Form 993315 - 09/24/2009

© 2007 Franklin Electric Co., Inc.

Little Giant® is a registered trademark of Franklin Electric Co., Inc.

Your product is guaranteed to be in perfect condition when it leaves our Factory.

It is warranted against defective materials and workmanship for a period of 12

months from date of purchase by the user.

Any product that should fail for either of the above two reasons and is still within

the warranty period will be repaired or replaced at the option of Little Giant

Pump Company, Inc. dba Franklin Electric Water Transfer Systems (hereafter

“the Manufacturer”) as the sole remedy of buyer. For our customers in the

CONTINENTAL UNITED STATES: Please return the defective unit, postage paid,

to the factory at 301 N. MacArthur, Oklahoma City, OK 73127-6616. All defective

product returned under warranty will be fully inspected to determine the cause

of failure before warranty is approved.

For our customers located elsewhere; it is not economical, due to duties

and freight, to return the product to the factory for inspection. Please return

the defective unit to any authorized distributor or dealer with a brief written

explanation of the problem. If there are no apparent signs of customer abuse,

unit will be repaired or replaced. If dispute arises over replacement of the

product, the distributor or dealer is to segregate such items and hold for

inspection by a representative of the Manufacturer or notify factory with details

of the problem for factory disposition and settlement of warranty claim.

DISCLAIMER:

THE FOREGOING WARRANTY IS AN EXCLUSIVE WARRANTY IN LIEU OF ANY

OTHER EXPRESS WARRANTIES. ANY IMPLIED WARRANTIES (INCLUDING,

BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE) TO THE EXTENT EITHER APPLIES

TO A PRODUCT SHALL BE LIMITED IN DURATION TO THE PERIODS OF THE

EXPRESS WARRANTIES GIVEN ABOVE.

Warranty will be VOID if any of the following conditions are found:

1. Sealed motor housing opened.

2. Product connected to voltage other than that indicated on nameplate.

3. Cord cut off to a length less than three feet.

4. Pump allowed to operate dry (fluid supply cut off).

5. Pump used to circulate anything other than fresh water at approximately

room temperature.

6. Product abuse by customer.

Any oral statements about the product made by the seller, the manufacturer,

the representatives or any other parties, do not constitute warranties, shall

not be relied upon by the user and are not part of the contract for sale.

Seller’s and manufacturer’s only obligation, and buyer’s only remedy, shall

be the replacement and/or repair by the manufacturer of the product as

described above. NEITHER SELLER NOR THE MANUFACTURER SHALL BE

LIABLE FOR ANY INJURY, LOSS OR DAMAGE, DIRECT, INCIDENTAL OR

CONSEQUENTIAL (INCLUDING, BUT NOT LIMITED TO INCIDENTAL OR

CONSEQUENTIAL DAMAGES FOR LOST PROFITS, LOST SALES, INJURY TO

PERSON OR PROPERTY, OR ANY OTHER INCIDENTAL OR CONSEQUENTIAL

LOSS), ARISING OUT OF THE USE OR THE INABILITY TO USE THE PRODUCT

AND THE USER AGREES THAT NO OTHER REMEDY SHALL BE AVAILABLE

TO IT. Before using, the user shall determine the suitability of the product for the

intended use, and user assumes all risk and liability whatsoever in connection

therewith.

Some states and countries do not allow limitations on how long an implied

warranty lasts or the exclusion or limitation of incidental or consequential

damages, so the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights

which vary from state to state and country to country.

The National Electric Code (in the USA) and similar codes in other countries

require a Ground Fault Circuit Interrupter (GFCI) to be installed in the branch

circuit supplying fountain equipment rated above 15 volts. 115 volt GFCI’s (with

various cord lengths) are in stock, and we recommend each product be used

with a GFCI.

LIMITED WARRANTY

1

9

4

3

7

6

5

8

2

12

11

8

10

13

ITEM NO.

PART NO.

DESCRIPTION*

MODEL AND CATALOG NUMBERS

4-MD 5-MD

582002

115V 60Hz

582012

230V 60Hz

582098

Pump less motor

583002

115V 50/60 Hz

583012

230V 50/60 Hz

583098

Pump less motor

1 977409 Motor, 115 volt 1 -- -- -- -- --

1 977909 Motor, 220/240 volt -- 1 -- -- -- --

1 977410 Motor, 115 volt w/sleeve bearing -- -- -- 1 -- --

1 977910 Motor, 220/240 volt w/sleeve bearing -- -- -- -- 1 --

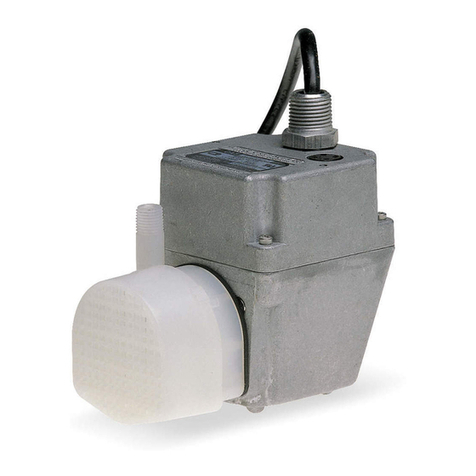

2 180031 Adapter w/base 1 1 1 -- -- --

2 183031 Adapter -- -- -- 1 1 1

3 183070 Volute 1 1 1 1 1 1

4 182005 Housing, magnet 1 1 1 1 1 1

5 182602 Drive magnet assembly 1 1 1 -- -- --

5 183602 Drive magnet assembly -- -- -- 1 1 1

6 182137 Impeller/magnet assembly 1 1 1 -- -- --

6 183142 Impeller/magnet assembly -- -- -- 1 1 1

7 182056 Shaft 1 1 1 1 1 1

8 921067 Washer, thrust 2 2 2 2 2 2

9 924007 O-ring 1 1 1 1 1 1

10 911403 Stud, collared 4 4 4 4 4 4

11 920003 Nut, wing #8-32 4 4 4 4 4 4

12 920006 Nut, wing #8-32 4 4 -- -- -- --

12 920008 Nut, hex #10-32 -- -- -- 4 4 --

13 921075 Washer, #8 plain 4 4 -- -- -- --

*Applies to catalog numbers shown. Other models are available, but parts may vary. For other

models, contact parts depot, factory, or distributor for replacement parts. Be sure to give the model

and six-digit catalog number when requesting parts.

For parts or repair, please contact . . . . . . . . . . . . . . . . . . . . 1.888.572.9933

For technical assistance, please contact . . . . . . . . . . . . . . . 1.888.956.0000

www.LittleGiantPump.com