3 Description of the device

6

3 Description of the device

Intended use

The water treatment unit with ion exchanger permits the production of demineralised (deionised) water.

This requires tap water of drinking water quality.

PLEASE NOTE

The water treatment unit does not provide low-germ water.

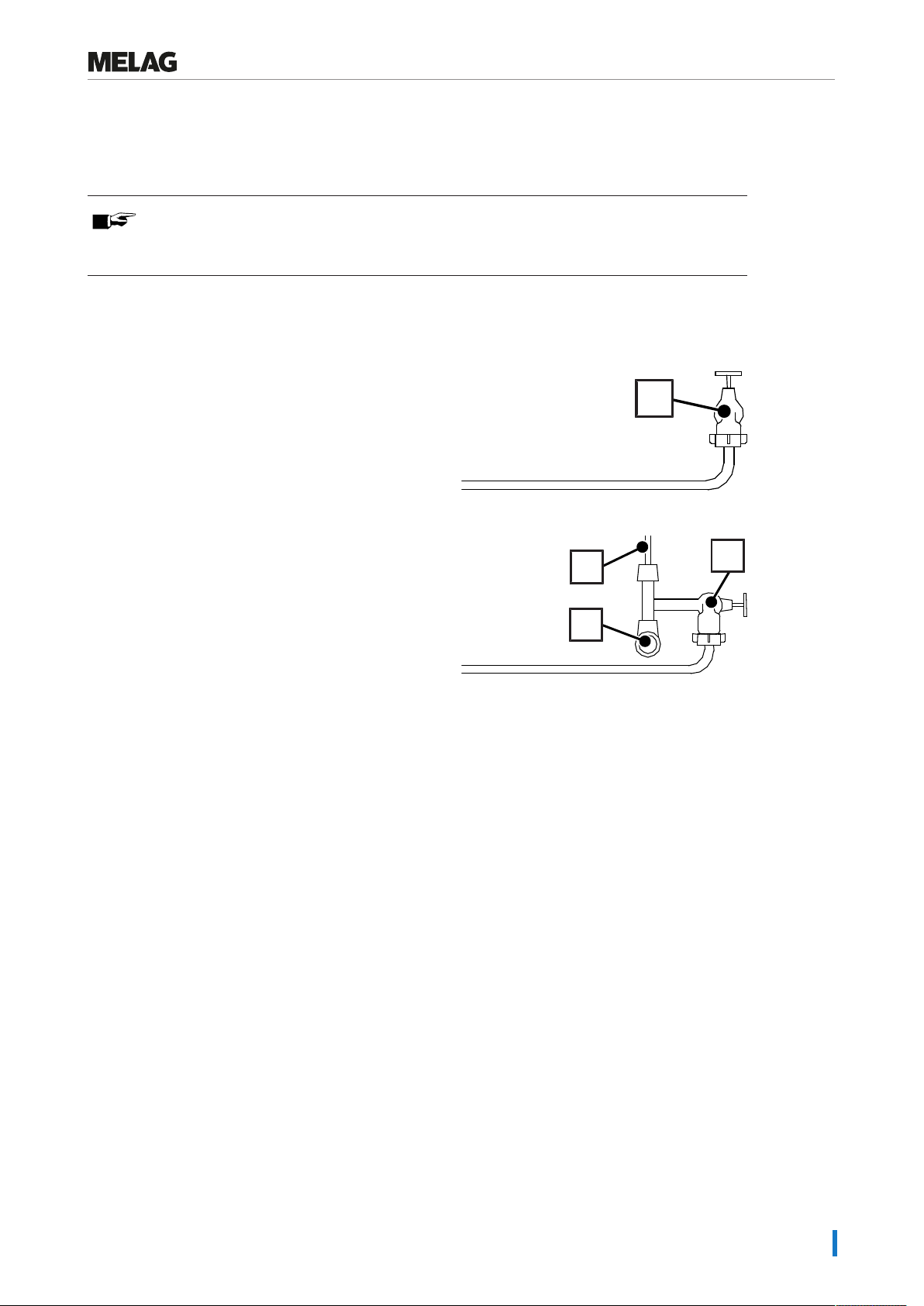

The water treatment unit is suitable for the supply of one or more small steam sterilizers with feed water.

Furthermore demineralised water can be extracted, e.g. with the delivered removal valve. The water treat-

ment unit is intended for use in the medical field, e.g. in clinics, medical and dental practices and other

medical care facilities outside the patient environment.

The water treatment unit MELAdem 47 is not a medical device within the meaning of European Regulation

2017/745 on medical devices.

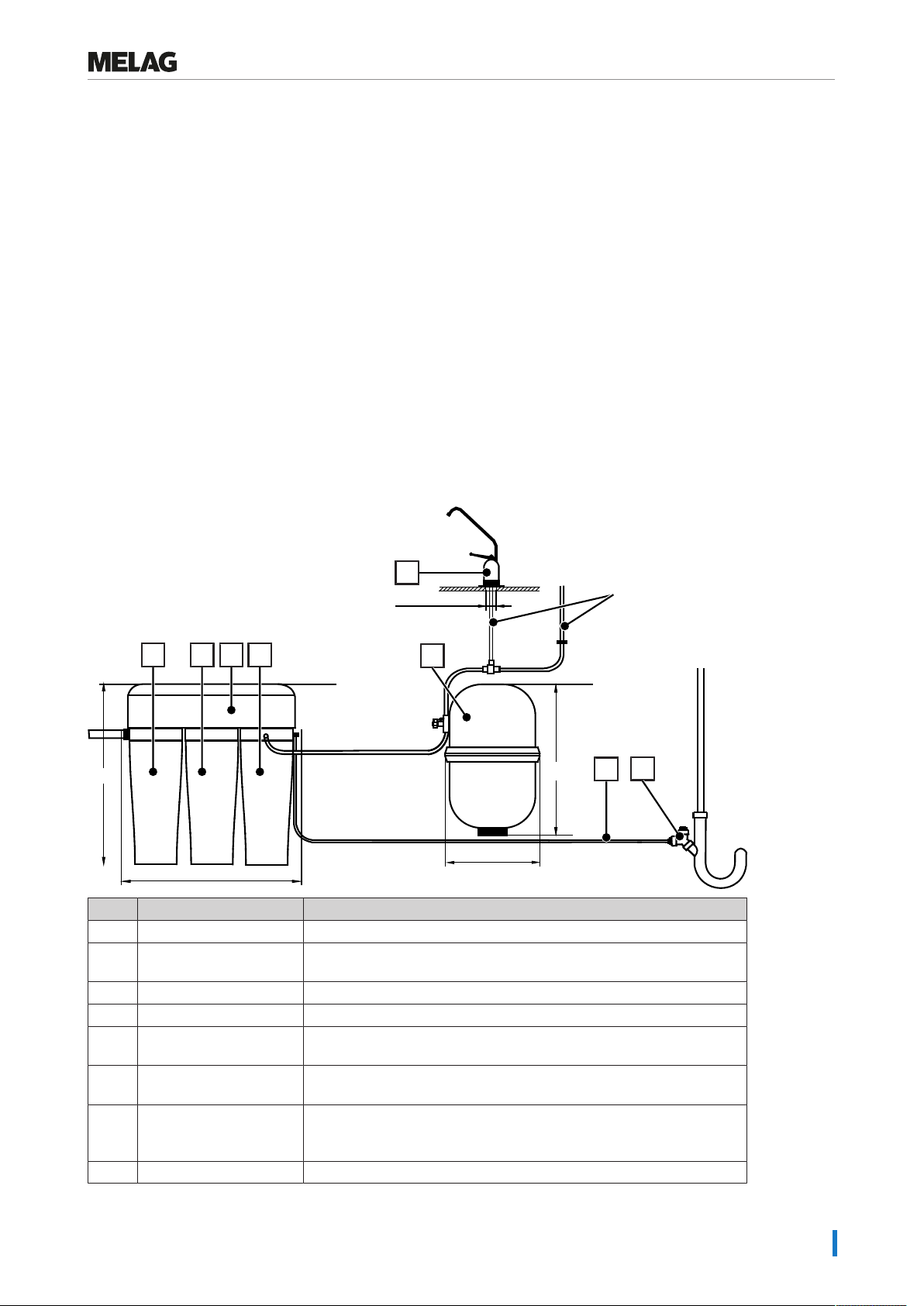

Mode of functioning

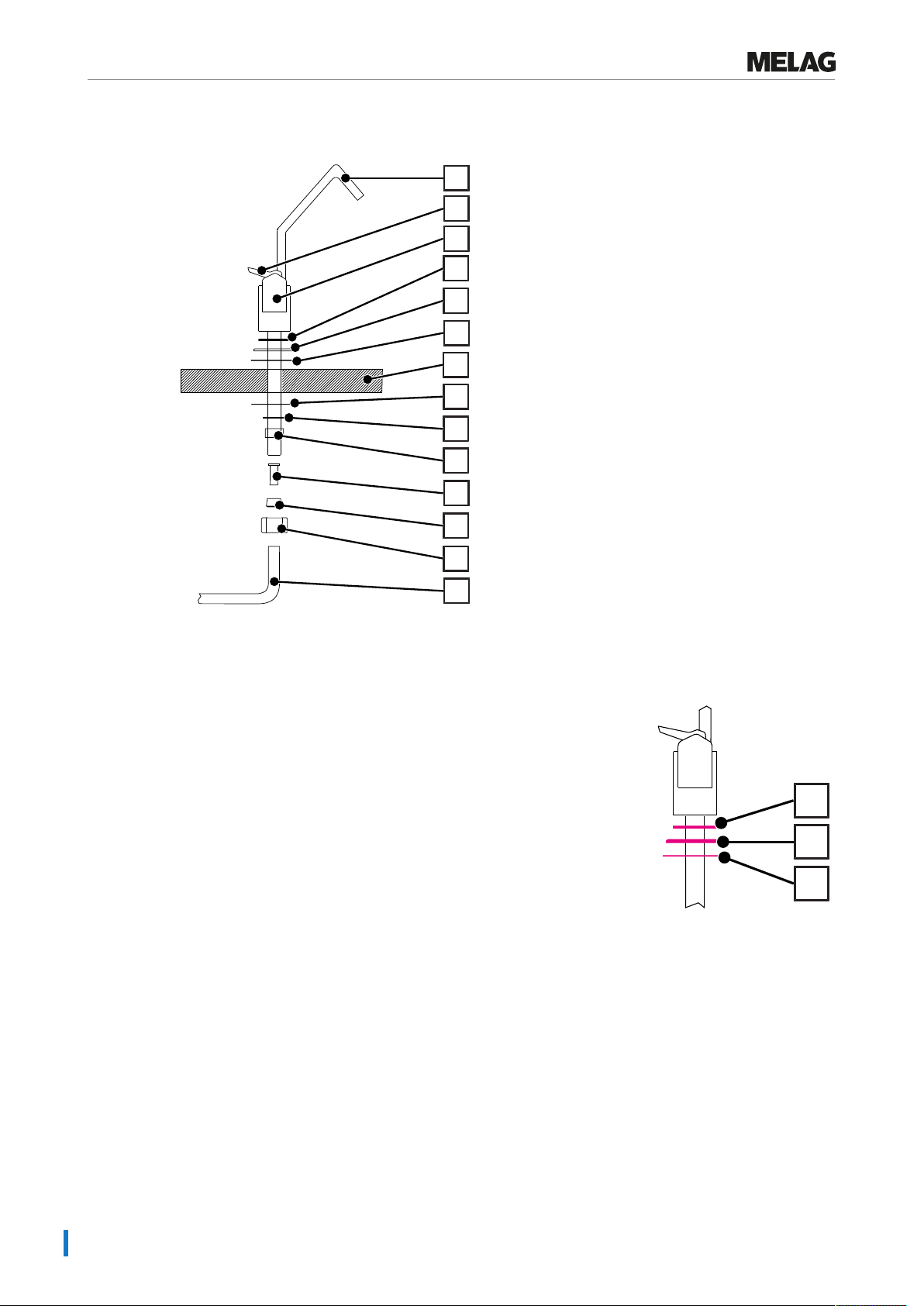

The water treatment unit works on the principle of reverse osmosis (reverse osmosis unit). This process

presses water through a semi-permeable RO membrane (osmosis module), reducing the salt content of

the cold water by some 95%. The inflowing water is separated into two flows:

▪ water with a low salt content (permeate)

▪ water with increased levels of salt (concentrate) which is disposed of via the outflow

An ion exchanger filled with mixed-bed resin is installed after the reverse osmosis unit to achieve the level

of water quality necessary for operation of the steam sterilizer, even with poor quality cold water. The ion

exchanger reduces the residual salt content of the permeate to a minimum. The permeate thus produced

is saved in the pressure tank, which is connected to the steam sterilizer via a hose. The cold water inflow

is switched off automatically when the pressure tank filled. All operating runs of the device are automatical-

ly controlled via its water pressure.

The permeate can be drawn through a separate removal valve for other uses.

The device can be can be connected directly with the following steam sterilizers for automatic water feed:

▪ Combination steam sterilizers (Careclave 618 using the MELAG pressure increase pump)

▪ Premium-Plus Class Evolution (Vacuklav 40 B+ Evolution, 41 B+ Evolution, 43 B+ Evolution, 44 B+

Evolution)

▪ Premium-Plus-Class (Vacuklav 40 B+, 41 B+, 43 B+, 44 B+)

▪ Premium-Class (Vacuklav 40-B, 41-B, 43-B, 44-B)

▪ Pro-Class (Vacuklav 23 B+, 24 B+, 24 BL+, 30 B+, 31 B+)

▪ S-Class (Euroklav 23 VS+, 29 VS+, 23 S+)

▪ Classic models (Vacuklav 23-B, 24-B, 24-B/L, 30-B, 31-B, Euroklav 23V-S, 29V-S, 23-S, 29-S)