– – – –

14 15

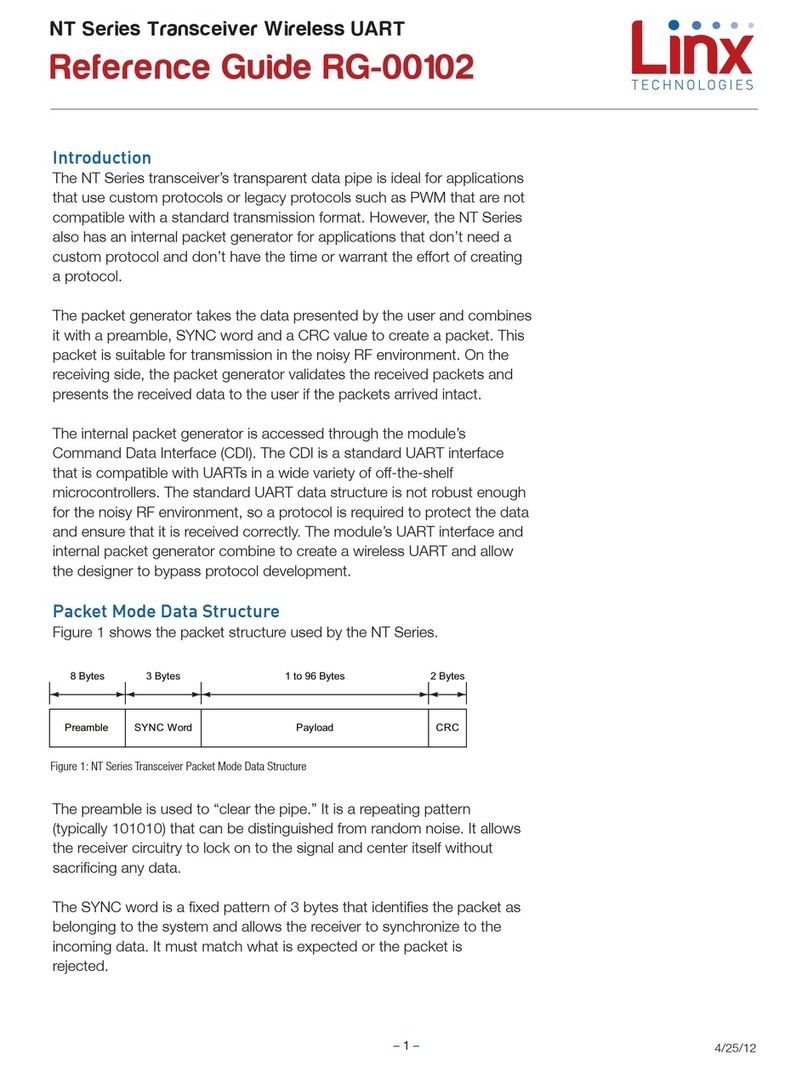

• Checking the Extended Preamble box configures the module to send a

long preamble at the beginning of every packet.

• Checking the Assured Delivery box enables RF acknowledgements

and retries when an acknowledgement is not received.

• MAXTXRETRY sets the maximum number of times that the module will

retry sending the packet before an exception is thrown.

• Checking the ENCRC box enables the CRC checks on the incoming

data. The CRC Errors box shows the number of errors since the last

power cycle or the last time the count was reset.

9. The Serial Port group configures all of the UART serial port settings.

• The UARTBAUD menu configures the serial port baud rate, which is

used by the module to set the over-the-air RF data rate.

• The Byte Count Trigger (BCTRIG) sets the number of bytes that the

UART receives before triggering the transmission of a packet.

• The UART Data Timeout (DATATO) sets the number of milliseconds

from the last character received on the UART before the module

transmits the data in its buffer.

• Selecting the WAKEACK box instructs the module to output the

acknowledgement (0x06) on the UART when the module wakes from

sleep or power cycle.

• Selecting the CMDHOLD box instructs the module to buffer any

received over-the-air data while processing configuration commands.

• Selecting the SHOWVER box instructs the module to output the

firmware version information when the module starts up from a power

cycle or reset.

10. The Packet Options group configures the explicit packet transmission

and reception, allowing the host microcontroller to control when

packets are sent and how they are received. These are set in the

PKTOPT register.

11. The Encryption Options group configures the encryption settings.

• Selecting the Encrypted Transmission box enables encryption.

• Clicking the Write Key button opens a window where the 128-bit AES

key can be entered (Figure 13).

• Clicking the Clear Key button opens a window where the key can be

cleared (Figure 13).

12. The Security Options group corresponds to the SECOPT register.

This configures the security options related to encryption and the Join

Process for setting up networks.

13. The Exceptions group configures the Extended Exception Flags and

Extended Exception Mask.

• Checking the boxes in the EEMASK0 and EEMASK1 rows sets which

exception conditions trigger the exception flags

• The EEXFLAG0 and EEXFLAG1 boxes show the current value for the

flags. 0x00 means no exceptions were detected. A non-zero value

means an exception flag is set. Clicking on the box opens a menu

showing which flags are set. Clicking on the flag clears it (Figure 14).

14. The Legacy Exception Registers group configures the Exception

Mask and Exception Flags associated with the older 250 Series

modules. These are included for backwards compatibility and are not

recommended for new designs.

15. The Module Identity group displays the RELEASE value and the

firmware version.

16. The Show Commands button opens a window that displays all of the

commands sent to the module. This is useful for seeing the UART

commands when developing and debugging firmware.

17. The Read All button reads all of the values from the active module.

18. The Write button writes all changes to the active module.

19. The Set Defaults button restores all settings to the factory defaults.

Figure 13: The Master Development System Software Write Key and Clear Key Windows

Figure 14: The Master Development System Software Exception Flags