LiquaGen 6 stage User manual

LIQUAGEN 5 STAGE RO INSTRUCTION MANUAL

INSTALLATION MANUAL

6 STAGE RO/DI

PRODUCT PART NUMBER: 2-OS-75

EMAIL:

Phone Support : (951) 400-3365

CONTACT:

1379 Pico St Suite 104, Corona, CA 92881, USA

ADDRESS:

TM

www.liquagen.com

Welcome to the LiquaGen family and thank you for

purchasing our RO/DI unit. You're one step closer to ultra-

pure water and the peace of mind that comes from knowing

the finest American water filtration technology is working for

you. We strive to offer you great value and lifelong service. If

you are satisfied with your purchase please take a moment

to leave a positive review on the product. At LiquaGen we

are always trying to improve and the best feedback we can

get is from our customers. If you have any ideas or

suggestions we'd love to hear from you!

18

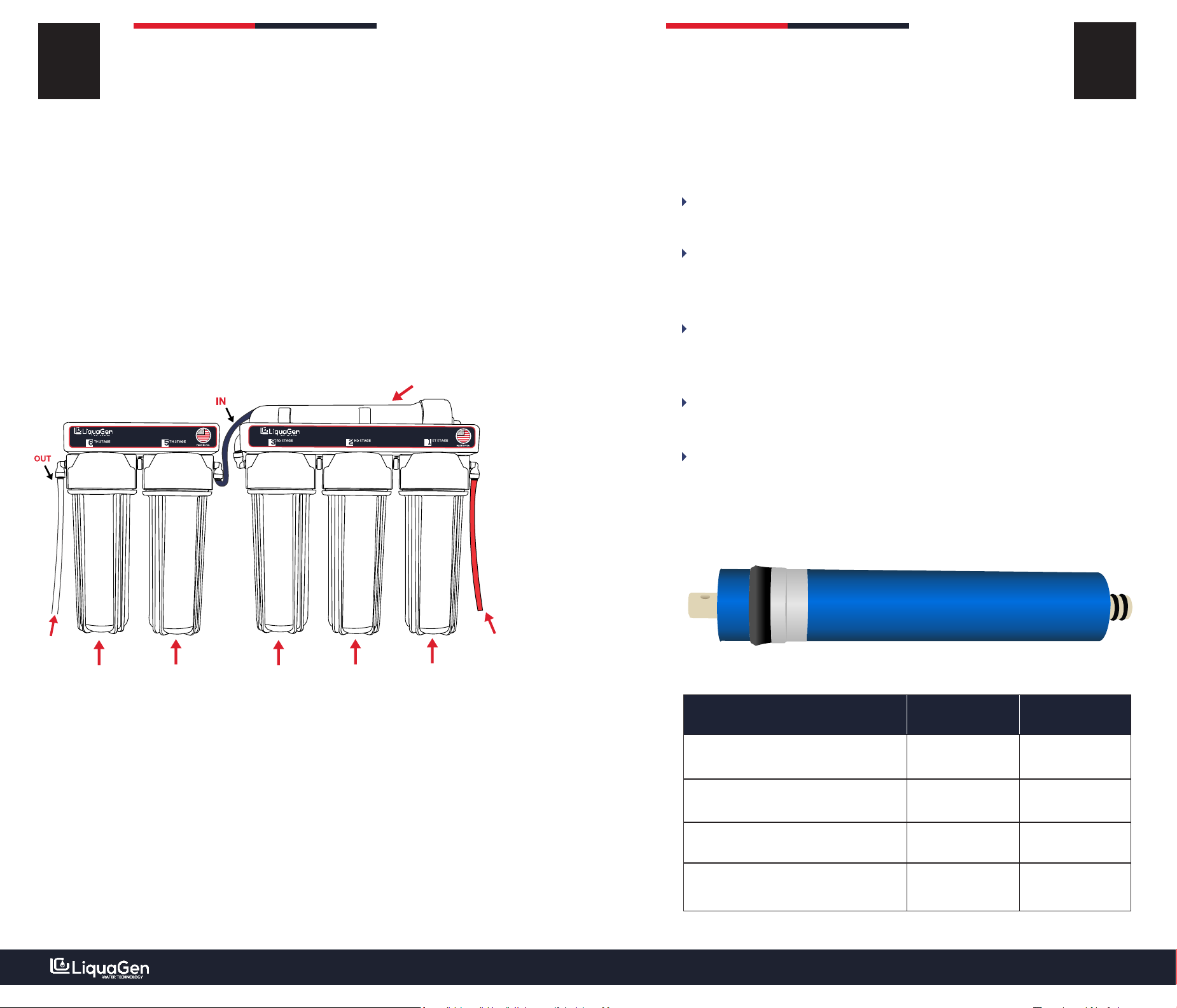

FINDING THE RIGHT REPLACEMENT

FILTERS

When replacing your filter, you have the option between two different

kits. The DIY kit will require you to empty your current DI canisters to fill

them with new resin. Your other option is the pre-filled cartridge with DI

resin, eliminating the need to transfer new media.

Reverse Osmosis Membrane Size Chart:

PRE-FILTER KIT + DI MEDIA BAG OR PRE-FILLED CARTRIDGE

Match the GPD to your membrane size. Each membrane size is written on

the bracket of the Reverse Osmosis System.

LiquaGen Website Part Number: 2-OS-75

MEMBRANE SIZE PART NUMBER

50 Gallons Per Day

100 Gallons Per Day

150 Gallons Per Day

75 Gallons Per Day ROM - 75

ROM - 150

ROM - 100

ROM - 50

Should you have any questions or concerns please feel free to

contact us on (951) 400-3365.

All replacement filters can be found on www.LiquaGen.com - Search for

the part number on the website and all the needed filters will show up.

NOTE:

www.liquagen.com

17 REPLACEMENT

FILTERS

WHEN DO I KNOW TO REPLACE MY FILTERS?

DI Media

When installing a pressure gauge you can see the pressure on the meter

drop for your pre-filters. When the pressure drops it is a good indicator that

the filters need to changed out. Another way to tell is by looking at your 1st

stage (Sediment) filter, when the color turns dark brown the pre-filters

need to be changed.

2. Increase in TDS - Reverse Osmosis Membrane & DI Media

Reverse Osmosis Membrane

1. Pre-Filter Replacement (S/UDF/C)

Pressure Gauges can be found on liquagen.com - # PG-100

When the RO membrane TDS increases above 25 is an indicator the

membrane is depleted and the membrane needs to be changed out.

Pressure Drop

When the DI Resin TDS increases above 25 is an indicator the membrane is

depleted and the membrane needs to be changed out.

Your filters need to be replaced every 6 to 12 months, depending on usage

and water quality. Only use LiquaGen OEM tested filters. Using alternative

filters will reduce performance, not filter properly and void your warranty.

On city water applications, the filters will last longer in comparison to well

water applications. Our DI cartridges are refillable, so you can purchase the

media instead of replacing the whole cartridge to save money. The reverse

osmosis membrane (stage 4) should be replaced every 2 to 4 years

depending on the water quality and usage.

Any feedback would be greatly appreciated!

Thank you for your business!

EMAIL:

Phone Support : (951) 400-3365

CONTACT:

www.liquagen.com

16

REVERSE OSMOSIS

WARRANTY

LIMITED LIFETIME MANUFACTURER

The membrane component is covered for 2 years and will be replaced at

prorated rate providing a membrane inspection does not show signs of

abuse or neglect including use with hot water, severely hard water without

proper flushing or bacterial issues from the water supply. For this reason

mechanical devices such as auto shut off valves, ball valves, pressurized

tanks, float valves, pressure gauges or check valves have a limited

replacement warranty of 2 years.

All LiquaGen Reverse Osmosis Systems are warranted to the original

purchaser to be free of defects in material and workmanship. LiquaGen will

replace or repair components of the system that LiquaGen has deemed to

be broken within the limits of the warranty without charge. All products

need to be registered for warranty to be valid if purchased on a 3rd party

market place and within the operating parameters. Customer may be

responsible for any freight involved with shipping the item back for

inspection and shipment of replacement items.

LiquaGen is not liable for anything that we deem was abuse of the system,

including but not limited to, misuse of product outside of intended use,

equipment modifications, unauthorized repairs, improper installation,

damage from freezing , hot water, fire or other acts of god outside of

LiquaGen's control. Filters are not under warranty as the service life

depends on feed water conditions and are considered a disposable item.

You may be required to ship the items in question back for proper

inspection, repair or replacement.

first and last name along with your order ID. We request the customer works

with us in good faith to resolve any issues.

A

G

U

E

Q

N

I

L

© Copyright 2019 LiquaGen Water Technology Corp.

All rights reserved.

All information contained herein is the property of LiquaGen.

LiquaGen makes no warranty of any kind with regard to this

material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. LiquaGen shall

not be liable for technical or editorial errors or omissions contained

herein or for incidental or consequential damages in connection

with the furnishing, performance, or use of this material. The

information is provided “as is” without warranty of any kind and is

subject to change without notice. This document contains

proprietary information which is protected by copyright. No part of

this document may be photocopied, reproduced, or translated into

another language without the prior written consent of LiquaGen.

www.liquagen.com

15 FREQUENTLY ASKED

QUESTIONS

Yes, this is called "TDS creep" and is normal on all RO systems. Allow the

RO system to run for 10 minutes before testing the TDS.

My DI resin seems to be depleting quickly, what's wrong?

Usable lifespan of the DI resin will vary widely. Feeding the DI resin from

the RO membrane will increase approximately five times the usable life of

the DI. Outside of that, carbon dioxide in your water supply or a poorly

performing RO membrane are the biggest causes of early DI exhaustion.

Is it normal for the DI stage to not fill completely with water?

Is it normal for the TDS to be higher when the system is first turned on?

My pressure gauge reads less than 50 PSI, do I need a booster pump?

We suggest flushing the membrane for a few minutes before and after

use. There is an auto flush kit available for a more automated process.

The membrane will not perform "optimally" below recommended

pressure, but the reduced performance may not be substantial enough

to warrant a booster pump. As it approaches 35 PSI mark, the

performance drop will become significant and you will likely want to

purchase a booster pump.

Yes, the air gets trapped in the top of the canister and has no way to

escape. This does not interfere with system performance, but if desired,

slightly open the canister while the unit is running to allow the air to

escape. Re-tighten the canister when the water reaches the top.

Is it okay to leave water in the canisters between uses?

Yes, it is advised to keep the system wet between uses and store in a cool,

dark location away from any environmental extremes. Exposure to

sunlight or freezing temperatures can cause damage to the filters or

canisters and should be avoided.

How often should I use the flush kit?

Q :

Q :

Q :

A :

A :

A :

Q :

A :

Q :

A :

Q :

A :

TABLE OF

CONTENT

1. Operating Parameters

What’s In The Box?2.

Installation Overview3.

Flow Chart 4.

Quick Connect5.

System Assembly6.

How To Replace Damage Elbow7.

Flush The Membrane8.

Understanding Performance9.

Installing ASOV & Check Valve10.

FAQ11.

Warranty Information12.

Replacement Filters13.

01

02

03

04

05

06 - 09

10

11

12

13-14

15

16

17-18

www.liquagen.com

14

GARDEN

HOSE

CARBON GAC

RO MEMBRANE

FLOW

SEDIMENT

WASTEWATER

DEIONIZATION

CARTRIDGE

AUTO SHUT OFF

IN OUT

CHECK VALVE

OPERATING

PARAMETERS

01

The system is tested and rated on regular water. The unit will be severely

damaged if extreme cold or hot water runs through it. RO systems thrive

on PSI. If your output is slow please test your water pressure. The best

way to measure PSI is by adding a pressure gauge or by contacting your

city water department as pressure is not testable by the naked eye. We

advise at least 50 to 85 PSI for optimal performance. Low water

pressure puts stress on the membrane leading to more wastewater and

less production. Adding a booster pump or low-pressure membrane are

the best solutions to solve low PSI issues.

50 PSI - 100 PSI (2.95 KG/CM²) 39 F - 113 F

At 45 PSI the unit will work, but the

flow will be significantly lower.

⁰ ⁰

Between 39 F & 50 F the flow rate will be

very slow. This is the outside

temperature not the home temperature.

OPERATING PRESSURE OPERATING TEMPERATURE

If your pressure exceeds 95 PSI, a pressure regulator must be installed

to reduce the PSI to prevent damages to your system.

It is recommended that the TDS (Total Dissolved Solids) entering the

system does not exceed 250 PPM.

NOTE:

WHAT’S IN THE 02

PRE-POST FILTERS

www.liquagen.com

BOX?

PRE-ASSEMBLED RO/DI SYSTEM

Sediment,

UDF/GAC,

Carbon

GARDEN HOSE

ADAPTER

MEMBRANE HOUSING

WRENCH

EXTRA

FITTINGS

RO MEMBRANE

(PRE-INSTALLED)

4FT RO TUBING

(PRE-INSTALLED)

www.liquagen.com

MANUAL FLUSH KIT

(PRE-INSTALLED)

INSTALLING THE

ASO &

CHECK VALVE

13

1/4” quick connect fitting

Fits standard 1/4” tubing used on most

RO systems.

1/4” quick connect fitting

Fits standard 1/4” tubing used on most

RO systems.

STEPS TO INSTALL ASO & CHECK VALVE

1.

2.

3.

Auto Shut Off & work together to shut off the water production Check Valve

of the unit if you are using a storage tank or a float valve. When the tank fills up it

creates back pressure, automatically shutting the system down. If there is no

storage tank or a float valve, no backpressure will be created thus the system

will continue to run. Both components are only to be used if your set up

includes a float valve or storage tank to hold the water, if not then the product

water production will heavily slow down.

Make sure the screws are facing you when you're installing the ASO Valve,

you're going to snip the red line that goes from the last carbon block

directly into the RO membrane, by cutting it in half.

Next, you're going to snip the purified water line that comes out of the RO

system, make sure to do it after you've installed the check valve. This goes

into the end and the other tube goes into the out.

The last step is to install the float valve itself. Take your purified water line

and locate the end of the tubing. Unscrew the cap on the float valve, place it

onto the purified water line, insert the tubing into the float valve and screw

it down tight.

INSTALLATION

OVERVIEW

03

www.liquagen.comwww.liquagen.com

1/4” Red

Tubing

STAGE 1

Sediment filter

STAGE 2

UDF/GAC

STAGE 3

Carbon

STAGE 4

RO Membrane

1/4” White

Tubing

STAGE 5

DI Cartridge

STAGE 6

DI Cartridge

UNDERSTANDING

PERFORMANCE

12

MEMBRANE CAPACITY PER DAY PER HOUR

50 GPD

75 GPD

100 GPD

150 GPD

40 GPD

60 GPD

80 GPD

120 GPD

1.67 GPH

2.5 GPH

3.33 GPH

5 GPH

In our 25 years of research and customer feedback, we've found that the

majority of the membranes operate at 80% capacity regardless of the

brand.

GPD refers to gallons per day. Reverse Osmosis systems are rated in the

number of gallons they produce in 24 hours.

Only under perfect conditions does the membrane perform at full GPD

capacity. The performance depends on water quality, pressure, and

temperature.

For every gallon produced, the system will waste roughly 3 gallons of

water.

To maintain a 99% rejection rate, it is imperative that you disregard the

amount of wastewater. This is a standard industry norm regardless of the

brand. Wastewater can be reduced by adding an ERP pump or a water saver

kit while still maintaining a 98 to 99% rejection rate.

www.liquagen.comwww.liquagen.com

REVERSE OSMOSIS

FLOW CHART 04

GARDEN

HOSE

CARBON GAC

RO MEMBRANE

FLOW

SEDIMENT

WASTEWATER

DEIONIZATION

CARTRIDGE

DEIONIZATION

CARTRIDGE

- - - - - - -

- - - - - - -

+ + + + + + +

+ + + + + + +

FLUSHING THE

MEMBRANE

11

Flushing the membrane is crucial before using the system. It removes the

carbon from the lower filter which are left in the membrane and housing.

This increases the reverse osmosis membrane life by 2 years.

The system is designed with a Manual Flush Valve. This helps ease the

process of flushing the system before usage.

After installing the system you need to flush the membrane for 20-30

minutes.

DIRECTIONS

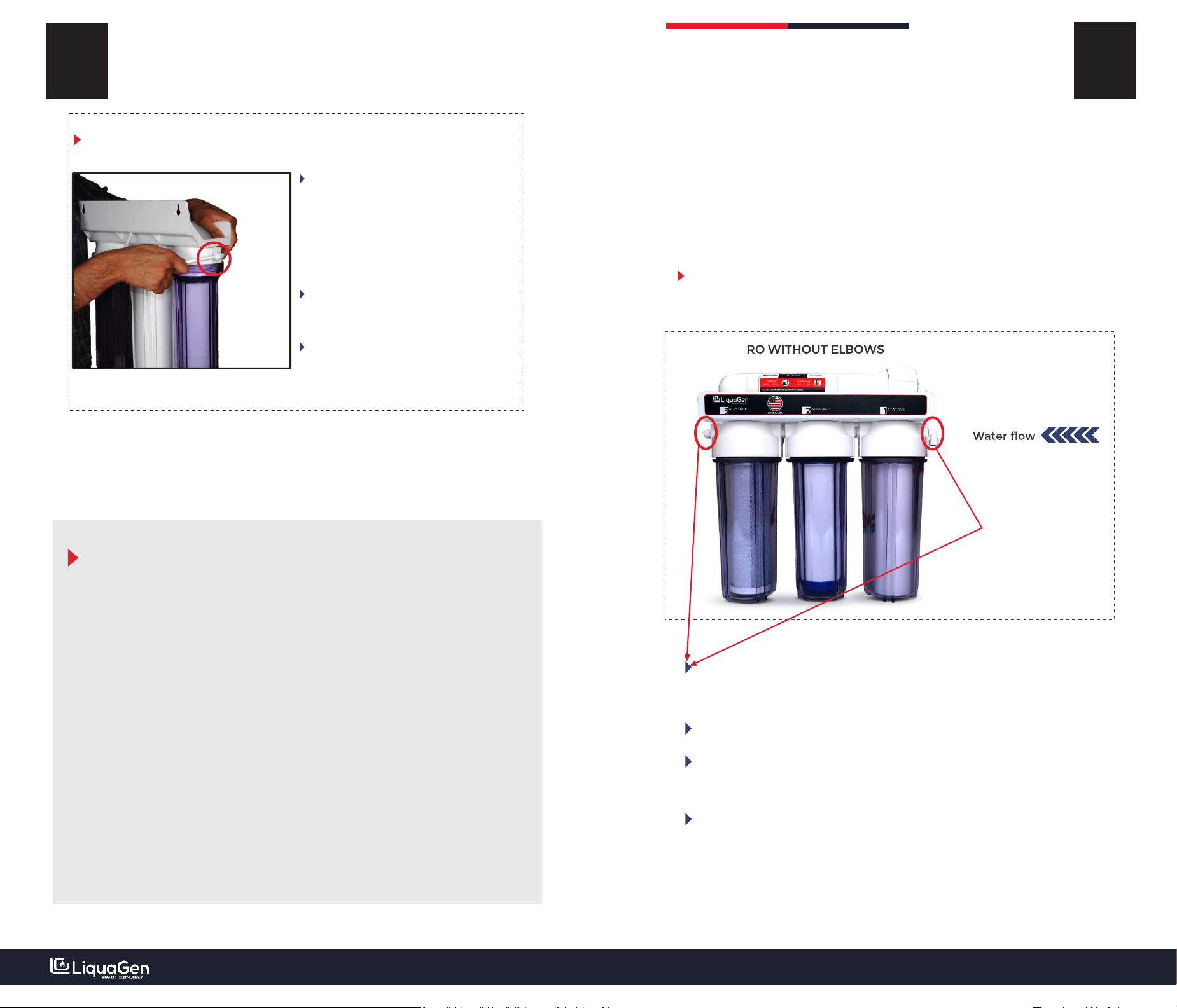

IMAGE #1

IMAGE #2

Let the water flow for 20-30 minutes.

In order to flush the membrane the blue valve needs to be in the “open

position”. You should see an increase of water coming out of the black

(waste) tubing.

turn the blue valve off. It should look like the

system is ready to be used!

The picture above (Image #1) shows the manual flush valve in the open

position.

picture below. Once this is completed your

After flushing the membrane please

1.

2.

3.

4.

www.liquagen.comwww.liquagen.com

QUICK

CONNECT

05

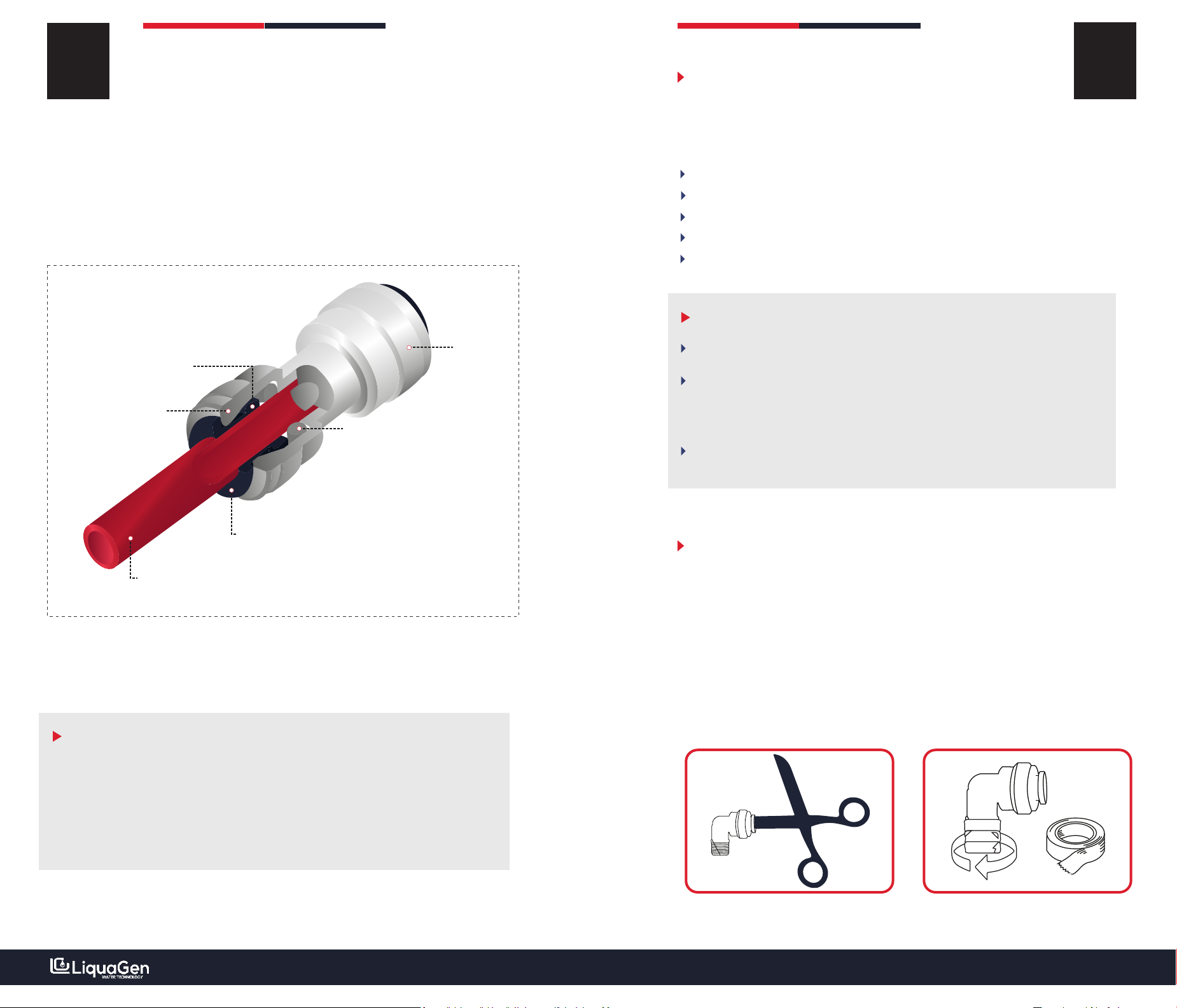

BODY

TUBES:

(Pex, PVC, PE-RT, PE, Copper)

CAP

COLLECTS

O-RING : NBR/EPDM

GRIPPER RING (STS)

Although the system is air tested before leaving our facility, the tubing

can become loose during transit. To prevent any leaks, it is crucial to

check each tubing connection is securely locked in place. First, pull and

then push each tube in to ensure it is securely inside.

IMPORTANT NOTE:

10

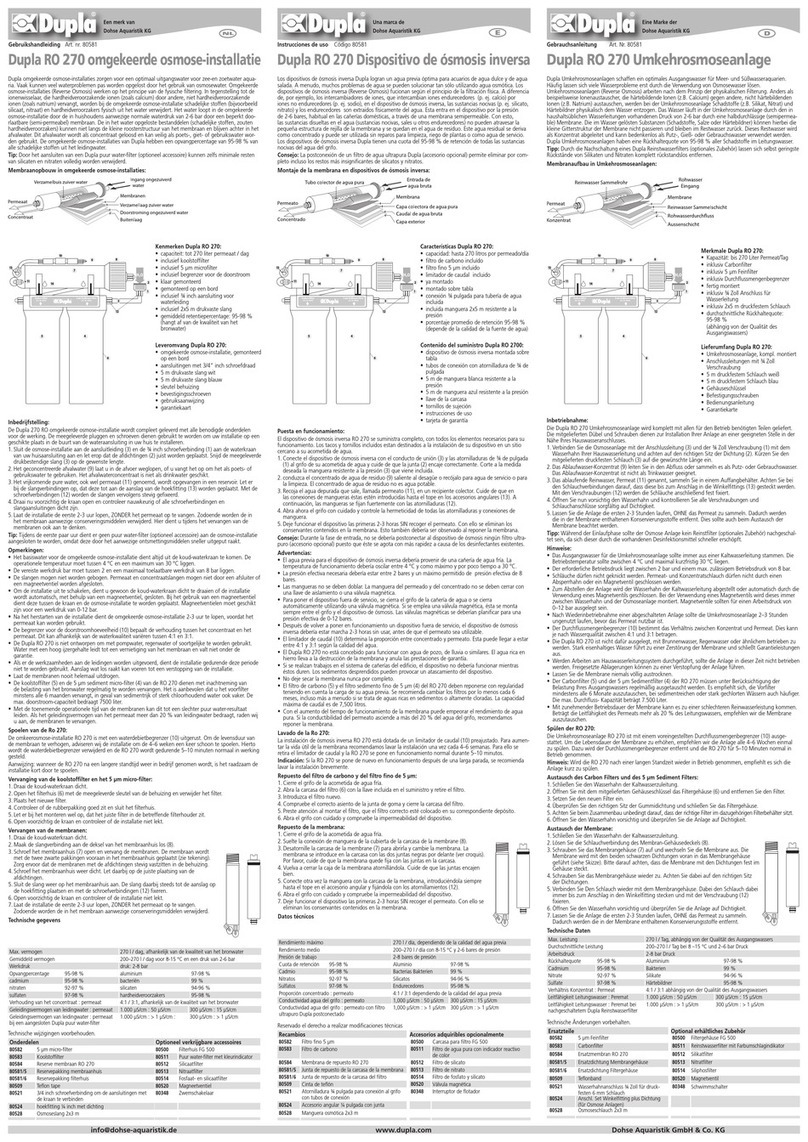

INSTRUCTION TO REPLACE DAMAGE

CONNECTORS

Take a pair of scissors and open them. Push one side into the broken

elbow and turn it anti-cockwise. The broken elbow should come out. Put

Teflon tape on the extra elbow which can be found in the box. With your

hand twist them on where the broken elbow was. Do not tighten the

elbows too much as they might break.

FIG 1# FIG 2#

PLEASE NOTE:

After installing the system and before running water, kindly make sure

all the tubing is properly pushed in and secure by first pulling and then

pushing all the tubing in.

All systems include extra connectors (elbows).

Tighten all canisters (housing) with the wrench before turing on the

water supply.

Take pair of scissors and open them.

Push one side into the broken elbow and turn it anti-clock wise.

Put Teflon tape on the extra elbow which can be found in the box.

With your twist them on where the broken elbow was.

Do not lighten the elbow too much as they might break.

HOW TO REPLACE

DAMAGE ELBOW

www.liquagen.comwww.liquagen.com

STEP 6: INSERT WHITE TUBE

09

Insert the white tubing in the

elbow connector.

Near the 3rd stage there should be

white tubing loose at the back of

the unit. This is NOT the white

tubing used for the outgoing water

connected to the ball valve.

Make sure you hear a slight click

sound to confirm the fitting is

properly secure.

CONNECTING THE SYSTEM

FOOD GRADED TUBING CONNECTIONS

Each tube color is designed for a specific purpose.

RED TUBING - Inserted in stage 1 (Sediment) and connects to the garden

hose adapter for the incoming cold water supply.

BLACK TUBING - Installed in stage 4 (RO Membrane Housing). It’s rejected

water and is essentially the water which is too impure to pass through your

system. This should go directly to your drain and we strongly advise not to

use this for any other applications.

WHITE TUBING - This is installed on your 5th stage (Inline DI Filter), which

is the line to provide ultra pure 0TDS water.

SYSTEM

ASSEMBLY 06

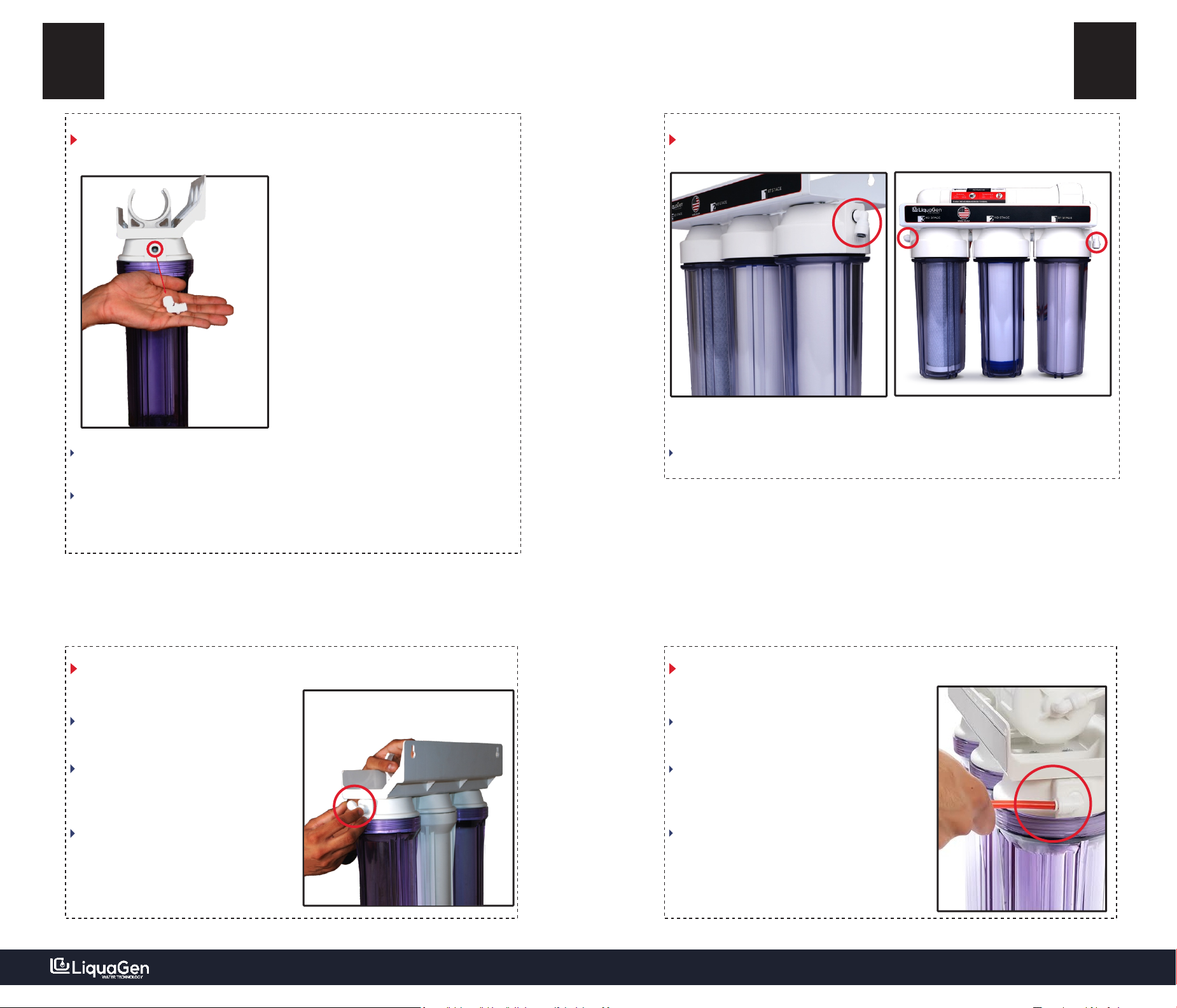

INSTALLING SIDE ELBOWS & INSERTING TUBES

STEP 1: QUICK OVERVIEW

⁰

The unit has two connectors (90 1/4“) which need to be installed on the

side of unit.

After installing the elbow connectors the tubing needs to be inserted.

We do not pre-installed them as they get damaged during the shipping

process.

System assembly is the same for RO/DI & portable/replacement

drinking water system.

www.liquagen.comwww.liquagen.com

STEP 4: DOUBLE CHECK

STEP 5: INSERT RED TUBE

Insert the red tubing in the elbow which

is near the first stage.

The red tube connects to your faucet

adapter or garden hose adapter and is

your incoming water supply.

Make sure you hear a sight click sound

that confirms the tubing is properly

secure.

Make sure all fittings are secure. #IMAGE2 is how the unit should look like.

#IMAGE 1 #IMAGE 2

08

STEP 2: ELBOW CONNECTOR

07

* We provide extra Teflon tape & connectors for emergencies.

STEP 3: INSERTING THE FITTINGS

Screw the elbow on to both sides of

the unit.

If the fittings break they are easy to

replace and at the end of the next

page we explain how to fix broken

elbows.

Make sure you do not tighten the

elbow too much or the fittings will

break.

In the box, there should be a small packet with all the fittings and Teflon

tape.

2 elbow will have Teflon tape pre-applied. Use those to screw into the end

of each side.

Other manuals for 6 stage

1

This manual suits for next models

2

Other LiquaGen Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Patching Panda

Patching Panda MOON PHASE user manual

Waterman

Waterman SF 122 Operating and assembly instructions

Whirlpool

Whirlpool TITANIUM P-06CRS Use & care guide

brondell

brondell H625 Pearl owner's manual

Dupla

Dupla RO 270 quick start guide

Pentair

Pentair EVERPURE Twin Installation and operation guide