15

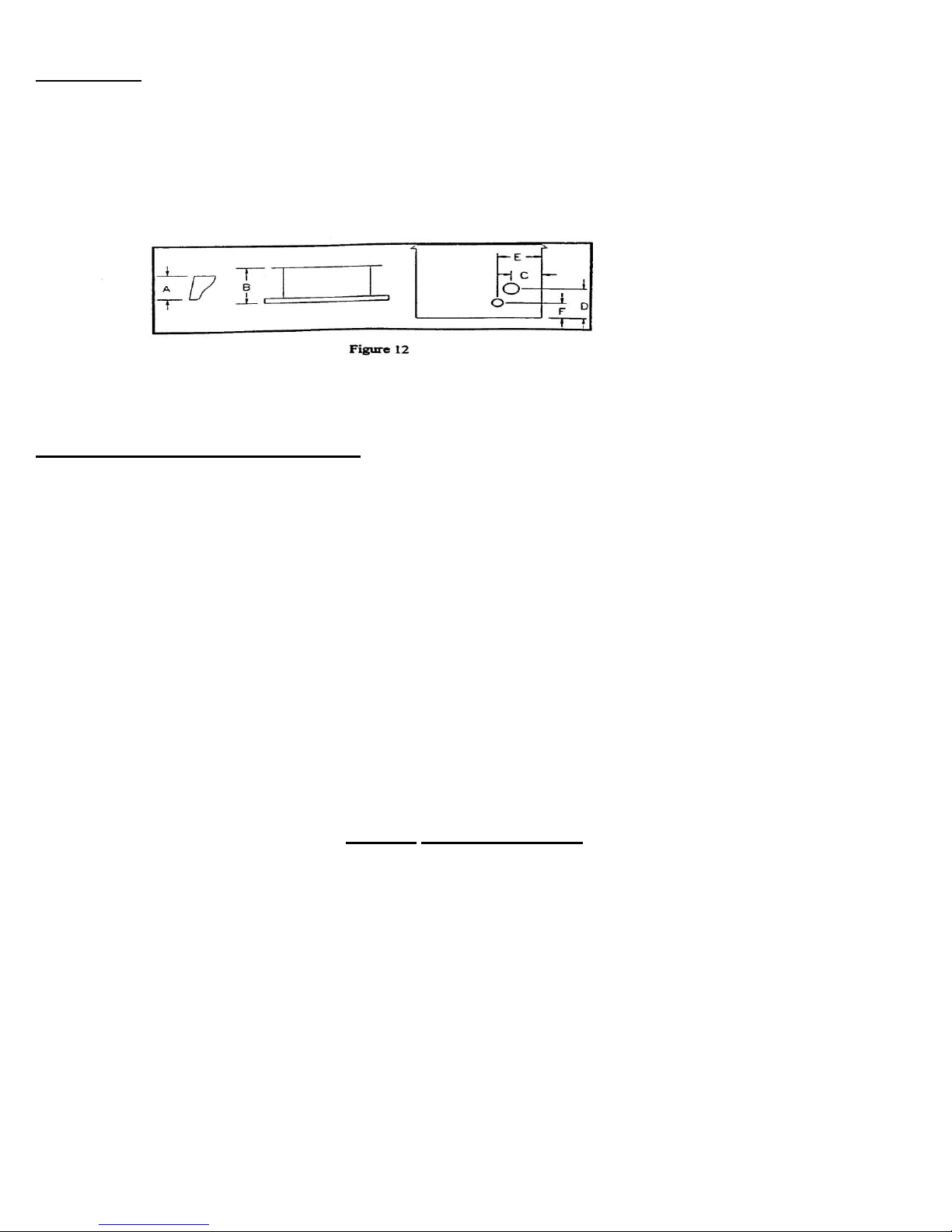

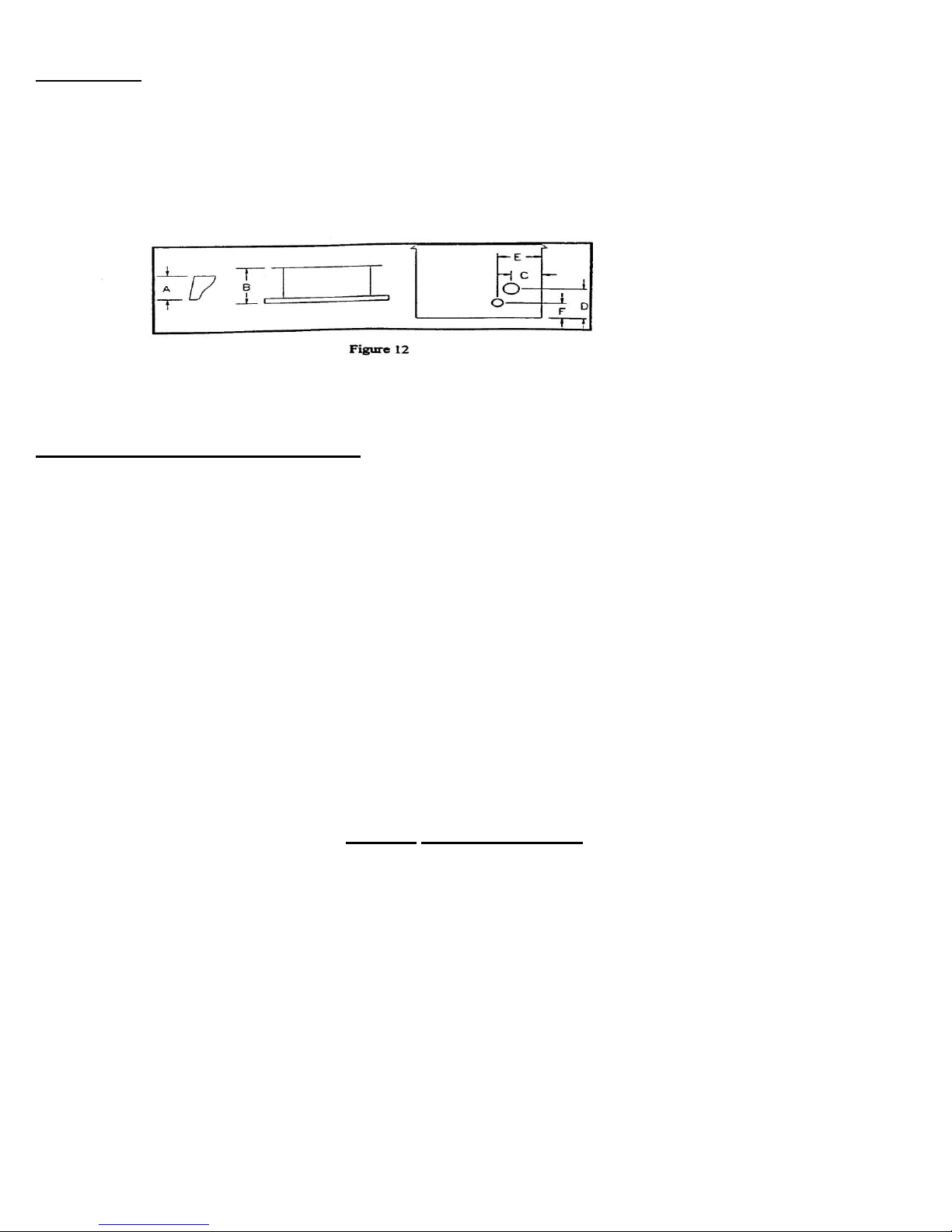

DIMENSION: Leg, pedestal, exhaust outlet and outside air outlet dimensions are (Figure 12)

Legs (A) 6 ¼” 6 ¼” Under Stove

Pedestal (B) 9 ½” 9 ½” 9 ½” From Stove’s Left Side

Center of the (C ) 3 7/8” 3 7/8” 3 7/8” 3 7/8” From Stove’s Left Side

Exhaust pipe (D) 7 5/8” 7 5/8” 7 5/8” 7 5/8” From Stove’s Bottom

Center of the (E) 8 3/8” 8 3/8” 83/4” 8 1/8” From Stove’s Left Side

Outside air (F) 3 7/8” 3 7/8” 3 7/8” 3 7/8” From Stove’s Bottom

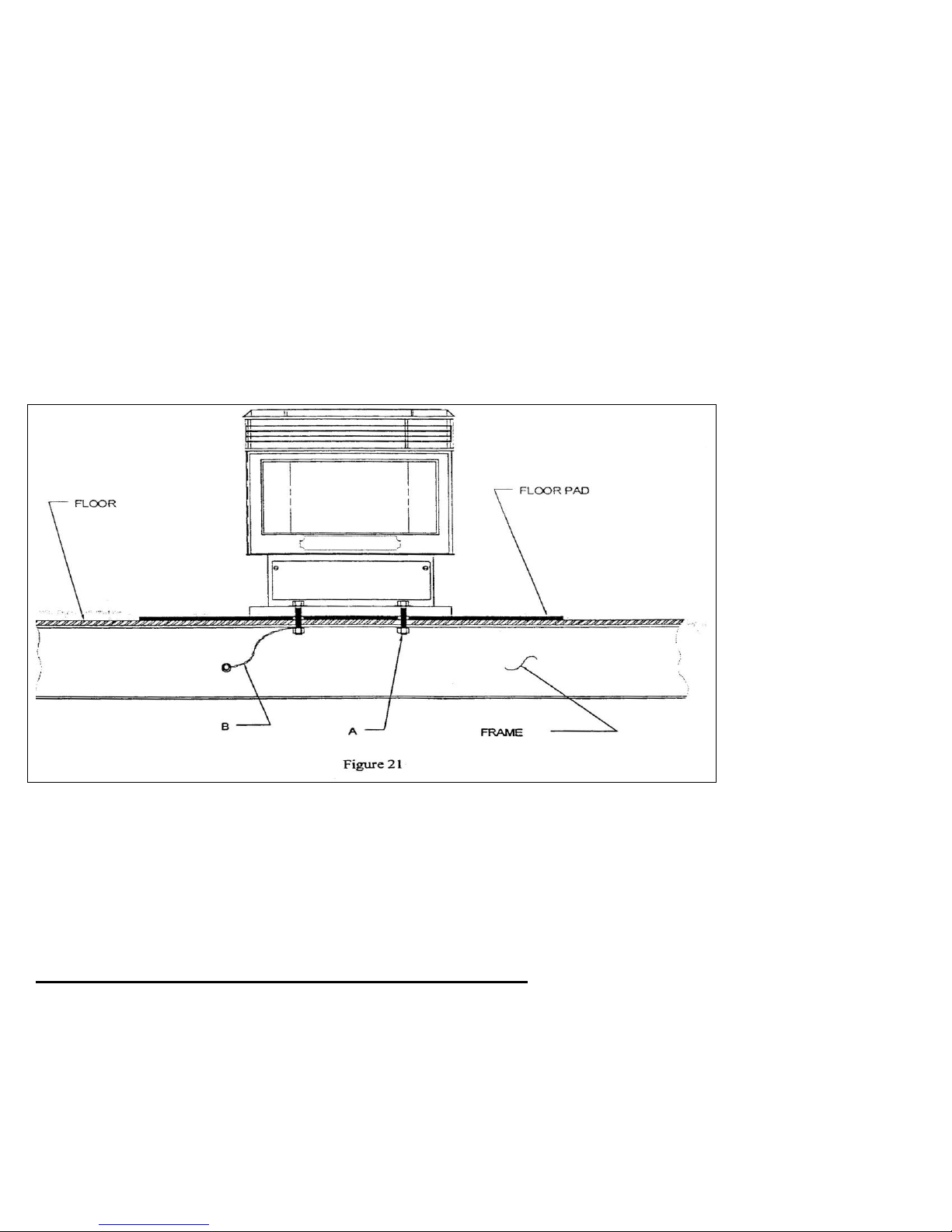

STOVE INSTALLATION

Through the wall, direct installation. (Figure 13)

1. Select the location for your stove, design and exhaust system and determine the brand and size

of “PL” vent to be used.

2. Following the “PL” vent manufacturer’s specifications, mark and cut a hole through the wall to

accommodate the wall thimble, (A), and the outside air pipe, (B), if outside air is to be used. Install

the wall thimble, (A).

3. Position the floor pad, (C). Insert the proper size of “PL” vent, (D) through the wall thimble, (A).

Place your stove on the floor pad, (C ) close to its final position. Leave room to connect the “PL”

vent to your stove. Place a bead of RTV silicone around the end of your stove’s exhaust pipe, (E).

Connect the length of “PL” vent, (D) which is in the thimble, (A), onto the stoves exhaust pipe (E).

Place your stove in its final position on the pad. Note: If 4” PL vent is required, use an increaser,

(K), on the stove exhaust pipe.

4. Required: On the outside of the building attach a 45 degree “PL” type elbow, (F) onto the end of

the horizontal “PL” vent, (D). Optionally, place a rodent screen cap, (G), (may be required in some

locals), on the end of the elbow, (E), (HIGHLY RECOMMENDED: RATHER THAN A 45-DEGREE

ELBOW outside of the bldg. AFTER ITEM D FIRST ATTACH a 90-degree elbow to the

horizontal “PL” vent. Place a 5’ length section of “PL” vent (NOT SHOWN IN DIAGRAM)

going up, and then attach a 90-degree elbow to the vertical section. This will give system

some natural draft, which will evacuate smoke in the event of a power failure.

5. If outside air is used, install the outside air pipe, (B). Seal the outside air pipe, (B), to your stove’s

outside air pipe, (I) with RTV silicone. Make sure the outside air pipe fits over, (not inside) your

stove’s outside air pipe, (I). Install either a 90-degree elbow on the end of the outside air pipe, (H) or

install a windshield, (J).