Sfere SFR-AHF User manual

Multifunctional Active Filter

SFR-AHF

User Manual

12.2020

Please follow the warnings in this manual and use the symbols shown below

Danger

Warning of the personal injury or property damage.

Caution

Special attention should be payed.

If you have to install, star-up or maintain the device, you should consider the below

reasons:

Please read this manual carefully before using the device

If this device and the symbol are not followed properly with this manual

may cause personal injury or damage to equipment.

SFERE is subject to notice use the device and specifications of the components in this

manual.

SFERE will revise the latest version of the specification of the device and the User’s

manual on its official website.

Improper operation or installation may cause personal injury and

equipment damage. In particular, operating with voltage may cause

electric shock, it can cause death or serious injury. Installation or

maintenance may also cause fire. Please read this manual before

installation. Please obey the instruction of installation and maintenance

during the entire use life of the device. The National electric standard

should be noted.

Security considerations

Disclaimer

Content

1. Inspection................................................................................................................... 1

1.1 Acceptance........................................................................................................ 1

1.2 Transportation and delivery.............................................................................. 1

1.3 Storage...............................................................................................................3

2. Product description.................................................................................................... 4

3. Installation.................................................................................................................. 5

3.1 Before installation............................................................................................. 5

3.2 Location of installation and ventilation requirements......................................6

3.3 Installation.........................................................................................................8

3.4 Cable connection...............................................................................................9

3.5 Device terminal............................................................................................... 11

3.6 Cable connection.............................................................................................13

4. Operating..................................................................................................................16

4.1 Operational principle.......................................................................................16

4.2 Resonance detection.......................................................................................16

4.3 Main parameters confirmation before operation...........................................16

4.4 Start................................................................................................................. 17

4.5 System info...................................................................................................... 18

4.6 Data logging.....................................................................................................19

4.7 Wave curve...................................................................................................... 20

4.8 Harmonic......................................................................................................... 20

4.9 Settings............................................................................................................ 21

5. RJ45 communication................................................................................................ 29

6. Common maintenance............................................................................................. 36

6.1 Daily checking..................................................................................................36

6.2 Monthly checking............................................................................................ 36

6.3 Other checking................................................................................................ 36

7. Common problems...................................................................................................37

1

1. Inspection

1.1 Acceptance

Please check the following points after received the device:

a. Is the specification of the device consist to description of your order.

b. Is the device in good condition without any damages during transportation.

c. Check the appearance of the device before opening it.

d. Check if the user’s manual is attached.

e. Check the internal condition and external condition of the device before cable

connection.

1.2 Transportation and delivery

If the device needs to be moved in short distance, the support at the bottom of the

device can be operated by hydraulic trailer or forklift.(Fig. 1)

Fig. 1:Use the hydraulic trailer

If there is any problem when you receive the device, please contact the

courier and/or SFERE's after-sales service.

When transporting, loading, unloading and handling device, proper

protection measures must be taken and appropriate manual and

mechanical tools shall be used to avoid damage to the device. If the

device does not need to be installed immediately, be sure to store it on a

solid and level ground and follow the storage conditions listed in the

technical parameters section. In this case, the original protective

packaging of the device is recommended for storage.

2

When unloading and moving the device, use a forklift with a fork long enough to

support the entire bottom. The fork should be able to support at least 3 / 4 of the

bottom. Forks must be flat and have a firm bottom support. Lift the device by placing

the fork under the bottom of the packaging. (Fig.2).

Fig.2

When use knives or scissors to unfold the packaging of the device, make sure not to

damage the device.

Some models may have a high center of gravity. Therefore, when

transporting by forklift, it is recommended to firmly fix the device to

avoid sudden movement. The height of the device from the ground shall

not exceed 20cm.

The uneven distribution of components in the device might cause the

center of gravity of the equipment not coincide with the center point of

the outer box. Necessary precautions must be taken to prevent the

device from toppling in case of sudden operation.

3

1.3 Storage

The device should be storage in the following conditions:

Keep on the flat floor.

Keep in dry and well ventilated indoor storage.

Away from high temperature,maximum ambient temperature: +50℃

Away from salty and corrosive environment

Do not store the device in the durst accumulate places or the place with chemical or

some other pollution risks.

If the device is not installed immediately after receiving, the following

recommendations must be followed in order to keep the equipment in good

condition:

Keep the device in a dry environment with a temperature between - 20℃and 45℃

Away from direct sunlight

Keep the device in its original packaging.

If the AHF is not powered for a long time, a particular process must be adopted to

restore the internal medium of the busbar. The operation instruction given by Table 1

accordance with their storage period.

Table 1:Start-up process is determined by the length of the storage.

Storage

Process

≤1 Year

No special treatment is required

>1 Year

One hour power on at least before start-up

4

2. Product description

SFERE Active harmonic filters can be used to:

✓Reduce 2-51 harmonic current.

✓Power factor correction. It is suitable for inductive (-) and conductive (+) systems.

✓Adjust the three-phase imbalance of electrical system.

AHF Products can be used in three-phase three-wire system or three-phase four-wire

system.

AHF products can be purchased by module or whole cabinet.

Rack type AHF capacity:

50A/75A/100A/150A

Note: 7 inch HMI is defaulted, 10 inch HMI optional.

5

3. Installation

3.1 Before installation

Installation and maintenance of the device must be operated by trained

and qualified personnel.

Please turn off the main switch before carrying out any maintenance

operation of active harmonic filter.

Improper installation or setup of device will cause serious damage to the

device itself and other equipment in the system.

For your safety, any operation must follow the safety standards

specified in the Nation/Region, use the necessary personal protective

device (rubber gloves, mask and qualified fire-proof clothing) to prevent

the injury caused by electric shock or electric arc caused by discharging

the current carrying conductor, and pay attention to various warnings

which shown in this manual.

The device is not suitable for life support systems, medical safety

equipment or similar applications. The device is also not suitable for

military or defense purposes.

Assembly shall be carried out only on concrete floor in restricted access

areas or other non flammable meters.

Before power on, make sure that the device is properly grounded. In the

case of lightning or other transients, any poor grounding may cause

electric shock to the user and damage the device itself.

6

3.2 Location of installation and ventilation requirements

3.2.1 The installation environment of the device must meet the

following conditions:

The external temperature of the cabinet is between - 20 ℃to 45 ℃, the maximum

humidity is 95%, no condensation.

Do not install the device in a high temperature environment,avoid direct sunlight.

3.2.2 Ventilation requirements

3.2.2.1 AHF Module

The AHF module applies forced ventilation cooling system, air intake on the front

panel, air outlet at the rear side. It must be ensured the air could be flow freely after

installation. At maximum power, the air flow speed of AHF module is 375 m³/h.

AHF module contains with the power control system,it could control the fan speed

and maximum power by the internal temperature. In order to maintain the best

performance of the AHF module under any conditions.

For the performance of the device,should guaranty the free air circulation of the AHF

module front panel,no obstruction at the rear, at least 300mm space.

Please note that the outward hot air may be sucked back by the fan of the device,

resulting in hot air back flow, thus reducing the performance of the device. The

situation is depending on the installation conditions of the cabinet and the external

environment of the device.

Before operating the current transformer, ensure that the secondary

circuit is short circuited. Do not open the secondary circuit of current

transformer under operation.

Please install the device away from water, dust, flammable liquids,

flammable gases and corrosive substances.

Make sure there is no reactive power compensation equipment sharing

the power supply with sfere AHF is installed.

If there is any,they must be turned harmonious, equipped with reactor

to prevent interference.

7

When selecting the installation location, the power consumption of the device

should be considered to ensure proper air re-circulation and inlet air temperature.

Fig.3

3.2.2.2 AHF Cabinet

AHF cabinet use forced ventilation and cooling system, with air inlet on the front

plate and air outlet at the rear of the module.

Do not block the ventilation grille on the top of the cabinet, leave enough space on

the top to dissipate heat. The specific distance depends on the surrounding

environment characteristics of the installation location.

Fig.4

8

3.3 Installation

3.3.1 AHF Module

50A-75A racked-type module height is 189mm, 100A-150A racked-type module

height is 240mm.

Fig.5

Fig.6

9

Multiple rack mounted AHF modules can be installed in one cabinet.

Install the modules in the cabinet as follows:

1. Extend the anti tilt support of rack type whole cabinet.

2. Open or remove the door of the cabinet.

3. Place the AHF module on the track or shelf of the cabinet. Make sure they support

the weight of the module; use cross brackets if necessary.

4. Fix the module to the fixed point. use 4 * M6 fixing screws.

3.3.2 AHF Cabinet

AHF Cabinet is a complete cabinet body with 4 supports above the ground.

3.4 Cable connection

Use cables that meet the rated current of the filter and meet the requirements of the

installed national standards.

It is recommended that BVR or RV copper core cables with rated dielectric strength

of AC 0.6kv/1kv and allowable working temperature up to 70 ℃are selected as

primary cables. The sectional area of the cable is as follows:

Unless the rack type cabinet is fixed on the ground, its anti tilting feet

must be extended and fixed on the ground to ensure maximum safety

during installation.

Do not use the front handle to move the module.

Please install the module with the help of others.

The mounting surface must be firm and level to support the weight of

the device.

Do not use arc welding to weld the cabinet to the ground, as this may

cause damage to internal components.

10

Table 2

Capacity

L1 L2 L3

Main circuit incoming line

N line

PE line

50A

25mm²

The Line-N cable is

1.5 times of the

copper core of the

three-phase

Line-1,Line-2,Line-3

main circuit cable.

(Note: there is no

Line-N for 3L AHF;

Line-N is available for

4L AHF)

25mm²

75A

50mm²

25mm²

100A

50mm²

25mm²

150A

50mm²

35mm²

200A

70mm²

50mm²

300A

95mm²

70mm²

400A

120mm² or 2 * 70mm²

95mm²

450A

150mm² or 2 * 70mm²

120mm²

550A

185mm² or 2 * 95mm²

150mm²

600A

240mm² or 2 * 120mm²

185mm²

Make sure the equipment is properly grounded to prevent electric shock

hazard.

In order to measure the current accurately, it is recommended to use

0.2S class current transformer.

The right connection of the current transformer is very important for

the normal operation of Sfere AHF. If L1, L2 and L3 mixed positions, the

filter will not work properly.

Sfere AHF has built-in fuse over-current protection element.

Please install the external protection equipment according to the device

type, maximum short circuit current, fusing current and current

regulations of installation place.

11

The capacity of the active harmonic filter must match the harmonic current to be

filtered and conform to the electrical characteristics of the device.

Fig.7

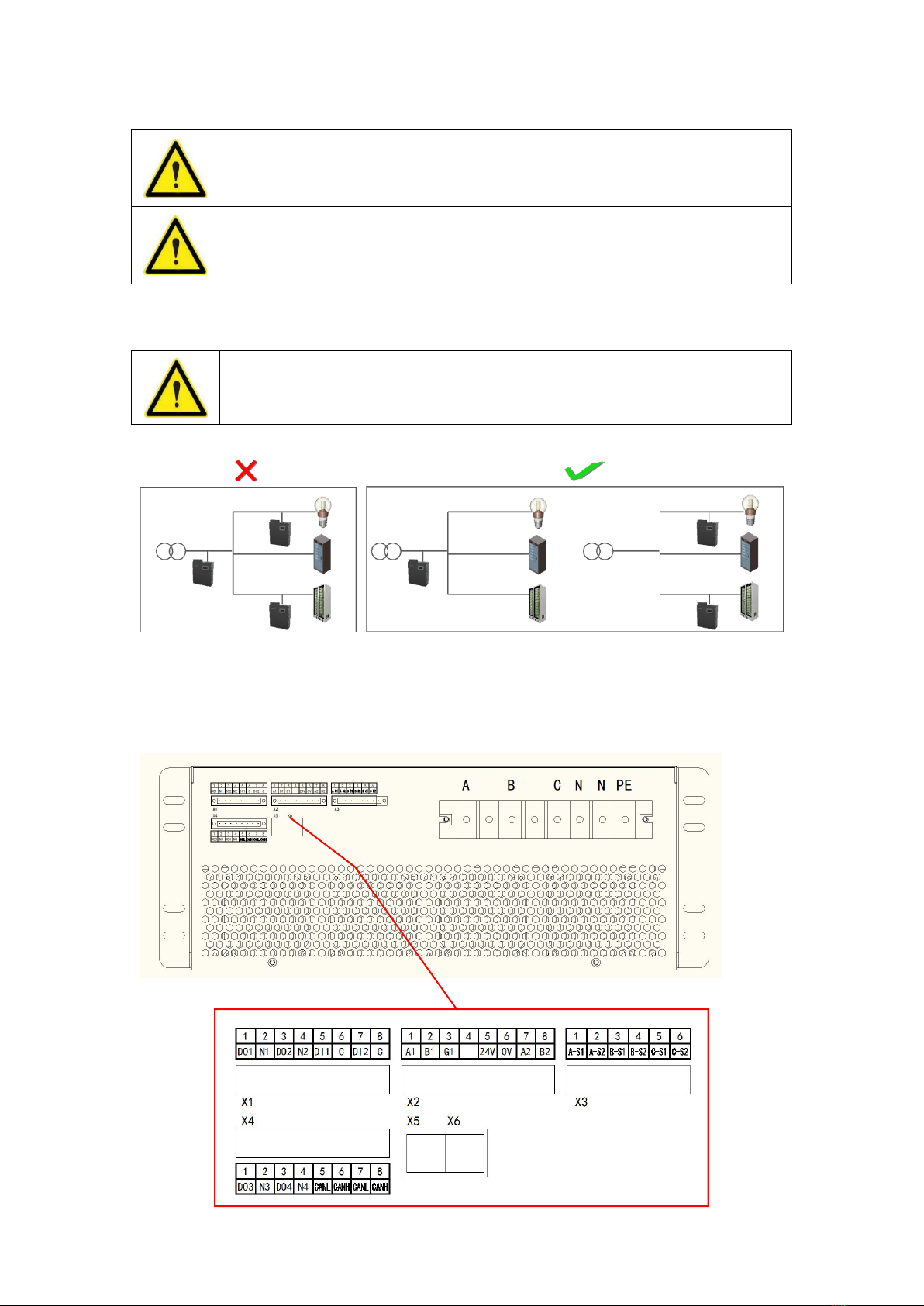

3.5 Device terminal

3.5.1 Rack type AHF

Fig.8

Table 3

If leakage protection is required by local regulations, only type B RCD

can be used. The AHF uses direct current inside. In case of failure, the

direct current may lead to the failure of type a RCD device.

Make sure the equipment installed in your distribution system (TN, VT,

it) meets current standards.

Do not install multiple filters in series connection within one harmonic

filtering system. It may cause over filtering for power instability (Fig.7).

12

Port type

Number

Function/description

X1 Control

signal port

DO1

Output of device fault relay

N1

DO2

Output of device relay on operation

N2

DI1

Device stop input port

(connected to external closed stop button)

C

DI2

External start switch input port

(connected to external open start / stop button)

C

X2

Communication

signal port

A1

External communications

B1

G1

Empty

24V

Power output positive + 24 V (power supply to HMI

touch screen)

0V

Power output negative pole 0V (power supply to HMI

touch screen)

A2

RS485 serial port with HMI touch screen+

B2

RS485 serial port with HMI touch screen-

X3

CT signal port

A-S1

S1 input port of A-phase current detection (connected

with S1 of A-phase transformer)

A-S2

S2 input port of A-phase current detection (connected

with S2 of A-phase transformer)

B-S1

S1 input port of B-phase current detection (connected

with S1 of B-phase transformer)

B-S2

S2 input port of B-phase current detection (connected

with S2 of B-phase transformer)

C-S1

S1 input port of C-phase current detection(connected

with S1 of C-phase transformer)

C-S2

S2 input port of C-phase current detection (connected

with S2 of C-phase transformer)

X4 port

DO3

Alarm Relay Output 1

N3

DO4

Alarm Relay Output 2

N4

Empty

Empty

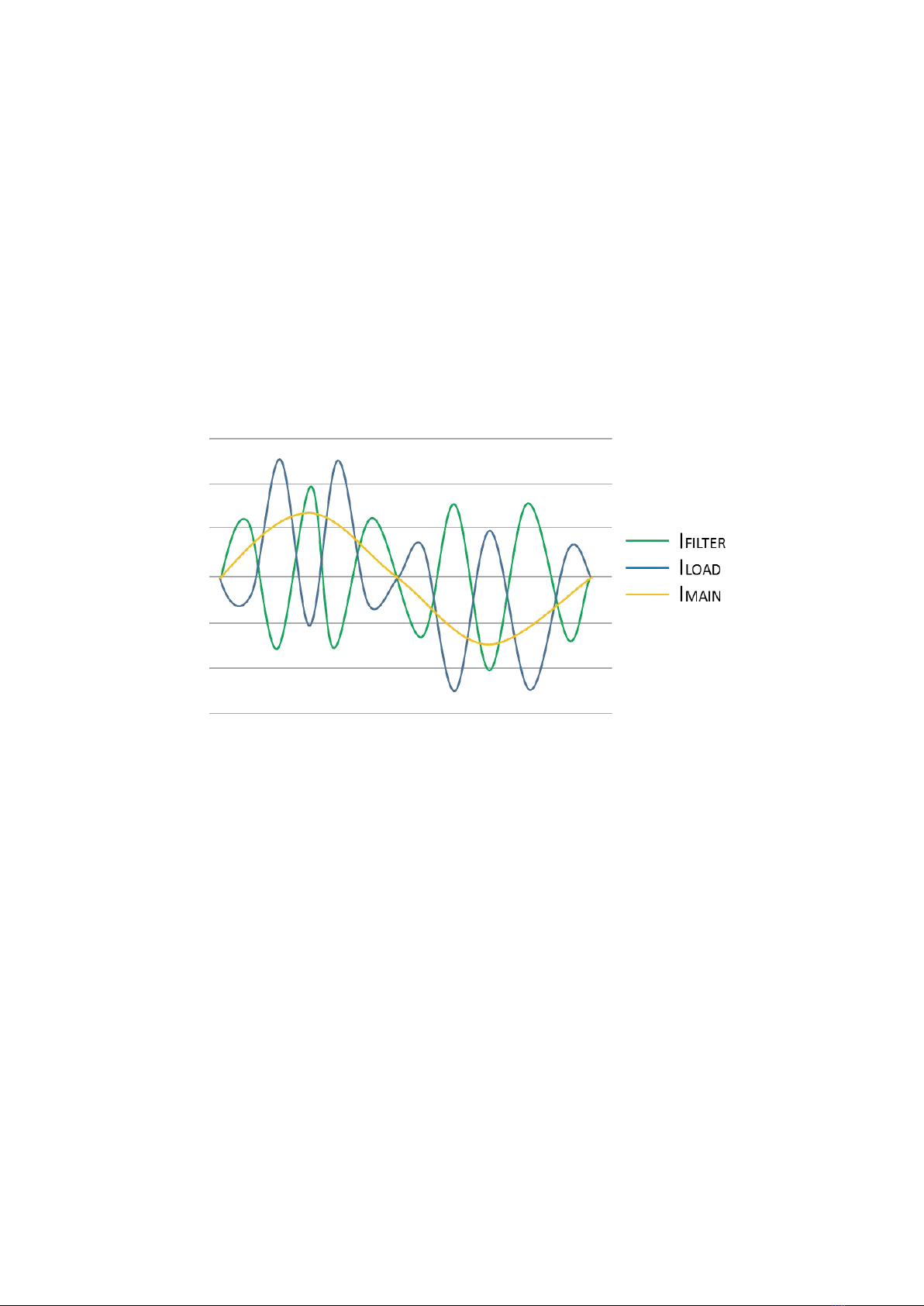

X5/X6

Online with other modules via network cable

13

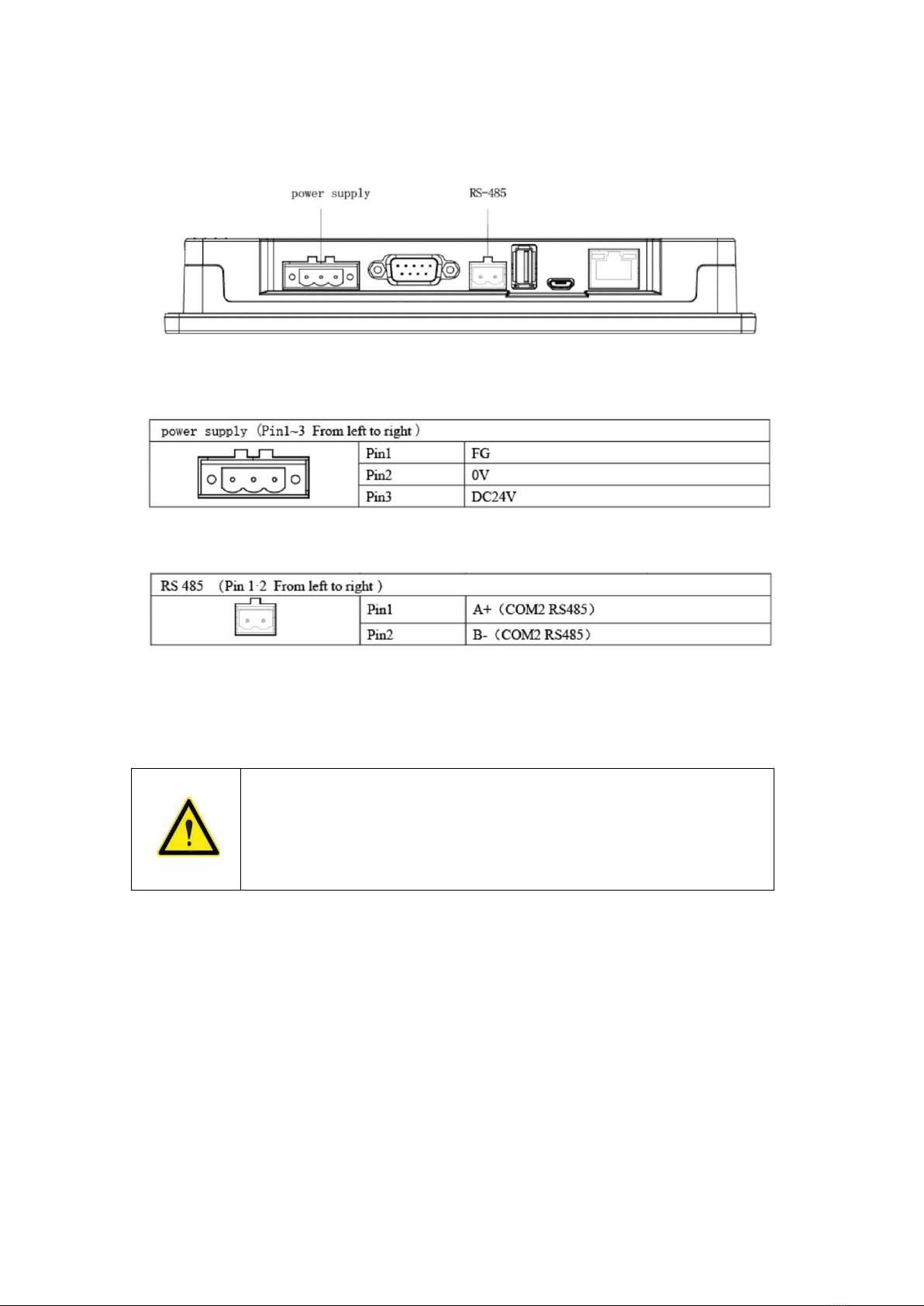

3.5.2 HMI

Table 4

Table 5

3.6 Cable connection

The main circuit wiring mode is shown in the figure. The connection shall ensure that

the phase sequence of the power grid is consistent with that of the device.

Otherwise, the device may not start normally. The installation direction of the

transformer is shown in the figure, and the P2 surface must be close to the load. S1

and S2 of each transformer must correspond to the port of corresponding label, and

open circuit at secondary side is strictly prohibited (open circuit may cause

transformer burnout).

Power supply equipment (e.g. transformer) should be off before

connecting all cables;

Make sure the power cable connection phase sequence is correct;

Adopt correct power distribution mode to ensure the safety of

module and user equipment;

14

3.6.1 Three phase four wire network side current measurement

Fig. 9

The CT configuration should be "grid side" when the CT is located in front of PCC

point.

3.6.2 Three phase four wire load side current measurement

Fig.10

When the CT is located behind PCC point, the CT configuration should be "load side"

15

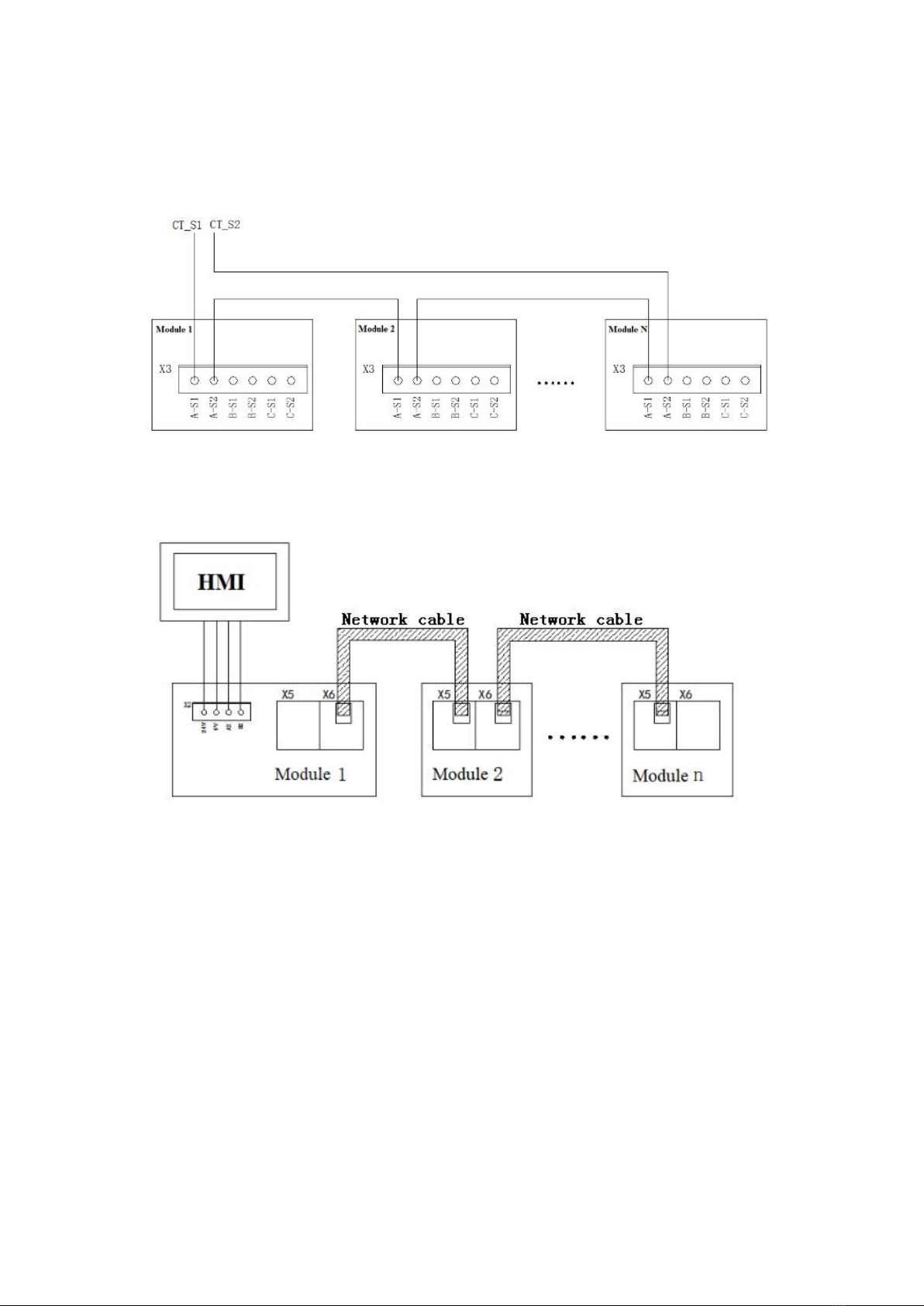

3.6.3 Connection diagram of CT lines for parallel operation of multiple

modules (Take Phase-A current as an example)

Fig.11

3.6.4 Connection diagram of multi-module parallel communication line

Fig.12

16

4. Operating

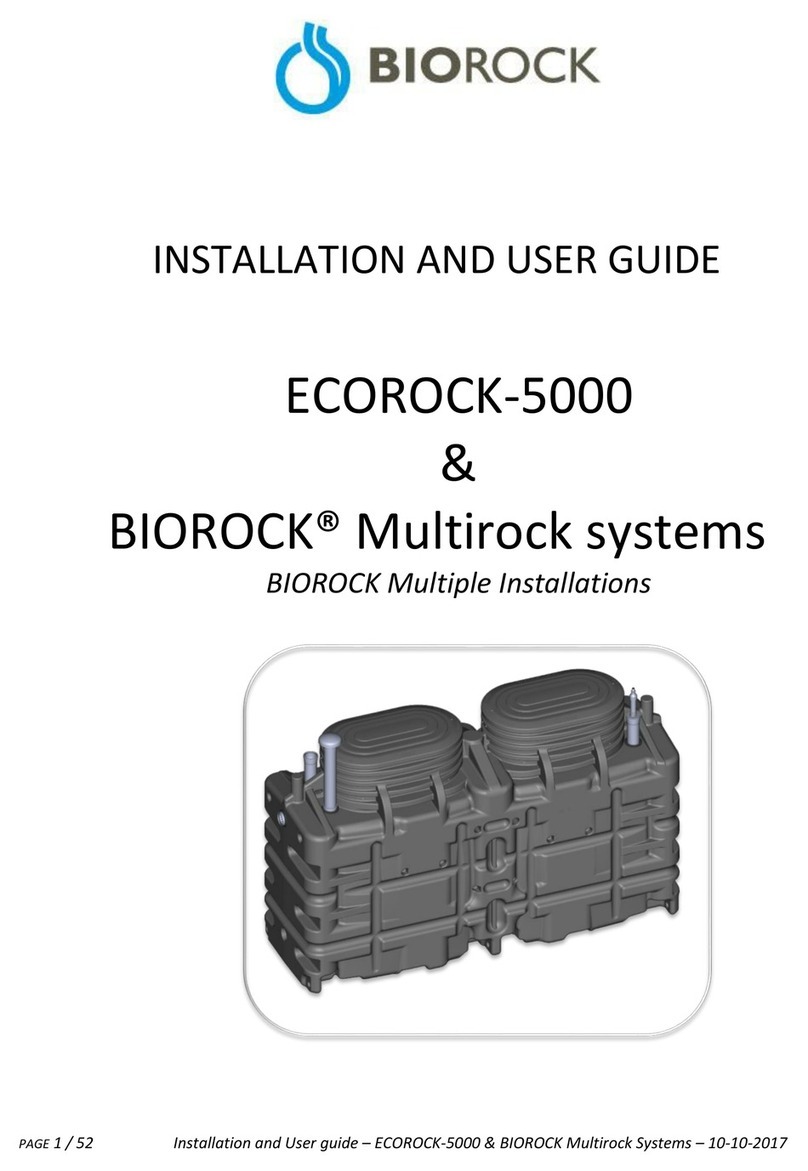

4.1 Operational principle

Active harmonic filters work as follows:

I filter=I main-I load

In other words, they can detect the difference from the desired sine wave of the

current (I main) and harmonic (I load) deformation signal, then injecting the

differential current (I load) before the two waveform .

Fig.13 shows the current waveform injected by the active filter.

These data are the expected waveform (I main), the existing distorted waveform (I

load) and the filter current (I filter).

Fig.13:I load,I main,I filter

4.2 Resonance detection

AHF will monitor and determine the occurrence of resonance in the system in real

time, adjust the compensation current automatically, and reduce the amplitude and

energy of resonance.

4.3 Main parameters confirmation before operation

After the installation of the device, confirm that the electrical connection of the

system is correct and power on.

1)Confirm the reliable connection between the device shell and the protective

ground to prevent the housing from being charged.

2) Check and confirm the distribution mode of the device, all power cables and

signal cables are connected correctly without short circuit.

3) Check and confirm that all input switches are disconnected and put warning

signs at these switches to prevent others from operating the switches。

17

4.4 Start

4.4.1 Light up the screen

The screen lights up after the power supply is powered on, enters the boot self-check,

carries on the inspection communication, the automatic network assignment address

and the initialization and so on work.

Fig. 14

4.4.2 Main interface

After the progress bar is loaded to 100%, it enters the main interface of the system

(Fig .15). The home page provides:

1 system information

2 event recording

3 waveform curve

4 harmonic

5 setting

6 help

Total 6 functions, in which the setting needs to log in and enter

Fig.15

At this point, the boot is complete, you can view information or parameter settings

and other operations

Table of contents

Popular Water Filtration System manuals by other brands

Biorock

Biorock ECOROCK-5000 Installation and user guide

West Marine

West Marine 13915137 instructions

Parker Hiross

Parker Hiross ESG2 user manual

DEKA Controls

DEKA Controls TOH Series installation manual

Envirco

Envirco MAC 10 LEAC Installation operation & maintenance

BWT

BWT Woda-Pure Clear S Installation and operating manual

Deltec

Deltec MCE 600 Operating instructions and spare parts list

Grizzly

Grizzly G5955 owner's manual

BWT

BWT Protector mini HWS C/R Installation and operating instructions

Oxyline

Oxyline X7N11 manual

BLUE COLLECTION

BLUE COLLECTION KIVI quick start guide

Watts

Watts PWFGAC1 Installation, operation and maintanance manual