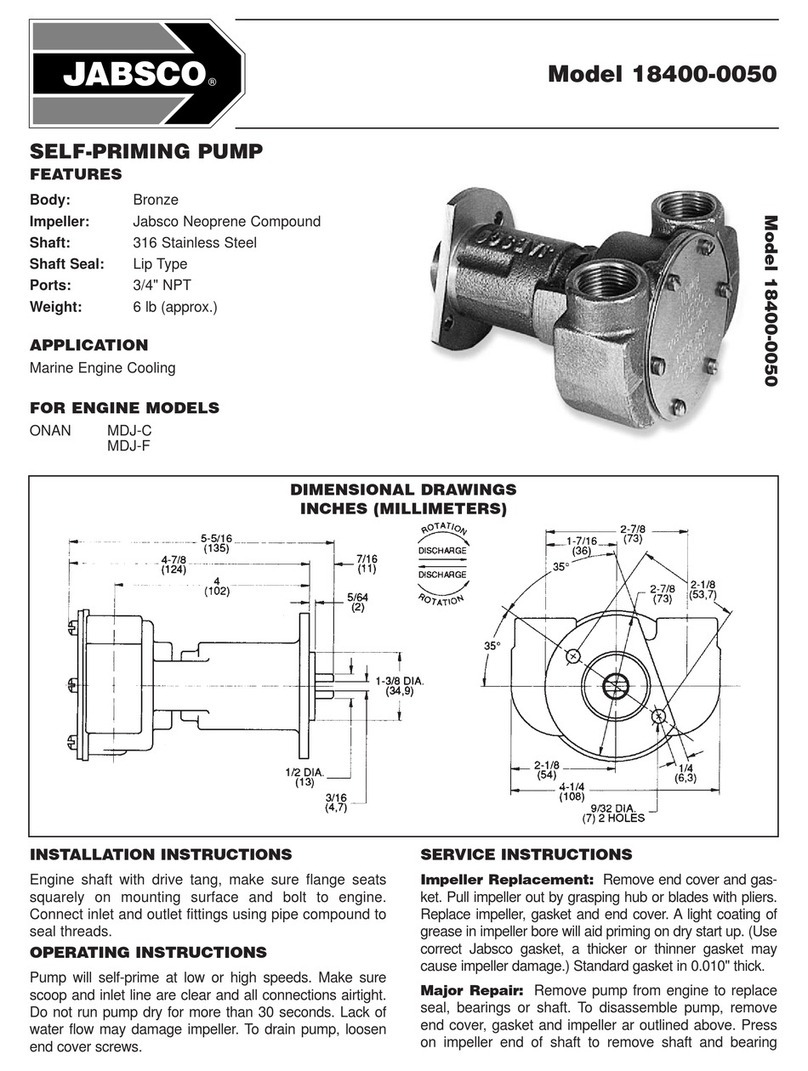

SERVICE INSTRUCTIONS

IMPELLER REPLACEMENT: Remove end cover gasket. Pull

impeller out by grasping hub with pliers. With rotary motion in the

direction the pump will be turning, push the impeller into the impeller

bore. A light coating of grease in the impeller bore will protect the

impeller during initial dry start up. Install gasket and end cover.

SHAFT SEAL REPLACEMENT, 11870-SERIES: Remove end cover,

gasket and impeller, as outlined above. Loosen cam screw several

turns. Give cam screw a couple of sharp raps with the handle of the

screwdriver to loosen the cam from the impeller bore. Remove the cam

screw and cam (clean sealant from cam and impeller bore). Remove

wearplate with hooked wire. Remove marcel washer, seal assembly

and seal s eat assembly from seal bore with hooked wire, taking care

not to scratch shaft or seal seat bore. Clean shaft surfaces behind

splines and inspect for scratches or wear. Replace if necessary.

Before installing new seal parts, clean any oil or grease from carbon

and ceramic seal faces. Dip seal seat and gasket assembly in water

and press into seal bore with boot first. Dip carbon seal assembly in

water and install over shaft, carbon towards ceramic seal seat, until it

bottoms firmly against ceramic seat. Slide marcel spring washer over

shaft and against the rubber boot (washer) on carbon seal assembly.

Replace wearplate, aligning notch with dowel pin in body. Apply sealant

to top surface of cam and cam screw threads and install cam in

impeller bore. Snug up but do not tighten cam screw. Replace

impeller, gasket and end cover as outlined above. Tighten end cover

screws. Tighten cam screw.

SHAFT SEAL REPLACEMENT, 11860-SERIES: Refer to major repair

instructions.

FIELD COIL REPLACEMENT: Remove drive belts from pulley.

Remove center bolt and washer from pulley (it may be necessary to

remove end cover to hold impeller from turning, while removing center

pulley bolt). Tap pulley with soft mallet to remove from shaft taper.

Remove 3 bolts and washers holding field coil to adaptor (11870) or

body (11860). Remove and replace field coil, tightening the 3 bolts

securely. With drive key in place in shaft, replace pulley assembly.

Secure to shaft, replace pulley assembly. Secure to shaft with center

bolt and washer (again, it may be necessary to hold the impeller from

turning to tighten center bolt). Replace drive belts. Do not over tighten

belts. A deflection of 1/2" midway between pulleys is generally con-

sidered normal.

MAJOR REPAIR: Remove pump from installation for major repair.

Disassembly: Remove end cover, gasket,impeller, cam and

wearplate as outlined in shaft seal replacement, 11870-Series.

Remove clutch as outlined in field coil replacement. Model 11870-

Series: Use a punch to drive roll pins (key 17) in toward shaft approx-

imately 3/8" (10mm). Remove clutch adaptor from body. Punch roll

pin out of adaptor. Model 11860-Series does not have adaptor, clutch

is secured directly to body. Remove bearing to body retaining ring.

Support bearing end of body on arbor press platten. Press on impeller

end of shaft to remove shaft and bearing assembly from body. Use

screwdriver to pry inner bearing seal from body. Take care not to

scratch or damage body bore.

11860-SERIES: Remove seal seat assembly from shaft. Support

impeller end of body on arbor press platten and, using suitable tube,

press seal out of seal bore towards impeller end.

11870-SERIES: Remove slinger from drain area. Carbon portion of

the seal assembly will be freed from shaft when shaft is remove

from body. Press seal seat assembly from bearing bore end towards

impeller bore.Remove bearing to shaft retaining ring. Support bear-

ing and press on clutch drive end of shaft to remove shaft from

bearing.

ASSEMBLY: Support inner race of bearing on arbor press platten.

Oil shaft, insert drive end of shaft into bearing and press shaft

through bearing until it bottoms firmly against shoulder.Install shaft

to bearing until it bottoms firmly against shoulder. Install shaft to

bearing retaining ring in groove of shaft. Support impeller bore end

of pump on arbor press platten.

Lubricate bearing seal with grease and press into bearing seal bore,

flush with bearing bore shoulder, with lip facing away from bearing

bore. For 11870-Series only: Insert slinger in drain slot, to be picked

up by shaft during shaft/bearing assembly. Insert splined end of

shaft through bearing seal (and slinger on Model 11870-Series).

Press on outer bearing race to assemble shaft/bearing assembly

into body, bottoming bearing firmly against bearing bore

shoulder.Install body to bearing retaining ring in groove in body with

flat side against bearing. For 11870-Series only: Install clutch adap-

tor in bearing bore. If re-using adaptor previously disassembled from

pump, line up dowel pin holes during assembly of adaptor to body.

If installing new adaptor (which does not have pre-drilled dowel pin

holes), insert into bearing bore until it bottoms and use dowel pin

holes in body to pilot drill dowel pin holes through adaptor in two

places, 180° apart. Clean any brass chips from bearing area. Press

roll pins into body to secure adaptor. Attach field coil to adaptor

(11870-Series) or body (11860-Series) with three round head bolts.

Turn body over and support on field coil.

11860-SERIES: Dip seal seat assembly, consisting of ceramic seal

seat and rubber washer, in water and push over shaft, with shiny

side of ceramic facing impeller bore, until bottoms firmly against

shaft shoulder. Press on outside edge of seal case with carbon seal

face towards ceramic seat to install seal assembly in seal bore.

Press flush with bottom of impeller bore.

11870-SERIES: Assemble rubber boot over ceramic seal seat so

that shiny surface of seal seat is outwards. Dip assembly in water

and insert into seal bore. Press firmly but carefully on seal seat until

it bottoms against shoulder of seal bore. Check to see that the seal

seat assembly remains in position and does not “pop” back out. A

slight twisting motion while pressing will seat it firmly in position.In

this pump, either a wave washer seal or coil spring carbon seal may

be used. The wave washer is used only if the carbon portion of the

seal does not have a coil spring attached.

Inspect shaft and seal seat bore to be sure sealing surfaces are free

of nicks or scratches. Clean shaft surface behind splines to ensure

proper O-ring seal on shaft. Apply light film of grease on shaft sur-

face behind spline area. Slide carbon ring assembly, with carbon fac-

ing ceramic, over the shaft and firmly up against the ceramic seat.

If carbon portion of seal does not have an integral coil type ten-

sioning spring, slide wave washer over the shaft and against the rub-

ber boot on metal case containing O-ring and carbon. Install

wearplate in bottom of impeller bore, locating slot in outside edge of

wearplate over dowel pin in body. Apply a small amount of sealant

to surface of cam and cam screw threads and install cam in impeller

bore. Edge of cam should be flush with flange face of body. With a

rotary motion in the direction the pump will be turning, push the

impeller into the impeller bore until it is firmly bottomed. Turn body

over to install clutch pulley assembly. Press key into shaft. Position

clutch/pulley assembly on shaft aligning key with slot in pulley hub.

Secure with bolt and washer. To tighten bolt securely, it may be nec-

essary to hold the impeller to prevent the shaft from turning. Turn

pump assembly over. Dip gasket in water, position on pump flange

face, install end cover and secure with end cover screws.