Linxon LX218 User manual

Operating Manual

LX218

Leak Detector

klna89en1-04-(1908)

Catalog No.

8200-000, 8200-001, 8200-002, 8200-003

From software version

1.18

LINXON is a brand of INFICON GmbH

INFICON GmbH

Bonner Strasse 498

50968 Cologne, Germany

LINXON Table of Contents

LX218-Operating-Manual-en1-04-(1908) iii

Table of Contents

1 About these instructions ...................................................................................................................................6

1.1 Target groups ...........................................................................................................................................6

1.2 Warnings...................................................................................................................................................6

1.3 Definition of terms.....................................................................................................................................6

2 Safety ...............................................................................................................................................................9

2.1 Intended use .............................................................................................................................................9

2.2 Owner requirements ...............................................................................................................................10

2.3 Duties of the operator .............................................................................................................................10

2.4 Dangers ..................................................................................................................................................10

3 Shipment, Transport, Storage ........................................................................................................................12

4 Description......................................................................................................................................................14

4.1 Function ..................................................................................................................................................14

4.2 Operation modes ....................................................................................................................................14

4.2.1 Operation mode "Vacuum" .........................................................................................................14

4.2.2 Operation mode "Sniffing"........................................................................................................... 14

4.3 Device setup ...........................................................................................................................................15

4.3.1 Overall device ............................................................................................................................. 15

4.3.2 Control unit.................................................................................................................................. 17

4.3.2.1 START button ....................................................................................................................18

4.3.2.2 STOP button ......................................................................................................................18

4.3.2.3 ZERO button ......................................................................................................................18

4.3.2.4 Meaning of the function symbols........................................................................................18

4.3.2.5 Structure of the display and menu .....................................................................................19

4.3.2.6 Measuring screen layout ....................................................................................................20

4.3.3 Vacuum connections................................................................................................................... 20

4.3.3.1 Inlet ....................................................................................................................................20

4.3.3.2 Exhaust gas connection .....................................................................................................21

4.3.3.3 Venting connection.............................................................................................................21

4.3.4 Connections for accessories and control signals........................................................................ 22

4.4 Technical data ........................................................................................................................................28

4.4.1 General data ............................................................................................................................... 28

4.4.2 Data on power connections ........................................................................................................ 29

Table of Contents LINXON

iv LX218-Operating-Manual-en1-04-(1908)

4.4.3 Ambient conditions...................................................................................................................... 29

4.4.4 Measurement data ...................................................................................................................... 30

4.4.5 Data for the turbo pump .............................................................................................................. 31

5 Installation ......................................................................................................................................................32

5.1 Setup ......................................................................................................................................................32

5.2 Connecting to the power supply system .................................................................................................34

5.3 Checking the operation of the device .....................................................................................................34

5.4 Connecting an external backing pump ...................................................................................................35

6 Operation........................................................................................................................................................37

6.1 Switching on ...........................................................................................................................................37

6.2 Standby...................................................................................................................................................37

6.3 Basic settings..........................................................................................................................................38

6.3.1 Global settings ............................................................................................................................ 38

6.3.1.1 Setting the display..............................................................................................................39

6.3.1.2 Access control....................................................................................................................41

6.3.1.3 Loading/saving parameters................................................................................................43

6.3.1.4 Volume and beeping ..........................................................................................................44

6.4 Settings for the measurements...............................................................................................................44

6.4.1 Selecting the operation mode and mass..................................................................................... 44

6.4.2 Setting filter and ZERO ............................................................................................................... 45

6.4.3 Setting vacuum ranges ............................................................................................................... 47

6.4.4 Setting the evacuation time and ventilation ................................................................................ 48

6.4.5 Setting gross leak protection....................................................................................................... 49

6.4.6 Setting pressure limits for operation mode "Sniffing".................................................................. 50

6.4.7 Setting the setpoint and alarm .................................................................................................... 50

6.4.8 Defining the calibration settings .................................................................................................. 51

6.4.9 Setting the calibration request .................................................................................................... 51

6.4.10 Calibrating................................................................................................................................... 52

6.4.10.1 Calibrating in the operation mode "Vacuum" .....................................................................52

6.4.10.2 Calibrating in the operation mode "Sniffing".......................................................................54

6.4.10.3 Checking the calibration using the internal calibration leak ...............................................55

6.5 Measuring ...............................................................................................................................................56

6.5.1 Measuring in the operation mode "Vacuum"............................................................................... 56

6.5.2 Measuring in the operation mode "Sniffing"................................................................................ 56

6.5.3 Measurement view...................................................................................................................... 57

LINXON Table of Contents

LX218-Operating-Manual-en1-04-(1908) v

6.6 Calling up information about the device..................................................................................................57

6.7 Calibrating with vacuum method.............................................................................................................59

6.8 Calibrating with sniff method...................................................................................................................62

6.9 Check internal calibration leak................................................................................................................64

6.10 Switching off the device..........................................................................................................................64

7 Warning and error messages .........................................................................................................................65

8 Cleaning and maintenance.............................................................................................................................76

8.1 Cleaning/replacing the filter mat for fan 1 ...............................................................................................77

8.2 Replacing power fuses ...........................................................................................................................78

9 Decommissioning the measuring instrument..................................................................................................79

9.1 Sending in the device .............................................................................................................................79

10 Accessories ....................................................................................................................................................81

10.1 Appendix.................................................................................................................................................81

11 Appendix.........................................................................................................................................................83

11.1 Menu path...............................................................................................................................................83

11.1.1 Run-up ........................................................................................................................................ 83

11.1.2 Standby....................................................................................................................................... 83

11.1.2.1 Configuration......................................................................................................................83

11.1.2.2 Calibration ..........................................................................................................................85

11.2 CE Declaration of Conformity .................................................................................................................86

Index...............................................................................................................................................................87

1 | About these instructions LINXON

6 / 90 LX218-Operating-Manual-en1-04-(1908)

1 About these instructions

This document applies to the software version stated on the title page.

Product names may occur in the document, which are added for identification

purposes only and belong to the respective owner of the rights.

1.1 Target groups

This instruction manual is intended for the operator of the device and at technically

qualified specialists, with experience in the field of leak testing technology.

1.2 Warnings

DANGER

Imminent hazard resulting in death or serious injuries

WARNING

Hazardous situation resulting in potential death or serious injuries

CAUTION

Hazardous situation resulting in minor injuries

NOTICE

Hazardous situation resulting in damage to property or the environment

1.3 Definition of terms

Mention of helium in the manual

The device is a helium leak detector. If you want to use a forming gas instead of

helium to detect the hydrogen contained therein, the information for helium also

applies to hydrogen.

Operation mode

The leak detector distinguishes between the "Vacuum" and "Sniffing" operation

modes. For the "Vacuum" operation mode, generally the tracer gas flows into the test

object. The pressure in the test object is less than the ambient pressure.

LINXON About these instructions | 1

LX218-Operating-Manual-en1-04-(1908) 7 / 90

In the "Sniffing" operation mode, the tracer gas flows out from the test object and is

extracted with a sniffer probe. The pressure in the test object is greater than the

ambient pressure.

FINE

FINE denotes the connection to the turbo molecular pump for inlet pressures up to 2

mbar. This is also used for the "Sniffing" operation mode.

Forming gas

Forming gas is a collective term for gas mixtures of nitrogen and hydrogen.

GROSS

GROSS donates the connection to the turbo molecular pump with the lowest

sensitivity. This allows high inlet pressures (up to 15 mbar).

Minimum detectable leak rate

The minimum detectable leak rate which can be detected by the leak detector under

ideal conditions (< 5 x 10-12 mbar l/s).

ULTRA

ULTRA denotes the connection to the turbo molecular pump for the measurement

range with the highest sensitivity at inlet pressures below 0.4 mbar (adjustable).

Background signal

Helium or hydrogen (as part of water) are natural components of air.

Operation mode "Vacuum": Before any leak detection, a certain amount of the

adjusted tracer gas is already in the volume on the surfaces of the test chamber,

supply lines, and even in the leak detector itself. This certain amount of tracer gas

generates a measurement signal which is called the "Background signal". The

ongoing evacuation of the test chamber continuously reduces this background signal.

Operation mode "Sniffing": Ambient air is continuously fed into the leak detector via

the sniffer line. The amount of helium or hydrogen occurring naturally in air creates a

constant background signal.

Foreline pressure

Pressure of the backing pressure between the turbo molecular pump and the backing

pump.

1 | About these instructions LINXON

8 / 90 LX218-Operating-Manual-en1-04-(1908)

ZERO

There is helium that is weakly bound to the surfaces of a specimen as a natural part of

the ambient air and is pumped bit by bit into the measurement system of the leak

detector. It produces a slowly decreasing measurement signal.

If you want to hide this background signal or the display of existing leaks, then use the

ZERO function.

LINXON Safety | 2

LX218-Operating-Manual-en1-04-(1908) 9 / 90

2 Safety

2.1 Intended use

The device is a leak detector for detecting and measuring leaks in test objects. The

device is suitable for leak detection using the vacuum method and the sniffer method.

• Operate the device only according to this instruction manual.

• Comply with application limits, see "Technical Data".

Improper use Avoid the following, non-intended uses:

• Use outside the technical specifications, see "Technical Data"

• Use in radioactive areas

• Use of accessories or spare parts, which are not included in this instruction

manual

• Test of wet or damp test objects

• Pumping down of explosive, aggressive, corrosive, flammable, toxic or reactive

substances

• Pumping down of condensible fluids and vapors

• Pumping down of gases contaminated with particles

• Shock loads or vibrations

• Pumping hydrogen concentrations, which can explode in combination with oxygen.

The allowable composition of venal gas mixtures can be read in the safety data

sheets of the respective manufacturers.

• Using the device in potentially explosive atmospheres

• Inspecting electrically live conductors or objects with a sniffer line

• Sudden venting of vacuum systems

• Using the device as a seat or step

• Connect a test object that is not vacuum resistant

• Pumping out gases containing halogens such as fluorine or chlorine in high

concentration or over a long period of time. Use with refrigerants or SF6.

• Operation without exhaust pipe in poorly ventilated rooms, depending on the type

of gases used

Note: This device is not intended to be used in residential areas and cannot ensure

adequate protection of radio reception in such environments.

2 | Safety LINXON

10 / 90 LX218-Operating-Manual-en1-04-(1908)

2.2 Owner requirements

The following notes are for companies or any person who is responsible for the safety

and effective use of the product by the user, employee or third party.

Safety conscious operation

• Operate the device only if it is in perfect technical condition and has no damage.

• Only operate the device in accordance with this instruction manual, in a safety and

risk conscious manner.

• Adhere to the following regulations and observe their compliance:

– Intended use

– General applicable safety and accident prevention regulations

– International, national and local standards and guidelines

– Additional device-related provisions and regulations

• Only use original parts or parts approved by the manufacturer.

• Keep this instruction manual available on site.

Personnel qualifications

• Only instructed personnel should be permitted to work with and on the device. The

instructed personnel must have received training on the device.

• Make sure that authorized personnel have read and understood the operating

instructions and all other applicable documents.

2.3 Duties of the operator

• Read, observe, and follow the information in this manual and in the work

instructions provided by the owner. This concerns in particular the safety

instructions and warnings.

• Always observe the complete operating instructions for all work.

• If you have any questions about operation or maintenance that are not answered

in this manual, please contact Customer Service.

2.4 Dangers

The measuring instrument was built according to the state-of-the-art and the

recognized safety regulations. Nevertheless, improper use may result in risk to life and

limb on the part of the user or third parties, or damage to the measuring instrument or

other property may occur.

LINXON Safety | 2

LX218-Operating-Manual-en1-04-(1908) 11 / 90

Dangers from electric

power

There is a danger to life from the contact of conductive parts inside the device.

• Disconnect the device from the power supply prior to any installation and

maintenance work. Make sure that the electric power supply cannot reconnected

without authorization.

The device contains electric components that can be damaged from high electric

voltage.

• Before connecting the device to the power supply, make sure that the supply

voltage specified on the device is the same as the local power supply.

Explosion hazard Hydrogen is a flammable and explosive gas.

• Use only tracer gases with a concentration of hydrogen that cannot explode in

combination with oxygen. The allowable composition of venal gas mixtures can be

read in the safety data sheets of the respective manufacturers.

Danger from suction

effect at the inlet flange

When operating the device in operation mode Vacuum there will be a negative

pressure created at the inlet flange.

The suction effect on hands or other body parts can cause injuries or trigger

uncontrolled movements from a person being frightened.

• Pay special attention to this danger when using a remote control!

• Connect the inlet flange with a test rig or seal it off using a blank flange.

Injury from bursting

objects

There is risk of injury from bursting objects causes by a test object notwithstanding the

vacuum pressure when a test object is connected.

• Take appropriate precautions.

Risk of injury from

slipping off or falling

down

• Place the device only on surfaces that are not tilted.

• Do not lift or carry the device by yourself.

3 | Shipment, Transport, Storage LINXON

12 / 90 LX218-Operating-Manual-en1-04-(1908)

3 Shipment, Transport, Storage

Item Quantity

LINXON LX218 1

Power cable 1

Replacement filter for fan 1

Set of fuses 1

Allen key set 1

Centering ring DN 25 ISO-KF 1

Power Subcon plug and housing for D-Sub plug 1

Adapter for ventilation connection 1

Instruction manual 1

Unpacking instructions 1

Inspection certificate calibration leak 1

Inspection certificate leak detector 1

Transport

NOTICE

Material damage due to leaked oil

If an oil-sealed pump is installed in the device, the oil may leak if you turn it more than

90 degrees. Hold the device upright.

CAUTION

Risk of injury from lifting the heavy device

The device is heavy and can slip out of hand.

► Lift and transport the device only with two people.

► To lift get hold below the floor panel.

NOTICE

Material damage if incorrect transport packaging is used

Transport over long distances

► Keep the original packaging.

► Only transport the device in its original packaging.

4 | Description LINXON

14 / 90 LX218-Operating-Manual-en1-04-(1908)

4 Description

4.1 Function

The device is a leak detector for detecting and measuring leaks in test objects. The

device is suitable for leak detection using the vacuum method and the sniffer method.

• When using the vacuum method the test object is evacuated and subjected to

helium or forming gas from the outside. To do this it is necessary to establish a

vacuum connection between the device and the test object.

• When using the sniffer method an overpressure is established in the test object

using helium or a forming gas. The test object is then inspected on the outside

using a sniffer line.

4.2 Operation modes

4.2.1 Operation mode "Vacuum"

The inlet flange is located on the upper side of the device.

To be able to calibrate using the vacuum mode a suitable external calibration leak

must be mounted on inlet flange. See also "Calibrating in the operation mode

"Vacuum" [}52]".

To be able to perform leak detection using the vacuum method the inlet flange must

be connected to the desired test object.

If the pressure in the specimen is less than the surrounding pressure, then helium

(which is sprayed over the specimen) can penetrate into the specimen if there is a

leak. Helium can be detected in the leak detector using a mass spectrometer.

4.2.2 Operation mode "Sniffing"

You can connect a sniffer line to the device.

Using a sniffer line, you can suck gas into the device to be used for detection.

To scan test objects under overpressure, use the sniffer line.

Connect the sniffer line to the back of the device, see "Connections for accessories

and control signals [}22]". This connector is used both to connect the sniffer line

and to connect the ventilation line.

LINXON Description | 4

LX218-Operating-Manual-en1-04-(1908) 15 / 90

4.3 Device setup

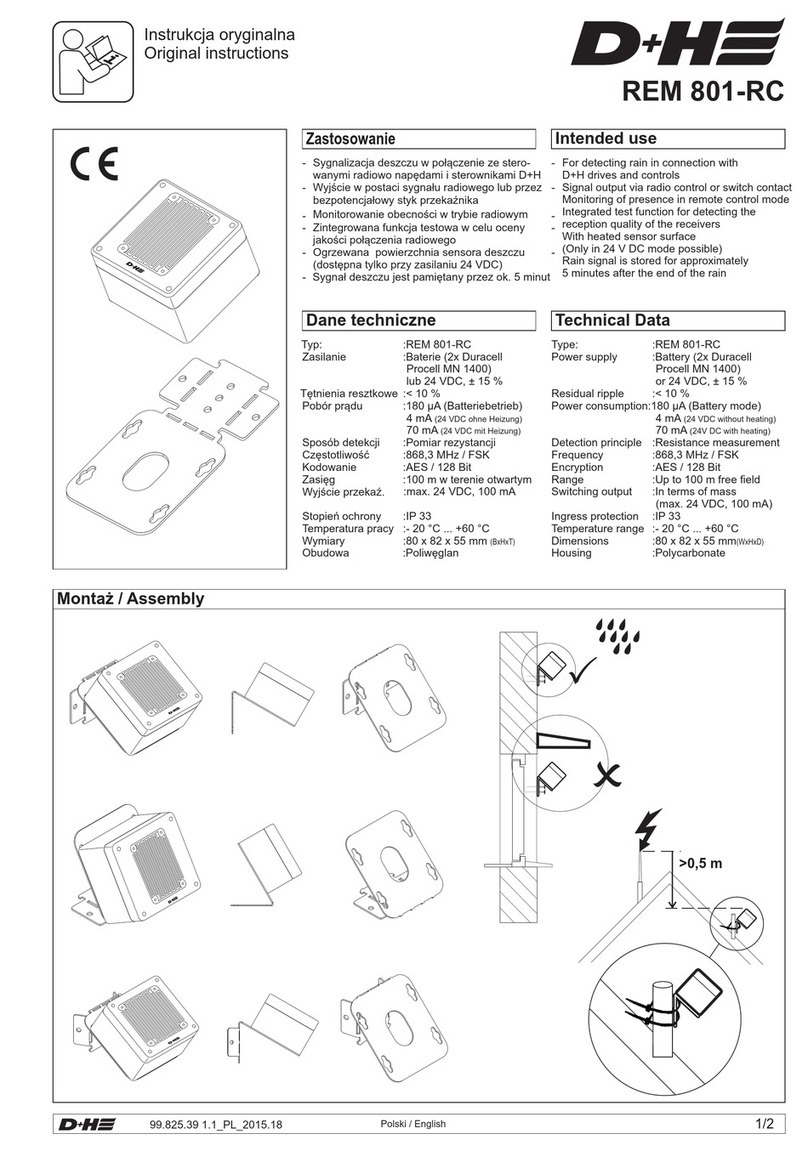

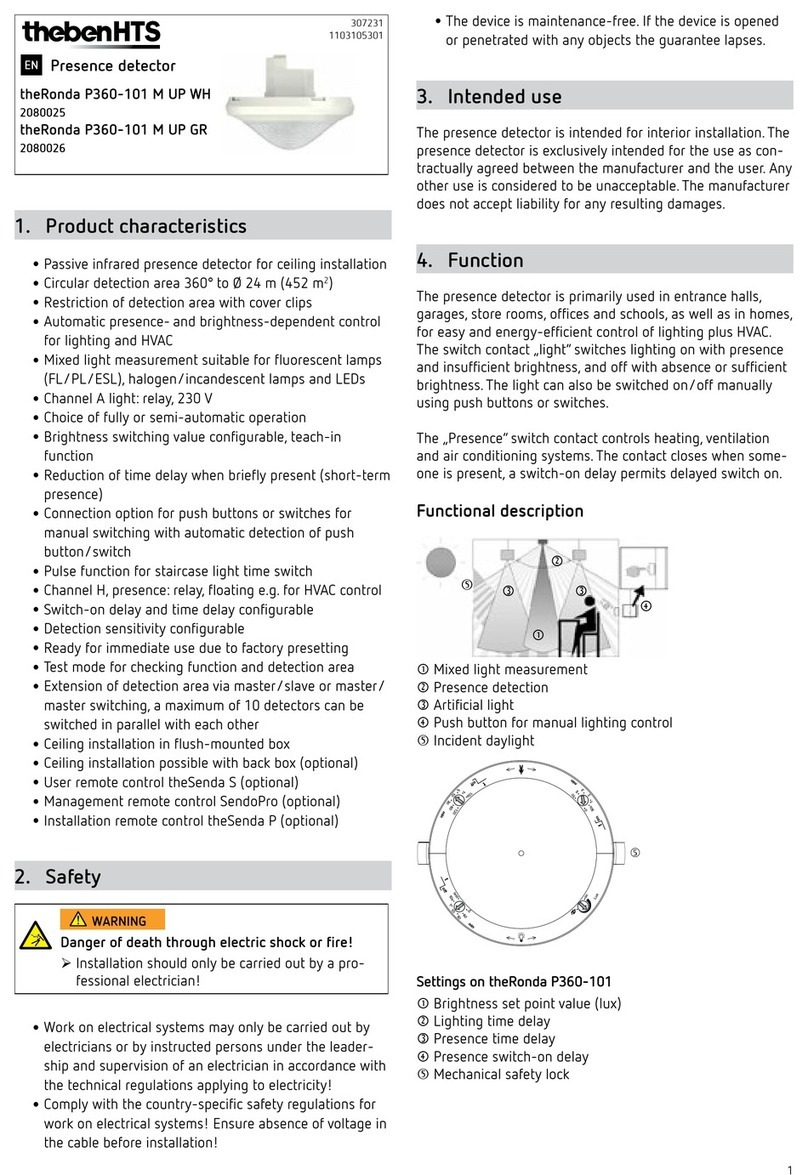

4.3.1 Overall device

12 3

65 4

Fig.1:

Front view

1 Inlet flange 2 Storage space

3 Operating unit 4 Speaker

5 Front hood 6 Fan opening

4 | Description LINXON

16 / 90 LX218-Operating-Manual-en1-04-(1908)

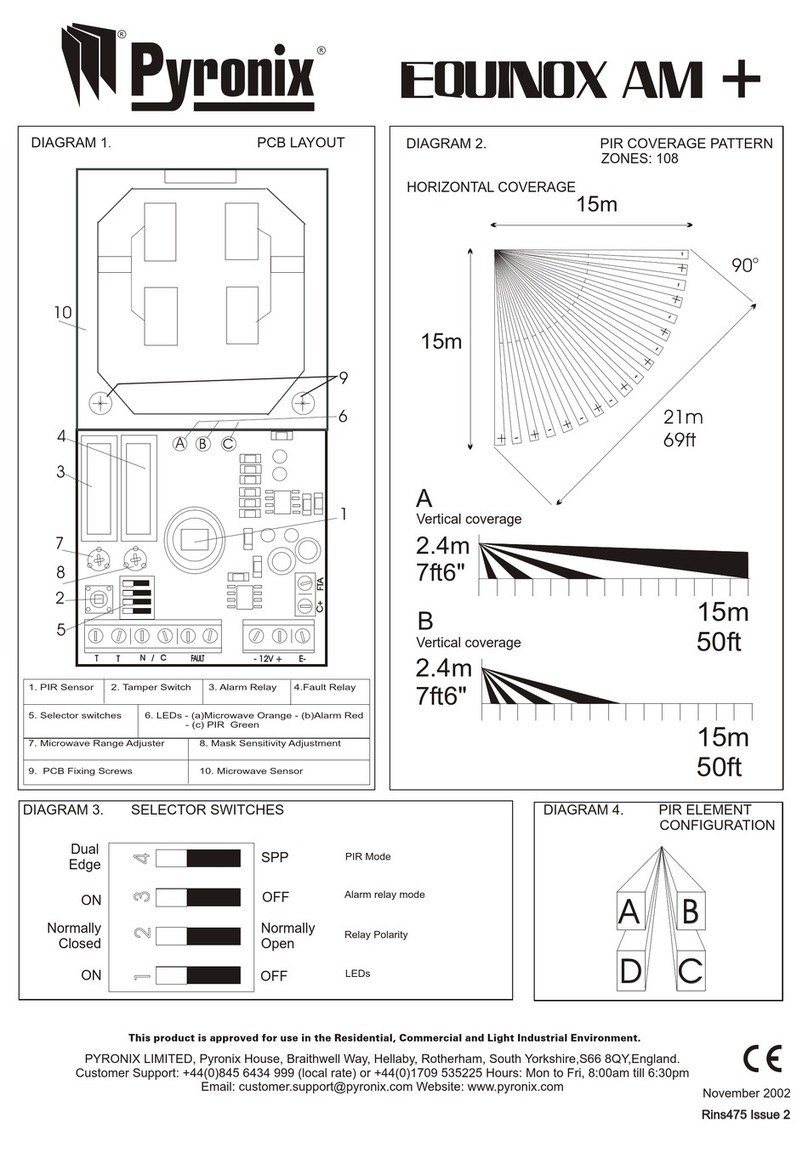

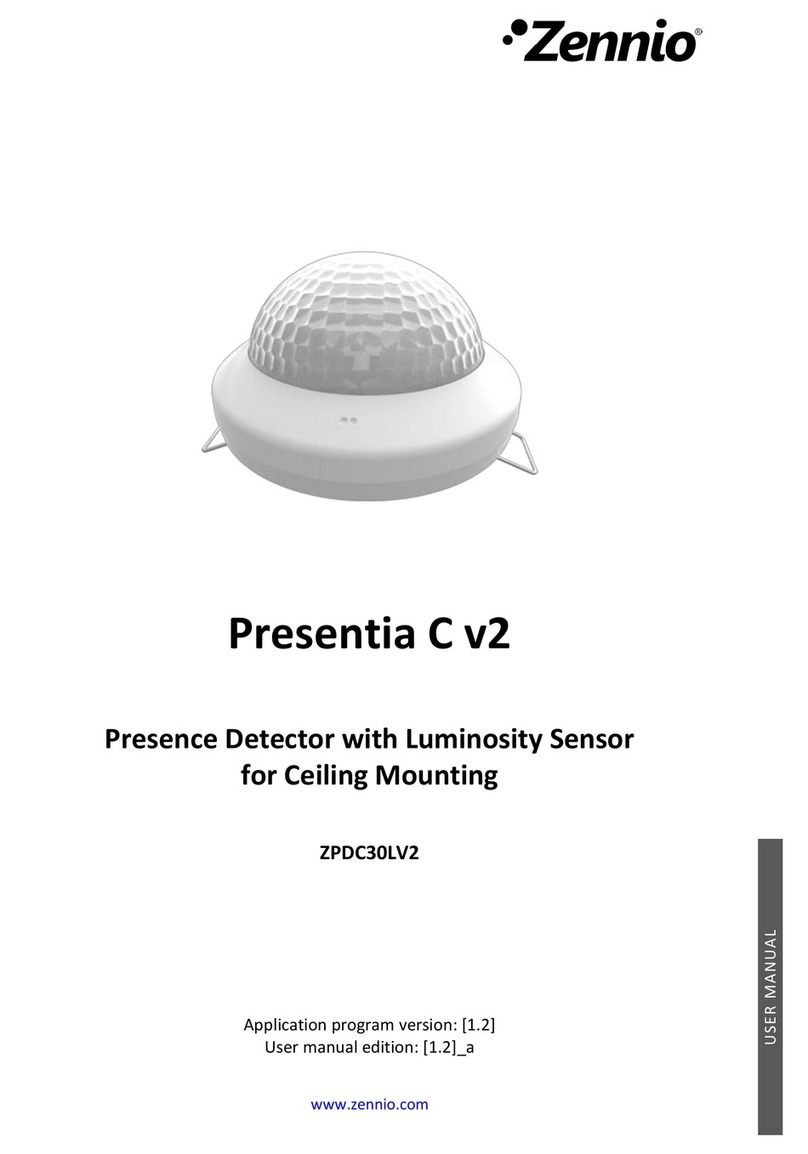

Fig.2:

Back view

1 INPUT/OUTPUT 2 Remote control connection

3 Electrical connection for the sniffer

line

4 Gas connection for the sniffer line

or the ventilation line (hose nipple

Ø 6/4 mm)

5 Exhaust gas connection

(¼‘‘ quick-change connector for

hose Ø 8.6 mm)

LINXON Description | 4

LX218-Operating-Manual-en1-04-(1908) 17 / 90

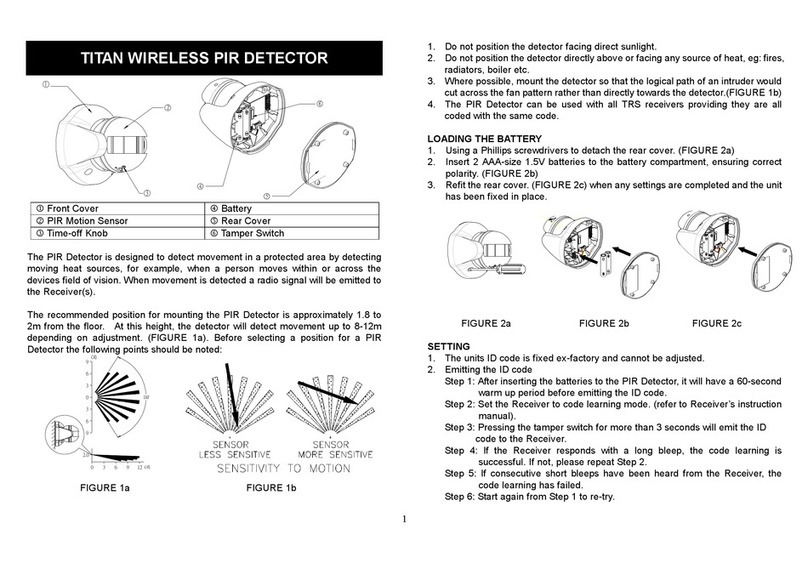

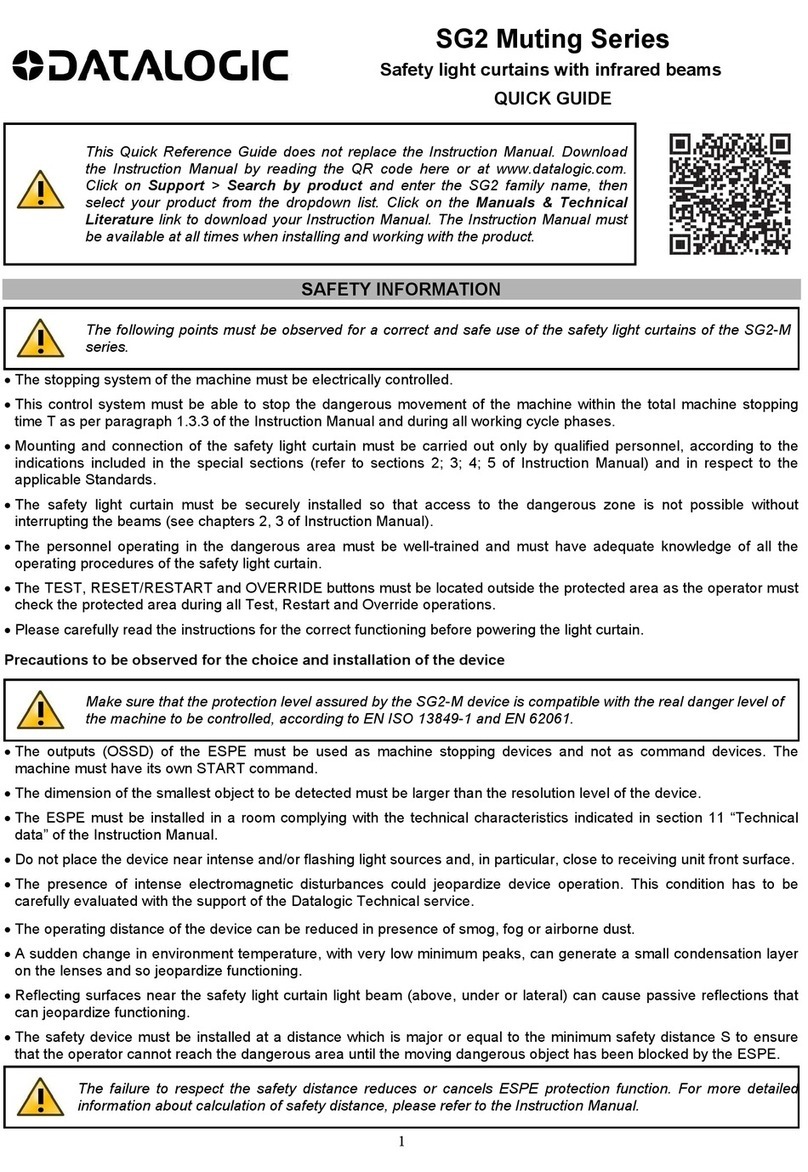

4.3.2 Control unit

1

2

543

2

Fig.3:

Control unit

The control unit consists of a display and a control panel.

1 Display The display shows measured values, operation modes,

device parameters and their values as well as the

meaning of the buttons.

2 Option buttons The function of these buttons depends on the current

operating state. The particular meaning appears on the

display.

3 STOP button STOP stops the measurement operation.

4 ZERO button ZERO activates background suppression in the

measuring mode. If the button is pressed for more than 3

seconds, background suppression will be disabled.

5 START button START starts the measurement operation.

• Switch between the windows by clicking the option buttons on the left and right

side of the display.

4 | Description LINXON

18 / 90 LX218-Operating-Manual-en1-04-(1908)

• If a value is selected in the windows, you can modify the selected processing

position with the button on the left side.

• If multiple values are present in the row, press the button on the left side again.

• You can change selected values at the edit position using the "+" or "-" buttons. If

you hold down the "+" or "-" buttons, the values change continuously in ascending

or descending order.

• Save the changed values to activate them. Press the button next to "Save".

• Modified values that are not stored are not enabled.

• Press [Back] to return to the last menu.

• Press [Home] to return to the "Standby" window.

4.3.2.1 START button

• To start the measurements.

During evacuation, the LED flashes. During the measurement, the LED lights up

continuously.

4.3.2.2 STOP button

• To stop the measurements.

4.3.2.3 ZERO button

• To hide the "Background signal", see also "Definition of terms [}6]”.

To switch off the function ZERO again, press the buttonZERO for about 3 seconds.

The function ZERO should be activated only if the leak rate signal is stable and no

leak is measured. See also "Setting filter and ZERO [}45]".

4.3.2.4 Meaning of the function symbols

Adjust the volume for the speaker.

Adjust volume: The currently adjusted volume is displayed at the bottom edge

of the display.

The value range is 0 (off) to 15 (max.).

Call up the "Configuration" menu.

ZERO is active.

Call up the calibration.

LINXON Description | 4

LX218-Operating-Manual-en1-04-(1908) 19 / 90

Call up information about the device.

This takes you to the measuring screen or "Standby".

Back to the previous menu item.

A warning or error message is active.

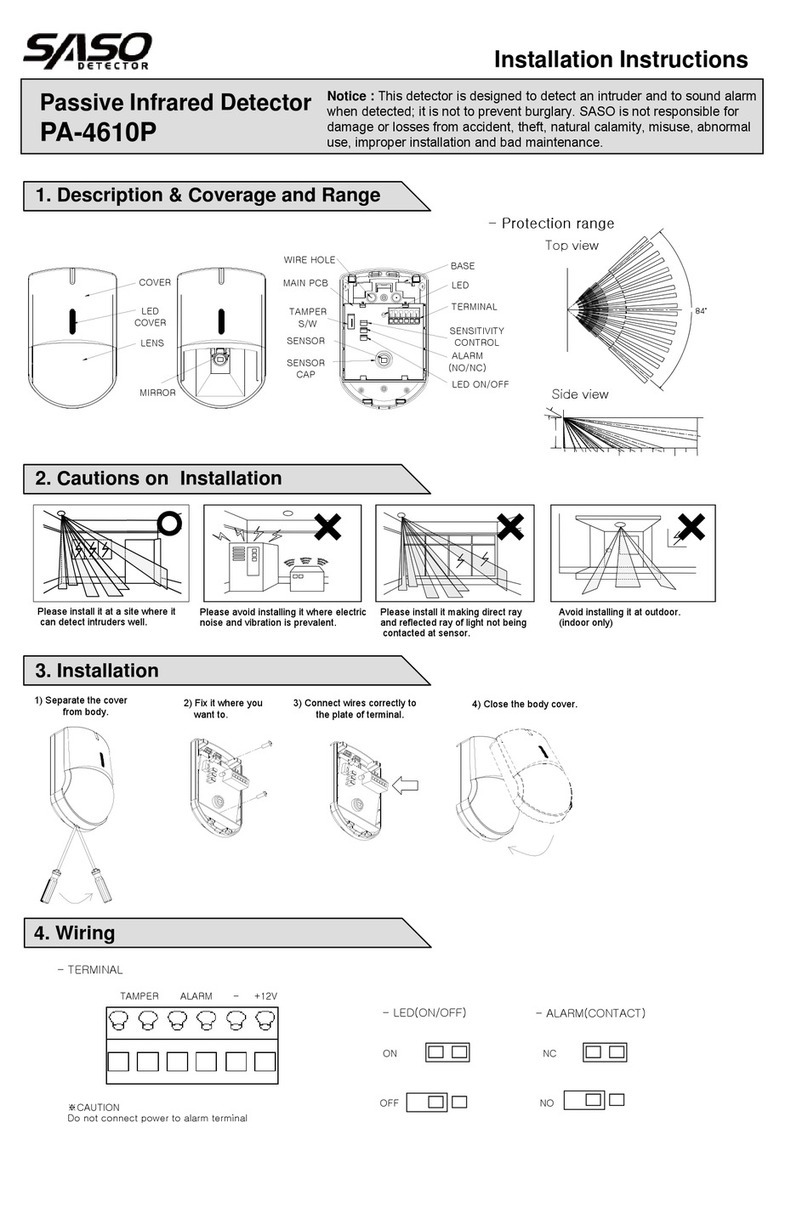

4.3.2.5 Structure of the display and menu

After the device has started up, the display will show the "Standby" window. The

device is ready for making measurements. You can change the settings for the

measurements.

Fig.4:

Menu window: Standby

1 Designation of the menu display 2 Main display area

3 Menu name

The main display area shows the current state of the device: operation mode,

measurement situation, background, tracer gas.

Menu name

Select the menus by pressing the adjacent round buttons immediately to the left or

right of the display.

4 | Description LINXON

20 / 90 LX218-Operating-Manual-en1-04-(1908)

4.3.2.6 Measuring screen layout

The measured leak rates are displayed numerically with a bar graph or graphically in a

diagram as a function of the measuring time. Use the bottom right button to switch

between the display options. Next to this button is the symbol for the analog display or

the graphical display.

Fig.5:

Numerical display, measuring screen

1 Information area

(volume, operation mode,

measuring situation, ZERO active,

tracer gas)

2 Currently measured value

(displayed using pressure at inlet

flange p2)

3 Bar graph

(the currently measured value is

displayed as a bar graph)

4 Switch to measuring screen

4.3.3 Vacuum connections

4.3.3.1 Inlet

The inlet is located on the upper part of the device. This is a DN 25 KF flange.

If you select the vacuum leak test mode, connect the test object or the vacuum

chamber to the flange.

If you are testing applications with dust or dirt, use the O-ring with filter, see

"Shipment, Transport, Storage [}12]”. In this case, the pump down times are

extended.

Also use this inlet for the connection of the sniffer line or the test chamber.

Table of contents