Billet Trim Tab Installation

Installing the pumps and hydraulic lines:

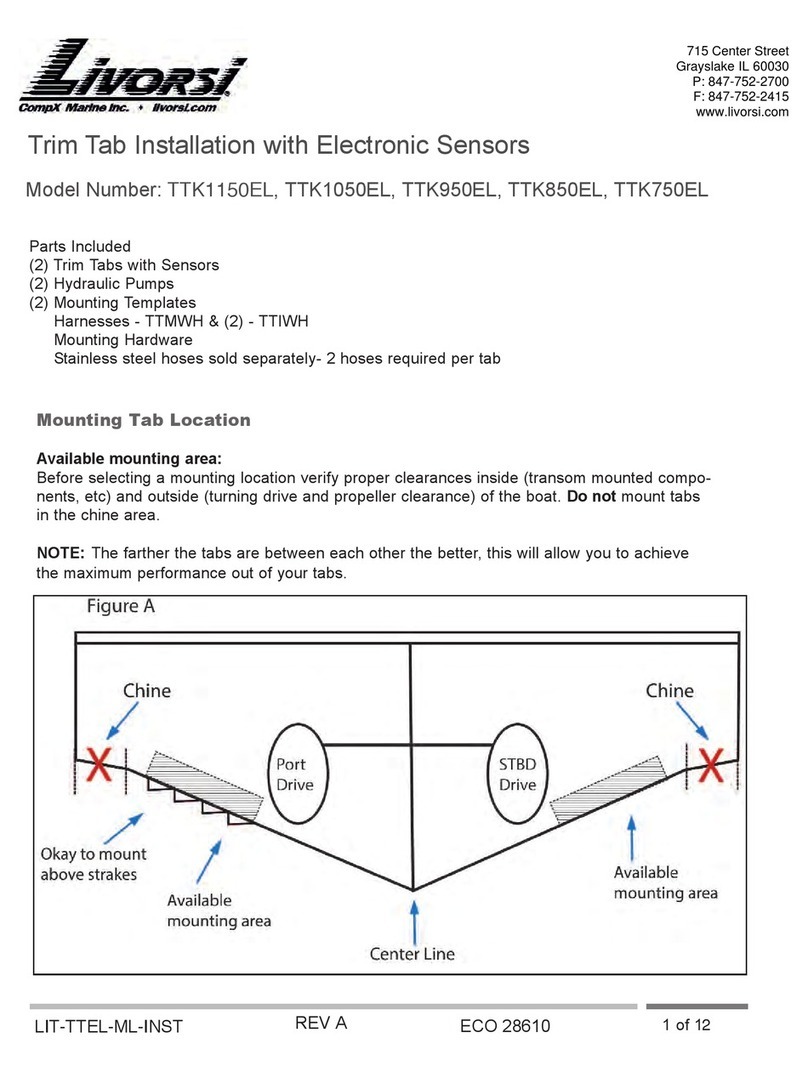

Select the location to mount the hydraulic pumps.

NOTE: Keep pumps as level as possible.

Once mounted, route the hydraulic lines from the tab to the pump. Make sure hydraulic lines

are routed and secured away from any moving components in the boat..

Mount the tab:

If the Livorsi Trim Tabs are replacing existing tabs, make sure to seal any unnecessary holes on the

transom. Use a high quality marine sealer suitable for underwater use.

Recommended sealant: Marine Grade RTV / silicone sealant 4200 or 5200.

Use this same sealer and apply liberally around each fastener, indicator wires and between transom

and upper trim plate. It is recommended to apply the same sealant to the inside of the boat.

You may want to apply a piece of tape to the ends of the hydraulic thru hull fittings to prevent debris

from entering the openings.

If equipped with the electronic sensor carefully feed the sensor wires thru the transom.

Secure all mounting hardware.

STARBOARD PORT

4 of 12

LIT-TTEM-MM-INST REV A ECO 28610