LOBSTER ARF-810E User manual

CONTENTS

英語/ENGLISH

ARF-810E

INTRODUCTION…………………………… 1

IMPORTANT SAFETY INSTRUCTIONS… 2

NOMENCLATURE……………………… 6

TECHNICAL DATA………………………… 7

PREPARATION BEFORE USE…………1 0

HOW TO OPERATE………………………11

CHANGE SIZE OF RIVETS………………13

CHANGE OF THE RIVETER USED……15

MAINTENANCE………………………… 1 6

ORDERING PARTS……………………… 1 6

TROUBLESHOOTING………………… 1 7

PARTS TABLE…………………………… 1 8

MODEL CHANGE AND PARTS LIST…22

AUTO RIVET FEEDER

AIR RIVETER

INSTRUCTION MANUAL

Professional

model

of

air

riveter

to

install

blind

rivets.

Thank you very much for purchasing “LOBSTER” air riveter. To ensure correct operation, please read

this instruction manual carefully, and keep it in a safe place for later reference.

CONTENTS

IMPORTANT

SAFETY

INSTRUCTIONS.................................1

NOMENCLATURE .............................3

TECHNICAL

DATA ...........................4

PREPARATION

BEFORE

USE .......5

OPERATING

THE

AIR

RIVETER ....7

MAINTENANCE .................................8

STORAGE........................................12

TROUBLESHOOTING .....................15

PARTS

TABLE ................................13

ORDERING

PARTS .........................14

MANUFACTURER

PRINTED IN JAPAN

英語/ENGLISH

BUILT-IN ON-DEMAND

VACUUM SYSTEM

R1A1

INSTRUCTION MANUAL

Professional model of auto rivet feeder to install blind rivets.

・Thank you very much for purchasing “LOBSTER” auto rivet feeder. To ensure correct operation,

please carefully read this instruction manual and keep it in a safe place for later reference.

・This is Original instructions.

Osaka 579-8053, Japan

12-8 Shijo-cho, Higashi-Osaka City

Telephone: +81(72)981-7466 Telefacs: +81(72)981-9420

URL https://www.lobtex.co.jp/

MANUFACTURER

International Marketing & Sales Division

AIR RIVETER

INSTRUCTION MANUAL

Professional

model

of

air

riveter

to

install

blind

rivets.

Thank you very much for purchasing “LOBSTER” air riveter. To ensure correct operation, please read

this instruction manual carefully, and keep it in a safe place for later reference.

CONTENTS

IMPORTANT

SAFETY

INSTRUCTIONS.................................1

NOMENCLATURE .............................3

TECHNICAL

DATA ...........................4

PREPARATION

BEFORE

USE .......5

OPERATING

THE

AIR

RIVETER ....7

MAINTENANCE .................................8

STORAGE........................................12

TROUBLESHOOTING .....................15

PARTS

TABLE ................................13

ORDERING

PARTS .........................14

MANUFACTURER

PRINTED IN JAPAN

英語/ENGLISH

BUILT-IN ON-DEMAND

VACUUM SYSTEM

R1A1

PRINTED IN JAPAN No .AF810ES11000

英語/ENGLISH

1

● INTRODUCTION

・This is the feeder for "LOBSTER" brand blind rivet which can be used with "LOBSTER" brand

riveter. It is not designed, produced or sold for any other purpose.

・This instruction manual shows how to operate and perform maintenance and inspection in

order to use safely and efficiently.

・ Use appropriate blind rivet which is fully designed and meets specications.

1

1

1

2

・Our warranty does not apply to direct and indirect damages and lost income caused by the

misuse, abuse, and unauthorized modification of the machine.

We do not guarantee the strength or quality of blind rivet.

・We do not guarantee any damages and failures caused by any modifications without our

written approval.

・We do not guarantee any damages and failures caused by use of parts other than our

recommendation.

IMPORTANT NOTICES

INDEMNIFICATION

・Read this manual carefully before using this machine. Follow instructions in this manual for

handling this machine, replacing accessories or parts as needed.

・If you have any questions, check the model (type)and contact the

“LOBSTER” dealer where you purchased the machine.

・It is impossible to foresee all potential dangers and describe them in this manual.

You must use this machine paying attention to safety as well as observing the instructions

in this manual.

・Lobtex Co., Ltd. has the copyright of this manual. It is prohibited to publish, copy or translate

to other language without prior consent.

2

英語/ENGLISH

◆Be sure to read the following Important Safety Instructions carefully and make sure that you

understand them thoroughly before using this machine.

1.Always wear protective goggles while you use the machine.

・The rivets may jump out by accident and cause injuries (e.g. blindness).

・Use a dust mask, safety shoes, hard hat and hearing protector appropriately to prevent accidents

and injuries.

2.Make sure that the machine and the power cable are connected securely.

3. Prior to use, check for damage to respective parts, and ensure that all parts are able to operate

normally and provide the functions specified. If they are unable to operate normally or provide the

functions specified, do not use them, but arrange for a repair by a competent person.

・ If the machine is used while any parts are damaged, injury may result.

・If the machine is damaged by objects being dropped onto it, the damaged part may break and

accident or injury may result.

・ When replacing or cleaning parts, observe the instructions in the instruction manual.

If you cannot nd the relevant instructions in the manual, arrange to have arepair carried out by

the supplier you purchased the product from, or by Lobtex.

・ If there is no power to the equipment even though the power switch is turned on, or the machine

cannot be started when the start button is pressed, do not use the machine.

Otherwise, it may operate abnormally, causing injuries.

4.Install and use on a stable work table that is horizontal and free from vibration.

・ Otherwise, the machine may not be able to achieve performance as specied, or it may be

dislodged, leading to breakage, injury, or damage.

・If you install it on the oor, there is a risk that people may step on it.

5.Keep the machine away from children.

・ Accidents or injury may result.

6.Do not use the machine in rain or in a wet place.

・ Accidents or injury may result.

1

日本語/JAPANESE

安全上のご注意

◆ご使用前に、この「安全上のご注意」すべてをよくお読みのうえ、十分理解されて正しく使用して

ください。

◆本機をご使用中は、必ず保護めがねを着用してください。切断されたリベットのマンドレルが飛び

出し傷害を及ぼす恐れがあります。

◆ここに示した注意事項は と に区分けしていますが、それぞれの意味は下記の通りです。

t警 告 t注 意

:誤った取扱いをした場合、使用者が死亡または重傷を負う可能性が想定される内容

のご注意

:誤った取扱いをした場合、使用者が傷害を負う可能性が想定される場合、及び物的

損害のみの発生が想定される内容のご注意

なお、 に記載した事項でも重大な結果に結び付く可能性があります。いずれも安全

に関する重要な内容を記載していますので、必ず守ってください。

t注 意

1. 使用空気圧0.49〜0.59MPa(5〜6kgf/cm2)を守ってください。

¡使用空気圧を超えて使用しますと、本機が破損して傷害や損傷を及ぼす恐れがあります。

2. 必ず安全カバーを取り付けてお使いください。

¡切断されたリベットのマンドレルが飛び出し傷害を及ぼす恐れがあります。

3. シリンダー部からの給油の際は必ずフレームヘッドをはずしてください。

¡フレームヘッドをはずさずに給油すると余分な油圧オイルが入り、本機が破損してけがをする恐れ

があります。(油止めネジ部からの給油はのぞく)

4. 本機とエアー源との接続は確実に行なってください。

¡ジョイントのネジが合わなかったり、ネジの入りしろが不十分であった場合、使用中にエアーホー

スがはずれてけがをする恐れがあります。

¡エアーホースジョイントとエアーホースの接続はホースバンドを用いて確実に行なってください。

接続が不十分ですと使用中にエアーホースがはずれてけがをする恐れがあります。

5. 本機をエアー源からはずす時は、エアーの供給を止めてください。

¡圧縮空気によりエアーホースが跳ねたりして、けがをする恐れがあります。

6. ご使用前に各部の損傷がないかをチェックし、損傷がある場合は、使用せずに修理に出して

ください。

¡損傷がありながら使用しますとけがをする恐れがあります。

¡物を落とすなどしてホースに傷等が生じますと、その部分が破損して事故やけがの原因になります。

¡工アーホースを持って本機を引きするなどしますと、本体に傷が生じたり、二ツプルが破損したり、

その他作動不具合が生じたりして、事故やけがをする恐れがあります。

~~~~~~~~~~~~~

~~~~~~~~~~~~~~

◆お読みになった後は、お使いになる方がいつでも見られる所に必ず保管してください。

t警 告

t注 意

t警 告

AR-2000S-M-H(A)取扱(日):AR-2000S_M-H(A)取扱(日) 14/08/25 11:49 ページ 1

◆Do not put your hands in the machine or close to the moving parts while you are using the

machine. Otherwise your hand may be caught and injury may result.

● IMPORTANT SAFETY INSTRUCTIONS

◆After reading this manual, keep it in a safe place where it is easily accessible to machine users.

IMPORTANT

SAFETY

INSTRUCTIONS

◆ Be sure to read the following Important Safety Instructions carefully and make sure that you

understand them thoroughly before using this tool.

◆ Always wear eye-protection at all times during use. If this is not observed, the cut mandrels

may eject out when the rivets are cut and cause serious injury.

◆ This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

◆ The Important Safety Instructions are divided into and .

The differences between these two levels are described below.

CAUTION

WARNING

: Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury to the operator.

: Indicates a potentially hazardous situation which, if not avoided, may result in moderate

injury to the operator or physical damage.

Moreover, failure to follow the instructions marked with the symbol or cautions without a

symbol which appear in the text of this manual may also have serious results in some cases.

Always be sure to observe the instructions given in the Important Safety Instructions.

CAUTION

CAUTION

CAUTION

WARNING

1.

The

air

pressure

should

be

kept

within

the

range

of

0.49

to

0.59

MPa

(5

to

6

kgf/cm2,

71

to

85

psi).

If an air pressure which is greater than this is used, the tool may become damaged, and injury or

damage to property may result.

2.

Never

look

into

the

nosepiece

of

the

tool,

and

never

point

the

nosepiece

toward

other

persons.

If the tool is used while the cut mandrels are still inside the tool not being ejected, these mandrels may

be ejected from the tool’s nosepiece during use and cause serious injury.

3. Always

attach

the

tank case

unit

before

use.

If this is not observed, the cut mandrels may be ejected when the rivets are cut and cause serious

injury.

4. Wear

protective

glasses

during

use.

Failure to do so may result in an accident or personal injury in case that a rivet or a piece of cut-mandrels

jumps out toward you.

5. Make

sure

that

the

tool

and

the

air

source

are

connected

securely.

If the threads of the joints do not match or if the screws are not inserted far enough, the air hose may

become disconnected during use and injury may result.

Use hose bands to securely connect the air hose joint and air hose. If they are not connected securely

enough, the air hose may become disconnected during use and injury may result.

6. Turn

off

the

air

supply

before

disconnecting

the

tool

from

the

air

source.

Compressed air may cause the air hose to whip around, and injury may result.

7. Check

that

all

the

tool

parts

are

free

from

damage

before

use.

Any

damaged

parts

should

be

repaired

before

the

tool

is

used.

If the tool is used while any parts are still damaged, injury may result.

If the tool is damaged by objects being dropped onto it, for instance, the damaged part may break and

accident or injury may result.

Don't pull and drag the tool by the air hose. It may trigger some damages on the tool body, breakage of

Rotary Joint or some other defects and lead serious troubles with injuries.

8. If

using

in

elevated

locations,

use

a

safety

harness,

and

take

care

to

avoid

dropping

rivets

or

the

tool

itself.

Accident or injury may result if this practice is not followed.

◆ After reading this manual, keep it in a safe place where it is easily accessible to tool users.

WARNING

英語/ENGLISH

1

1. Before

starting

maintenance

or

disassembling

the

unit

to

replace

parts,

be

sure

to

stop

air

supply.

Performing maintenance or disassembly with air supplied may cause a part to jump out, oil to squirt out,

or the unit to perform unexpected behavior, and may result in an accident or personal injury.

3.

2.

Do

not

operate

the

tool

with

the

Frame

Head ‘CJM’

removed .

Tighten

the

Bleed

Plug

firmly

before

use.

Items such as fingers may become caught in the mechanism.

If the Bleed Plug is loose or coming off during use, oil may squirt out resulting in an accident or personal

injury.

4. Do

not

bring

your

face

close

to

the

air

outlet

holes.

Pressurized air containing fine particles is discharged from the air outlet holes during use. Keep eyes

away from this area.

5. Avoid

skin

contact

with

substances

such

as

hydraulic

oil,

lubricating

oil

and

grease.

Such substances may cause inflammation of the skin. If they come into contact with your skin, wash

the affected area thoroughly.

6. The

parts

to

be

used

must

be

those

supplied

from

us

or

recommended

by

us.

Select

and

attach

parts

applicable

to

your

rivet.

Otherwise the unit may not produce maximum performance and may sometimes malfunction resulting

in an accident or personal injury.

7. Make

sure

that

the

workplace

is

safe,

clean

and

organized.

Accidents can easily occur in untidy workplaces.

If the cut-mandrels are allowed to fall onto the floor, you may slip on them, and injury may result.

8. Avoid

uncomfortable

postures

while

working.

You may fall down and injury may result.

9. Keep

people

who

are

not

involved

in

work

away

from

the

workplace.

Accidents or injury may result.

10. Maintain

the

tool

with

due

care.

Refer to the Instruction Manual for details on replacing parts and attachments, otherwise injury may occur.

11. Keep

the

handgrip

always

dry

and

clean,

and

avoid

adhesion

of

oil

and

grease.

Otherwise the grip may slip from your hand resulting in falling of the unit.

12. Do

not

leave

the

floor

littered

with

cut-mandrels.

Cut-mandrels are dangerous because their ends are sharp. Stepping on them is also dangerous easily

causing a slip and fall accident.

13. Use

the

tool

carefully

and

concentrate

on

correct

operation

at

all

times.

Use the tool with proper care, paying full attention to methods of handling and operation and

surrounding conditions. Accidents and injury may result if this practice is not followed.

Use common sense at all times, otherwise accidents or injury may result.

When you are tired, do not use the tool, otherwise accidents or injury may result.

14.

Ask

Lobtex

to

carry

out

any

repair

work

required.

Repair work should only be carried out by a qualified technician. Please contact your nearest

“LOBSTER” distributor, representative, or direct to Lobtex Co., Ltd., Osaka. If the tool is repaired by

someone without the necessary qualifications and experience, the tool may not perform to optimum

standards, and accidents or injury may result.

15.

Do

not

attempt

to

modify

the

tool.

Unauthorized modifications may cause malfunctions which can lead to accidents or injury.

16.

Only

for

EU

countries,

do

not

dispose

of

electric

tools

together

with

household

waste

material

!

In observance of European Directive 2002/96/EC on waste electrical and electronic equipment and

its implementation in accordance with national law, electric tools that have reached the end of their

life must be collected separately and returned to an environmentally compatible recycling facility.

CAUTION

英語/ENGLISH

2

◆This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

◆Always wear protective goggles while using the machine.

The rivets may jump out by accident and cause injuries.

◆These Important Safety Instructions are divided into and .

The dierences between these two levels are described below.

: Indicates a potentially hazardous situation which, if ignored, may result in death

or serious injury to the operator.

: Indicates a potentially hazardous situation which, if ignored, may result in moderate

injury to the operator or physical damage.

Moreover, failure to follow the instructions marked with the symbol or cautions without a

symbol which appear in the text of this manual may also have serious results in some

cases. Always be sure to observe the instructions given in the lmportant Safety Instructions.

⚠WARNING

⚠WARNING

⚠CAUTION

⚠CAUTION

⚠CAUTION

⚠CAUTION

⚠WARNING

1

日本語/JAPANESE

安全上のご注意

◆ご使用前に、この「安全上のご注意」すべてをよくお読みのうえ、十分理解されて正しく使用して

ください。

◆本機をご使用中は、必ず保護めがねを着用してください。切断されたリベットのマンドレルが飛び

出し傷害を及ぼす恐れがあります。

◆ここに示した注意事項は と に区分けしていますが、それぞれの意味は下記の通りです。

t警 告 t注 意

:誤った取扱いをした場合、使用者が死亡または重傷を負う可能性が想定される内容

のご注意

:誤った取扱いをした場合、使用者が傷害を負う可能性が想定される場合、及び物的

損害のみの発生が想定される内容のご注意

なお、 に記載した事項でも重大な結果に結び付く可能性があります。いずれも安全

に関する重要な内容を記載していますので、必ず守ってください。

t注 意

1. 使用空気圧0.49〜0.59MPa(5〜6kgf/cm2)を守ってください。

¡使用空気圧を超えて使用しますと、本機が破損して傷害や損傷を及ぼす恐れがあります。

2. 必ず安全カバーを取り付けてお使いください。

¡切断されたリベットのマンドレルが飛び出し傷害を及ぼす恐れがあります。

3. シリンダー部からの給油の際は必ずフレームヘッドをはずしてください。

¡フレームヘッドをはずさずに給油すると余分な油圧オイルが入り、本機が破損してけがをする恐れ

があります。(油止めネジ部からの給油はのぞく)

4. 本機とエアー源との接続は確実に行なってください。

¡ジョイントのネジが合わなかったり、ネジの入りしろが不十分であった場合、使用中にエアーホー

スがはずれてけがをする恐れがあります。

¡エアーホースジョイントとエアーホースの接続はホースバンドを用いて確実に行なってください。

接続が不十分ですと使用中にエアーホースがはずれてけがをする恐れがあります。

5. 本機をエアー源からはずす時は、エアーの供給を止めてください。

¡圧縮空気によりエアーホースが跳ねたりして、けがをする恐れがあります。

6. ご使用前に各部の損傷がないかをチェックし、損傷がある場合は、使用せずに修理に出して

ください。

¡損傷がありながら使用しますとけがをする恐れがあります。

¡物を落とすなどしてホースに傷等が生じますと、その部分が破損して事故やけがの原因になります。

¡工アーホースを持って本機を引きするなどしますと、本体に傷が生じたり、二ツプルが破損したり、

その他作動不具合が生じたりして、事故やけがをする恐れがあります。

~~~~~~~~~~~~~

~~~~~~~~~~~~~~

◆お読みになった後は、お使いになる方がいつでも見られる所に必ず保管してください。

t警 告

t注 意

t警 告

AR-2000S-M-H(A)取扱(日):AR-2000S_M-H(A)取扱(日) 14/08/25 11:49 ページ 1

1.Before starting maintenance or disassembling the unit to replace part, be sure to take off

power cable.

・ By unexpected action such like parts jumps out may cause accidents.

2.When you handle grease, obtain the safety data sheet (SDS) from the supplier, and follow the

described instructions.

3.The parts to be used must be those supplied from Lobtex or recommended by Lobtex.

Select and attach parts applicable to your rivet.

・ Otherwise the unit may not produce maximum performance and may malfunction resulting in an

accident or personal injury.

4.Make sure that the workplace is safe, clean and organized.

・ Accidents can easily occur in untidy workplaces.

5.Ensure sound footing and do not work in an unnatural posture.

・ You may fall and injure yourself.

6.Keep people who are not involved in work away from the workplace.

・ Accidents or injury may result.

7.Avoid a sudden start of the machine. Before connecting it to the power supply, confirm that the

switch is not turned on.

8.When replacing parts or accessories, follow the steps specified.

9.Be sure to use the provided AC adapter for the power supply.

10.Wear clothes appropriate for work. Cover long hair with a cap or hair cover.

Do not wear loose clothes or accessories including necklaces.

・ Otherwise, your hair, clothes, or accessories may be caught in the machine.

11.Do not use the machine if it cannot be started or stopped using its switches.

・ Otherwise, it may operate abnormally, leading to injuries. Arrange for a repair by a competent

person.

12.Keep the machine away from children. Prevent anyone except for workers from touching a power

cable or the machine.

・ Otherwise, it may lead to injuries.

13.Check thoroughly for damage to the machine. If any loose or damage to parts are found, do not

use the machine, but arrange for a repair by a competent person.

・ Failure to perform this step may lead to accidents or injuries due to malfunctions.

14.Use specified accessories or replacement parts only.

・ Otherwise, unexpected motion of the machine may be caused, leading to accidents or injuries.

15.Be sure to turn off the power before performing work such as changing the rivet size.

16.Never put your hand inside the rotating drum

・Otherwise, unexpected motion of the machine may be caused, leading to accidents or injuries.

・ Be sure to take out the remaining rivets by riveter supply

17.Do not intentionally press the switch that is pressed by opening and closing the lid (rivet slot).

18.Use specified genuine parts only, and only allow persons having technical knowledge and skills to

repair the machine.

・ If no such competent person is available, arrange to have a repair carried out by the supplier

you purchased the product from or by Lobtex.

19.If the machine is faulty or any abnormal noise is heard while in use, immediately turn off the switch

to stop it, and arrange to have a repair carried out by the supplier you purchased the product from

or by Lobtex.

・ Continued use of the equipment may cause injuries.

3

英語/ENGLISH

⚠WARNING

⚠CAUTION

7.Maintain the machine with proper care.

・ Refer to the Instruction Manual for details on replacing parts and attachments, otherwise injury

may occur.

8.Use the machine carefully and concentrate on correct operation at all times.

・ Use the machine with proper care, paying full attention to methods of handing and operation and

surrounding conditions. Accidents and injury may result if this practice is not followed.

・ Use common sense at all times, otherwise accidents or injury may result.

・ When you are tired, do not use the machine, otherwise accidents or injury may result.

9.Ask Lobtex to carry out any repair work required.

・ If you nd any fault, arrange to have an inspection and a repair.

・ Repair work should only be carried out by a qualified technician. Please contact your nearest

“LOBSTER” distributor, representative, or direct to Lobtex Co.,Ltd.,Osaka. If the machine is

repaired by someone without the necessary qualifications and experience, the machine may

not perform to optimum standards, and accidents or injury may result.

10.Do not modify the machine. Any modification to the equipment impairs the validity of safety devices

leading to a higher risk to operators.

・ This machine conforms to applicable safety standards. Do not modify it.

Otherwise, accidents or injuries caused by abnormal operation may occur.

11.When disposing of the machine or packing materials, observe local laws and codes on waste

disposal.

12.The year and month of production of the machine is indicated by a code and four-digit number on

the warning seal. (See page 6)

13.Warning seal include important information and tips on using the machine. If the labels become so

dirty or damaged that they cannot be read, order and replace them with new labels.

You can order new labels from Lobtex Co., Ltd. through our dealers.

14.This machine is a feeder for professional use. Operators who use it for the first time must

understand its instruction manual completely before maintaining or using the machine.

・ If the machine is broken, do not operate.

15.Slips, trips and falls are major causes of injury at workplace. Be aware of trip hazards caused by

power cable.

16.This machine is not intended for use in potentially explosive atmospheres and is not insulated

against contact with electric power.

17.Preventative maintenance should be carried out, after a specified time of operation, a specified

number of cycles/operations or a stated number of times per year.

18.Store the machine appropriately when not in use.

・ Store it in a dry and high place where it can be locked away or is out of the reach of children.

Otherwise, it may cause injury.

19.Do not use more than ability.

・ Use the equipment according to the capacity of the machine and in accordance with its design

specication. Use of the machine incorrectly may lead to accidents.

20.Do not handle any power cable roughly.

・ Do not pull the power cable to remove it from the receptacle outlet.

・ Keep the power cable away from heat, oil, and sharp edges.

・ Pay close attention to prevent the power cable from being stepped on, hooked, or damaged by

the use of excessive force. Otherwise, it may cause an electric shock or a short-circuit, leading to

re.

英語/ENGLISH

4

⚠CAUTION

英語/ENGLISH

5

21.Check for damage to respective parts prior to use and arrange for a repair by a competent person

if any damage is found.

・ Check thoroughly for damage to respective parts prior to use and ensure that the machine

operates normally and the specied functions can be provided.

・ When replacing or cleaning parts, observe the instructions in the instruction manual. If you cannot

nd them in the manual, arrange to have a repair carried out by the supplier you purchased the

product from, or by Lobtex.

・ If there is no power to the equipment even though the power switch is turned on, or the machine

cannot be started when the start button is pressed, do not use the machine.

Otherwise, it may operate abnormally, causing injuries.

22.If you find rust, or experience unusual odor, heat, or other abnormalities when using the machine

for the first time after purchase, do not use it, but contact the supplier you purchased the product

from, or contact Lobtex.

23.Keep your fingers away from around the rotating shaft or the inside of the machine.

・ Otherwise, your ngers may be caught, causing injury.

24.Using the machine repeatedly may cause fatigue in your hands, shoulders, neck, and other locations.

・ To avoid pain and fatigue, assume an appropriate and natural posture, and change your

posture as necessary.

・ If you suer from continuous discomfort, pain, numbness, palpitations, stiness, or hot

flashes, do not ignore it. Consult with your employer and health manager.

⚠CAUTION

6

英語/ENGLISH

■ ACCESSORIES ■ Check at the time of purchase

・Easy guide

・AC adapter AIKOH ELECTRONICS CORP. AKA-12030 (Input AC100-240V Output 12V 3.0A)

・Tweezers

◇ Substance

◇ Front panel (operation buttons)

Start button

Power switch

Count display

LED(green) LED(red)

Button(Λ) Button(>) Reset button

Lock button Lock button

Power entry point External output

Warning seal

Supply port

(Frame Head Holder)

Front panel

Cover unit

Rivet slot

● NOMENCLATURE

・ Power Cable

Operating voltage DC 12V

Current consumption Below 1. 5A

Dimensions (Length×Height×Width)420mm ×350mm ×240mm

Weight 10.5kg

Operation-guaranteed

environment

Temperature 5~40℃

Relative humidity 80%RH max (No condensation)

Storage temperature range - 5~55℃

Noise 75dB or less

Cycle time 3min/pcs.

Basket capacity 1000pcs. (φ2.4 ・ φ3.2) ・ 500pcs. (φ4.0)

Frame head insertion port dia 21mm ・ 23mm

英語/ENGLISH

7

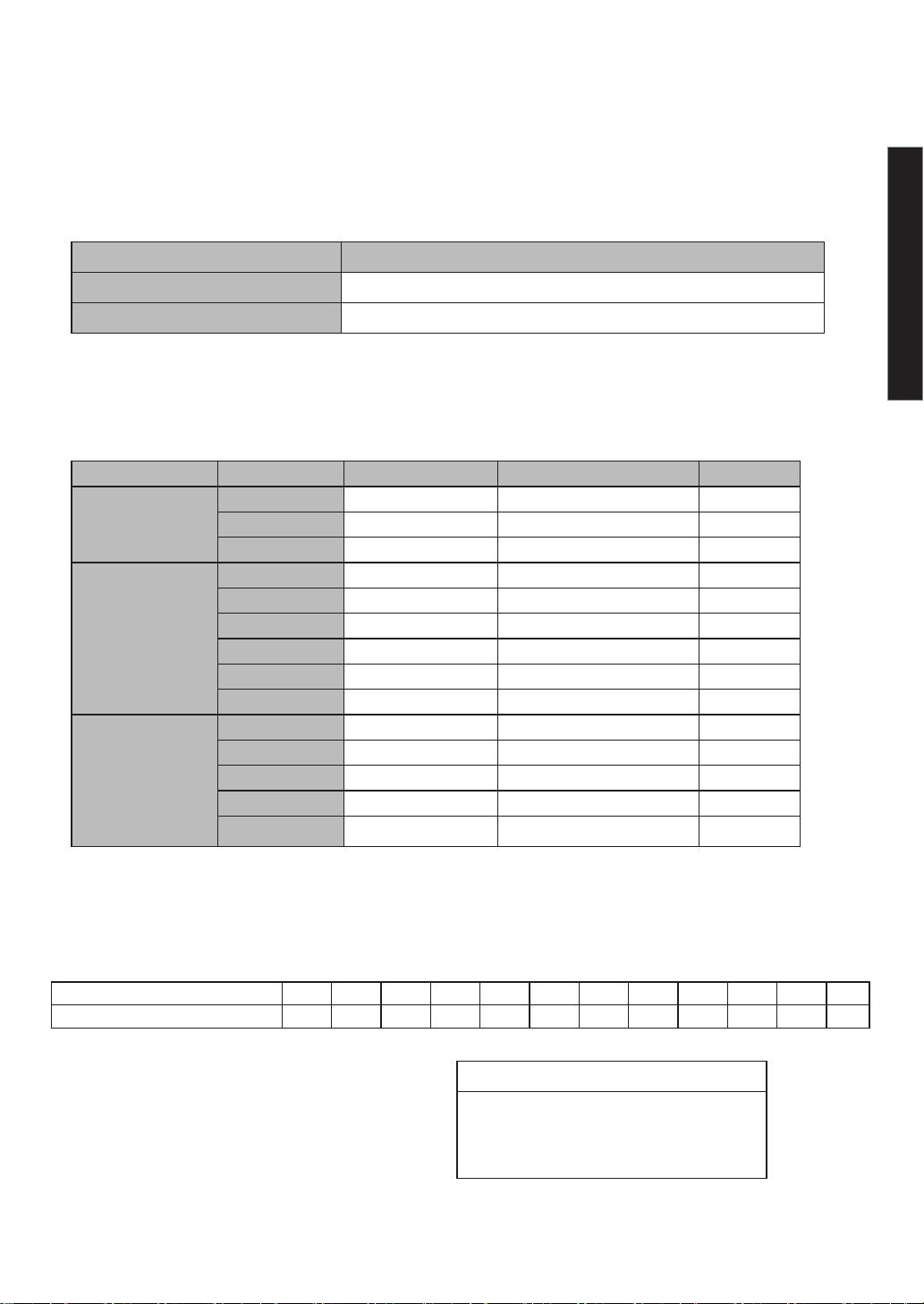

◇ MODEL

◇ Product specication

*Product specifications and design are subject to change for improvement without notice.

*Weight and dimensions given are standard values. Actual products may dier slightly from the

values given.

*The rating plate (warning plate attaching location) is on the back side of the machine.

*The year and month of production of the machine is indicated by a code and four-digit numbers.

*Measured at equivalent noise measurement level.

*Be careful not to exceed the basket capacity. If it is exceeded, it may cause a malfunction.

*When using a retaining Nosepiece, if a spent mandrel protrudes from it after riveting, you may not

pick up a rivet. Then push the rivet into the Nosepiece so that you can pick it up.

Frame head

holder diameter

21 21mm

23 23mm

Rivet diameter

24 2.4mm (Type 3)

32 3.2mm (Type 4)

40 4.0mm (Type 5)

ARF-810E-□-□

◇ Operating modes

Count display Operating modes Function

Total Count Mode

(TCNT)

Count the number of times rivet is picked up, which starts

from 0000.

Preset Count Mode

(PSET)

Count down the number of rivet you picked up, which starts

from the preset number. When coming down to 0000, the

number returns to preset number.

No-Count Mode

(NCNT)No counting. The display always shows "_ _ _ _ "

● TECHNICAL DATA

8

英語/ENGLISH

Rivet diameter Rivet size Round head rivet Countersunk head rivet AP rivet

φ2.4

3-2 ○ ○ 一

3-3 ○ ○ 一

3-4 ○ ○ 一

φ3.2

4-1 ○ 一 一

4-2 ○ ○ 一

4-3 ○ ○ ○

4-4 ○ ○ 一

4-5 ○ ○ ○

4-6 ○ ○ 一

φ4.0

5-2 ○ ○ 一

5-3 ○ ○ 一

5-4 ○ ○ ○

5-5 ○ ○ 一

5-6 ○ ○ 一

◇ Applicable riveter

Use R2B1 ・ R2A1 ・ R1A1 ・ AR2000MV ・ ARV011M ・

ARV015MX ・

ARV022M

ARV025M (can be used without vacuum function when using Retaining Nosepiece)

Use NSA・NTA・NA・NST・NSS・NS・AP・LST・or LSS For rivet sizes, see the list below.

*Do not insert anything other than the blind rivet to be used into the rivet slot (see P6).

*Use a riveter appropriate for the frame head holder.If dierent-size Frame Head is used, it does not

work properly.

Diameter of Frame Head Applicable riveter

21 R2B1 ・ R2A1 ・ R1A1 ・ AR2000MV

23 ARV011M ・ ARV015MX ・ ARV022M ・ ARV025M

◇ Rivet size

◇ How to read the year and month of production

Revision history of instruction manual

Item :Auto rivet feeder

Model : ARF-810E

Date of first edition: March 2023

M N

a year/month of manufucture 1 2 3 4 5 6 7 8 9 10 11 12

An English character A B M N K W T Y U O L Z

Exsample

year: 2023 month: 4 → BMN○○○○

↓ ↓ ↓

(Serial No.)

↓

B

9

英語/ENGLISH

◇ External output

◇ Error indication

The display and processing details when an error occurs are shown in the table below. If the

condition is not improve, stop using the product and contact the store where you purchased the

product or our call center.

Display Condition Cause Motion Return condition

motor lock Motor stopped due to rivet

clogging, etc. Behavior 1Remove the abnormality

and press the start button

motor overload Overload due to overcurrent,

overheating, etc. Behavior 1Remove the abnormality

and press the start button

Control board

failure Abnormality caused by the board Behavior 1Remove the abnormality

and press the start button

Voltage anomaly Power supply voltage exceeds

the range of 12V±10% Behavior 1Remove the abnormality

and press the start button

Rivet supply

abnormality

Insucient insertion of riveter,

rivet clogging near supply port,

etc.

Behavior 1

Press the start button while

the rivet is in the arrowed

part of the gure below.

No rivet

(LO-R)Rivet not aligning on a rail Behavior 2Replenish rivets and press

the start button

Terminal No Function

1for xing screws

2empty

3empty

4empty

5OUT 1(count up)

6OUT 2(preset completed)

7ground

8for xing screws

8 ← 1

Counting data can be output to an external device such as a PLC. The connecting way is as

below.

*The maximum electric current is 7mA.

*Do not connect to vacant terminals.

*Incorrect connection may cause failure.

【Behavior 1】

・Motor stop

・Buzzer sounds for 5 seconds

・LED red lights, LED green lights o

・Do not count up (down)

【Behavior 2】

・Motor stops

・Buzzer sounds for 3 seconds

・Count up (down) execution

*If rivets are clogged, open the front panel and remove the rivets. (See pages 6 and 13)

*If "Er05" appears, returning without rivets will cause a dierence in the number of counts.

main circuit

1

1Open the rivet slot and remove the rail spacer

(for transportation).

*Rivets cannnot be supplied if the spacer is left on the rail.

In addition, there is a risk of parts damage.

1

2

Put the rivet into the rivet slot.

*Maximum capacity is 1000 pcs (2.4 and 3.2mm rivet) or 500 pcs (4.0mm rivet).

*If rivets are on the rail, remove them.

*If you open the rivet slot during operation, the feeder stops.

1

3

Turn on the power "O"→"

l "

*The current operating mode is displayed for 3 seconds. The initial value is "total count mode".

*After the operation mode is displayed, the number counted last time blinks.The initial value is

"0000".

1

4

Press the start button

*Operation begins. Motion stops when a certain amount of rivets are aligned on the rail.

1

5

10

Insert the riveter into the supply port.

*Rivets are not supplied for the rst time.When the riveter is inserted into the supply port and

pulled out, the rivet is set in a state where it can be supplied, and the green LED lights up.

*After the second time, the buzzer sounds and the green LED ashes when the riveter is

inserted into the supply port and pulled out. rivets are supplied and the count number

changes.

*Be sure to insert the riveter until the buzzer sounds and the green LED ashes.

*Always activate the riveter vacuum when not using the retaining nosepiece.

1

6

Put the rivet into the rivet slot

Green LED lights

First time

Supply port

英語/ENGLISH

Connect a power cable to AC adapter and make it plugged in.

(Refer to cable entry point on P.6)

Rail spacer

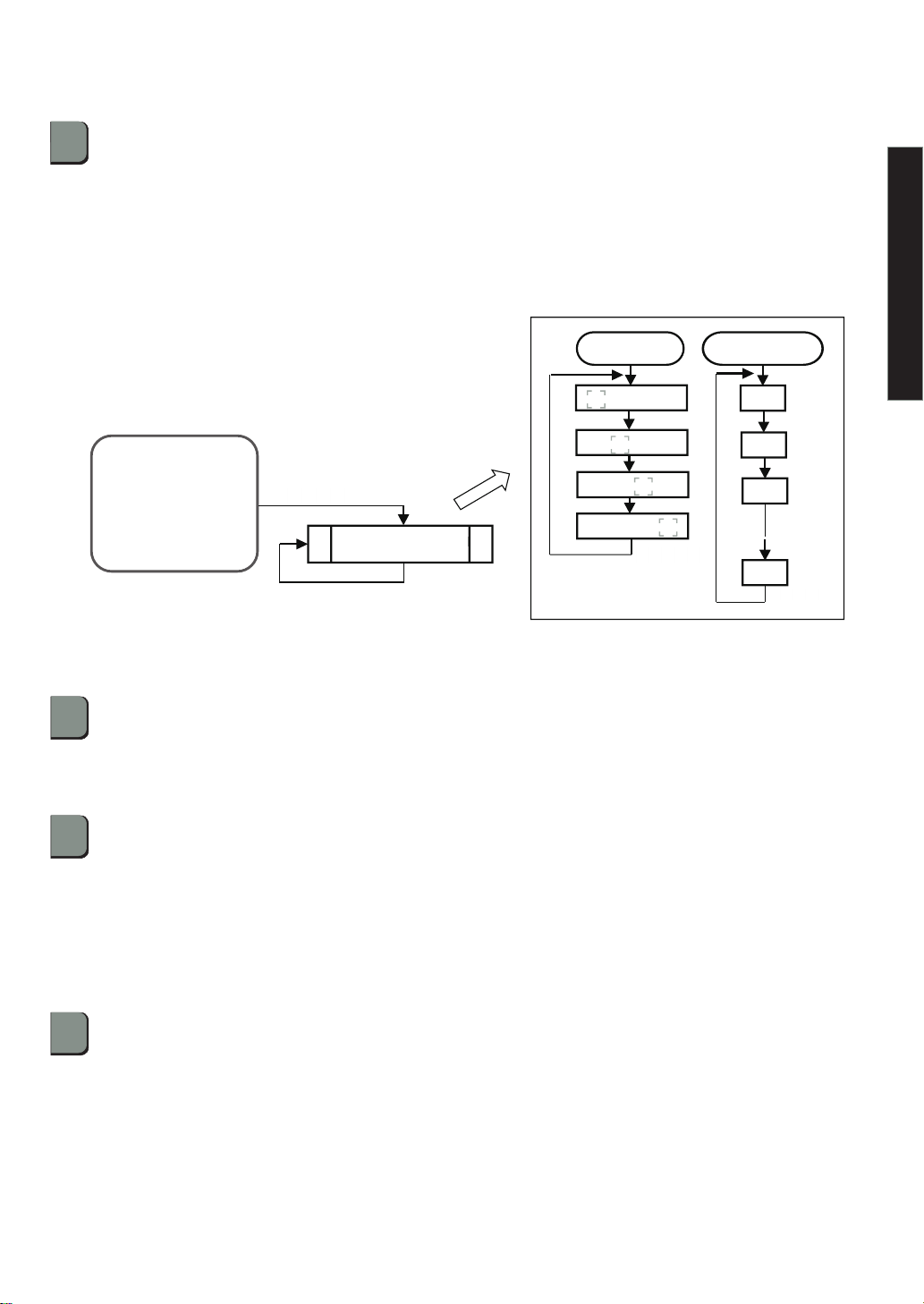

● PREPARATION BEFORE USE

Remove remaining rivets

Remaining rivets

switch

● HOW TO OPERATE

Press the button (Λ) and select the mode you want to change.

*Each time the button (>) is pressed, the display changes from "TCNT" → "PSET" → "NCNT".

1

2

Press the button ( >) to determine the operation mode.

*If you use total count mode or no count mode, proceed to step .

*When using the preset count mode,set the number of presets according to the following procedure.

1) Press the button ( >) to change the blinking digit.

2) Press the button (Λ) to increase the number of the blinking digit.

3) Set it to any setting value.

1

3

Press and hold button (>) (2second)

*The current mode ashes in the count display.

1

1

◇Change operating mode

Follow the steps below to make various settings and changes. (Refer to page 6 for button layout.)

*For details of each operation mode, see P.7.

1

4Press the start button.

*It will start working in the modied mode.

Input digit shift Change the value

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

button (>)

Button(Λ)

0

9

2

1

英語/ENGLISH

11

1

4

Total Count Mode

(TCNT)

Preset Count Mode

(PSET)

No-Count Mode

(NCNT)

MODE CHANGE

Button(Λ)

Button(Λ)

Button(Λ)

Button(>)

Setting the number

of presets

Start button to restart operation

◇How to change the count number

Follow the steps below to change the count number.

1) Press the button ( >) to change the blinking digit.

2) Press the button (Λ) to increase the number of the blinking digit.

3) Change the count number.

*When using the preset count mode, the count cannot be changed beyond the set value.

If you change it, set it to the preset setting value or less.

1

2

Press and hold button (Λ)

*The 4th digit of the count display blinks.

*Changes are limited to use in total count mode or preset count mode.

1

1

1

3Press the start button.

*Operation starts from the changed count quantity.

Used when the count number needs to be changed.

Press and hold the button (Λ)

Change Count

Start button to restart operation

1

1

◇ How to reset the number of counts

Press and hold the reset button (2 seconds). The count number returns to the

initial value.

*When using in total count mode, the count number becomes "0000".

*When using the preset count mode, the count number becomes the set value.

12

英語/ENGLISH

Total Count Mode

(TCNT)

or

Preset Count Mode

(PSET)

Input digit shift change the value

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

Button(>)

Button(Λ)

0

9

2

1

1

2

13

◇ How to open the front panel

1

1Press the lock button (2 places) to release the button. (ref P6)

Remove front panel.

*Be sure that front panel is locked during operation.

*If rivets are clogged, remove unnecessary rivets with the included tweezers.

● CHANGE SIZE OF RIVET

When changing the diameter of the rivet to be used, it is necessary to change the size of the separator

unit and rail unit.Follow the steps below to replace. Be sure to turn o the power before starting work.

*Always check that there are no rivets left inside the feeder before inserting the rivets to be changed.

*If you only change the length of the rivet you are using, you do not need to replace the part.

*The model will be changed by replacing the separator unit and rail unit. Please refer to page 22 for

a list of required parts and models for replacement.

1

1Remove the cover unit.

*Use a hexagonal key wrench

(2.5 mm opposite ats)

*Loosen the 4 locations.

*If the cover unit is dicult to remove,

spread it horizontally.(Bolts will not fall o.)

1

2Remove the separator unit.

*Use a hexagonal key wrench(2.5 mm)

*Loosen the stainless steel screw in the dashed line.

(2 locations)

When you want to check the supply port, or any trouble such as rivet clogging occurs near the supply

port, open the front panel and check. Also, make sure power turned o, to do this.

locked unlocked

英語/ENGLISH

Cover unit

Loosen the hexagon socket

button bolt. (4locations)

Separator unit

Separator unit

14

英語/ENGLISH

◇ Option parts

Separator unit (Type 3) Code No.: 69128

Separator unit (Type 4) Code No.: 69129

Separator unit (Type 5) Code No.: 69130

Rivet rail unit (Type 3) Code No.: 69097

Rivet rail unit (Type 4) Code No.: 69098

Rivet rail unit (Type 5) Code No.: 69099

Clearance gauge Code No.: 70219

Rivet rail unit Separator unit

1

3Remove the rivet rail unit.

*Use a hexagonal key wrench(3 mm)

*Loosen the stainless steel screw in the dashed line. (2 locations)

Enlargement of the circled

part in the left gure

1

4Install the rail unit of the size to be replaced and the separator unit in reverse order.

*The clearance between the separator unit and the rail should be 2 to 2.8mm.

*Improper clearance dimensions can cause rivet jamming.

*If it is dicult to set clearance dimensions, use an optional jig (clearance gauge).

*Insert the clearance gauge into the separator unit as shown in the gure, and attach it so that

it stops naturally with the stopper.

Stopper 2.8mm

Pass 2.0mm

Rivet rail unit

Separator unit

Rivet rail unit

Clearance gauge

Clearance gauge

15

英語/ENGLISH

1

1Remove the frame head holder.

*Use a hexagonal key wrench(3 mm)

*Loosen the stainless steel screw in the dashed line. (3 locations)

◇ Option parts

Frame head holder (21) Code No.: 69154

Frame head holder (23) Code No.: 69168

When changing the riveter to be used, it is necessary to replace the frame head holder. Follow the

steps below to replace. Be sure to turn o the power before performing this work.

*Refer to P8 for replacement, and select the frame head holder that matches the riveter you use.

*The model will be changed by exchanging the frame head holder. Refer to page 22 for a list of

required parts and models for replacement.

1

2Install the frame head holder of the size to be replaced.

*The frame head holder (21) is blue and the frame head holder (23) is black.

Frame head holder

● CHANGE OF THE RIVETER USED

16

英語/ENGLISH

Specify the model name, part name, code No., and quantity as shown below, and place an order with

the store where you purchased the product.

Model Parts name Code No. Qty.

ARF810E Separator unit(Type 3) 69128 1

ARF810E Frame head holder (21) 69154 1

*Note that if the parts are improved, the inventory of the old product will be 5 years.

1.Cleaning each parts.

2.Check parts for damage.

●If there is any damage, contact the store where you purchased

the product.

●Perform maintenance inspections once a week. If neglected, it may

not work properly.

● If there is dirt, wipe it o with a waste cloth.

●Remove dirt and dust from the area around the rivet insertion

port and the supply port by using an air blower, etc.

●If the supply unit does not move smoothly, blow air through the

cleaning hole at the bottom of the supply unit.

* Remove the cover unit before doing this. (See page 13)

Perform the following tasks and checks on a daily basis. Be sure to turn o the power before performing

this work.

●Store the device in a well-ventilated place with little dust and humidity, and in a stable place where

there is no risk of it falling.

●In order to use this machine for a long time, please request regular overhauls from us. (Overhaul

is charged) For overhaul and repair, contact the store where you purchased the product or call us.

3.Storage

Cleaning hole

Supply unit

3.Apply grease.

●If you feel that the riveter insertion is heavy, apply

grease to the locations shown in the gure on the

right.

●Apply grease thinly. If too much, the movement of the

supply unit may be adversely aected.

Slide base L、 R

Push holding

arm stopper

● MAINTENANCE

● ORDERING PARTS

17

英語/ENGLISH

If a problem occurs, check the following.If the problem persists after checking the items in the table be-

low, contact your nearest “LOBSTER” dealer or contact Lobtex.

In making any inquiries about this product or requests for repair work, rst check the troubleshooting

items below and then make a note of the model number, the usage conditions and the trouble symp-

toms in as much detail as possible. If you can provide this kind of information, it may reduce the amount

of time required for delivery or repairs to be completed.

Trouble Cause Countermeasure

The machine will not

operate even though the

start button is pressed.

1The power supply plug or power

supply jack is disconnected.

Connect the power supply plug or

power supply jack.

2The lid is open and the safety

switch is working Close the lid tightly

Rivets will not feed to the

riveter. 1Rivet jammed in the rail Open the lid and remove the jammed

rivet

2Size of Nosepiece is not

appropriate for blind rivets.

Change the size of nosepiece to that

appropriate for blind rivets.

3The vacuum mechanism of the

riveter is not turned on.

Turn on the vacuum mechanism.

4Volume of blind rivets loaded

exceeds appropriate level.

Reduce the volume of loaded rivets

to the appropriate level.

5Items other than rivets are inserted Insert rivets only

6Rivet clogging in the supply section Open the front panel and remove the

clogged rivet (see page 13).

7The rails of the rivet rail unit are

dirty.

Clean the rails and remove any dirt.

8The riveter is not correctly inserted

into the inner side of the frame

head holder.

Plug it in until the green LED ashes

and the buzzer sounds

9Separator clogged with rivets Open the lid and remove the jammed

rivet.

10 Poor movement of supply unit Use the cleaning hole to blow air.

(See page 16)

● TROUBLESHOOTING

18

英語/ENGLISH

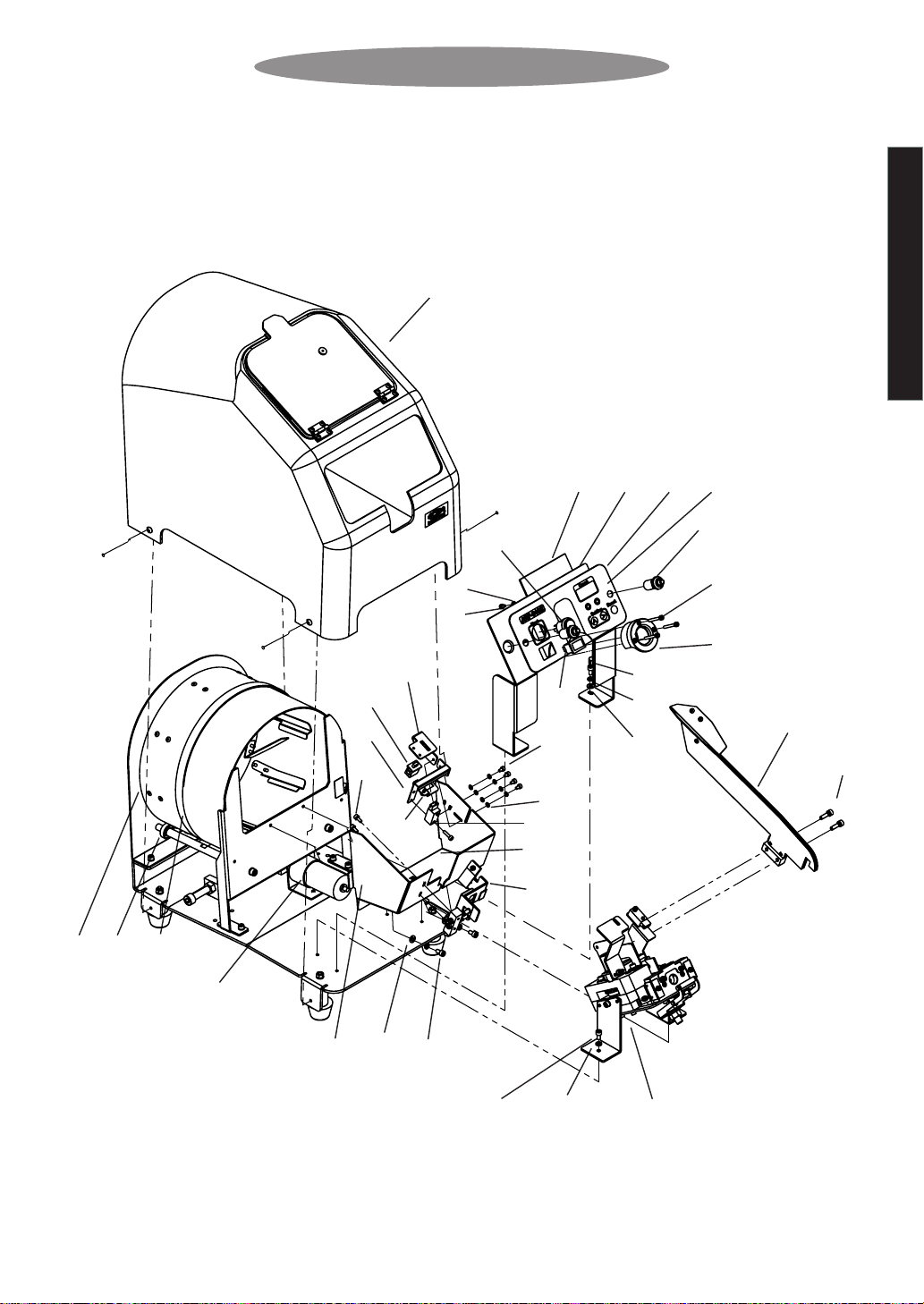

● PARTS TABLE

ARF-810E main unit

2

4

7

11

5

8

10

9

6

3

13

12

15

14

17

18

19

16

20

21

29

22

23

24 25

1

28

27

32

30

31

26

6

6

5

28

18

17

19

英語/ENGLISH

Index No. Part name Code No. Material

1Drum unit Stainless

2Supply port unit 69083 Steel

3-A Rivet rail unit (Type 3) 69097 Steel、Stainless

3-B Rivet rail unit (Type 4) 69098 Steel、Stainless

3-C Rivet rail unit (Type 5) 69099 Steel、Stainless

4-A Separator unit (Type 3) 69128 Steel、Stainless

4-B Separator unit (Type 4) 69129 Steel、Stainless

4-C Separator unit (Type 5) 69130 Steel、Stainless

5Spring washer M4 20930 Steel

6Hex socket bolt M4×8 20918 Steel

7Electric feeder substrate unit 69167 Electronic device

8Sensor plate 70218 Stainless

9Hex socket head bolt with spring washer M 4×15 69157 Stainless

10 Alignment check sensor 69161 Electronic device

11 Hex socket head bolt with spring washer M 3×8 61443 Stainless

12 Power switch 69164 Electronic device

13 Start button 69163 Electronic device

14 Safety switch mounting plate 69174 Steel

15 Safety switch 69165 Electronic device

16 Hex socket bolt M 3×12 61337 Steel

17 Spring washer M3 12442 Steel

18 Hex socket bolt M3×5 43736 Steel

19 Camlock fastener 69162 Plastic

20 Front basket 69136 Stainless

21 Substrate mounting plate 69138 Steel

22-A Frame head holder φ21 69154 Plastic

22-B Frame head holder φ23 69168 Plastic

23 Cover unit 69715 Plastic、

Stainless、Steel

24 Front panel 69159 Stainless

25 Panel sheet 69169 Plastic

26 Safety swich xing plate 70336 Steel

27 Hex socket bolt M 3×25 67673 Steel

28 Plain washer M4 25585 Steel

29 Plain washer M3 21539 Steel

30 Motor 69105 Electronic device

31 Bearing 69120 Steel

32 Belt 69111 Rubber

Parts with circled Index No. are consumable parts.

They should be replaced periodically.

Other manuals for ARF-810E

1

Table of contents