUT

CMD_DATA_IN

GND

GND

+

C1

4.7uF

C4

0.01uF

L1

600R/1.3A

GND

C6

47pF

R4

0

C2

0.1uF

VCC 12

VCCIO 3

3V3OUT

10

GND

5

GND

13

USBDM

9

USBDP

8

RESET#

11

TXD 1

RXD 4

RTS# 2

CTS# 6

CBUS0 15

CBUS1 14

CBUS2 7

CBUS3 16

U2

FT230X

C5

47pF

PWREN#

C7

0.1uF

GND

5V 1

DAT- 2

DAT+ 3

NC 4

GSHD

6GSHD

7

GND 5

J1

Micro USB

5VUSB

5VUSB

D1

TX/RX_IND ORANGE

RTS

CTS

R2 27

R3 27

R5

330

USB AREA POWER SUPPLY AREA RF MODULE CARRIER AREA

SIGNAL ROUTING

GND

CRT_LRNIN 1

VCC 2

GND 3

NC

4

COM

5

NO

6

U1

MAX4544EUT

GND

C3

0.1uF

SER_I

SER_O

VCC

SER_I/O

U8

VDC

1

RA5

2

RA4

3

MCLR

4

RC5

5

RC4

6

RC3

7RC2 8

RC1 9

RC0 10

RA2 11

ICSPCLK 12

ICSPDAT 13

GND 14

PIC16F1825-I/ST

VCC GND

PGM

CMD_DATA_IN

CMD_DATA_OUT

CSB RS

SI

SCL

RST

PGC

PGD

R42

DNP

VCCP

R46

0 Ohm

VCC

RS

SI

SCL

RST

CSB

VCC

GND

GND

C13

1uF

GND

C14

1uF C1-

2

C1+

3

VOUT

4

VCC

5

GND

6

SI

7

SCL

8

CSB

9

RS

10

LED+

1

LED-

12

RST

11

LCD1

2x16 LCD

R6

0 Ohm

CRT_LRN

CMD_DATA_IN

CMD_DATA_OUT

MODE_IND_MT

SER_ISER_O

RTS

CTS

DIR

1

A1

2

A2

3

A3

4

A4

5

A5

6

A6

7

A7

8

A8

9

GND

10 B8 11

B7 12

B6 13

B5 14

B4 15

B3 16

B2 17

B1 18

OE 19

VCC 20

U6

SN74AHC245

VCCVCC

/IDENTITY

GND

CRT_LRN

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

IDENTITY R9 10k GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

R35 10k

R34 10k

R33 10k

R32 10k

R30 10k

R28 10k

R22 10k

R21 10k

R18 10k

R15 10k

R14 10k

R13 10k

R12 10k

R10 10k

R36 1k

GND

R38 10k VCC

R41

0 Ohm

R40

0 Ohm

VCC

GND

SW1

VCC

R1

1 Ohm

MODE_IND

CMD_DATA_IN

CMD_DATA_OUT

GND

GND

GND GND

GND

VCC

1

23

45

67

89

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 29

30 31

32 33

34 35

36 37

J2

Carrier Interconnect

SER_I/O

R29 10k

GND

GND

VCC

GND

VCC

VCC

R27 10k

R25 10k

R20 10k

R17 10kR1610k

R1910k

R3110k

VCC

PAIR

GND R7 10k

GND R2310k

GND R2610k

GND R3710k

GND R3910k

GND R4310k

R44 10k GND

R45 10k GND

RF 1

GND

2-5

ANT1

GND

GND

X1

1nH X3

DNP

GND

X2

DNP

MICROCONTROLLER AREA

Figure 44: Programming Dock Board Power Supply Area Schematic

C12

0.1uF

VCC

GND

GND

MODE_IND

R8

330

D4

MODE_IND BLUE

IN 1

VCC2

GND3

NC

4

COM

5

NO

6

U5

MAX4544EUT

MODE_IND_MT

GND

C10

0.1uF

//IDENTITY

VCC

GND

IDENTITY

GND

VCC

A

1

GND

2

B

3/B 4

VCC5

/A 6

U7

NC7WZ04

GND

C11

0.1uF

/IDENTITY

/IDENTITY //IDENTITY

R24

10k

S2

VCC

PAIR

PAIR CRT_LRN

GND

GND

+C8

100uF

VCC

GND

Vin

1

GND

2

Vout 3

U4

LM3940IMP 3.3V

C9

0.47uF

GND

IN

1

GND

2

EN

3FAULT 4

ILIM 5

OUT 6

U3

TPS2552

GND

5VUSB VCCU

GND

R11

53.6k

PWREN#

CMD_DATA_OUT

CMD_DATA_IN

GND

GND

+

C1

4.7uF

C4

0.01uF

L1

600R/1.3A

GND

C6

47pF

R4

0

C2

0.1uF

VCC 12

VCCIO 3

3V3OUT

10

GND

5

GND

13

USBDM

9

USBDP

8

RESET#

11

TXD 1

RXD 4

RTS# 2

CTS# 6

CBUS0 15

CBUS1 14

CBUS2 7

CBUS3 16

U2

FT230X

C5

47pF

PWREN#

C7

0.1uF

GND

5V 1

DAT- 2

DAT+ 3

NC 4

GSHD

6GSHD

7

GND 5

J1

Micro USB

5VUSB

5VUSB

D1

TX/RX_IND ORANGE

RTS

CTS

R2 27

R3 27

R5

330

USB AREA POWER SUPPLY AREA RF MODULE CARRIER AREA

SIGNAL ROUTING

GND

CRT_LRNIN 1

VCC 2

GND 3

NC

4

COM

5

NO

6

U1

MAX4544EUT

GND

C3

0.1uF

SER_I

SER_O

VCC

SER_I/O

U8

VDC

1

RA5

2

RA4

3

MCLR

4

RC5

5

RC4

6

RC3

7RC2 8

RC1 9

RC0 10

RA2 11

ICSPCLK 12

ICSPDAT 13

GND 14

PIC16F1825-I/ST

VCC GND

PGM

CMD_DATA_IN

CMD_DATA_OUT

CSB RS

SI

SCL

RST

PGC

PGD

R42

DNP

VCCP

R46

0 Ohm

VCC

RS

SI

SCL

RST

CSB

VCC

GND

GND

C13

1uF

GND

C14

1uF C1-

2

C1+

3

VOUT

4

VCC

5

GND

6

SI

7

SCL

8

CSB

9

RS

10

LED+

1

LED-

12

RST

11

LCD1

2x16 LCD

R6

0 Ohm

CRT_LRN

CMD_DATA_IN

CMD_DATA_OUT

MODE_IND_MT

SER_ISER_O

RTS

CTS

DIR

1

A1

2

A2

3

A3

4

A4

5

A5

6

A6

7

A7

8

A8

9

GND

10 B8 11

B7 12

B6 13

B5 14

B4 15

B3 16

B2 17

B1 18

OE 19

VCC 20

U6

SN74AHC245

VCCVCC

/IDENTITY

GND

CRT_LRN

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

IDENTITY R9 10k GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

R35 10k

R34 10k

R33 10k

R32 10k

R30 10k

R28 10k

R22 10k

R21 10k

R18 10k

R15 10k

R14 10k

R13 10k

R12 10k

R10 10k

R36 1k

GND

R38 10k VCC

R41

0 Ohm

R40

0 Ohm

VCC

GND

SW1

VCC

R1

1 Ohm

MODE_IND

CMD_DATA_IN

CMD_DATA_OUT

GND

GND

GND GND

GND

VCC

1

23

45

67

89

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 29

30 31

32 33

34 35

36 37

J2

Carrier Interconnect

SER_I/O

R29 10k

GND

GND

VCC

GND

VCC

VCC

R27 10k

R25 10k

R20 10k

R17 10kR1610k

R1910k

R3110k

VCC

PAIR

GND R7 10k

GND R2310k

GND R2610k

GND R3710k

GND R3910k

GND R4310k

R44 10k GND

R45 10k GND

RF 1

GND

2-5

ANT1

GND

GND

X1

1nH X3

DNP

GND

X2

DNP

MICROCONTROLLER AREA

Figure 45: Programming Dock Board Signal Routing Schematic

C12

0.1uF

VCC

GND

GND

MODE_IND

R8

330

D4

MODE_IND BLUE

IN 1

VCC2

GND3

NC

4

COM

5

NO

6

U5

MAX4544EUT

MODE_IND_MT

GND

C10

0.1uF

//IDENTITY

VCC

GND

IDENTITY

GND

VCC

A

1

GND

2

B

3/B 4

VCC5

/A 6

U7

NC7WZ04

GND

C11

0.1uF

/IDENTITY

/IDENTITY //IDENTITY

R24

10k

S2

VCC

PAIR

PAIR CRT_LRN

GND

GND

+C8

100uF

VCC

GND

Vin

1

GND

2

Vout 3

U4

LM3940IMP 3.3V

C9

0.47uF

GND

IN

1

GND

2

EN

3FAULT 4

ILIM 5

OUT 6

U3

TPS2552

GND

5VUSB VCCU

GND

R11

53.6k

PWREN#

CMD_DATA_OUT

CMD_DATA_IN

GND

GND

+

C1

4.7uF

C4

0.01uF

L1

600R/1.3A

GND

C6

47pF

R4

0

C2

0.1uF

VCC 12

VCCIO 3

3V3OUT

10

GND

5

GND

13

USBDM

9

USBDP

8

RESET#

11

TXD 1

RXD 4

RTS# 2

CTS# 6

CBUS0 15

CBUS1 14

CBUS2 7

CBUS3 16

U2

FT230X

C5

47pF

PWREN#

C7

0.1uF

GND

5V 1

DAT- 2

DAT+ 3

NC 4

GSHD

6GSHD

7

GND 5

J1

Micro USB

5VUSB

5VUSB

D1

TX/RX_IND ORANGE

RTS

CTS

R2 27

R3 27

R5

330

USB AREA POWER SUPPLY AREA RF MODULE CARRIER AREA

SIGNAL ROUTING

GND

CRT_LRNIN 1

VCC 2

GND 3

NC

4

COM

5

NO

6

U1

MAX4544EUT

GND

C3

0.1uF

SER_I

SER_O

VCC

SER_I/O

U8

VDC

1

RA5

2

RA4

3

MCLR

4

RC5

5

RC4

6

RC3

7RC2 8

RC1 9

RC0 10

RA2 11

ICSPCLK 12

ICSPDAT 13

GND 14

PIC16F1825-I/ST

VCC GND

PGM

CMD_DATA_IN

CMD_DATA_OUT

CSB RS

SI

SCL

RST

PGC

PGD

R42

DNP

VCCP

R46

0 Ohm

VCC

RS

SI

SCL

RST

CSB

VCC

GND

GND

C13

1uF

GND

C14

1uF C1-

2

C1+

3

VOUT

4

VCC

5

GND

6

SI

7

SCL

8

CSB

9

RS

10

LED+

1

LED-

12

RST

11

LCD1

2x16 LCD

R6

0 Ohm

CRT_LRN

CMD_DATA_IN

CMD_DATA_OUT

MODE_IND_MT

SER_ISER_O

RTS

CTS

DIR

1

A1

2

A2

3

A3

4

A4

5

A5

6

A6

7

A7

8

A8

9

GND

10 B8 11

B7 12

B6 13

B5 14

B4 15

B3 16

B2 17

B1 18

OE 19

VCC 20

U6

SN74AHC245

VCCVCC

/IDENTITY

GND

CRT_LRN

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

IDENTITY R9 10k GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

R35 10k

R34 10k

R33 10k

R32 10k

R30 10k

R28 10k

R22 10k

R21 10k

R18 10k

R15 10k

R14 10k

R13 10k

R12 10k

R10 10k

R36 1k

GND

R38 10k VCC

R41

0 Ohm

R40

0 Ohm

VCC

GND

SW1

VCC

R1

1 Ohm

MODE_IND

CMD_DATA_IN

CMD_DATA_OUT

GND

GND

GND GND

GND

VCC

1

23

45

67

89

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28 29

30 31

32 33

34 35

36 37

J2

Carrier Interconnect

SER_I/O

R29 10k

GND

GND

VCC

GND

VCC

VCC

R27 10k

R25 10k

R20 10k

R17 10kR1610k

R1910k

R3110k

VCC

PAIR

GND R7 10k

GND R2310k

GND R2610k

GND R3710k

GND R3910k

GND R4310k

R44 10k GND

R45 10k GND

RF 1

GND

2-5

ANT1

GND

GND

X1

1nH X3

DNP

GND

X2

DNP

MICROCONTROLLER AREA

Figure 46: Programming Dock Board USB Area Schematic

Other manuals for TT Series

1

This manual suits for next models

13

Table of contents

Other Linx Technologies Microcontroller manuals

Linx Technologies

Linx Technologies TT Series User manual

Linx Technologies

Linx Technologies HumDT Series Service manual

Linx Technologies

Linx Technologies HumDT Series User manual

Linx Technologies

Linx Technologies NT Series User manual

Linx Technologies

Linx Technologies MDEV-GPS-SG User manual

Linx Technologies

Linx Technologies HumPRO Series Service manual

Linx Technologies

Linx Technologies QS Series User manual