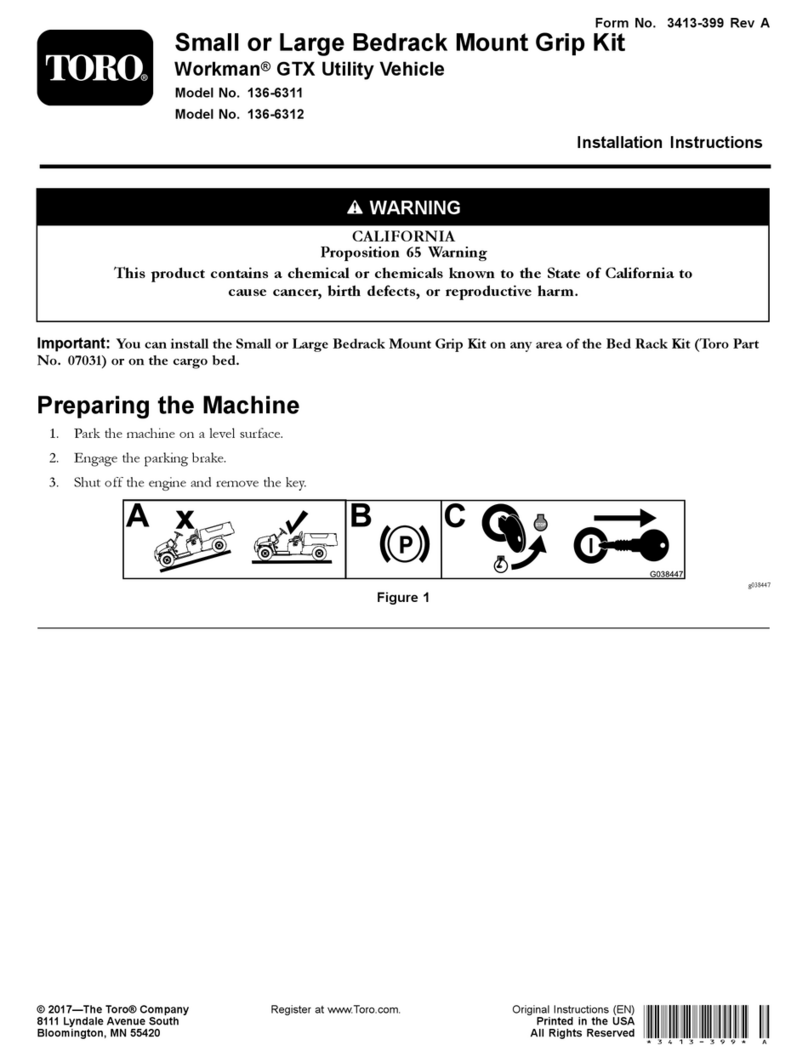

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395andANSIB71.4:2017.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeet.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingthemachine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepclearofanydischargeopening.

•Keepbystandersandchildrenoutoftheoperating

area.Neverallowchildrentooperatethemachine.

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Lowerthecuttingunit(s).

–Disengagethedrives.

–Engagetheparkingbrake(ifequipped).

–Shutofftheengineandremovethekey(if

equipped).

–Waitforallmovementtostop.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

CuttingUnitSafety

•Thecuttingunitisonlyacompletemachinewhen

installedonatractionunit.Readthetraction

unitOperator’sManualcarefullyforcomplete

instructionsonthesafeuseofthemachine.

•Stopthemachine,removethekey(ifequipped),

andwaitforallmovementtostopbeforeinspecting

theattachmentafterstrikinganobjectorifthere

isanabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Useonlyaccessories,attachments,and

replacementpartsapprovedbyToro.

BladeSafety

Awornordamagedbladecanbreak,andapieceof

thebladecouldbethrowntowardyouorbystanders,

resultinginseriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthe

bladesorweargloves,andusecautionwhen

servicingtheblades.Onlyreplaceorsharpenthe

blades;neverstraightenorweldthem.

•Onmulti-bladedmachines,takecareasrotating1

bladecancauseotherbladestorotate.

SafetyandInstructional

Decals

Safetydecalsandinstructionsare

easilyvisibletotheoperatorandare

locatednearanyareaofpotential

danger.Replaceanydecalthatis

damagedormissing.

decal137-9706

137-9706

1.Cuttinghazardofthehandorfoot—shutofftheengine,

removethekeyordisconnectthesparkplug,waitforall

movingpartstostop,andreadtheOperator’sManual

beforeperformingmaintenance.

3