Page 1

REV. 0-A-030818

MP8000 Motor Protection Relay

TABLE OF CONTENTS

SECTION PAGE

1 Preface .......................................................................................3

1.1 Manual Overview.................................................................3

1.2 Safety Information ...............................................................3

1.2.1 Dangers, Warnings, and Cautions...........................3

1.2.2 Safety Symbols........................................................3

1.2.3 Warnings, Cautions, and Notes ..............................4

1.2.4 Compliance Approvals.............................................4

1.3 General Information .............................................................4

1.3.1 Typographic Conventions.........................................4

1.3.2 Examples..................................................................4

1.3.3 Product Labels .........................................................4

1.3.4 Instructions for Cleaning and Decontamination......4

2 Introduction and Specifications ...........................................5

2.1 Overview ..............................................................................5

2.2 Features................................................................................5

2.2.1 Standard Protection Features..................................5

2.2.2 Monitoring Features ................................................5

2.2.3 Communications and Control ..................................5

2.2.4 Connectivity .............................................................5

2.2.5 Security....................................................................5

2.2.6 Power Supply...........................................................5

2.3 Models, Options, and Accessories ......................................5

2.3.1 Models.....................................................................5

2.3.2 Accessories..............................................................5

2.4 Applications .........................................................................6

2.5 Getting Started.....................................................................7

2.5.1 Powering the Relay..................................................7

2.5.2 Establishing Communication ...................................7

2.6 Specifications.......................................................................7

2.6.1 Compliance ..............................................................7

2.6.2 General ....................................................................7

2.6.3 Type Tests ................................................................8

2.6.4 Current Transformers (CTs) ......................................9

2.6.5 Relay Elements ........................................................9

2.6.6 Metering ................................................................11

3 Installation..............................................................................12

3.1 Overview ............................................................................12

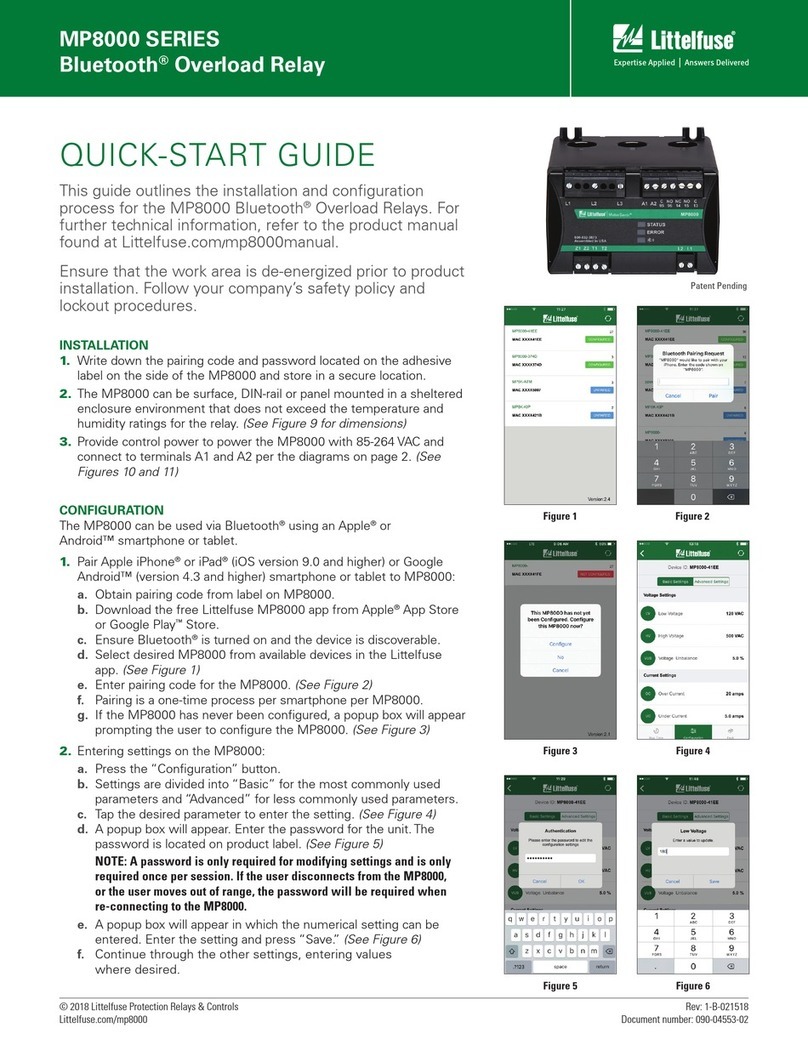

3.2 Phone Application ..............................................................12

3.3 Relay Placement.................................................................12

3.3.1 Physical Location ...................................................12

3.4 Relay Features and Connections........................................12

3.4.1 Relay Mounted on DIN Rail...................................13

3.4.2 Relay Mounted on Solid Surface or Panel ............14

3.5 Relay Connections..............................................................14

3.5.1 Terminal Block Connections ..................................14

3.5.2 Wire Sizes..............................................................14

3.5.3 Voltage Connections (L1, L2, L3)............................14

3.5.4 Power Supply Connections (A1, A2)......................15

3.5.5 Relay Contacts (1 Form C and 1 Form A)

Connections ...........................................................15

SECTION PAGE

3.5.6 Current Connections .............................................15

3.5.7 Power Supply Connections (A1, A2)......................15

3.5.8 Inputs, PTC, ZSCT Connections .............................15

3.5.9 Input Connections (I.1)...........................................15

3.5.10 PTC Connections (T1, T2).......................................16

3.5.11 Zero-Sequence Current Transformer (ZSCT)

(Z1, Z2) (for Ground Fault detection)......................16

3.5.12 Connecting to a PC ................................................16

3.5.13 Connecting to the Littelfuse MP8000 App ............16

3.6 AC/DC Control Connection Diagrams ................................16

3.6.1 Three-Phase Motor under 100 FLA with

optional ZSCT and PTC connected ........................16

3.6.2 Three-Phase Motor over 100 FLA..........................17

3.6.3 Single-Phase Applications.....................................18

4 Littelfuse MP8000 Smartphone and Tablet App...............19

4.1 Overview ............................................................................19

4.2 Installing the Android App .................................................19

4.3 Installing the iPhone App...................................................19

4.4 Running the Littelfuse MP8000 App..................................19

4.5 Advertising Page ................................................................19

4.6 Configuration Pages ...........................................................20

4.7 Configuration Basic Page (Protective Features).................21

4.7.1 Low Voltage (LV) ....................................................21

4.7.2 High Voltage (HV)...................................................22

4.7.3 Voltage Unbalance (VUB).......................................22

4.7.4 Overcurrent (OC) ....................................................22

4.7.5 Undercurrent (UC) ..................................................22

4.7.6 Current Unbalance (CUB).......................................22

4.7.7 Trip Class (TC) ........................................................22

4.7.8 Restart Delay Zero (RD0) .......................................22

4.7.9 Restart Delay One (RD1)........................................23

4.7.10 Restart Delay Two (RD2)........................................23

4.7.11 Restart Delay Three (RD3) .....................................23

4.7.12 Undercurrent Restart Attempts (RU) .....................23

4.7.13 Other Faults Restart Attempts (RF)........................23

4.7.14 Basic Settings Default Values...............................23

4.8 Configuration Advanced Page (Protective Features)..........23

4.8.1 Current Transformer Ratio (CT)..............................23

4.8.2 Potential Transformer Ratio (PT)............................24

4.8.3 Undercurrent Trip Delay (UCTD) ............................24

4.8.4 Linear OC Trip Delay (LINTD) .................................24

4.8.5 Ground Fault Trip Current (GFTC)...........................24

4.8.6 Ground Fault Trip Delay (GFTD) .............................24

4.8.7 Low Power Trip Limit (LKW) ..................................24

4.8.8 High Power Trip Limit (HKW).................................24

4.8.9 High Power Trip Delay (HPTD) ...............................25

4.8.10 Stall Percentage (STLP) .........................................25

4.8.11 Stall Trip Delay (STTD)...........................................25

4.8.12 Stall Inhibit Delay (STID) .......................................25

4.8.13 Advanced Settings Default Values........................25