–– – –

12 13

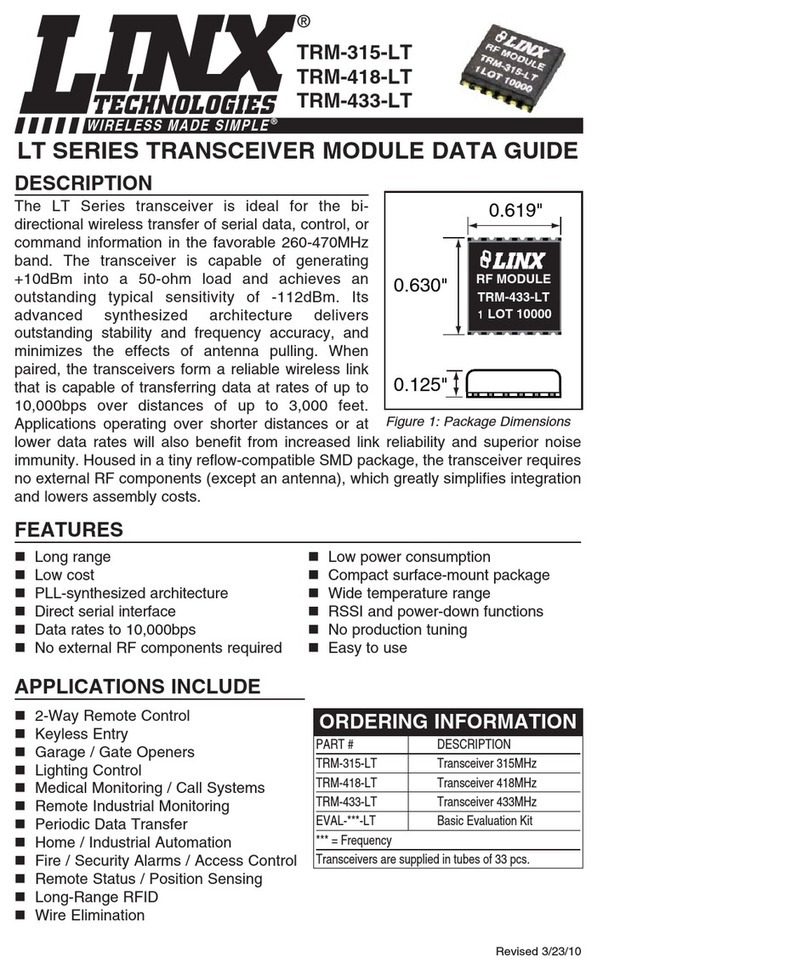

Pin Assignments

GND

NC

GND GND

NC

NC

GND

NC

NC

NC

NC

NC

GND

NC

GND

ANTENNA

1

2

3

4

5

6

7

7

38

39

40

41

42

43

44

S0

S1

GND GND

PAIR

C1

ACK_OUT

C0

CMD_DATA_OUT

LATCH_EN

S2

S3

LVL_ADJ

RESET

ACK_EN

MODE_IND

9

10

11

12

13

14

15

16 29

30

31

32

33

34

35

36

GND

S7

S6 S5

VCC

POWER_DOWN

GND

S4

RSSI

GND

GND

CMD_DATA_IN

17

18

19

20

21

22

23

24

25

26

27

28

Figure 18: TT Series Transceiver Pin Assignments (Top View)

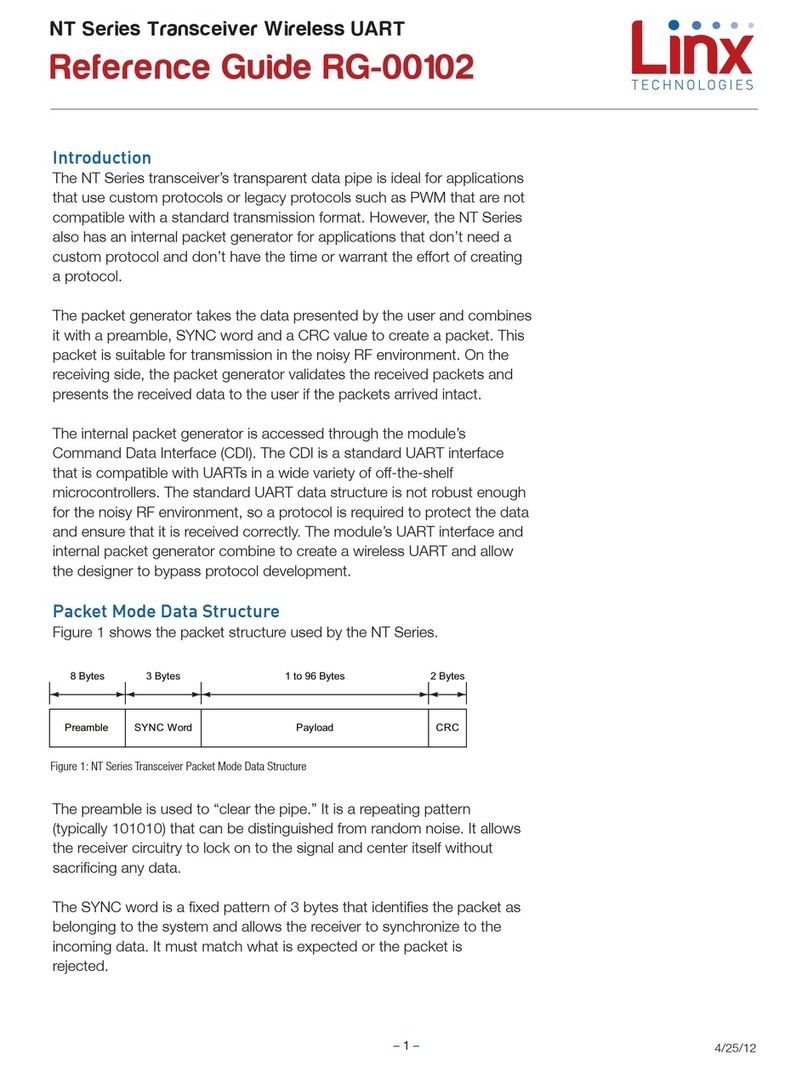

Pin Descriptions

Pin Number Name I/O Description

1, 3, 6, 11,

17, 22, 23,

28, 34, 39,

42, 44

GND — Ground

2, 4, 5, 7, 8,

37, 38, 40, 41 NC — No Electrical Connection. Do not connect

any traces to these lines.

9, 10, 12, 13,

18, 19, 20, 26 S0 - S7 I/O

Status Lines. Each line can be configured

as either an input to register button or

contact closures or as an output to control

application circuitry.

14 LVL_ADJ 1I

Level Adjust. This line sets the transmitter

output power level. Pull high or leave open

for the highest power; connect to GND

through a resistor to lower the power.

Pin Descriptions

Pin Descriptions Continued

Pin Number Name I/O Description

15 LATCH_EN I

If this line is high, then the status line

outputs are latched (a received command

to activate a status line toggles the output

state). If this line is low, then the output lines

are momentary (active for as long as a valid

signal is received) and which are latched.

16 RESET I

Pull low to perform a soft reset of the

module. This line has an internal pull-up to

POWER_DOWN, may be left unconnected

21 RSSI O

Received Signal Strength Indicator. This line

outputs an analog voltage that increases

with the strength of the received signal. It is

updated once a second.

24 POWER_DOWN I

Power Down. Pulling this line low places the

module into a low-power state. The module

is not functional in this state. Pull high for

normal operation. Do not leave floating.

25 VCC — Supply Voltage

27 CMD_DATA_IN I Command Data In. Input line for the serial

interface commands

29 CMD_DATA_OUT O Command Data Out. Output line for the

serial interface commands

30 C0 I

This line sets the input/output direction for

status lines S0-S3. When low, the lines are

outputs; when high they are inputs.

31 ACK_OUT O

This line goes high when the module

receives an acknowledgement message

from another module after sending a control

message.

32 C1 I

This line sets the input/output direction for

status lines S4-S7. When low, the lines are

outputs; when high they are inputs.

33 PAIR I

A high on this line initiates the Pair process,

which causes two units to accept each

other’s transmissions. It is also used with

a special sequence to reset the module to

factory default configuration.

35 MODE_IND O

This line indicates module activity. It can

source enough current to drive a small

LED, causing it to flash. The duration of the

flashes indicates the module’s current state.

36 ACK_EN I

Pull this line high to enable the module to

send an acknowledgement message after a

valid control message has been received.

43 ANTENNA — 50-ohm RF Antenna Port

1. This line has an internal 100kΩpull-up resistor

Figure 19: TT Series Transceiver Pin Descriptions