3

Emergency Response Guide

// CONTENT

CONTENTS.........................................3

Legal notice ..........................................4

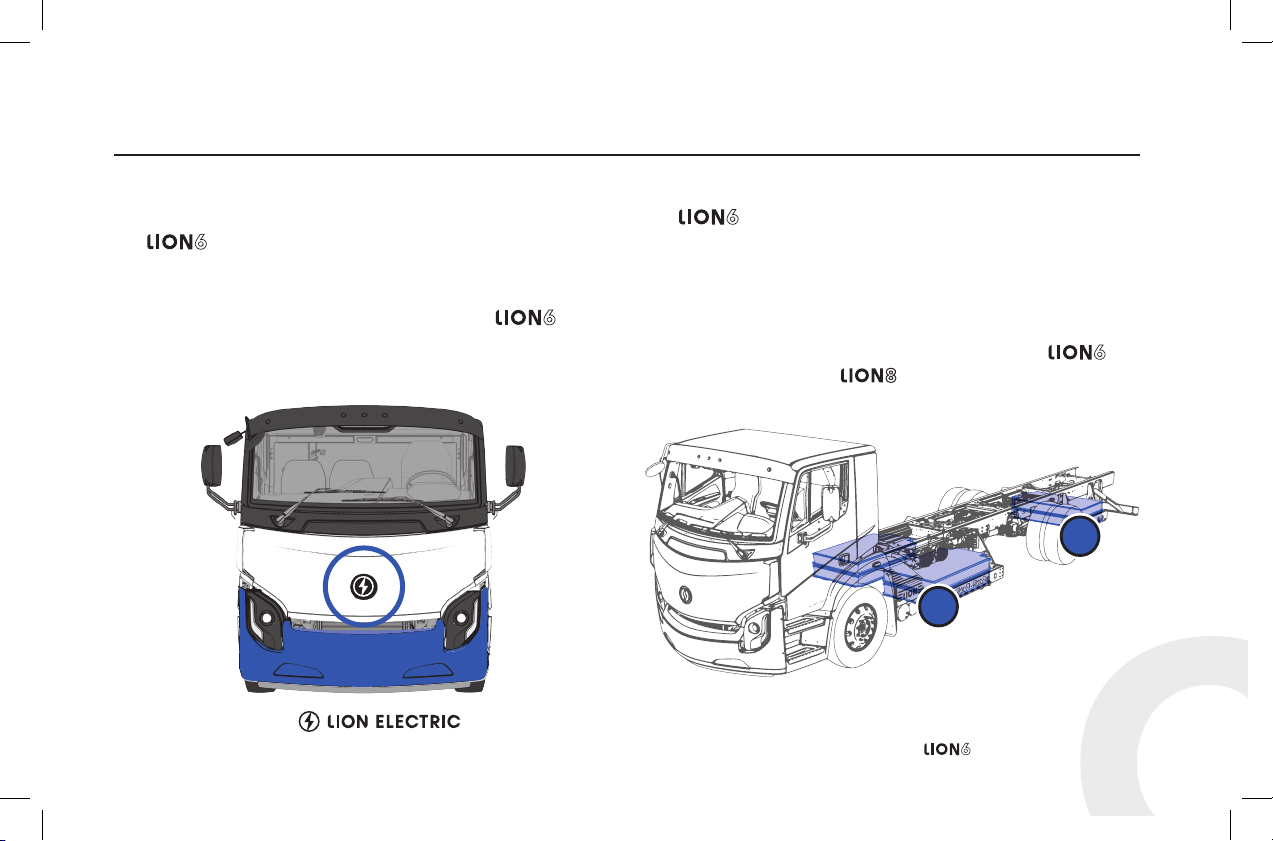

IDENTIFYING THE VEHICLE ........................5

Logo ................................................5

Batteries location .....................................5

HIGH-VOLTAGE COMPONENTS ................... 6

Schematics ..........................................6

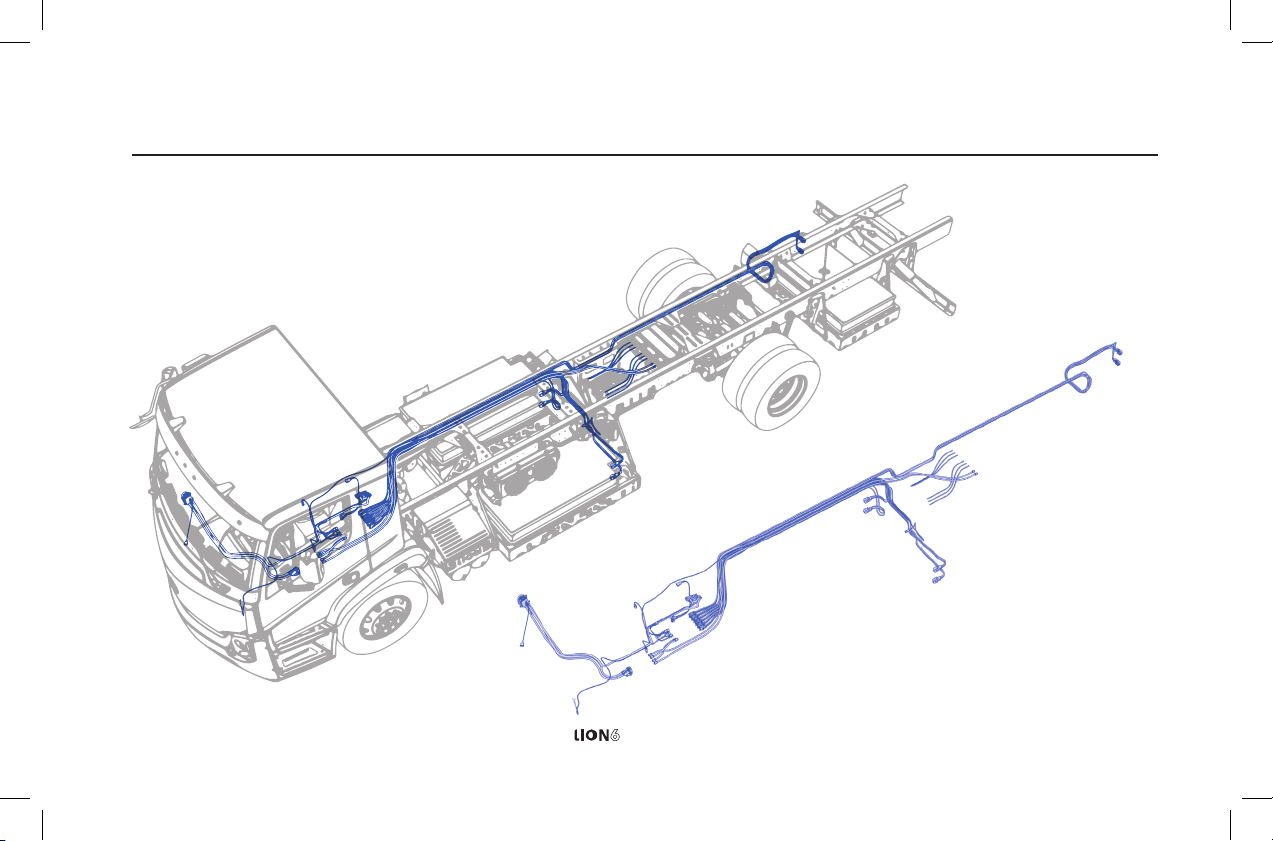

High-voltage cables routing .............................7

Warning labels........................................9

ACCESSORIES COMPARTMENT ...................10

TURNING OFF THE VEHICLE ......................11

Turning o the vehicle.................................11

DISABLING THE HIGH VOLTAGE...................12

Disabling the high voltage..............................12

CRASH SAFETY IMPACT DETECTOR ...............13

FIRE AND WATER IMMERSION ....................14

ACCESSES ........................................15

Opening the front hood ...............................15

Tilting the cab .......................................16

REINFORCEMENTS AND LIFTING THE VEHICLE ...18

Reinforcements ......................................18

Lifting the vehicle.....................................19

TOWING THE VEHICLE ........................... 20

Releasing the parking brakes ...........................20

Removing wheel axle half shaft .........................22