Flexible SILICONE

SILICONESILICONE

SILICONE RGB LED Tape – 60 LEDs Per Meter (20/03/12)

Although the product is tested after manufacturing, it is highly advisable to remove the LED Tape if on a reel and test the

Flexible LED Tape before cutting or fixing in place to make sure it has not been physically damaged in transit, and that it is the

correct colour.

onnect the Black (+) wire to the positive (+) wire of a 12 Volt D Switchmode Power Supply* (a 9v PP3 will also work for

testing), then separately connect the 3 remaining coloured wires to the negative (-) wire of the power supply (or battery) to

confirm that each of the primary colours – Red, Green, and Blue are all working. Ensure that all of the LEDs are fully lit, but

AVOID VIEWING THE LEDS DIRECTLY

Next identify the location where the Tape is to be fixed. Do not fix the Tape where it will be permanently wet. With suitable

insulation covering any exposed wired connections the tape will not be damaged by moderate amounts of atmospheric

moisture or the occasional water spray. If the tape is powered-up while submerged in water there is a risk of short-circuit and

possibly even fire in the long term. Equally, do not affix the tape directly to a metal surface where there is a risk of creating a

short-circuit on the back of the tape if accidentally perforated.

Once the location for the Tape has been decided upon simply remove the 3M Adhesive backing strip and carefully lay the

Tape in place working from one end to the other ensuring there are no raised sections. Using a lint-free cloth gently press

between the LEDs on the tape to remove any air bubbles and activate the adhesive, however, make sure you do not press

directly on the LEDs themselves as this could damage them.

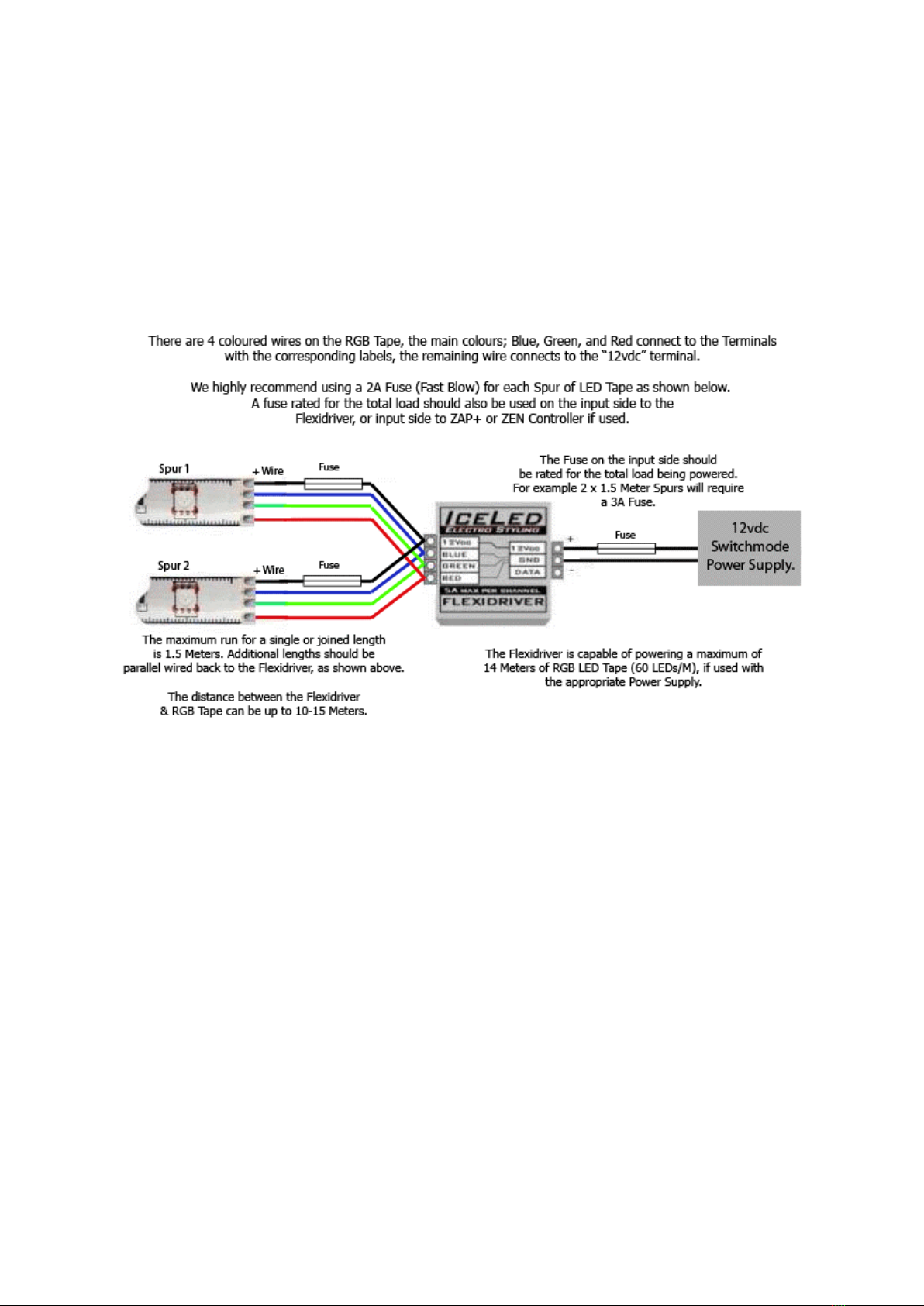

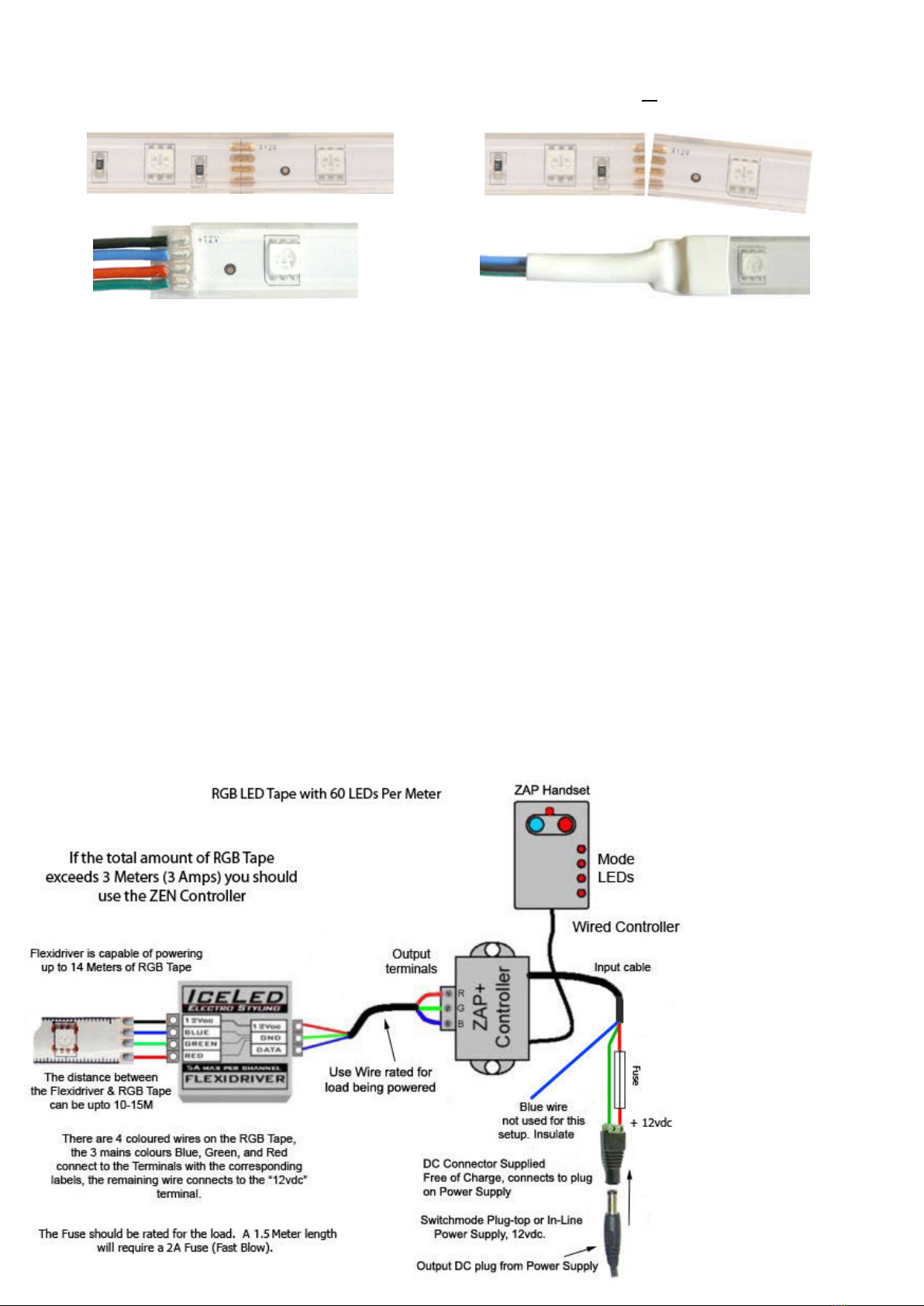

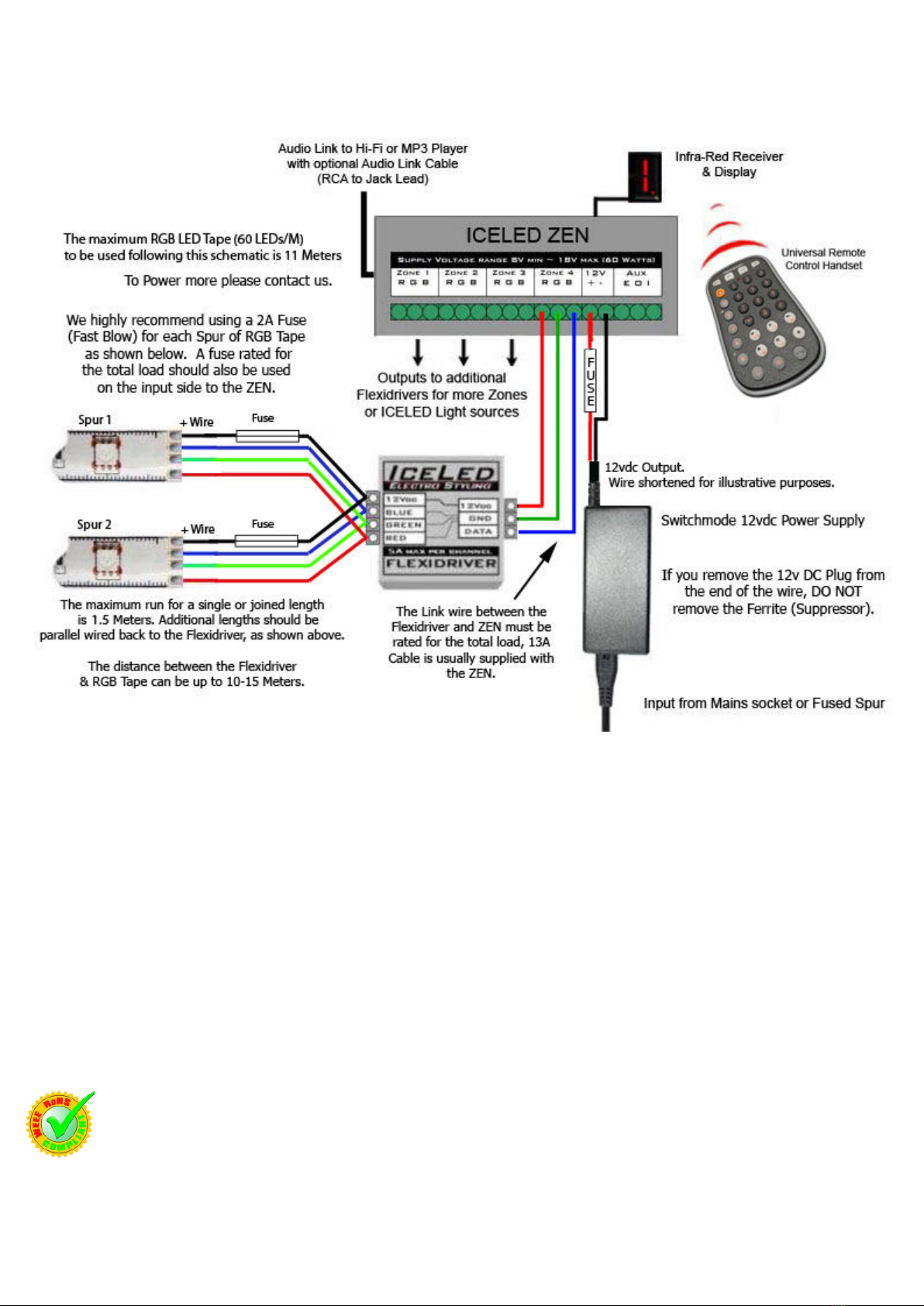

Wiring

The 4 wires from the LED Tape can be extended if necessary by using any low-voltage 4- ore cable with a current rating of 3

Amps or greater. With long cable runs the use of a cable with a higher current rating will ensure minimal voltage-drop in the

wiring which could otherwise affect the colour rendering. 1.5M of RGB Tape i the maximum recommended length for

a continuous run (spur) or joined lengths of 60LED/M RGB LED Tape otherwise colours may not appear uniform along the

entire length and the Tape may be overloaded. If longer runs are required, and the power supply has adequate capacity,

additional lengths should be wired back directly to the supply or driver forming separate spurs. The tape itself is unsuited to

carrying more than 3 Amps so do not extend it with excess lengths or other types of current load.

If a power supply having a significantly greater current capacity than the current requirement for the LED Tape is to be used

then a safety fuse will be required along the positive input wire to the product. This is to prevent excess current flowing in the

supply wiring or the LED Tape under fault conditions such as accidental damage. Such a fuse must be located as near to the

supply or driver to protect the installation wiring and shall have a current rating just higher than the load anticipated in the

spur. Each additional Spur will require its own separate fuse.

If linking the Flexidriver to a ZAP+ or ZEN ontroller, the cable or wire between the ontroller and the Flexidriver should be

rated according to the total load being powered, see cable and fuse ratings.

Note that a fuse may only be omitted from the low voltage side if the power supply provides its own overload protection and

is unable to significantly exceed the maximum rating of the wiring and LED product before it trips.

If hard-wiring the input of the Power Supply to the AC main it i e ential to u e a fu ed wall witch or outlet.

The fu e on the main ide hould be 3A or le . Only a qualified electrician hould hard-wire the Main PSU.

Power Supplie hould be in talled in a dry location.

WARNING

WARNINGWARNING

WARNING

Before use please remove the LED Tape from its bag and allow the odour to dissipate in an unused room or outdoor building.

Wash Hands after handling.

This product uses High Brightness LEDs. Direct viewing of the SMD LEDs at close range should be avoided.

Keep product away from children.

lean the LED Tape with damp a tissue only.

Litewave LTD. Will not accept responsibility for any other issues arising from improper use or fitting of this product where such

matters are beyond our control.

Having highlighted a number of safety issues and warnings in this installation guide Litewave LTD. will accept NO responsibility

issues arising from any failure to comply with these instructions and recommendations.