INTRODUCTION

This instruction sheet will provide you with information required to

safely own and operate the Little Giant MDQ series aquarium pumps.

The pump you have purchased is a magnetic driven pump intended

for aquarium use, to provide water movement through filtration

systems. The pumps are installed external to the aquarium and

filtration systems, and are generally mounted below the aquarium

in the cabinet that houses the filtration systems. The pump head

parts are made of glass filled polypropylene. The spindle shaft

and thrust washers are ceramic. The impeller driven magnet is

coated ceramagnet A (barium ferrite) type ceramic. O-ring seals

are nitrile. The motor is thermally protected.

This instruction sheet covers the standard models in this pump

series. This form is applicable to other models in this series not

listed by catalog number in the replacement parts list section of

this pamphlet. If the catalog number of your pump is not listed in

the replacement parts section, then caution should be exercised

when ordering replacement parts. Always give the catalog number

of your pump when ordering replacement parts.

The Little Giant unit you have purchased is of the highest quality

workmanship and material. It has been engineered to give you

long and trouble-free service.

The Little Giant pumps are carefully inspected, tested and

packaged to insure safe operation and delivery. When you receive

your pump, examine it carefully to determine that there are no

broken or damaged parts that may have occurred in shipment.

If damage has occurred, make notation and notify the firm from

which you purchased the pump. They will assist you in the

replacement or repair, if required.

READ INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO

INSTALL, OPERATE OR SERVICE THE LITTLE GIANT PUMP.

KNOW THE PUMP APPLICATION, LIMITATIONS, AND POTENTIAL

HAZARDS. PROTECT YOURSELF AND OTHERS BY OBSERVING

ALL SAFETY INFORMATION. FAILURE TO COMPLY WITH

INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/

OR PROPERTY DAMAGE! RETAIN INSTRUCTIONS FOR FUTURE

REFERENCE.

SAFETY GUIDELINES

DANGER: To avoid possible electric shock, special care

should be taken in the use of aquarium equipment. For each

of the following situations, do not attempt repairs yourself;

return the appliance to an authorized service facility for

service or discard the appliance.

1. DO NOT USE TO PUMP FLAMMABLE OR EXPLOSIVE FLUIDS

SUCH AS GASOLINE, FUEL OIL, KEROSENE, ETC. DO

NOT USE IN EXPLOSIVE ATMOSPHERES. PUMP SHOULD

ONLY BE USED WITH LIQUIDS COMPATIBLE WITH PUMP

COMPONENT MATERIALS.

2. DO NOT HANDLE PUMP WITH WET HANDS OR WHEN

STANDING ON A WET OR DAMP SURFACE, OR IN WATER.

3. THIS PUMP IS SUPPLIED WITH A GROUNDING CONDUCTOR

AND/OR GROUNDING-TYPE ATTACHMENT PLUG. TO REDUCE

THE RISK OF ELECTRIC SHOCK, BE CERTAIN THAT IT IS

CONNECTED TO A PROPERLY GROUNDED GROUNDING-

TYPE RECEPTACLE.

4. IN ANY INSTALLATION WHERE PROPERTY DAMAGE AND/OR

PERSONAL INJURY MIGHT RESULT FROM AN INOPERATIVE

OR LEAKING PUMP DUE TO POWER OUTAGES, DISCHARGE

LINE BLOCKAGE, OR ANY OTHER REASON, A BACKUP

SYSTEM(S) AND/OR ALARM SHOULD BE USED.

5. SUPPORT PUMP AND PIPING WHEN ASSEMBLING AND

WHEN INSTALLED. FAILURE TO DO SO MAY CAUSE PIPING

TO BREAK, PUMP TO FAIL, MOTOR BEARING FAILURES, ETC.

6. A. Do not handle the pump with wet hands or when standing

on a wet or damp surface or in water.

B. If the appliance falls into the water, DON’T reach for it! First

unplug it and then retrieve it. If electrical components of

the appliance get wet, unplug the appliance immediately

(nonimmersible equipment only).

C. Carefully examine the appliance after installation. It should

not be plugged in if there is water on parts not intended to

be wet.

D. Do not operate the pump if it has a damaged cord or plug,

or if it is malfunctioning or if it is dropped or damaged in

any manner.

E. To avoid the possibility of the pump plug or receptacle

getting wet, position aquarium stand and tank to one side

of a wall mounted receptacle to prevent water from dripping

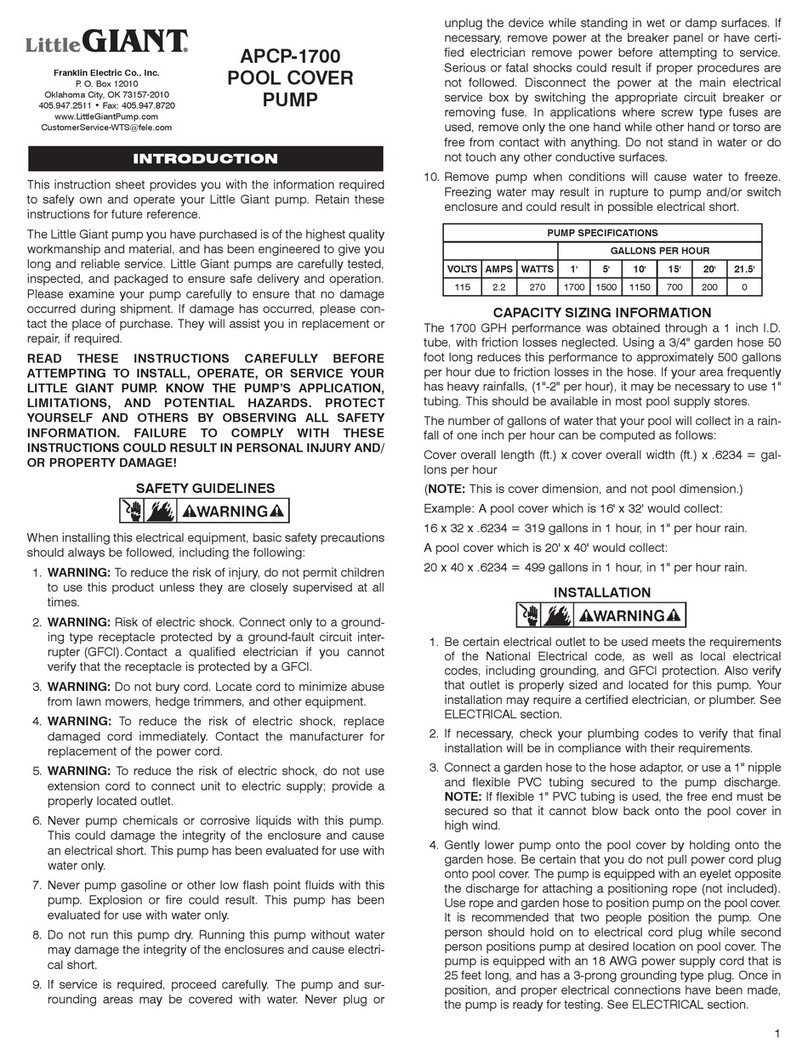

onto the receptacle or plug. A “drip loop”, shown in Figure 1,

should be arranged by the user for each cord connecting

1

1.5-MDQ-SC

Figure 1

Franklin Electric Co., Inc.

P. O. Box 12010

Oklahoma City, OK 73157-2010

405.947.2511 • Fax: 405.947.8720

www.LittleGiantPump.com