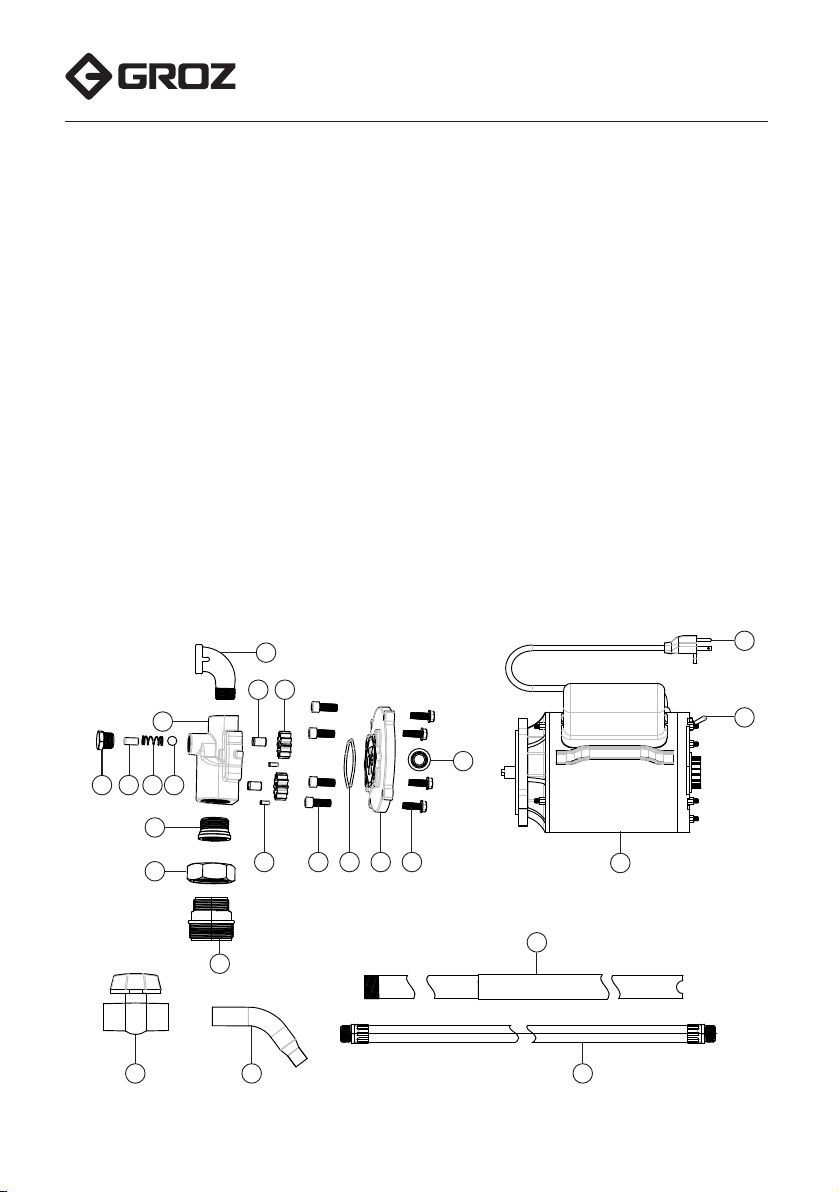

2

• Male threads between the 2 suction tube

(19) parts

• Male threads on the suction tube (19) end

that fits into the pump inlet.

2. Now hand tighten the elbow (10) to the pump

outlet. Once the elbow (10) can no longer be

hand tighten, take the adjustable spanner &

tighten the elbow (10) by about half a turn.

Open end of the elbow (10) should be facing

away and not in the direction of the motor (1).

3. Take the bung adaptor (14) & hand tighten it

onto the 2" drum opening. Bung adaptor (14)

has a large 2" thread & a small 1-1/2" thread. 2"

thread goes into the drum, whereas the 1-1/2"

thread is for connecting the bung adaptor (14)

to the pump.

4. Connect the two halves of the suction tube

(19). Now connect the suction tube (19) to the

pump inlet and hand tighten it.

5. Lift the pump from the handle and insert the

suction tube (19) into the drum through the 2"

opening on the drum. Use the convenient spin

collar (13) mounted at the pump inlet to fasten

the pump onto the Bung adaptor (14).

6. Ensure that there is about 2" (50 mm) gap

between the bottom of the tank / drum & inlet

of the suction tube (19) allowing easy entry of

media into the suction tube (19).

7. Take about 30 ml of oil being dispensed &

pour it into the pump outlet through the elbow

(10). This will ensure that the gear (7) stays

lubricated & makes it easier for the pump to

prime.

8. Take the hose (20) & connect one threaded

end to the elbow (10) at the pump outlet. Hose

(20) has a hex nut at the threaded end which

can be tightened to the elbow (10) using

adjustable spanner.

9. Connect the other end of the hose (20) to the

ball valve (21).

10. Connect the discharge spout (22) to the ball

valve (21).

11. Turn the toggle switch (24) to ‘OFF’ (up)

position and connect the power cable (23) to

the AC power socket.

12. The pump is now ready for use.

In-line pump installation

This pump can additionally be mounted on a wall

for in-line operation. This is particularly done in a

shop environment where the pump may be used

with waste oil.

Note: For waste oil application, pump already has

a strainer installed at the bottom of the suction

tube (19).

Pump can be installed using a mounting bracket

(not provided, but can be ordered separately).

This bracket is a simple right angle bracket with

two mounting holes that uses the motor (1)

mounting holes on one side of the motor (1) to

attach it to the bracket. The bolts (6) used to

SAFETY INFORMATION

• Keep the work area clean and dry. Damp or

wet work areas can result in injury.

• Store idle equipment. When not in use, tools

and equipment should be stored in a dry

location to inhibit rust

• Use the right tool for the job. Do not attempt

to force small equipment to do the work of

larger industrial equipment.

• Do not modify this equipment and do not use

this equipment for a purpose for which it was

not intended.

• Check for damaged parts. Before using this

product, carefully check that it will operate

properly and perform its intended function.

Replace damaged or worn parts immediately.

WARNING!

• Read and understand all instructions. Failure to

follow all instructions listed above may result in

electric shock, fire and/or serious injury.

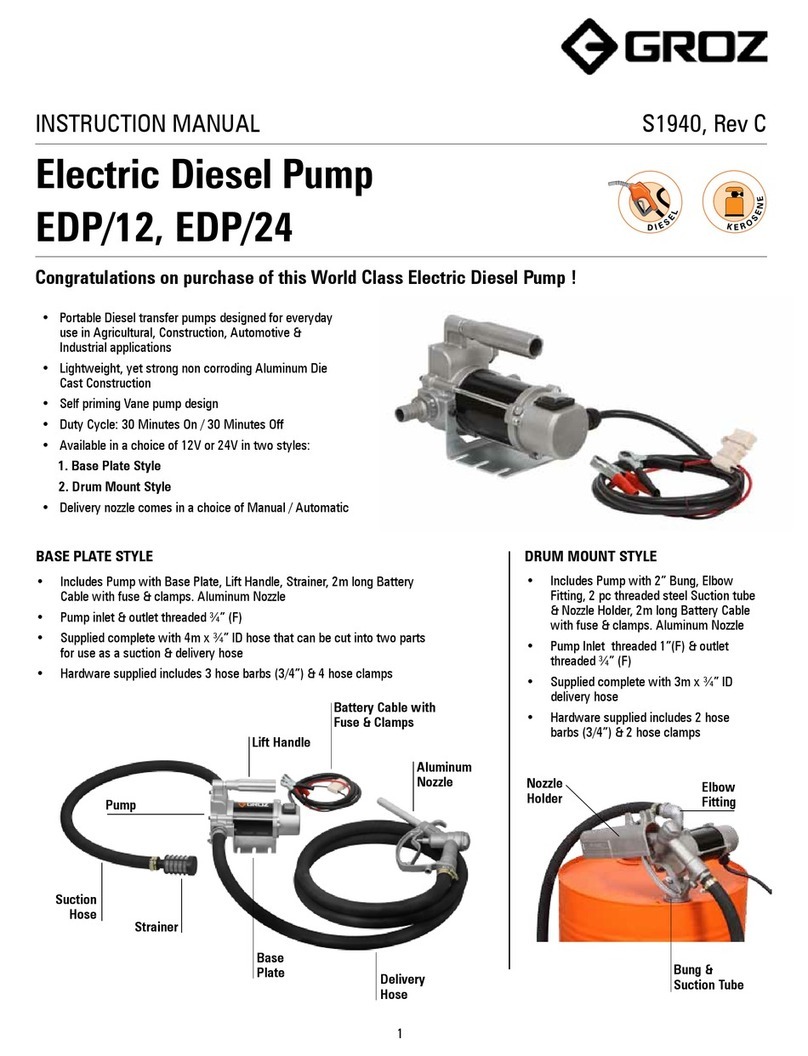

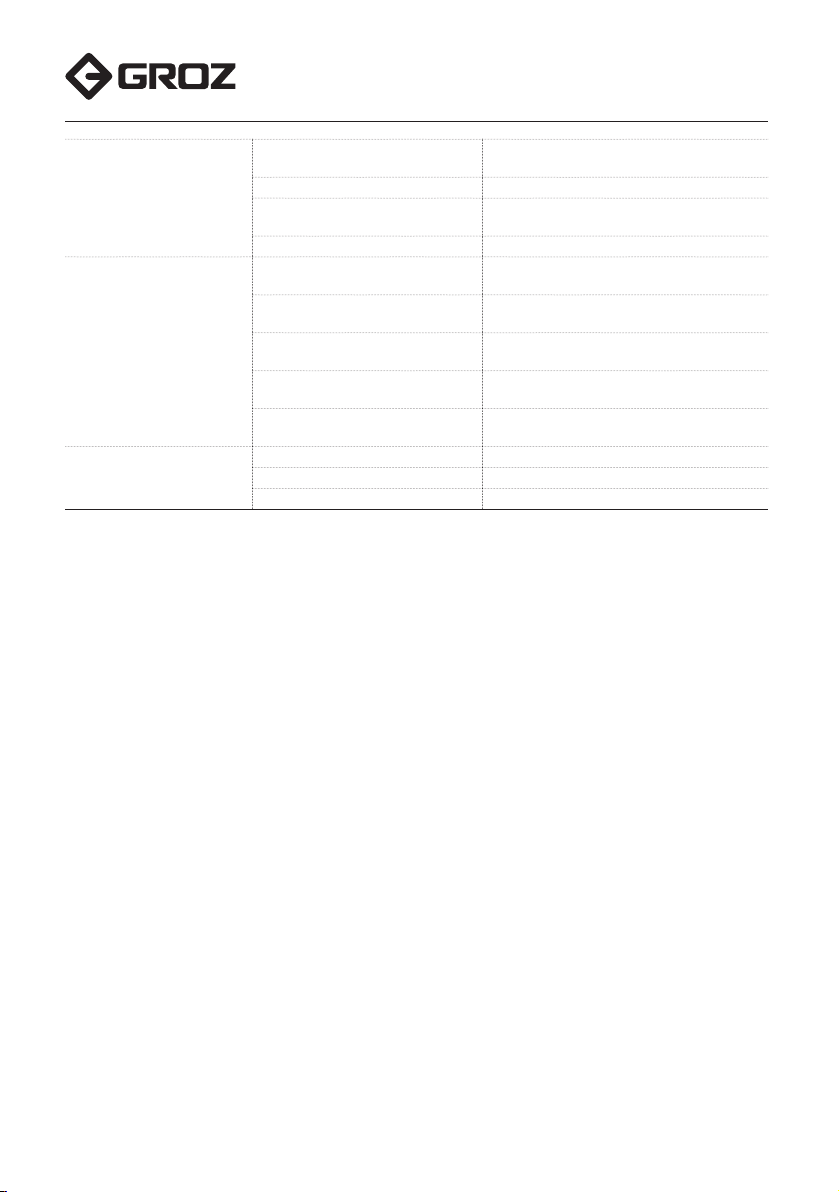

PACKAGE CONTENT

DESCRIPTION QUANTITY

Pump & motor assembly fitted with power cable 1

Suction tube (2 parts) 1

Bung adaptor 1

Elbow 1

Hose 1

Ball valve 1

Discharge spout 1

PTFE tape 1

O.I.P.M. 1

TOOLS NEEDED

• Adjustable spanner

BEFORE INSTALLATION

• Eyes protection: Wear a protective mask or

protective eyewear.

• Skin protection: Avoid repeated and

prolonged contact of fluids with the skin by

wearing impermeable protective gloves.

• Check that the product has not suered any

damage during transport or storage. Clean the

inlet and outlet openings, removing any dust

or residual packing material.

• Keep the pump away from heat and sharp

edges. Check the pump for wear and make

certain that all connections are secure.

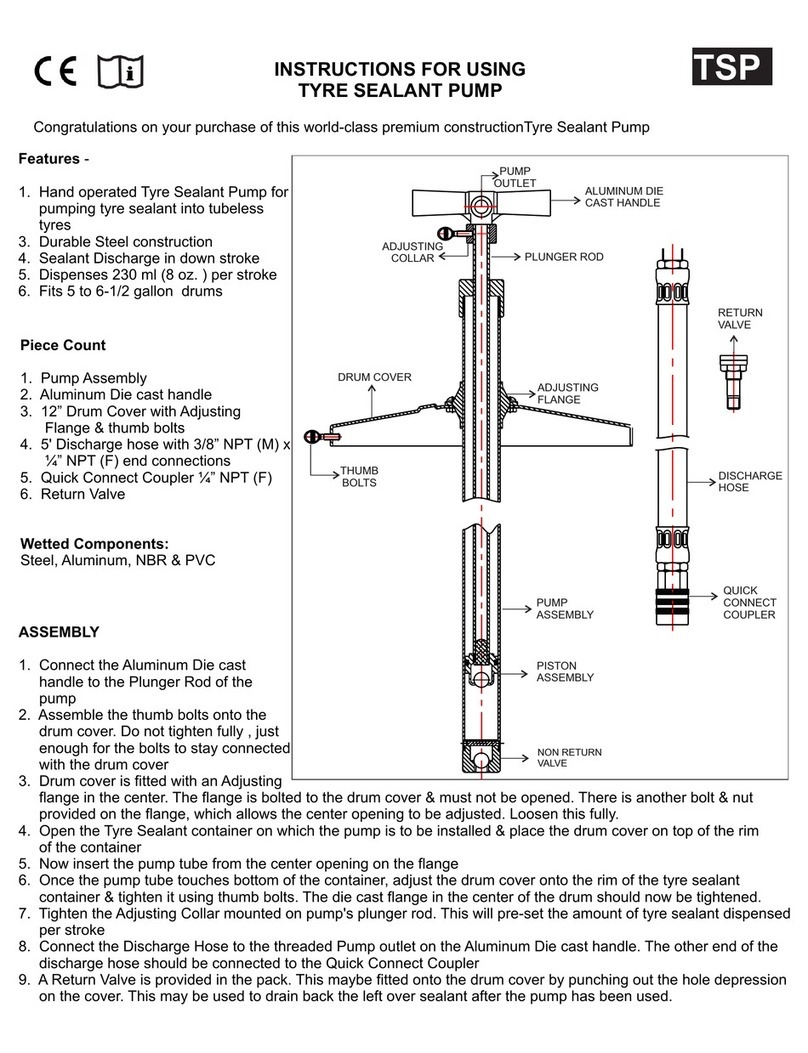

INSTALLATION

(Refer “EXPLODED VIEW”)

1. Wrap around PTFE tape on the following male

threaded joints. This will ensure a leak-proof

connection

• Male threads on the elbow (10)

• Male threads on the fitting ends of the hose

(20)

OPM.indd 2 12-09-19 4:02:14 PM