STAINLESS STEEL

Pony Pump®

REPAIR KIT

INTRODUCTION

This instruction sheet provides you with information required to safely own and operate your

Little Giant pump. It primarily covers the standard models of each pump series. The form is

applicable to other models in the series not listed by catalog number in the replacement parts

list section of the instruction sheet. If the catalog number of your pump is not listed in the

replacement parts list section, then caution should be exercised when ordering replacement

parts. Always give the catalog number of your pump when ordering replacement parts.

The Little Giant unit you have purchased is of the highest quality workmanship and material. It has

been engineered to give you long and reliable service. Little Giant pumps are carefully packaged,

inspected, and tested to ensure safe operation and delivery. When you receive your pump, exam-

ine it carefully to determine that there are no broken or damaged parts that may have occurred

during shipment. If damage has occurred, make notation and notify the firm that you purchased

the pump from. They will assist you in replacement or repair, if required.

READ INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL, OPERATE OR

SERVICE THE LITTLE GIANT PUMP. KNOW THE PUMP APPLICATION, LIMITATIONS,

AND POTENTIAL HAZARDS. PROTECT YOURSELF AND OTHERS BY OBSERVING ALL

SAFETY INFORMATION. FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT

IN PERSONAL INJURY AND/OR PROPERTY DAMAGE! RETAIN INSTRUCTIONS FOR

FUTURE REFERENCE.

SAFETY GUIDELINES

1. Make certain that the unit is disconnected from the power source before attempting

to service or remove any component.

2. Do not use to pump flammable or explosive fluids such as gasoline, fuel oil, kerosene,

etc. Do not use in explosive atmospheres. Pump should only be used with liquids

compatible with pump component materials.

3. Do not handle pump with wet hands or when standing on a wet or damp surface or

in water.

4. For DC (direct current) versions, when attaching pump leads to battery terminals, be

sure that the area is adequately ventilated to prevent an explosion or fire from explo-

sive or flammable vapors that may be present. Consult the battery manufacturer for

additional safety information.

a. Batteries emit hydrogen gas, which is explosive. Avoid smoking, sparks, or open

flame anywhere in batteries’ vicinity.

b. Explosion from battery can cause blindness. Shield eyes when working near any battery.

c. Batteries contain sulfuric acid. In case of contact with eyes, skin or clothing, flush

immediately with large amounts of water and get medical attention.

d. Do not add acid or electrolyte to a battery.

e. Keep out of reach of children.

ELECTRICAL CONNECTIONS

1. Check the pump label for proper voltage required. Do not connect to voltage other

than that shown.

2. For DC (direct current) versions, when using a battery as the power source, attach the red

positive (+) lead wire to the positive (+) battery terminal, followed by attaching the black

negative (–) lead wire to the ground (–) battery terminal. When disconnecting the pump,

first disconnect the black negative (–) lead wire from the battery ground (–) terminal, and

then disconnect the red positive (+) lead wire from the positive (+) battery terminal.

3. To operate properly, the DC (direct current) version pump must be connected to a

steady DC power source or a battery in good condition supplying the proper voltage

according to the pump label. Low voltage power source may cause critical overheating

and premature failures. To avoid this condition, be sure proper voltage is maintained.

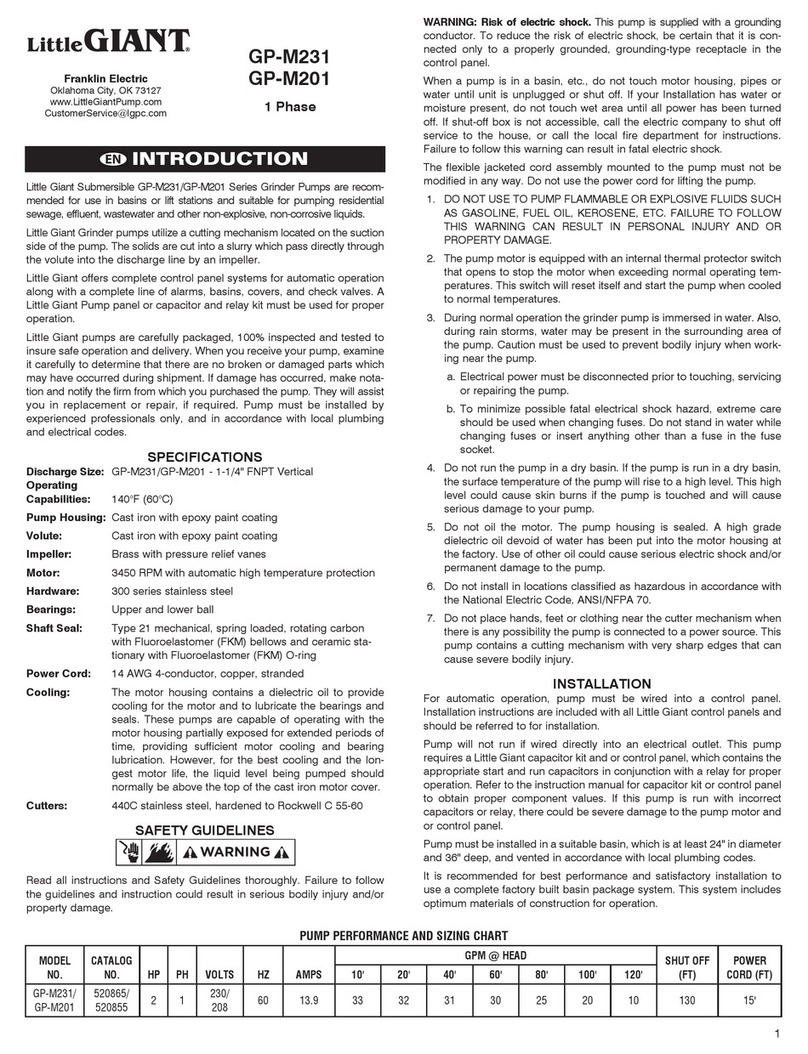

SERVICE INSTRUCTIONS

1. CAUTION: Disconnect from power source when making adjustments and repairs. On

DC (direct current) versions, first disconnect the black negative (–) lead wire, and then

lastly disconnect the red positive (+) lead wire.

2. TO REPLACE IMPELLER: Replace impeller when it has become worn or damaged.

a. Remove 4 volute cover mounting screws (1).

b. Remove volute cover (2) and gasket (3).

c. Slide impeller (4) off motor shaft.

d. Clean the inside of the pump head and the gasket sealing surface. Make certain that

there are no foreign materials that would obstruct the impeller’s operation.

e. Apply petroleum jelly or similar lubricant to the inside of the pump head using cotton

swab. Do not get lubricant on gasket sealing surface; this surface must be lubricant-free.

f. Align the flat on the inside of the impeller (4) shaft bore with the flat on the motor shaft.

Push the impeller into place, while twisting the impeller vanes in a clockwise rotation.

g. Place new gasket (3) onto pump head face, align holes, and replace cover (2).

h. Tighten cover mounting screws (1) evenly and snugly.

3. TO REPLACE CAM: Replace cam (5) when it has become worn or damaged.

a. Remove impeller (4) according to step 2.

b. Remove handle mounting screw (not shown) and handle.

c. Remove cam screw (7) and cam screw gasket (6).

d. Gasket sealant is used between cam and pump head, and will require that the cam be

pried from pump head. Be careful not to damage the cover gasket sealing surface.

e. Clean the gasket sealant from the pump head.

f. Apply gasket sealant to new cam (5) and mating surface of pump head.

g. Install new cam into pump head. Install new cam screw gasket (6) and secure new

cam with new cam screw (7). Tighten new cam screw snugly to prevent leakage.

h. Clean any excess gasket sealant from pump head.

i. Reinstall handle and handle mounting screw.

j. Install impeller (4) according to step 2.

4. TO REPLACE SHAFT SEAL: Replace shaft seal (8) when it has become worn or

damaged.

a. Remove pump head mounting screws (not shown) and slide pump head off of motor

shaft. Do not remove slinger washer (11) from motor shaft.

b. Pry retaining ring (10) from the backside of the pump head.

c. Remove the felt washer (9) and shaft seal (8) from seal bore in the pump head.

d. Install new shaft seal and new felt washer into seal bore in the pump head.

e. Press new retaining ring (10) into seal bore in the pump head.

f. Place pump head onto motor shaft, carefully aligning the shaft seal inside diameter

with motor shaft. There is a flat on the motor shaft and a mating flat on the impeller

inside diameter. To fully seat the pump head onto the motor, the flats on the motor

shaft and the impeller must be aligned. Rotate the pump head until the flats align and

the pump head can be fully seated onto the face of the motor.

g. Align the pump head mounting holes with the mounting holes on the face of the mo-

tor. Reinstall the pump head mounting screws, tightening them evenly and snugly.

Franklin Electric Co., Inc.

Oklahoma City, OK 73127

www.franklinwater.com

Repair Kits

555702

HRK-360S

555706

IRK-360

555713

IRK-360S

555714

ISRK-360S

Item No. Description Component Quantity

1Screw, volute cover 4 -- -- --

2Volute cover, SST 1 -- -- --

3Cover gasket, Nitrile 2222

4Impeller, Nitrile w/SST insert 2 -- 2 2

4Impeller, Nitrile w/brass insert -- 2 -- --

5Cam, SST 1 -- -- --

6Gasket, fiber washer, cam screw 1 -- -- --

7Screw, cam 1 --- -- --

8U-cup seal, Fluoroelastomer (FKM)- -- -- -- 1

9Felt washer -- -- -- 1

10 Internal retaining ring -- -- -- 1

11 Slinger washer, neoprene -- -- -- 1

Form 998258 - 10/2013, Rev. 001