– – – –

14 15

Sending Data

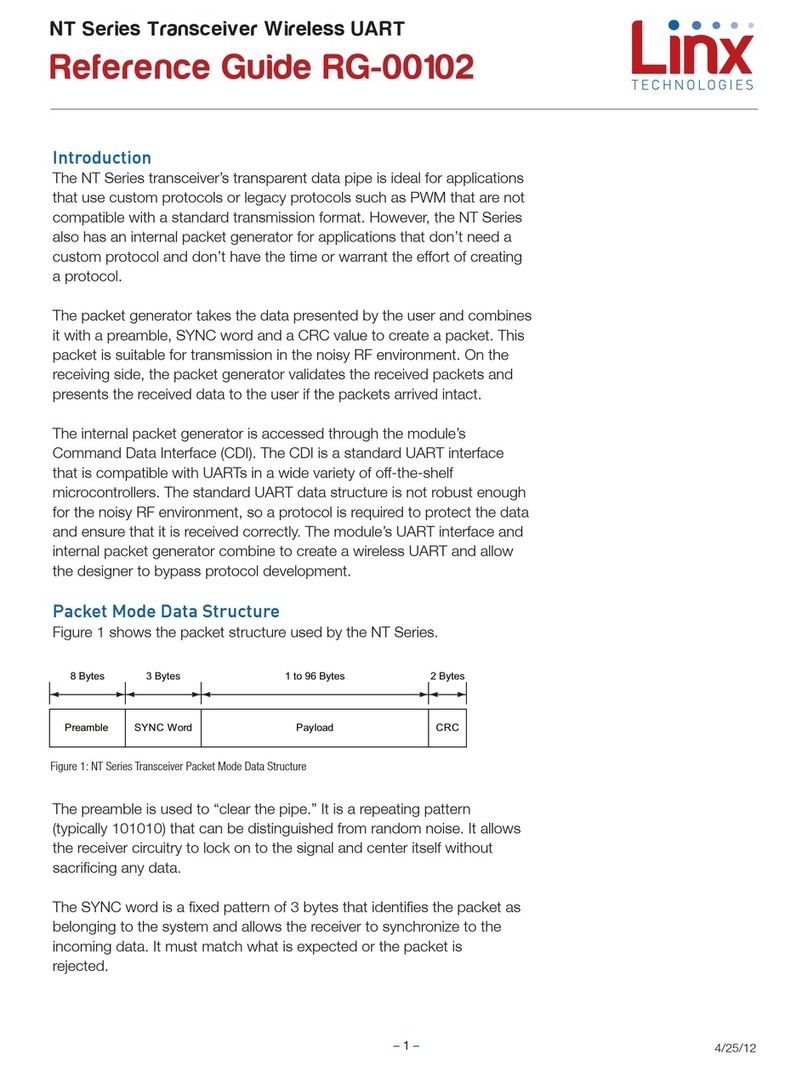

The NT Series transceiver module has two interfaces for sending data. One

interface uses a UART to pass data in and out of the module. The modules

put the data into a packet and take care of the transmission, reception and

error check. This is a very low level over-the-air protocol and does not have

any networking capabilites built in, but these capabilities can be added in

a microcontroller outside the module. This interface and the protocol are

detailed in RG-101 (NT Series Command Data Interface Reference Guide)

and RG-102 (NT Series Transceiver Wireless UART Reference Guide).

This guide details the modules transparent interface. Through this interface

the module does not encode or packetize the data in any manner. The

data present on the DATA_IN line is used to modulate the transmitter. The

received data is output on the DATA_OUT line and the transmit/receive

state is controlled with the T/R_SEL line. This transparency gives the

designer great freedom in software and protocol development, allowing the

creation of unique and proprietary data structures. This mode also allows

the use of PWM and non-standard baud rate data.

The READY line outputs a logic low when the module is ready for use and

logic high when it is busy. It can be used as hardware flow control to send

streaming data and ensure that data is not missed.

The Data Input

Transmit Mode is enabled when the T/R_SEL line is logic high. The data

on the DATA_IN line is transmitted over the air. The DATA_IN line may be

directly connected to virtually any digital peripheral, including microcon-

trollers and encoders. It can be used with any data that transitions from 0V

to VCC peak amplitude within the specified data rate range of the selected

baud band. While it is possible to send data at higher rates, the internal

filters will cause severe roll-off and attenuation.

Many RF products require a fixed data rate or place tight constraints on

the mark/space ratio of the data being sent. The transceiver architecture

eliminates such considerations and allows virtually any signal, including

PWM, Manchester, and NRZ data, to be sent at rates from 1kbps to

300kbps.

The Data Output

Receive Mode is enabled when the T/R_SEL line is logic low. The

demodulated data is output on the DATA_OUT line. Like the DATA_IN line,

this line may be directly connected to virtually any digital peripheral such as

a microcontroller or decoder.

It is important to note that the transceiver does not provide squelching of

the DATA_OUT line when in receive mode. This means that in the absence

of a valid transmission, the DATA_OUT line switches randomly. This noise

can be handled in software by implementing a noise tolerant protocol as

described in Linx Application Note AN-00160 (Figure 44).

Using the RSSI Line

The receiver’s Received Signal Strength Indicator (RSSI) line serves a

variety of functions. This line has a dynamic range of 64dB and outputs a

voltage proportional to the incoming signal strength. The RSSI Voltage vs.

Input Power graph in the Typical Performance Graphs section shows the

relationship between the RSSI voltage and the incoming signal power. This

voltage is updated once a second. This line has a high impedance and an

external buffer may be required for some applications.

It should be noted that the RSSI levels and dynamic range will vary from

part to part. It is also important to remember that RSSI output indicates

the strength of any in-band RF energy and not necessarily just that from

the intended transmitter; therefore, it should be used only to qualify the

presence and level of a signal. Using RSSI to determine distance or data

validity is not recommended.

The RSSI output can be utilized during testing or even as a product feature

to assess interference and channel quality by looking at the RSSI level

with all intended transmitters shut off. The RSSI output can also be used

in direction-finding applications, although there are many potential perils to

consider in such systems. Finally, it can be used to save system power by

“waking up” external circuitry when a transmission is received or crosses a

certain threshold. The RSSI output feature adds tremendous versatility for

the creative designer.