Page 1

REV. 0-B-013118

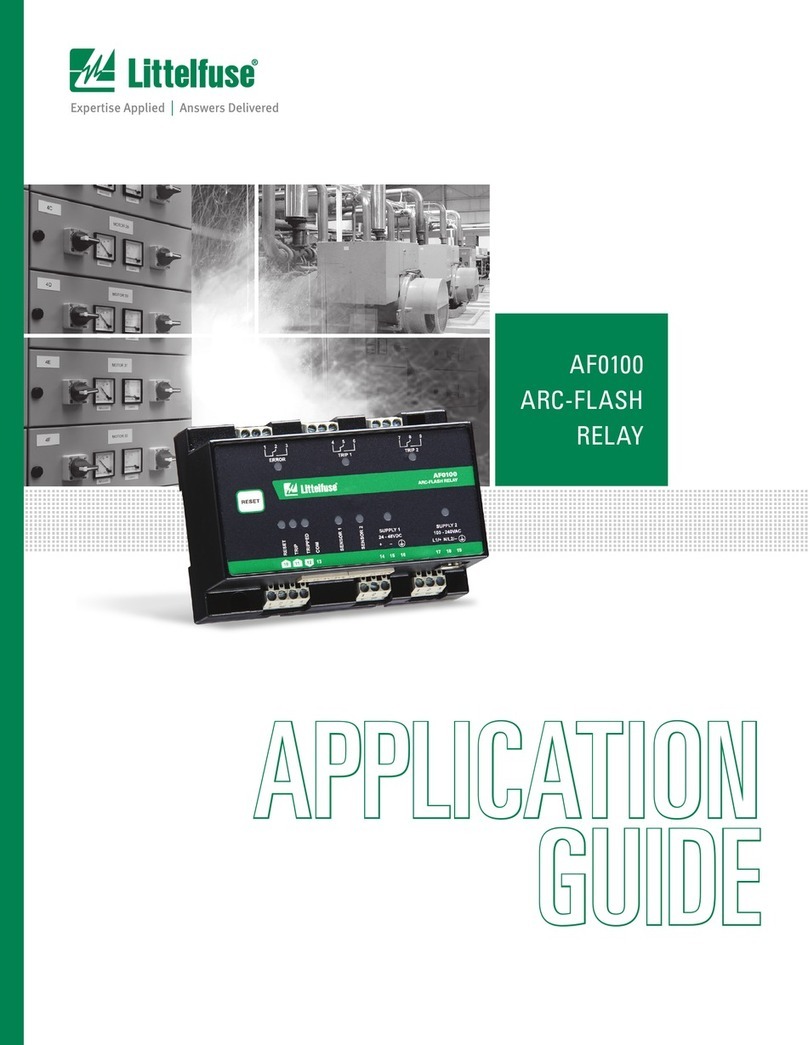

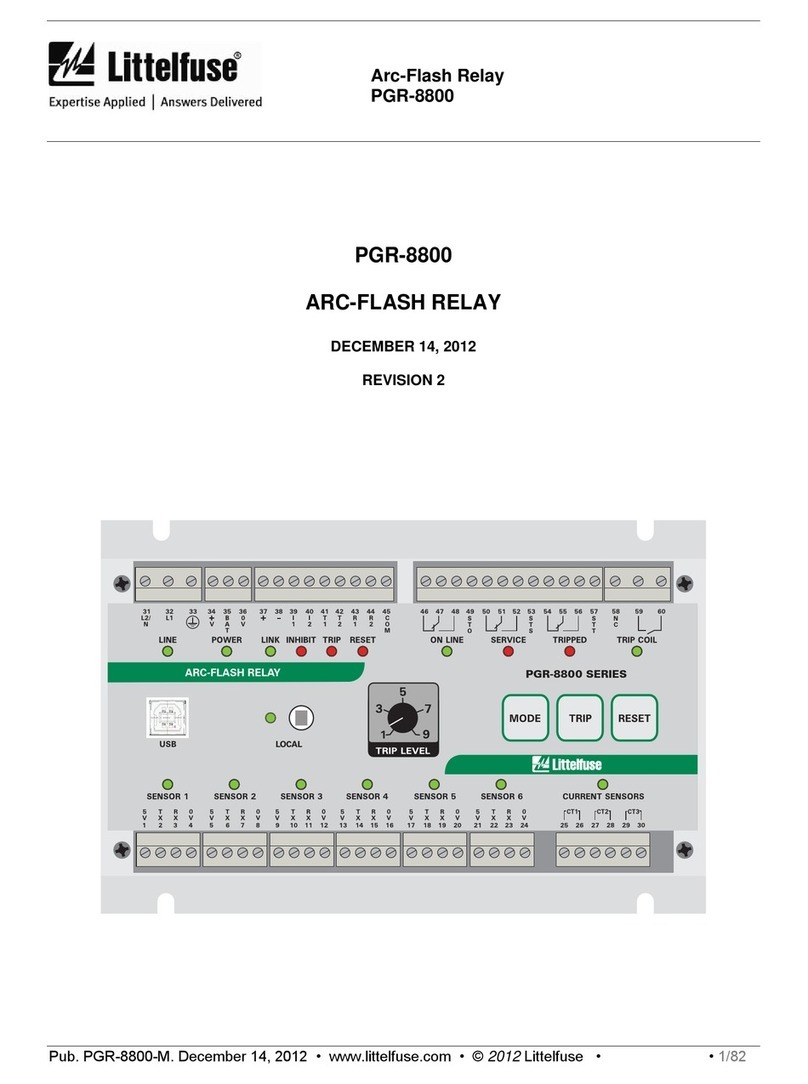

AF0100 Arc-Flash Relay

1 KEY FEATURES

The AF0100 Arc-Flash Relay is a high-speed, arc-detection

device for electrical power-distribution systems. The AF0100

has two Form-C Trip relays, and has inputs for up to two

optical sensors for optimal arc detection. The inputs support

both point sensors and fiber-optic line sensors, which cover

a larger area.

Using optical sensors rather than relying strictly on current

measurement allows a much faster detection time than

overcurrent relays or a circuit breaker alone can typically

provide, as the light from the arc is unique to arc faults,

whereas current pulses above the nominal level are part of

normal operation for many systems.

On the occurrence of an arc fault, the AF0100 detects the

fault and activates the trip relays, which trips the circuit

breaker(s) supplying the fault. In a typical system, a trip occurs

within 5ms. The total arcing time is effectively reduced to

the mechanical opening time of the circuit breaker, typically

between 30 and 75 milliseconds. This reduces the energy of

the arc fault significantly, increasing worker safety, reducing

fault damage, and improving uptime.

The AF0100 can be used on ac or dc electrical systems and

can be powered from either an ac or dc supply, or both. For

all available ordering options, see section 10.7.

1.1 Easy Installation

The AF0100 includes two sensor inputs, two trip relays,

one error relay, and a digital input and output interface

which makes it possible to connect additional AF0100 or

AF0500 units. See Fig. 1. The complete configuration and

“programming” of the system can be done by simply wiring

the inputs and outputs marked with green arrows – no

external software is needed.

A system with multiple zones and upstream circuit breakers

can be implemented such that in many applications, the

switchboard wiring diagram can completely describe how

the arc-flash system works.

The relay will automatically learn which sensors and

power supplies are connected, and will indicate an alarm

if a previously connected wire breaks or is unplugged. If a

configuration change is needed, the redetection process

can be triggered by pressing the Reset button for 20 s, see

section 7.1.

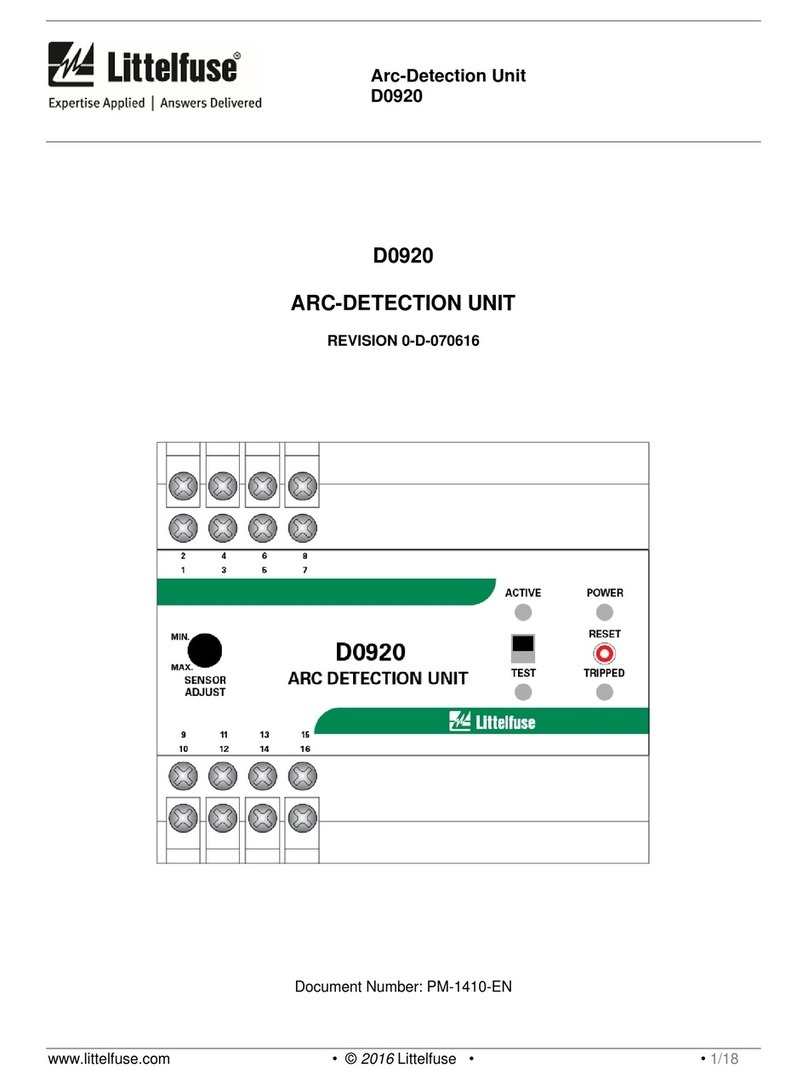

1.2 Fail-Safe Operation

The AF0100 continuously monitors its internal circuitry as

well as the connected optical sensors. Any system faults,

including a sensor-cable fault, are indicated by an Error relay

and the Error LED on the front panel.

A redundant trip circuit ensures that the AF0100 will trip

the circuit breaker on an arc flash even if a primary trip-

circuit component fails (shunt trip mode only). The design

of the redundant trip circuit also provides a significantly

faster response to an arc on power-up (for example, after

maintenance during a shutdown) than is possible with

microprocessor-only relays, which is an advantage in smaller

self-powered systems.

1.3 Fast Error and Fault Location

The optical sensors used with the AF0100 have built-in LED’s

for indication of health and for easy location of arc faults.

The AF0100 also has one LED per optical sensor on the front

panel to indicate which sensor(s) have caused a trip and for

indicating problems in the installation.

1.4 USB Interface

A USB interface on the lower panel of the AF0100 provides

easy PC access to configuration settings. No PC driver or

software installation is required.