Little Giant WRS-6 User manual

BEFORE INSTALLATION:

Little Giant Wastewater Kits are carefully packaged,

inspected and tested to insure safe operation and

delivery. When you receive your unit, examine it carefully

to determine that there are no missing, broken or

damaged parts that may have occurred during shipment.

If damage has occurred, make notation and notify the firm

you purchased the unit from. They will assist you in

replacement or repair, if required. Read this manual

carefully and also the enclosed pump manual.

This unit is designed to pump wastewater from laundry

trays, washing machines, sinks or dehumidifiers. Unit is

not designed to pump raw sewage, fluids other than

water, or fluids with solids. Inlet screen will remove many

solids over 1/8" diameter, but large amounts of solids can

clog screen and result in pump failure. Maximum fluid

temperature is 125ºF. Unit is designed to fit under most

sinks so in many cases it is not necessary to recess the

unit into the floor.

ITEMS TO PURCHASE:

NOTE: Some state or local codes require all electrical

and/or plumbing connections to be made by a licensed

contractor. It is the customer’s responsibility to determine

codes involved and to comply with these codes. If user

can install unit, items to purchase are:

1. Inlet piping, with trap and union (basin cover has 11/2“

FNPT fitting).

2. Discharge piping, with swing check valve and union

(basin cover has 11/2“ FNPT fitting).

3. Vent piping (basin cover has 2" FNPT fitting).

3810 North Tulsa Street

Oklahoma City, Oklahoma 73112

(405) 947-2511

Little Pump Company

GIANT

OWNERS MANUAL

For

Little Giant®

MODEL WRS-6 WASTEWATER

REMOVAL SYSTEM WITH 6-CIA PUMP

·INSTALLATION

·OPERATION

·REPAIR PARTS

·SAFETY

SAFETY GUIDELINES

1. CAUTION: To reduce the risk of electric shock, pull

plug before servicing this pump.

2. Read all instructions and safety guidelines

thoroughly. Failure to follow the guidelines and the

instructions could result in serious bodily injury and/or

property damage.

3. Check local electrical and building codes before

installation. The installation must be in accordance

with their regulations.

4. During normal operation the pump is immersed in

water. Caution must be used to prevent bodily injury

when working near the pump:

a. The plug must be removed from the receptacle

prior to touching, servicing or repairing the pump.

b. To minimize possible fatal electrical shock hazard,

extreme care should be used when changing

fuses. Do not stand in water while changing fuses

or insert you finger into fuse socket.

ELECTRICAL CONNECTIONS

All wiring must meet local codes, and a licensed electrical

contractor is recommended. The pump is supplied with a

3-prong vented plug. Plugs must be plugged into a

grounded receptacle and vent tube must remain

unobstructed for proper pump operation. Pump should

be on a separate circuit with fuse or circuit breaker and

GFCI (ground fault circuit interrupter). Be sure electrical

supply matches pump nameplate data. Do not use

extension cord. If installed in basement, plug connection

should be 4 feet or more above floor, especially if

basement floods. Be sure electrical connections cannot

be reached by rising water. Under no circumstances

should outlet box or receptacle be located where it may

become flooded or submerged by water.

INSTALLATION

All plumbing must meet local codes. A licensed plumbing

contractor is recommended. All fixtures connected to the

WRS-6 Basin Kit must be vented according to state and

local codes.

STEP 1: Determine proper location for unit. Unit should

be located so that inlet is gravity-fed. Unit will not draw

water up from a lower level. Position and level basin. Keep

basin away from any item that could puncture basin.

Position selected should be convenient to inlet, discharge

and vent piping and electrical supply.

STEP 2: Plumb inlet. Using 1-1/2" threaded pipe, plumb

inlet to basin cover fitting. Use a P-trap and a union next to

the basin. Use pipe joint compound and hand tighten only

on plastic fittings. Do not reduce below 1-1/2" piping.

STEP 3: Plumb discharge. Using 1-1/2" threaded pipe,

plumb discharge to basin cover fitting. Use a swing

check valve no more than 3" from top of basin cover

and a union. Be sure check valve is installed in proper

flow direction.

If check valve is installed backwards, no water will flow

out of unit. Be sure discharge piping is sealed with pipe

joint compound and that lift height of pump is not

exceeded. Hand tighten only on plastic fittings.

STEP 4: Plumb vent. Plumb vent using 2" threaded

pipe to fitting in basin cover. Use pipe joint compound

on threads and hand tighten only on plastic fittings.

The basin must be vented in accordance with state and

local codes. The vent is essential for proper switch

operation and must not be omitted or restricted.

CAUTION: Do not use a mechanical vent with this

product. A mechanical vent will cause improper

operation of the automatic switch.

STEP 5: Test Unit. Connect power cord to electrical

supply as stated under “Electrical Connections.”

Secure power cord to piping with ties or tape. Fill unit

with water through inlet. Pump should turn on with

7"–10" of water in tank, and turn off when 1"–3" of water

is left in tank.

MAINTENANCE

Maintenance operations consist of cleaning basin inlet

screen in cover, cleaning basin and limited pump

maintenance. WARNING: Before any maintenance is

performed, shut off water inlet and disconnect power cord

from supply outlet. Pump may become hot in operation.

Allow pump to cool before servicing.

Basin Screen – Remove (4) 1/4-20 screen cover plate

screws, plastic cover plate, o-ring and screen. Clean inlet

screen using a mild detergent and water. Examine o-ring

and if deformed, replace with new o-ring. See

replacement parts list.

Basin – Sediment may build up in basin causing pump to

operate improperly. Remove (10) 1/4-20 screws from

cover. Remove cord grommet and loosen cords to allow

slack and then remove cover.

Remove pump and clean basin using a mild detergent

and water. Reassemble in reverse order.

Torque screws 18-20 in.-lbs.

If pump alignment plate is removed, it must be reinstalled

per pump alignment diagram.

Pump – Sediment or lint can clog pump and cause

improper operation. If necessary, remove pump and

pull off the pressed-in screen. Clean using a mild

detergent and water and reinstall. Plastic pump base

may also be removed to clean around impeller and

inside base. Remove the 6 base screws and clean base

using a mild detergent and water. Do not remove

impeller. When reinstalling base, be sure seal ring is

seated properly in groove and torque screws to 10-15

in.-lbs. See pump manual for other information. For

any other pump repair, return the pump to a Little Giant

authorized service center.

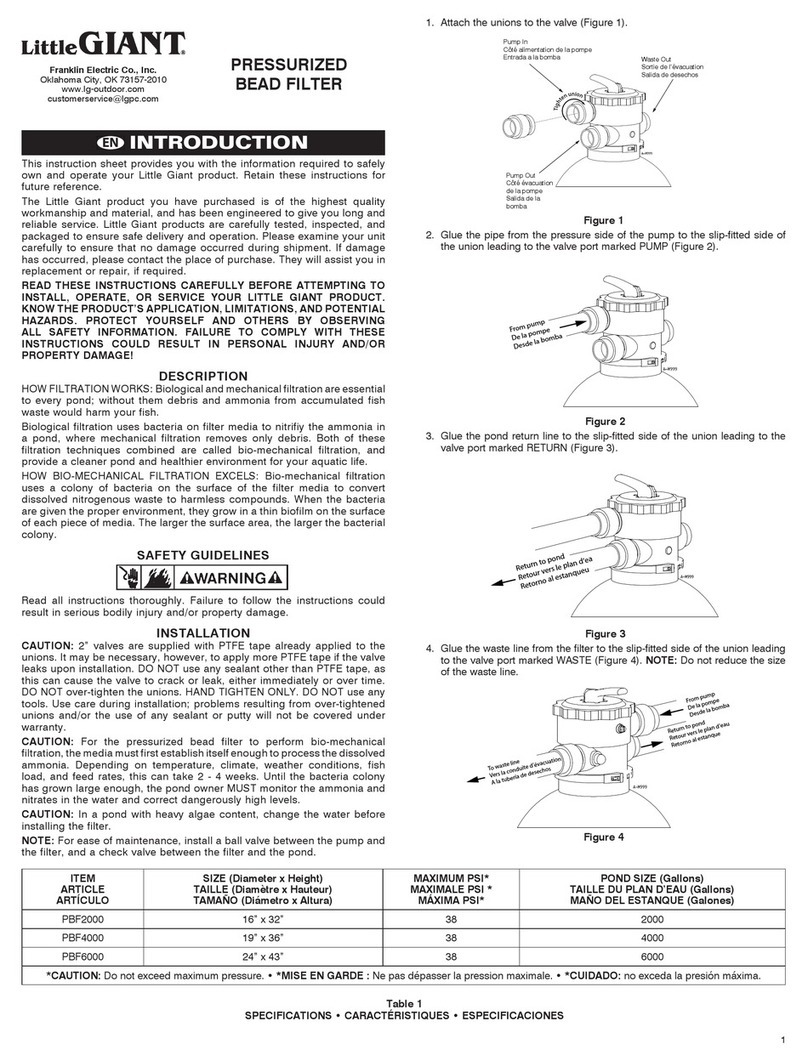

TYPICAL INSTALLATION

FOR TROUBLE-SHOOTING INFORMATION

SEE PUMP OWNERS MANUAL INCLUDED WITH

WRS-6 BASIN KIT.

SPECIFICATIONS

MODEL

NUMBER VOLTS HERTZ AMPS WATTS GALLONS PER HOUR (GPH) AT HT. SHUTOFF

(FT.)

MAX.

PSI

5’ 10’ 15’

WRS-6 115 60 9 720 2750 1750 750 18 7.8

8 FT. POWER CORD

(CORD GROMMET INCULDED)

*2" VENT PIPE

FILTER ACCESS COVER

WITH O-RING

FILTER

*UNION

*1-1/2" INTAKE

COVER O-RING

14.50"

*- ITEMS NOT INCLUDED WITH WRS-6 BASIN KIT

*1-1/2" CHECK VALVE

*1-1/2" UNION

*1-1/2" DISCHARGE PIPE

BASIN COVER

BASIN

1-1/2" DISCHARGE PIPE

LITTLE GIANT PUMP

MODEL 6-CIA

15.56"

10.63" DIA.

13.88" DIA.

REPLACEMEMT PARTS LIST

ITEM PART # DESCRIPTION QTY.

1 113130 BASIN COVER 1

2 901709 SCREW, 1/4"-20 X 1/2" 14

3 924125 O-RING, 11.975 I.D. 1

4 113129 BASIN 1

5 113140 DISCHARGE PIPE 1

6 506158 PUMP, 6-CIA, 115V 1

7 925016 CORD GROMMET 1

8 113131 INTAKE SCREEN 1

9 924126 O-RING, 3.225 I.D. 1

10 113132 COVER PLATE, SCREEN 1

11 113135 ALIGNMENT PLATE 1

ONE YEAR LIMITED WARRANTY

For one year from date of purchase, Little Giant

Pump Company will repair this unit if defective in

material or workmanship. Warranty service is

available by returning the unit prepaid to the factory.

For further details, please consult the warranty

statement on carton. This warranty gives you

specific legal rights and you may also have other

rights which vary from state to state.

KEEP THIS FOLDER

File this for safekeeping. It may be valuable to your for service under the terms of the warranty.

Date of Purchase ___________________________ Name of Dealer __________________________________________________

Serial #______________________ Product # _____________________________ Model # _______________________________

©Copyright 2001 Little Giant Pump CompanyFORM 993801 — 04/24/2001:

Printed by Little Giant DocServ

Other manuals for WRS-6

3

Other Little Giant Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Atlantic Ultraviolet

Atlantic Ultraviolet Mighty Pure MP16A owner's manual

SunSun

SunSun CBG-500 Operation manual

Hayward

Hayward XStream Filtration Series owner's manual

Contech

Contech DownSpout StormFilter Operation and maintenance

Teka

Teka Airfilter MINI operating instructions

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual

STA-RITE

STA-RITE VERTICAL GRID DE FILTERS S7D75 owner's manual