Updated 4/21/2023 © 2023 LittleMachineShop.com Page 3of 54

Contents

Introduction ................................................................................................5

Specifications...............................................................................................5

Safety Considerations .....................................................................................6

General Safety...........................................................................................6

Milling Machine Safety..................................................................................6

Electrical Safety.........................................................................................6

Machine Safety ..........................................................................................7

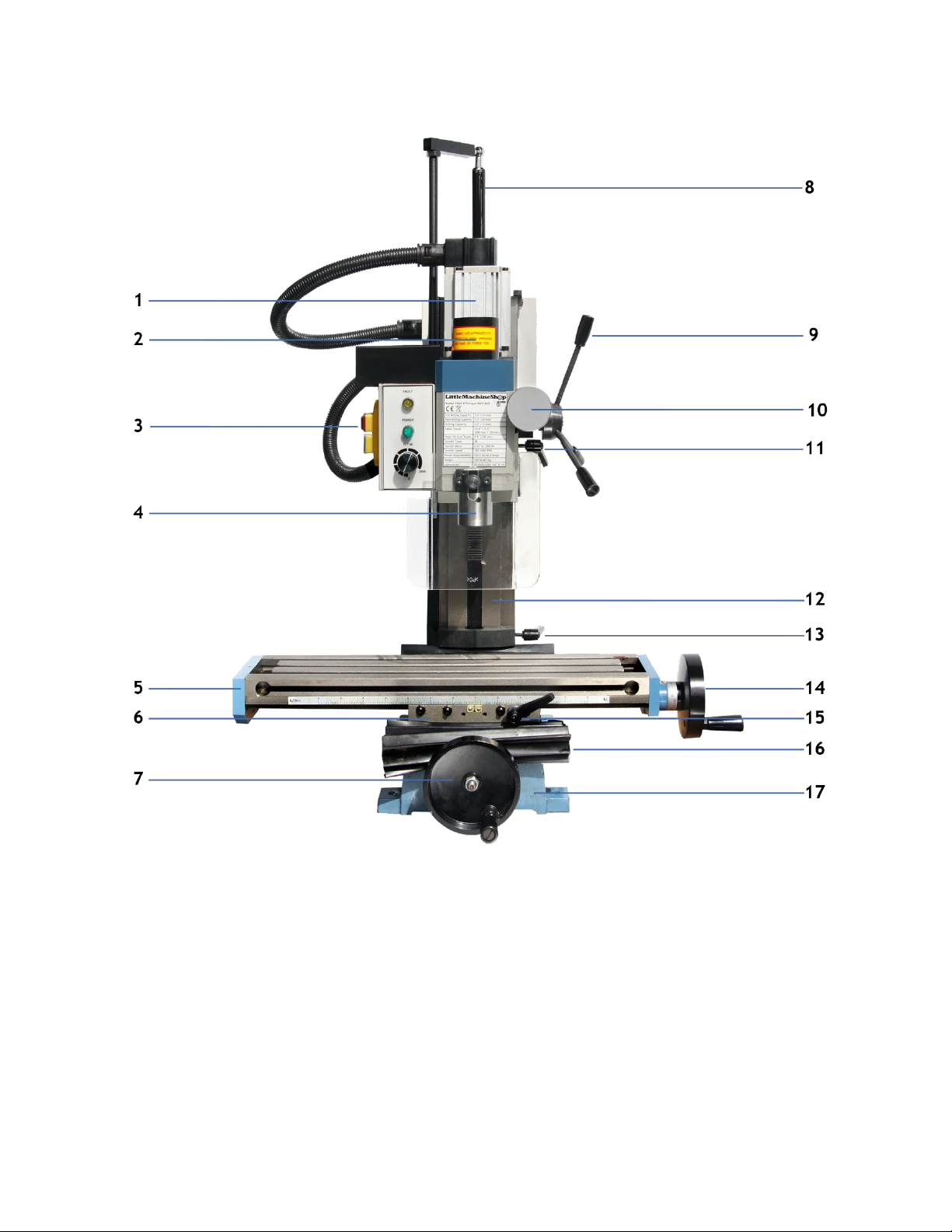

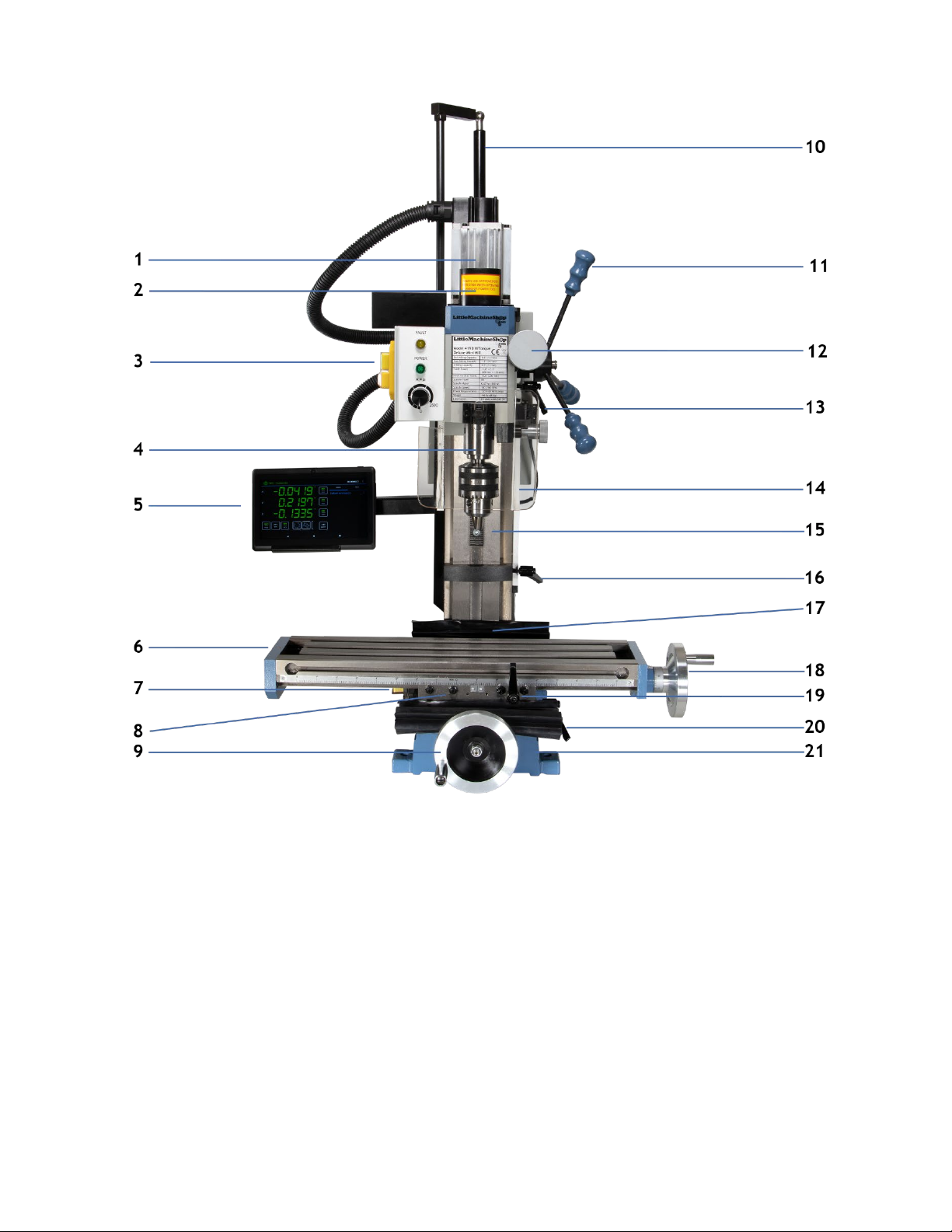

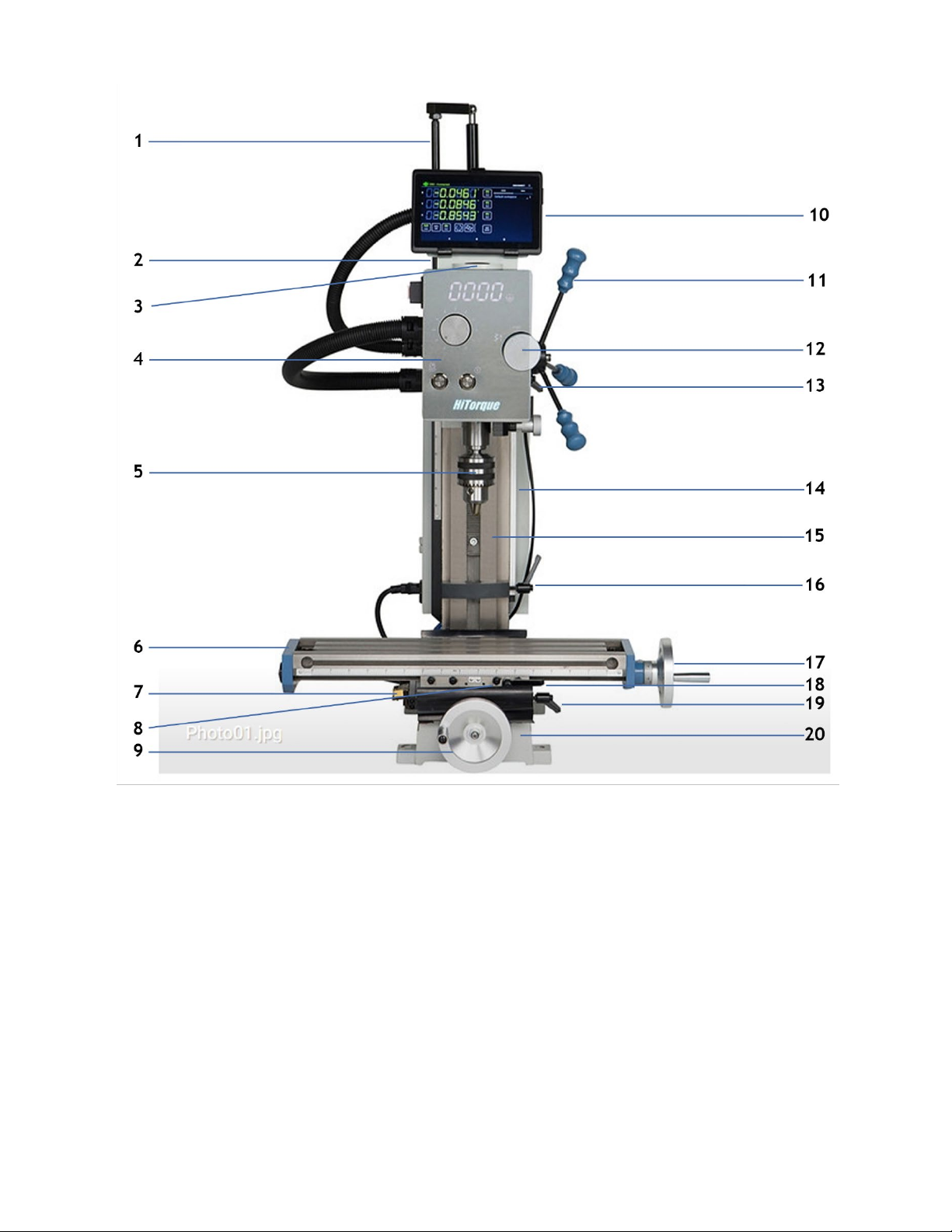

Features .....................................................................................................8

Basic Accessories......................................................................................... 11

Cleaning ................................................................................................... 11

Assembly .................................................................................................. 11

Mounting Your Mill ....................................................................................... 12

Operating Controls....................................................................................... 13

Motor Controls ......................................................................................... 13

Using the Motor Controls............................................................................. 15

X-Axis Hand Wheel .................................................................................... 16

X-Axis Lock Lever ..................................................................................... 16

Y-Axis Hand Wheel .................................................................................... 16

Y-Axis Lock Lever ..................................................................................... 17

Z-Axis Coarse Feed Handles ......................................................................... 17

Z-Axis Fine Feed Knob ................................................................................ 17

Z-Axis Lock Lever...................................................................................... 17

Bluetooth DRO (Models 4190 & 6450) ................................................................. 18

Using the app .......................................................................................... 19

Axis detail settings.................................................................................... 20

Absolute vs incremental coordinates............................................................... 20

Points and workspaces ............................................................................... 21

Tools .................................................................................................... 21

Starting a work piece................................................................................. 22

Centering a work piece............................................................................... 22

Adjustments .............................................................................................. 24

X-Axis Gib .............................................................................................. 24

Y-Axis Gib .............................................................................................. 25

Z-Axis Gib .............................................................................................. 25

Tramming the Mill..................................................................................... 25

Lubrication................................................................................................ 27