Lipco UF 70 Setup guide

Translation of

Reversing harrow

UF 70 / 80 / 90 / 100

original instruction

Standard version

Gearbox right turning

Reversing Harrow

UF 70 L

Special edition

Gearbox left turning

LIPCO GmbH

Am Fuchsgraben 5b

D-77880 Sasbach

Tel.

+49 7841 6348-0

Fax

+49 7841 6348-300

E-mail

Web

www.lipco.com

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

2 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

1. Introduction

Dear Customer,

We thank you for having chosen a LIPCO Reversing Harrow. We hope

that you will be happy with your choice.

In order that your LIPCO Reversing Harrow UF will serve you well for

many years, we ask you to pay close attention to the operating

instruction, which you will find in this manual. This will help you to

prevent breakdowns and accidents resulting from non-observance of

the operating instructions, for which our company will not accept

responsibility.

This Instruction and Maintenance Manual is to be considered as an

integral part of the machine itself and therefore it must always

accompany the machine when it is sold, even in the event of its sale

to third parties.

If you keep this manual in a safe place and in good condition, you -

and whoever must use the machine - will be able to have a complete

reference on hand at all times.

Note:

The illustrations, descriptions and specifications in this manual are not

binding. LIPCO reserves the right to make modifications without

notice.

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

3 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

2. Contents Page

1. Introduction 2

2. Contents 3

3. Designated use 4

4. Warning signs attached to the machine 5

5. Safety regulations 6

6. Accident prevention 7

7. Design features 9

8. Preparation 11

9. Technical data 12

10. Connection to the engine-driven machine 13

11. Adjustment of working depth/roller adjustment 15

12. Working instruction (Release of overload clutch) 16

13. Maintenance 18

14. Replacement of the cutting blades 20

15. After use 21

16. Disposal after end of lifetime of the machine 21

17. Notices 22

18. Warranty 26

19. EC Declaration of conformity 27

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

4 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

3. Designated use

The LIPCO Reversing Harrow UF, when connected to engine-driven

machines from 6,0 →10,0 kW, is designed to till and level the ground

in a single operation, thus preparing it for seeding.

Any other use for purposes other than those described here is not

according the designated use. Do not held the manufacturer liable for

damage resulting from such use; the risk for such use lies entirely with

the user.

Operating the unit within the limits of its designated use also means

following the instructions for operation, transport and maintenance

described by the manufacturer.

Persons who are familiar with the unit and informed about possible

risks must carry out any work, maintenance and repair on the LIPCO

Reversing Harrow UF!

Please observe the relevant accident prevention regulations as well

as the other generally recognized maintenance, safety, industrial

medicine and road traffic rules and instructions.

The manufacturer cannot be held liable for damage resulting from

unauthorized modifications of the LIPCO Reversing Harrow UF.

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

5 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

4. Warning signs attached to the machine

Before starting operation, the personnel must have

read the operating and safety instructions and must

observe them.

Before commencing maintenance and repair work,

switch off the engine and pull the key.

With the drive switched on and the motor running,

maintain sufficient distance to rotating tools.

With the motor running, there is a risk of parts being

hurled away –maintain safety distance.

Do not reach into rotating tools.

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

6 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

5. Safety regulations

The operation of machines containing rotating or moving tools always

bears risks. Please always follow the safety regulations:

•Before starting operation, the personnel must have read the

operating and safety instructions and observe them.

•Never remove or alter the safety devices!

•Do not touch rotating or moving parts!

•Secure the unit carefully before lying down beneath the unit for

repair or control purposes!

•Use the machine only in technically perfect condition!

•For maintenance work switch off the device!

•Maintain safety distance! (Take note of the danger sign on the side

of the machine)

•Let the work carry out only by people who are familiar with the unit

and are been informed about possible risks!

•Please observe the relevant accident prevention regulations as

well as the other generally recognized maintenance, safety,

industrial medicine and road traffic rules and instructions.

•The warnings and signs attached to the unit give important

information on safe operation; observing this instruction will ensure

your safety!

•Do not wear wide or loose clothes (e.g. scarves)!

•When working with the machine, you must wear safety shoes.

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

7 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

6. Accident prevention

Most accidents that occur during work, maintenance or transport of a

machine are due to non-observance of the most elementary rules of

accident prevention.

It is, therefore, necessary that all licensed users (relatives, employees,

colleagues) read and observe the rules given below and written on the

adhesive labels of the machine itself:

•Turn off the engine of the engine-driven machine, before carrying

out any adjustments, maintenance or cleaning on the machine!

•Prior to any work on the machine, place the machine on level and

solid ground! When working with the unit lifted, always secure the

unit mechanically by means of adequate supporting elements!

•In order to achieve the highest possible performance of the LIPCO

Reversing Harrow, it must always be in perfect condition. Only well

trained people may carry out maintenance and repair. Spare parts

must at least comply with the technical requirements specified by

the manufacturer! Only use of LIPCO original spare parts will

guarantee this!

•Before each use, check screws and nuts, especially those of the

cutting blades and the drive, that they are firmly tight!

•Before starting up, please make sure that no people or animals

are in the vicinity!

•Take special caution when working alongside roads or pathways!

•Do not leave the machine running without supervision!

•During service or repair work, make sure that no one can start up

the machine accidentally!

•Do not wear wide or loose clothes (e.g. scarves)!

•Do not, for any reason, climb onto the machine during operation!

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

8 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

•Never work without machine protection!

•Do not act with any objects on the machine during operation!

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

9 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

7. Design features

The LIPCO Reversing Harrow, when connected to any type of engine-

driven machine from eight to 10 kW, is capable of tilling and levelling

the ground in a single operation, thus preparing it for seeding. The

LIPCO Reversing Harrow dugs stones, clods, old lawn, etc. into the

ground.

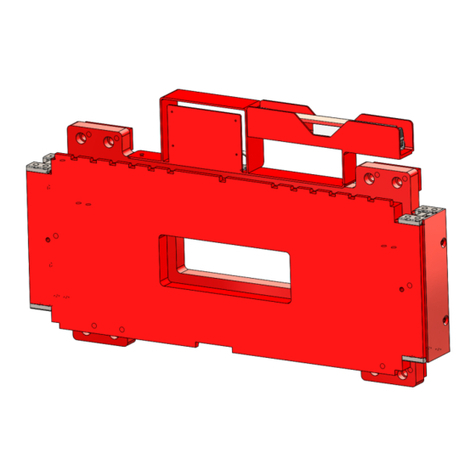

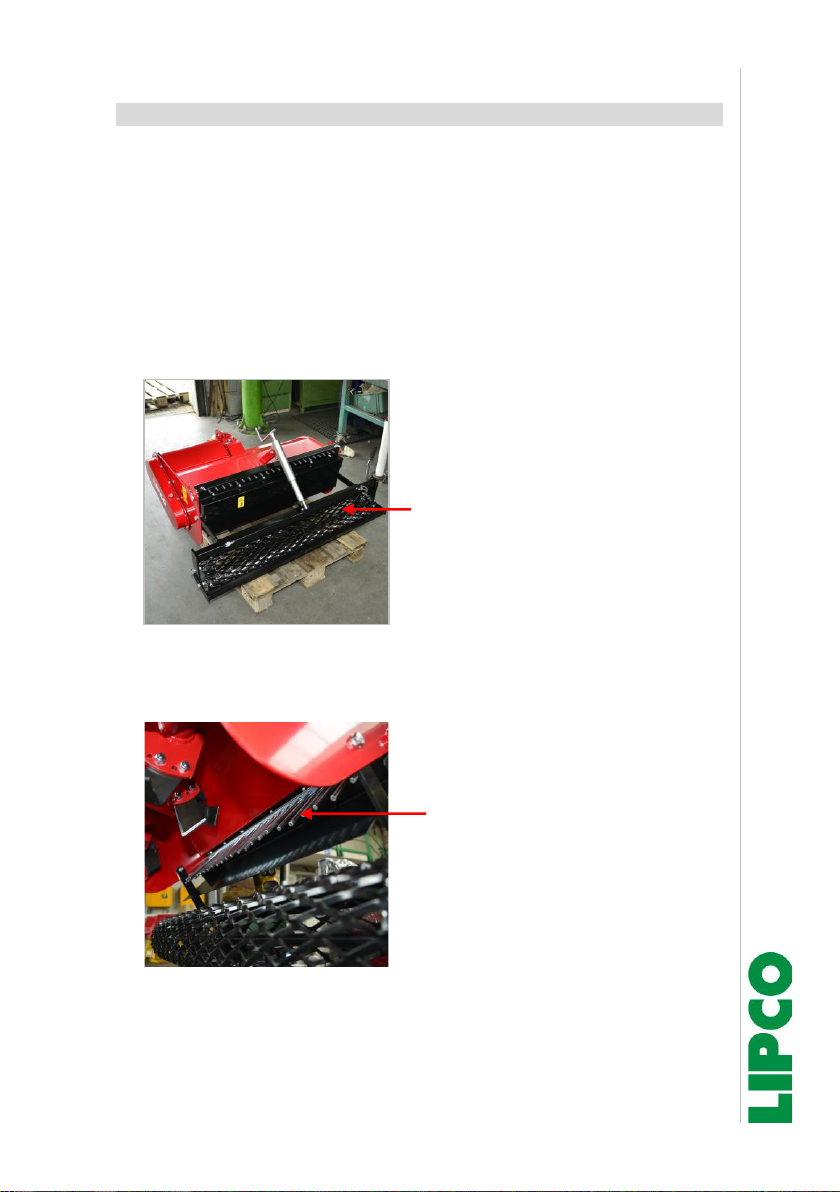

•LIPCO Reversing Harrow is equipped with a grid roller, which

makes it possible to adjust the working depth of the cutter and to

ram the earth. (Fig. 1)

Grid roller

Fig. 1

•The integrated rake pulverizes the earth smoothly. (Fig. 2).

Rake seen from the bottom

Fig. 2

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

10 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

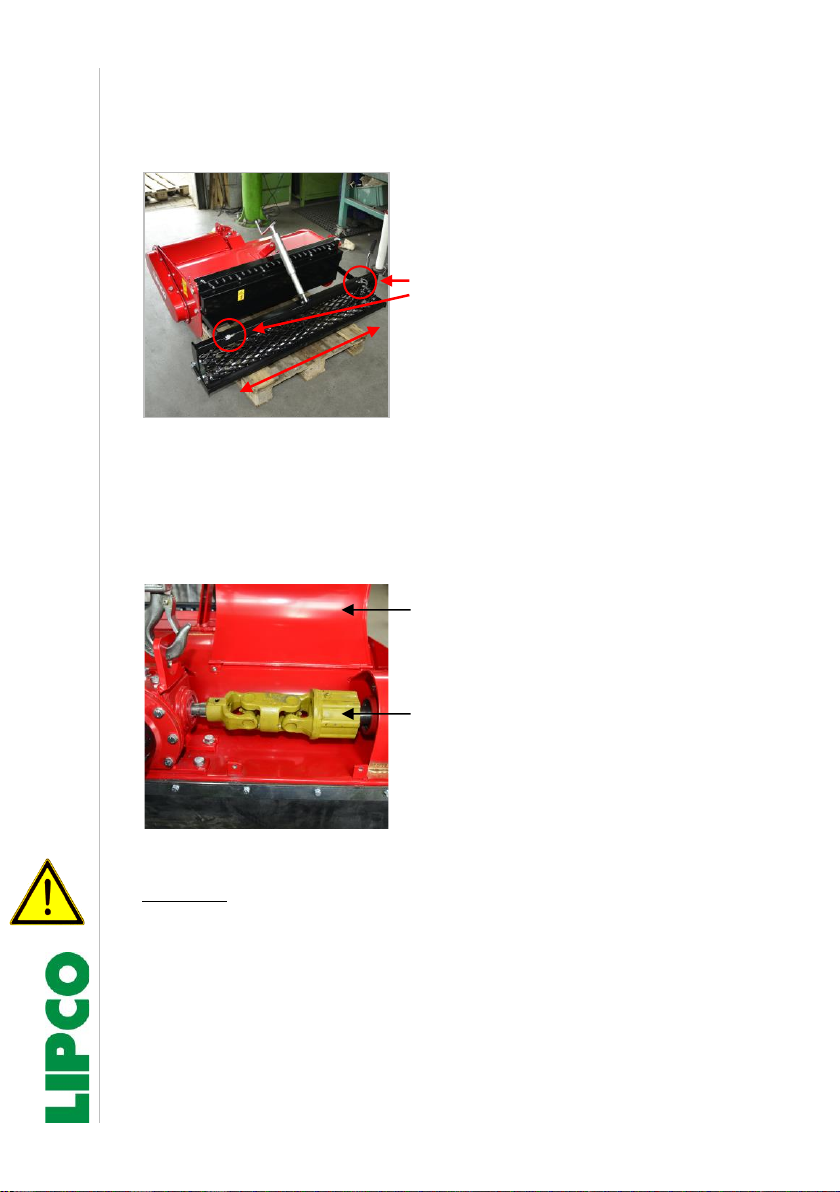

•The machine is also equipped with a lateral roller adjustment,

enabling to work right to the edge, for example on path borders.

Adjustable grid roller

Clamping studs for cage roller

adjustment

Fig. 3

•The LIPCO Reversing Harrow is equipped with an overload

coupling, a so-called star ratchet (Fig. 4). This will limit the torque

in case of overload. The noise produced in this process serves as

warning signal.

Protective hood on top of star

ratchet is open.

Star ratchet

Fig. 4

Attention!

When you hear a rattling noise of the locking body, turn-off the

power take-off shaft immediately!

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

11 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

8. Preparation

•Make sure that the unit is in perfect working order and that all

safety devices are in place!

•Check the oil level in the angular gear! (See chapter "13.

Maintenance")

•Check the lubrication in the chain drive! Run the machine for a

short time, in order to distribute the grease evenly. (See chapter

"13. Maintenance")

•Check whether all screws are tightened, especially important are

the screws of the cutter blades and the drive flange!

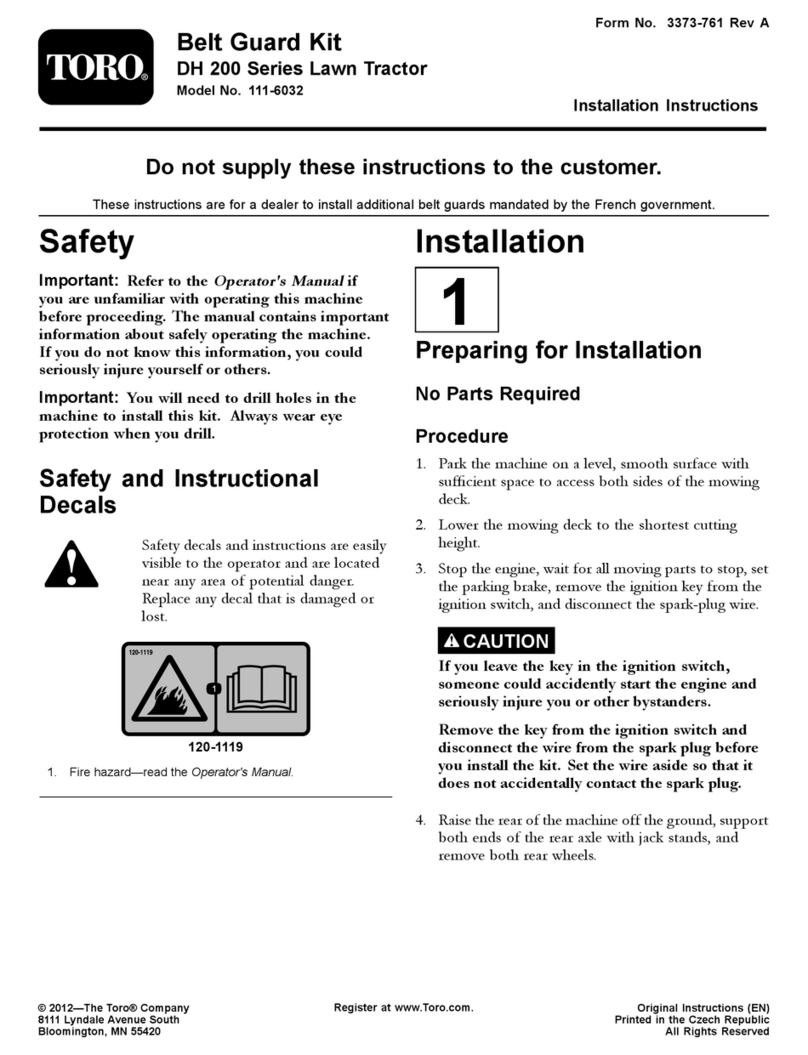

•Lubricate overload coupling (star ratchet Fig. 5) and universal joint

shaft of the drive prior to startup and then every eight working

hours.

•To do so, open the protective hood (Fig. 5).

Protective hood opened.

Lubricating nipple (3x)

Fig. 5

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

12 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

9. Technical data

Type

Weight

(kg)

Required drive

power

(kW)

Number of

Discs / cutters

UF 70 L

120

6

5

10

UF 70

120

6

5

10

UF 80

150

8

6

12

UF 90

165

9

7

14

UF 100

175

10

8

16

Main dimensions

L

B

H

UF 70 L

1020

900

455

UF 70

1020

900

455

UF 80

1020

1080

455

UF 90

1020

1230

455

UF 100

1020

1320

455

The Reversing Harrow is designed for a maximum working depth

of 15 cm.

Remarks about noise and vibration:

The values for noise and vibration of this attachment unit will not

exceed the values of the engine-driven machine.

Working direction

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

13 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

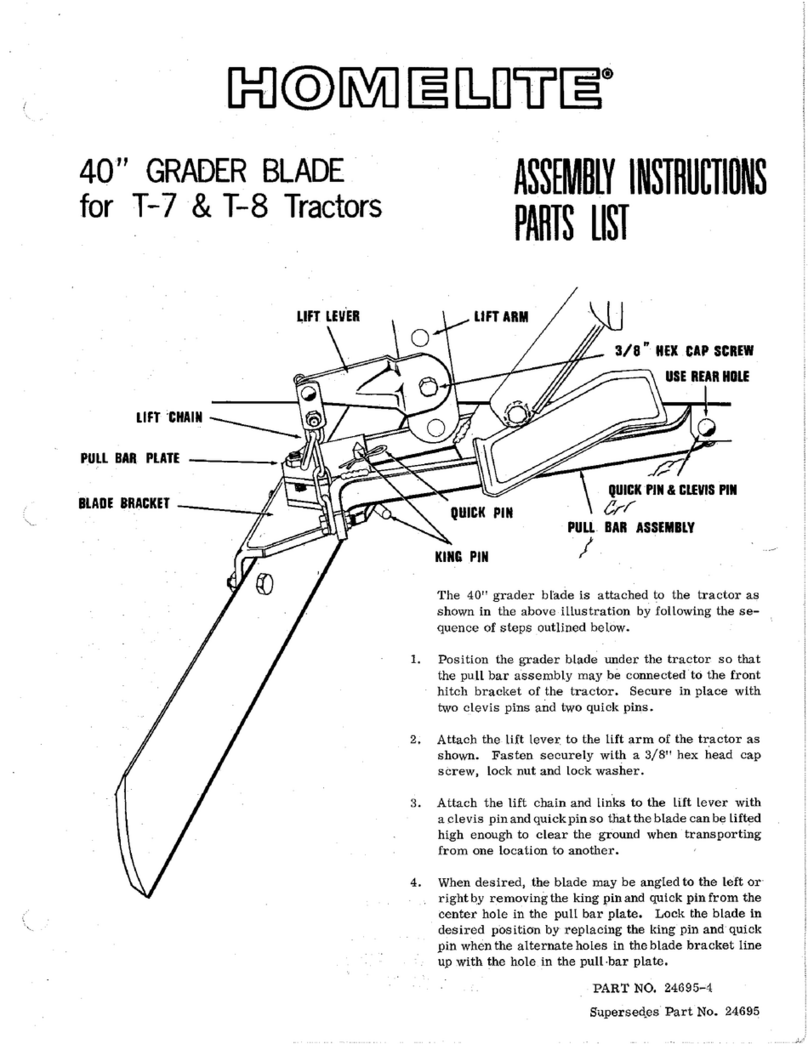

10.Connection to the engine-driven machine

Note:

In standard version, reversing harrow is equipped with rotation

gear.

As UF 70 reversing harrow is also available with an anti-clockwise

gear (version UF 70 L), make sure, when attaching reversing harrow

to the engine-driven machine, that both directions of rotation are

identical.

The direction of rotation of the reversing harrow must correspond to

the direction of rotation of the engine-driven machine, otherwise

malfunctions / damages will occur.

•Before attaching the machine-flange (Fig. 6) corresponding to the

type of engine-driven machine you have, it is recommended

spreading grease on the outer diameter of the machine hub (Fig.

6, Ref. B). Then insert the flange with its two threaded pins (Fig. 6,

Ref. C) and the two lock nuts. To attach the flange to the hub,

proceed as follows:

Fig. 6

•Screw the threaded pins in as far as possible and then unscrew

them by one turn. Tighten the lock nuts. After this operation, make

sure that the flange oscillates freely without squeezing or blocking.

•After having greased the connecting shaft (Fig. 4, Ref. D), insert it

on the machine shaft of the Reversing Harrow. When these steps

are complete, move the engine-driven machine close to the unit.

Ensure that the gearing of the connecting shaft engages correctly

A

B

C

E

D

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

14 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

•with the power takeoff shaft of the engine-driven machine and the

flange has a centered contact with the engine-driven machine.

Then secure the connection between the engine-driven machine

and the unit.

Before beginning to work, lubricate drive flange on the lubricating

nipple (Fig. 6, Ref. E)!

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

15 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

11.Adjustment of working depth/roller adjustment

•Adjust the working depth with the spindle (Fig. 5, Ref. B). It is

important, that the machine rest on its cage roller while working.

Spindle for working depth

adjustment

Fig. 7

•You can shift the cage roller of the LIPCO Reversing Harrow

sideward (Fig. 8) to enable driving right to the edge of enclosures

or walls. To shift the cage roller, loose the two clamping screws

(Fig. 8) shift the cage roller to the desired position and re-tighten

the two clamping screws again.

Cage roller adjustable

Clamping screws for roller

adjustment

Fig. 8

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

16 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

12.Working instruction (Release of overload clutch)

Attention:

Note

the working direction!

Working against the specified working direction can cause heavy

damages on the machine, for which LIPCO denies any

responsibility!

Working direction –pulling,

See direction of arrow

Fig. 9

•The blades are by their shape and cutting position designed for

this working direction.

•Working against the prescribed working direction leads to an

overload of the cutters and drive, and can thus cause damage to

the machine.

•Simultaneously with non-observing the working direction, the

harrowing result will get worse.

•The LIPCO Reversing Harrow is equipped with an overload clutch

(star ratchet), which is pre-set at the factory. Do not change the

setting of the overload clutch.

The overload torque depends on the size of the machine.

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

17 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

Troubleshooting:

If there is an overload –indicated by a ratcheting noise –turn off

the PTO immediately.

An overload can happen by:

- Too big stones in working area

- Other obstacles

- Jammed part in cutter area like stone, branch, root

Remove obstacle carefully from working area of turned-off

machine.

If there are generally too big stones or other obstacles in the

working area, then remove them manually prior to starting any work

with the LIPCO Reversing Harrow.

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

18 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

13.Maintenance

In order to maintain the machine in good working condition, carry out

following steps:

•Grease the roller bearings on both sides (Fig. 10).

Bearing on both ends of grid

roller

Fig. 10

•Check the oil level in the angular gear (Fig. 8). Oil level 2-3 cm in

horizontal gear drive position. Make the first oil change after 30 to

50 operating hours. Further oil changes after every 200 operating

hours or once a year. Use gear oil SAE 90. (Amount of oil 0.3 L)

Oil filler neck to check oil level in

gearbox.

Fig. 11

•Tighten all cutting blade screws. Replace damaged screws

immediately (refer to chapter "14. Replacement of the cutting

blades"). Note: Always use the original steel nuts with fine pitch

thread.

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

19 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

•Lubricate the drive flange once a month via the lubricating nipple

provided especially for this purpose and then turned once to allow

the grease to become distributed!

•Make sure it runs smoothly.

•Remove drive flange once a year, clean and regrease it.

•Lubricate the overload coupling (star ratchet) and universal joint

shaft of the drive every 8 operating hours and after a longer

standstill! (Fig. 12)

Protective hood opened.

Lubricating nipple (3x)

Fig. 12

•Check the level of lubricant in the chain drive via the corresponding

plug (Fig. 11). Make the check, when the machine has already

been running for a few minutes. This ensures that the grease has

warmed up and is distributed evenly. Then check the grease level

with a dipstick (grease level should be at least 5 cm, measured

from the lowest point of the chain case to ensure that the chain is

always sufficiently lubricated).

Instructions

Reversing Harrow UF 70/80/90/100 _ 70L

20 - 28

110030-11-EN BA UF 70_80_90_100 UF 70 L / 29.06.2020

Plug for grease level

check in chain box

Fig. 13

If necessary, add liquid gear grease (based on sodium bicarbonate

- type GP 00).

14.Replacement of the cutting blades

For replacing the cutting blades, secure the machine against

unintentional tilting! When working with the unit lifted, always ensure

mechanical protection by means of adequate supporting elements!

When replacing them, it is very important to maintain the blade

arrangement, especially the direction of the cutting edge. Mount the

blades in the cutting direction towards the supporting roller.

Note location of cutter blade

front side

Fig. 14

This manual suits for next models

4

Table of contents

Popular Tractor Accessories manuals by other brands

Toro

Toro 111-6032 installation instructions

Kubota

Kubota BX25 Deluxe ROPS Cab installation manual

Grouser Products

Grouser Products 1300 Groomer Owner's manual & parts book

LS tractor

LS tractor LS3150-B Operator and parts manual

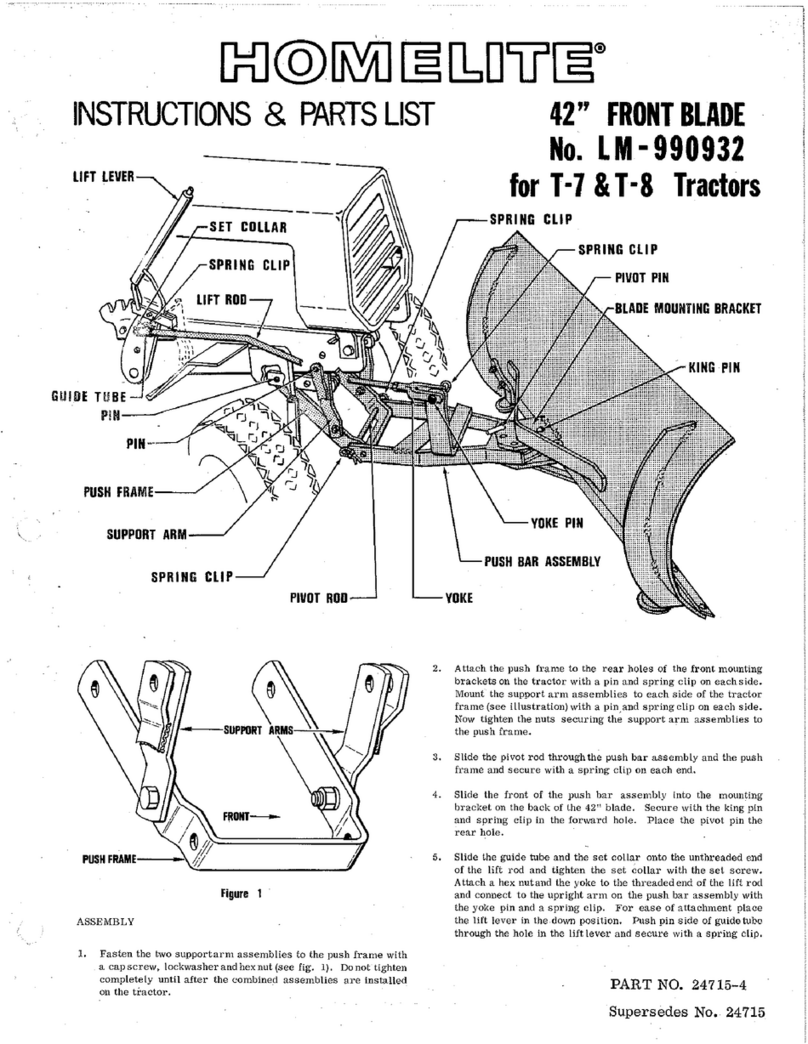

Homelite

Homelite LM-990932 Instructions-parts list

Homelite

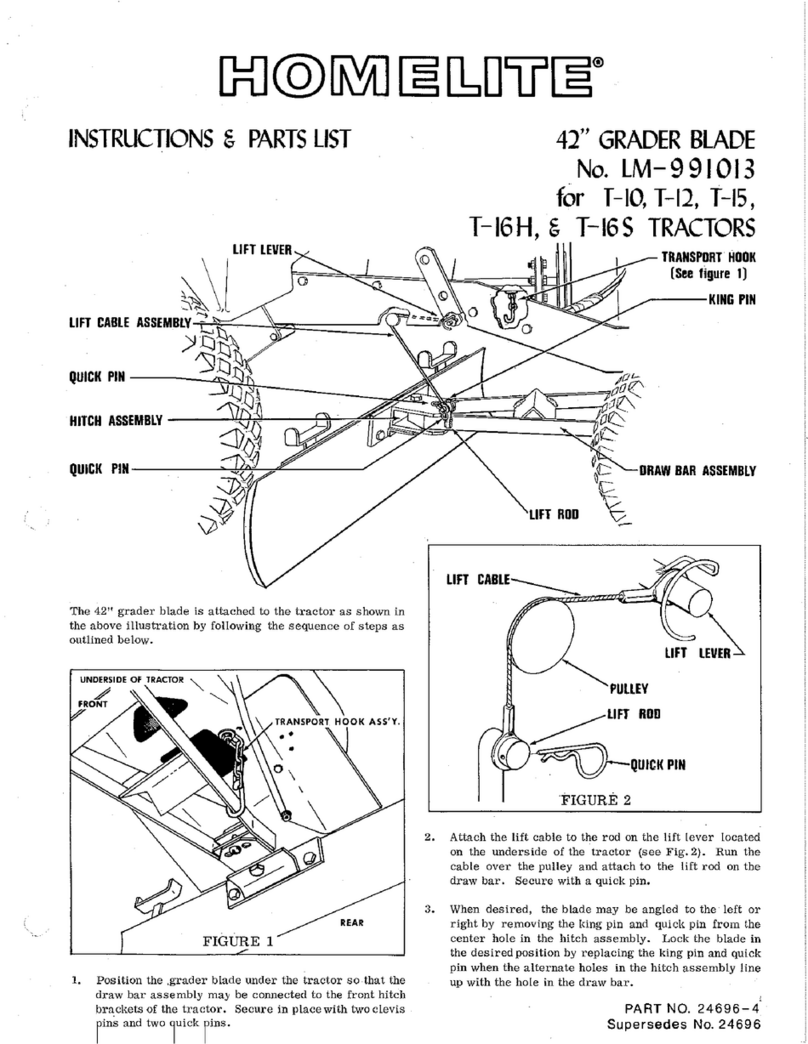

Homelite LM-991013 Instructions-parts list