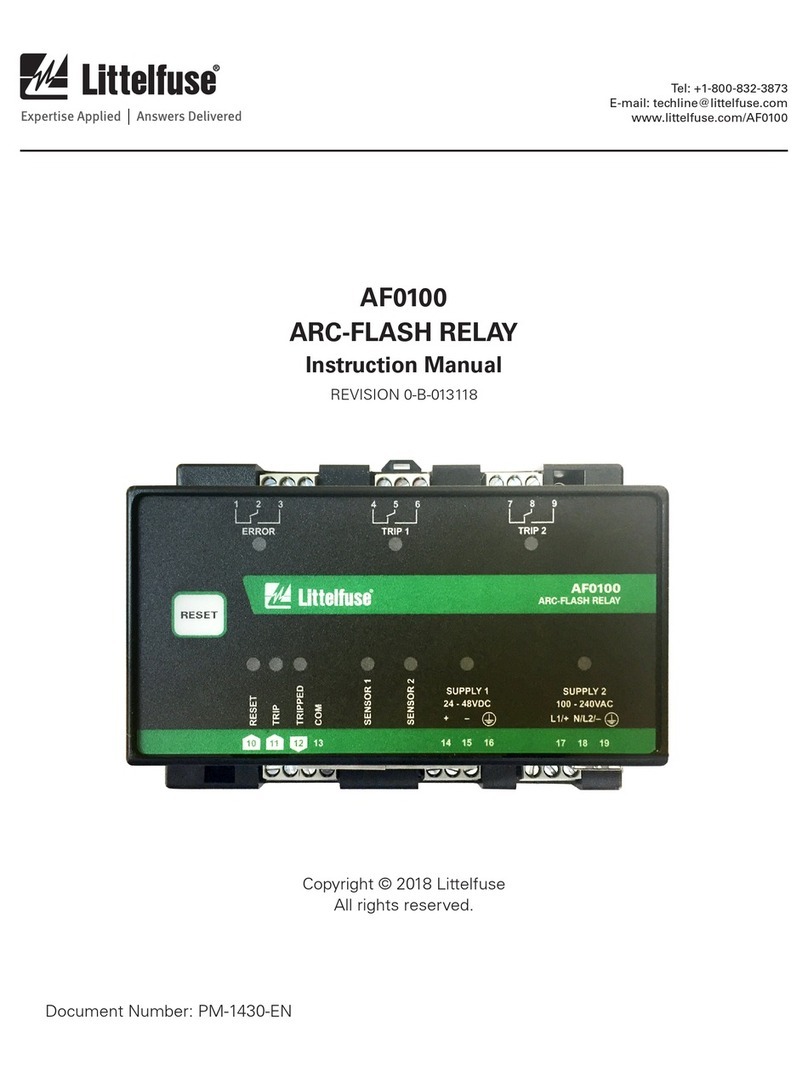

AF0100 Arc-Flash Relay

APPLICATION GUIDE

4Littelfuse.com/ArcFlash© 2018 Littelfuse Products

Fiber

The fiber is the light-collecting element of the PGA-LS20 and PGA-LS30. It must be installed so it has line-of-sight

to all current-carrying parts. In some cases this may be accomplished by mounting in a position that follows the bus

bars along the back wall of the cabinets.

Connect the black-sleeve-covered end to the receiver using the black thumb nut, and the white uncovered end to

the transmitter using the white thumb nut. Ensure the fiber is inserted completely into the transmitter and receiver

and the nuts are tightened. Pull gently on the electrical cable to verify a secure connection.

The fiber should not be sharply bent or pinched. The minimum bending radius is 5 cm.

Point or Fiber-Optic Sensors?

The AF0100 supports two types of arc-flash sensors, point sensors (PGA-LS10) and fiber-optic sensors

(PGA-LS20 and PGA-LS30). Both sensor types gather light and transmit the intensity of the light back to the

AF0100. The point sensor monitors the light from a single collection point while the fiber-optic sensors collect

light along their entire length. The decision to use point sensors or fiber-optic sensors comes down to the

geometry of the equipment to be monitored and the importance of fault location. In a switchgear installation with

many small cabinets, it may be more cost-effective to pass a single fiber-optic sensor through all the cabinets

than to install one point sensor per cabinet. However, this is done at the expense of using the fault location

features of the AF0100 to determine the location of the arc-flash within those cabinets, not which sensor sees

the fault. Sensor types can be combined to further customize the solution. An understanding of the two sensor

types and their properties is important for selecting the correct sensors.

2 DESIGN

2.1 Typical Arc-Flash Protection Applications

Although an arc flash is improbable on systems operating at 208 V or less, systems with higher voltages have

sufficient capacity to cause an arc flash and should use proper protection. Arc-flash protection is especially

important in the following applications:

gSolidly grounded electrical distribution systems: It is estimated that over 95% of all electrical faults are, or

begin as, a ground fault*. Ground-fault current on a solidly grounded system is only limited by the resistance of

the fault and system impedance, and has the potential to cause an arc flash.

gAlarm-only systems: When ground faults are allowed to persist on a system, particularly in an ungrounded

system, the faults can cause rapid deterioration of electrical safety and escalation into an arc flash.

gHigh-Current Systems: The 2017 US NEC, section 240.87 includes “active arc-flash mitigation system” in a

short list of options that shall be used to reduce clearing time “Where the highest continuous current trip setting

for which the actual overcurrent device installed in a circuit breaker is rated or can be adjust is 1200 A or higher.”

gAir-cooled transformers: On air-cooled equipment, the winding insulation, terminals, and ground points are

exposed to the environment. Pollution, dust, and other contaminants can cause premature insulation failure and

can lower the resistance of the air gap between energized conductors, and between energized conductors and

ground. Insulation failure and lower air-gap resistance increase the probability of an arc flash.

gGenerators: Incident energy levels are typically very high on generators, and portable generators are often in

enclosed trailers which make maintenance difficult and dangerous.

gRack-out breakers: As a circuit breaker is racked out, there is a potential for an arc flash to develop when the

electrical contacts are disconnected while energized.

gDevices with high inrush currents: Transformers, capacitor-banks, surge arrestors, large motors, and other

reactive loads will cause a high-inrush current when energized. To allow these systems to operate properly,

instantaneous-current settings on circuit breakers will either be set very high or not used, allowing an arc-flash

to remain on the system for longer, or not be detected at all.

gLow-voltage equipment: Higher fault currents at lower voltage and a mentality that lower voltages are safer

than high voltages mean that many arc-flash incidents actually occur on low-voltage equipment.

*Source: Industrial Power System Grounding Design Handbook by J.R. Dunki-Jacobs, F.J. Shields, and Conrad St. Pierre, page xv.