Lockformer Corner Cadet Manual

C

CO

OR

RN

NE

ER

R

C

CA

AD

DE

ET

T

O

OP

PE

ER

RA

AT

TI

IO

ON

N

&

&

M

MA

AI

IN

NT

TE

EN

NA

AN

NC

CE

E

M

MA

AN

NU

UA

AL

L

E186 Rev1

June2011

WARRANTY

Ourguarantee on the productswemanufactureislimited torepairorreplacementwithoutcharge,ofanypart

found tobe defectiveinmaterialsorworkmanship.Thisguarantee isforaperiod ofone year(unless

otherwisespecified)fromthe dateofshipmentfromourfactory,forallmechanicalfeaturesofthe machine,

exceptpurchased componentsthat carrythe warrantyof the originalmanufacturer.

Warrantypartsand componentswillbe shipped freightcollectfromLisle,Illinois.Ifthe defectiveparthasnot

been received byLockformerwithin15 working daysafterreceiving the replacementpart,yourcompanywill

be responsibleforthe cost ofreplacement.

The warrantyprovided inthisclauseisinlieu ofallotherwarranties,express orimplied,arising bylawor

otherwise,including the implied warrantiesofmerchantabilityand fitness foraparticularpurposewhichare

herebydisclaimedbyLockformerand excluded fromthisagreement.Thiswarrantyshall notbe modified for

anyreason. Inno event shallLockformerbe liableforconsequentialorincidentaldamages.

©Copyright2010byLockformer

All RightsReserved

The information inthisdocumenthasbeen reviewed and isbelieved tobe completelyaccurate.However,no

responsibilityisassumed forinaccuracies.Furthermore,LOCKFORMERreservesthe righttomakechanges

toanyproductsherein,atanytime,toimprovereliability,function,ordesign.LOCKFORMERdoesnot

assumeanyliabilitiesarising outof the application oranyuseof anyproductdescribed herein,neitherdoesit

conveyanylicenseunderitspatentrightsnorthe rightsofothers.

TRADEMARK NOTICES

Lockformerisaregistered trademark.Allotherbrand and product namesaretrademarksorregistered

trademarksof theirrespectivecompanies.

i

CORNERCADET

TABLEOFCONTENTS

TABLEOFCONTENTS

SAFETYSUMMARY

LOCKOUTGUIDE

ELECTRICALSCHEMATIC (Back of Manual)

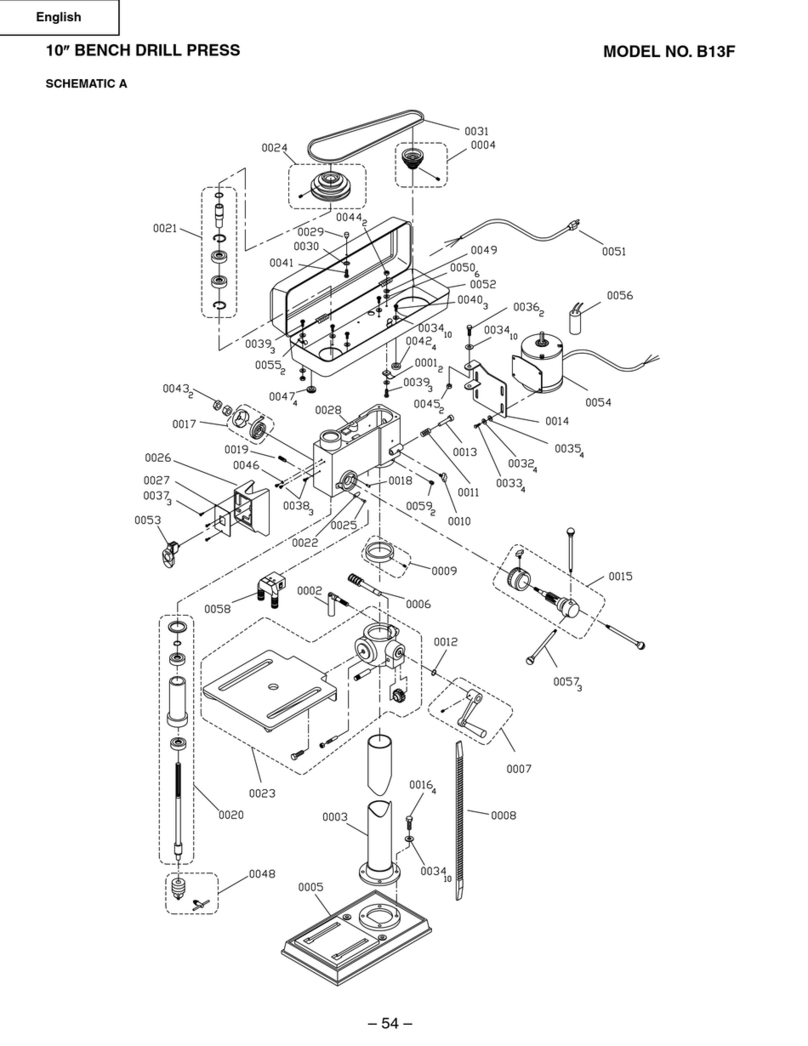

ASSEMBLYDRAWINGS (Back ofManual) Section/Page

1. INSTALLATION......................................................................................................................1-1

A. SELECTING ALOCATION...........................................................................................................1-1

B. PNEUMATICREQUIREMENTS...................................................................................................1-1

C. ELECTRICAL REQUIREMENTS..................................................................................................1-1

D. RECEIVING AND ASSEMBLINGTHEEQUIPMENT....................................................................1-1

E. SAFETYREQUIREMENTS..........................................................................................................1-5

(1) SafetyPrecautionsBeforeStartingTheMachine......................................................1-5

(2) SafetyPrecautionsWhenOperatingtheMachine.....................................................1-5

2. SYSTEMOVERVIEW.............................................................................................................2-1

A. INSULATEDDUCT.......................................................................................................................2-2

3. SYSTEMOPERATION...........................................................................................................3-1

A. SAFETYPRECAUTIONS.............................................................................................................3-1

(1) BeforeStartingTheMachine.....................................................................................3-1

(2) When OperatingTheMachine...................................................................................3-1

B. PREPARATIONFOROPERATION..............................................................................................3-2

C. SYSTEMSHUT-DOWN................................................................................................................3-3

4. MAINTENANCE.....................................................................................................................4-1

A. TORQUEVALUESFORGENERAL ASSEMBLY.........................................................................4-1

B. MAINTENANCESAFETY.............................................................................................................4-4

C. SERVICING..................................................................................................................................4-4

(1) Lubrication,GeneralRequirements...........................................................................4-4

(a) LubricationSchedule.............................................................................................4-4

D. FEEDADJUSTMENT PROCEDURE............................................................................................4-5

(1) Adjustment Procedure...............................................................................................4-5

E. PNEUMATICADJUSTMENTS.....................................................................................................4-6

(1) AirValveStation........................................................................................................4-7

F. PREVENTIVEMAINTENANCE....................................................................................................4-8

(1) Preventivemaintenancechecks:...............................................................................4-8

G. CLEANING...................................................................................................................................4-8

H. LUBRICATION.............................................................................................................................4-9

ii

CORNERCADET

I. TROUBLESHOOTING..................................................................................................................4-9

J. INSTALLING NEWPLCE-PROM...............................................................................................4-10

LISTOFTABLES

Table4-1. MetricBoltAnd CapScrewTorqueValues.........................................................4-2

Table4-2. UnifiedInchBoltAndCap ScrewTorqueValues................................................4-3

Table4-3. TroubleshootingChart......................................................................................4-10

LISTOFFIGURES ANDILLUSTRATIONS

Figure1-1Removing CornerCadet.....................................................................................1-2

Figure1-2Handle&RegulatorInstallation..........................................................................1-2

Figure1-3InstallingCornerMagazine.................................................................................1-3

Figure1-4DuctGuide Installation.......................................................................................1-3

Figure1-5Deck MountingHoleLocations...........................................................................1-4

Figure2-2TDC and TDFDuctFlangesDimensionRequirements......................................2-1

Figure2-3CornerAreaFreeofInsulationPins...................................................................2-2

Figure3-1AluminumLoadingSticks...................................................................................3-2

Figure3-2AirRegulatorAssembly......................................................................................3-2

Figure4-1FeedAdjustment Components...........................................................................4-5

Figure4-2FeederSpeedAdjustment..................................................................................4-7

Figure4-3AirValveStation.................................................................................................4-8

Figure4-4Lubrication Points...............................................................................................4-9

Figure4-5PLCController.................................................................................................4-11

a

E186Rev1

CORNERCADET

SAFETYSUMMARY

INTRODUCTION

Safetyiseveryone’sbusiness... Whetheryouareanequipmentoperator, amaintenance

person,asupervisor,orbusiness owner, you aredirectlyresponsibleforthe day-to-daysafe

operationoftheequipmentunderyourcontrol. It isyourresponsibilitytomaintainand

operatethisequipment instrict compliancewithallapplicablelaws, safetyregulations,and

themanufacturer’srecommendedprocedures.

PROMOTING SAFETY

Instituteacompanysafetyprogram. Managementhasamoralandlegalresponsibilityfor

promoting industrialsafety.Theformation of anorganized safetyprogramisstrongly

recommended.Thissafetyprogramshouldincludethe formationof asafetycommittee to

reviewandupdatecompanysafetypoliciesonaregularbasis.Establishafirm policy on

safetyregulationsintheworkplace.Publishtheseobjectives,spelling out eachemployee’s

responsibilities. Makecertainthateachemployeeknowswhatisexpectedofthem.

SAFETYPROGRAM

Thefollowing stepsaresuggestions thatacompanydeveloping,orexpanding,a

comprehensivesafetyprogramshouldconsider:

1.Industrialequipmentmanufacturerscarefullydesign safeguardsintotheirproductsin

ordertominimizehazards.However,themannerinwhichequipment isincorporatedinto

amanufacturingprocess mayinadvertentlycreateahazardorotherwisedefeatbuilt-in

safeguards. Closelyexaminetheoperationof yourcompany’sprocessingequipment.

Takenoticeofpotentialhazards. Install guardsortakeotherappropriateactionto

eliminatehazardrisks.

2.Makecertainequipmentoperatorsandmaintenancepersonnelareproperlytrained.

3.Setupaprogramof daily, weekly,andmonthlymachineryinspection.Makeachecklist.

Keepahistoricalrecordof all maintenancework, repairs, andadjustments.

4.Frequentlyevaluatesafetyguardsanddevicesduring actualproductionruns.Correct

anyunsafepractice orsituation immediately.

5.Establishsafe, convenient materialhandlingsystems. If conveyorequipment isinstalled

inyourfacility, it shouldconform torecommendationspublished inthe‘AmericanNational

Standard,ConveyorsandRelatedEquipment, SafetyStandardsforANSI/ASMEB20.1’

whichisavailablefromtheAmericanNationalStandardsInstitute(ANSI).

6.Providepersonalprotectiveequipment, suchassafetyglasseswithsideshields,safety

helmets, tongs,gloves,handpads, spats,andprotectivesleeves, asrequiredtosuit the

operation.

7.Organizeacompanysafetycommittee.Scheduleperiodicmeetingsonaregularbasisto

reviewandupdateall safetypolicies.

8.Establishafirm policy on safetyregulationsintheworkplace.Publishtheseobjectives,

spellingouteachemployeesresponsibilities. Makecertainthateachemployeeknows

whatisexpectedofthem.

b

E186Rev1

CORNERCADET

9.Investigateall accidentsandclosecalls.Takeimmediateactiontopreventarecurrence

oftheincident. Keeprecordsoftheinvestigation andthe correctivemeasurestaken.

10.Postalistof names,addresses,andphone numbersof physiciansandotherswhoareto

be calledinemergency situations.

CUSTOMER'SRESPONSIBILITIES

Therearecertainhazardsassociatedwiththeoperationof anyequipmentorsystemof

machinerythatareimpractical, ifnot impossible,forequipment supplierstosafeguard.The

usermustaddress thesehazardsandberesponsibleforprovidingguardsorbarriersfor

establishingappropriateworkproceduresandfortrainingpersonnelinthesafeoperationof

that equipment.

Withrespecttocoil andstripprocessing equipment, thefollowinghazardsshouldbenoted:

•Openpitsanddepressionsorraisedareasinthefloor.

•Spacebetween machines,wherestripedgesandendsareexposedduringfeed-up,

run,andtail-out conditions. Thisincludescarry-overtablesand bothrollerandbelt

conveyors.

•Nipand pinchpointsofmachinery, coils,andstripwhichmaybeexposedinfeed-up,

run,andtail-out.

•Areassurroundingpayoff reelsandrecoilers, whereclock-springingstripends

presentahazardduringbanding,un-banding,feed-upand tail-out conditions.

•Sheetand packhandlingdevices(includingconveyors)wherethe motion,aswell as

shiftingofsheetsorpacks,maypresent ahazard.

•The areasurroundingsheet stacking devices,whichmust beapproached forsetup,

butwhichshouldbeclearofpersonnelduringoperationbecauseof moving

machineryormaterial.

•Areasassociatedwithhightemperatures,high pressurefluids(hydraulic,air, or

water)andelectricaldevicesandconnections.

•The vicinityofmachinerywhichmovesintooroutoftheline.

REFERENCESOURCES

Questionsconcerningspecifichazardsorsafeguarding ofequipmentmaybeaddressedto

theequipment manufacturer.Foradditionalinformation, refertothesourceslistedhere:

AmericanNationalStandardsInstitute (ANSI)

ANSIB11.18,”MachineryandMachineSystemsfortheProcessingof CoiledStrip,

Sheetand Plate-SafetyRequirementsforConstruction, CareandUse.”ANSI

B11.4, “Shears:SafetyRequirementsforConstruction,Careand Use.”ANSI

B11.14,”Coil-SlittingMachines/SystemsSafetyRequirementsforConstruction, Care

andUse.”ANSIB11.18, ”MachineryandMachine SystemsfortheProcessingof

Coiled Strip,SheetandPlate-SafetyRequirementsforConstruction,Careand Use.”

NationalFireProtection Association (NFPA)

NFPA79, “ElectricalStandardsforIndustrialMachinery.”

EuropeanUnion

c

E186Rev1

CORNERCADET

“DirectivesonSafetyof Machinery” and “CEMarking”

WARNING LABELS

Warningand safetyrelatedinformationallabelsareplacedon theLockformers’equipmentat

strategicpoints.It isimportant thattheselabelsarenot removed,covered,hidden,or

defaced.Thepurposeof theselabelsistoalert personneltopotentialpersonalinjury

hazardsor other direct orindirect safetyconcerns.

DANGER indicatesan imminentlyhazardoussituationwhich, if not

avoided, will result indeathorseriousinjury.

WARNING indicatesapotentiallyhazardoussituation which,ifnot

avoided, could result inminororseriousinjury.

CAUTION indicatesapotentiallyhazardoussituation which,ifnot

avoided, may result inminorormoderateinjury.

NOTICE indicatesacompanypolicy thatrelatesdirectlyorindirectly

tothesafetyof personnelorprotectionofproperty.

“It isimportant that the meaningof asafetysignisclearlyunderstood

bythosewhomaycomeincontact withthehazard. Toincreasetheunderstandingof asafetysign’s

components, the ANSIZ535committee encouragessafetysignmanufacturersandownersof

facilitiestopublishandexhibit thefollowing(above)informationon safetyposters,safetybulletinsor

thelike.Doingsowill assistintheobjectiveofachievinganationaluniform systemforthe

recognitionofpotentialpersonalinjuryhazardsandaccidentprevention.” -ANSI Z535.2, AnnexA1

d

E186Rev1

CORNERCADET

WARNINGMESSAGES INTHISMANUAL

Throughout thismanualvarious DANGER, WARNING, CAUTION, andsafety

related NOTICE messagesappear.Theintent istoalert operatorand maintenance

personneltopotentialhazards.Inaddition, important operationandmaintenancedetailsare

emphasizedwiththe NOTE heading.

SAFETYFIRST

The equipmentinthislinewasdesignedandmanufacturedforaspecifictask.DONOT use

theequipmentforanyotherfunctionortoprocessmaterialthat isbeyond theequipment’s

designspecifications.Modificationsoradditionstothisequipment lineshouldnotbemade

withoutfirstconsulting Lockformer. Replacementandmaintenancepartsshouldbeequalto

originalequipment. Useofotherpartsmayresultinunsafeoperating conditions.If thereisa

questionastothe suitabilityofapart,Lockformershouldbeconsulted.

Ingeneral,everypieceof equipment must betreated asdangerous. Whileoperatingor

maintainingthisequipment, eachperson mustbeawareof theirownsafetyaswell asthe

safetyofall othersaroundtheline.

MaterialCoils

Coilspresent numeroushazards. Theymayshift, roll orfall without warning.Some

coilsmayspringopenwithout warning. Sharpedgesofthestripinthecoil are

hazardous.Stayclearofcoilsastheyarebeingmoved. Useextremecautionany

timeacoil isapproached orhandled.

MetalStrips

The metalstripmayhavesharporraggededges.Thestripisundertensionandis

subject toabrupttensionchanges. Thiscanresultinstripbreakagewiththeends

flying without warning.Stayclearofthestripwheneverpossible. Whenit is

necessarytoapproachorhandlethe strip,useextremecaution.Useprotective

devicessuchastongs,gloves,eyeprotection,andwrist guardsasrequiredfor

safety.Thestrippresentsmanypinchhazardswiththe machinery.Stayclearof

these.Neverstep onoroverstripintheline.

Machinery

Neverreachintoanypieceofmachinerywhichisoperatingorwhichiscapableof

operation.Looseclothing orjewelryshouldbekept clearofmachineryat all times.

When workingononepieceof equipment, beawareof hazardsof surrounding

equipment.Anyiteminsertedintoamachinemaybethrownormaycausea

dangerousmalfunctionorbreakage.

SafeGuards

Noequipment shouldbe operatedunlessthesafeguardsordevicessupplied with

theproduct aresecurelyinplaceandproperlyadjusted.

e

E186Rev1

CORNERCADET

LOCKFORMERhasconductedhazardevaluation and riskanalysisstudiesfortheirproducts.

Safeguardsinstalledontheequipmentarethereforareason. BEFOREEQUIPMENTIS

PLACEDINTO SERVICE, ALL SAFEGUARDSORDEVICESMUSTBEINPLACEAND

PROPERLYADJUSTED.

Maintenance

Beforeperforming anymaintenanceonapieceofequipment,insurethat all poweris

lockedoff inaccordancewithyourcompany’slockout/tagoutpolicy. Besurethatall

movablemembers(suchasrolls, arms,tables, etc.)aresecurelyblockedfrom

inadvertentmotionwhichmightbehazardous.Treatall electricallinesasbeing live

andall pipingasbeingunderhighpressure. Insurethatall itemsareproperly

reassembledbeforeplacing themintooperation.Beforeequipmentisreturnedto

service,ALLsafeguardsordevices MUSTBE inplaceandproperlyadjusted.

NOTICE

Beforedoing anyWELDINGONEQUIPMENT, thefollowingprecautionsmust

be taken toinsureagainstdamage:

1)All powerisremoved fromsystem.

2)Theweldground isconnected totheclosestpossiblelocation ontheunit

wheretheweldingisbeingperformed.

3)All encoders, senseeyes,and controlsshouldbe electronically

disconnectedif atall possibletoavoidpossibledamage.

Operation

Thisequipment iscapableof speeds,tensions,andadjustmentswhichmaybe

hazardousforsomeofthematerialswithintheline specification.Forexample,thin,

narrowstripmaybesubjectedtotensionssufficient tocausebreakage.Never

attempttoprocess anymaterialunlessthe safeadjustmentsforthatparticularare

knownandcanbe implemented.

TrafficAround Equipment

Careshouldbe takenatall timesinmovingaroundthe equipment, whetheron footor

inavehicle.Changesinfloorelevation, machinebasesanddebrisaroundthe

equipmentaretriphazards.Takecarethatpersonnelarenot trappedbetween

vehiclesandequipment.

Donotattempttowalkorclimbon anymachinewhileinoperation. Failuretoobservethis

warning mayresultindeathorseriousinjury.

HAZARD REMINDER

Usethe following HAZARD REMINDERsheet toreinforceawareness of thehazards

associatedwithcoil processinglines.Thisremindercanbeausefulsupplementtoyour

company’ssafetyprogram. IPIsuggeststhefollowingsteps:

f

E186Rev1

CORNERCADET

1.SHOWeachindividualthe HAZARD REMINDERsheetandexplaineachcategoryof

hazard.

2.POINTOUTEXAMPLESofeachtypeof hazardonthe actualequipmenttheindividual

operatesorworks around.

3.EXPLAINHOWTOAVOIDHAZARDSintheindividualsworkenvironment.

4.GIVE acopyoftheHAZARD REMINDERsheettoeachindividual.

Safety iseveryone’sbusiness!

THINK SAFETY FIRST

NIPPOINT

WHENONEOBJECT ROTATESNEARANOTHER,IT CANPULLYOU

IN and CRUSHYOU

PINCH POINT

WHENONEOBJECT MOVESCLOSERTO ANOTHER, IT CANCUT or PINCH

YOU.

MOVING EQUIPMENTandCOILS

CANKNOCK YOUOFF BALANCE or CRUSHYOU

STRIPEDGES and ENDS

CANCUT or STRIKEYOU.

ELECTRICAL and FLUIDSYSTEMS

CANSHOCK and BURN YOU and CANEXPLODE.

CLIMBINGONMACHINES

CANMAKEYOUFALL -MAYBEINTOONEOFTHEHAZARDSABOVE.

A

E186Rev1

CORNERCADET

LOCKOUTGUIDE

The protection oflifeandlimbthroughresponsibleactionsandadequatesafeguardsarethe

responsibilityofall individualsinaworkplaceenvironment,oranyenvironmentwhereactionormiss-

actioncouldpossiblyendangerthesafetyand wellbeingofothers.

All maintenance, repairand adjustmentproceduresperformedonthisequipment shall complywith

existingestablished Lockout requirements.Ataminimum, theserequirementsmustincludetheuse

ofakeyedpadlock orsimilardeviceutilizedtophysicallyand securelyremoveandisolateany

powersourcefromthe equipment, preventingaccidentalreapplicationwhilepersonnelmaybein

exposedcircumstances,subjecttopossibleinjuryordeath.

Theserequirementsmustalsoincludethe tagging ofthelockout devicetonotifyall individuals

working inthearea,oranyonewhocouldforwhateverreasonisinapositiontopossiblyremoveor

otherwisedefeat thepurposeofthelockout device, astoitsinstallation, why, andthe individual

responsibleforitsapplication.

Powersourcesincludeelectrical, pneumatic,hydraulic,oranyotherhazardousenergysource. This

procedureshall beusedtoensurethat themachineisstoppedandisolatedfromall potentially

hazardousenergysourcesandthat theseenergysourcesarelockedoutbeforeemployeesperform

anyservicingormaintenancewhenthe unexpectedenergization,start-upof themachine,orthe

releaseof storedenergycouldcauseinjury.

FORTHISUNIT (whereapplicable)

•Hydraulicpower sourcesareprovidedwithalockablevalvetoblock hydraulicpressure

fromthesystem. Whereapplicable, thisvalveshallbe placedintheoff position andlockedin

place.

•Electricalpower sourcesareprovidedeitherwithamaleplugforconnectiontotheelectrical

source,orarehardwiredtothesourcedistributionpanel.Whenaplug isprovided,theplug

shall be disconnectedfromthesourcepowerandsecuredwithinacoveringandtagged

appropriately.

When hardwiredtothesourcedistributionpanel, the panelshall haveamanualdisconnect

whichislockableintheoff position,orintheeventofacircuitbreaker, the panelwill havea

lockabledoorwhichwill denyaccess tounauthorized personnel.

•Pneumaticpower isapplied tothemachinethrough aquick disconnect fitting.Thisquick

disconnectfittingshall bedisconnected fromthepneumaticpowersourceand securedwithin

acoveringandtaggedappropriately.

B

E186Rev1

CORNERCADET

Page1-1

E186Rev1

CORNERCADET

INSTALLATION

1. INSTALLATION

A.SELECTINGALOCATION

Select alocationthat will savethe most workandtimeinmovingductworkabout inyourshop.

Atablethat matchestheheightof thebottomheadbaseplateof theCornerCadet isamust in

helping topositionthe duct sectionsintotheCornerCadet, especiallyifonlyoneperson may

be handling theduct.

B.PNEUMATICREQUIREMENTS

Aclean,dryairsupplyof 5CFM at 100PSI (not toexceed120PSI) mustbemadeavailable

totheequipment. Thiscan bearigidsupplylinesuchaspipe,buttheterminatinglinetothe

equipment shouldbeanon-rigidairlinetoisolatethecompressorandmachine fromeach

other’svibrations.

NOTE

Adedicatedfilter, lubricator,andregulatorisrecommended fortheairsourcesupplyingtheCorner

Cadet.

C.ELECTRICALREQUIREMENTS

Electricalpowerrequiresonlythe availabilityofa 115VAC three pronggrounded 15Amp

outlet toplugintheconnectoron theCornerCadet. The machine shouldalsobelocated

awayfromgrindingmachines,sandingmachines, spraypaintingareas, andothersourcesof

contaminationifatall practical.Answerstoquestionsregardingsitepreparation andother

technicalassistanceisavailablebycallingourServiceDepartment.

D.RECEIVINGAND ASSEMBLING THEEQUIPMENT

When theequipmentarrives, inspect it carefullybeforeacceptingthe shipment. It isimportant

tonoteanydamageon theBill ofLadingorothershippingdocumentssothataclaimcanbe

filedwiththecarrier.Payspecialattentiontothecontrolwiring,airregulator,gauges,etc.

Check forphysicaldamagetotheswitchesandthecomponentsinsidethe CornerCadet. If

anythinglooks damaged,notifyboththecarrier (tofileaclaim) andtheServiceDepartmentat

thefactory (toorderreplacementparts). It isimportanttonotifythefactorypromptlysothe

newpartsarrivebeforethemachineisinstalled, asit maynot bepossibletostartand run the

machinewithout them.

1.Carefullyuncratemachine,ensuringNOTTO DAMAGETHESHIPPINGPLATFORM

(A). Thisplatform isdesignedtobe positionedatthefrontoftheunit, thusfacilitating

easy insertionof duct.

2.Removeanydebris, packingmaterial,etc., that mayhaveaccumulatedduring

shipping.

3.Removethefourmountingscrews(B)and carefullyremovethe machine.

NOTICE

DO NOTdryrun theCornerCadet, ordamagetothemachinewillresult.

Page1-2

E186Rev1

CORNERCADET

Figure1-1Removing CornerCadet

4.Movethemachineandaccompanying partstoalevelassemblyarea.

5.Slide thehandle(C)ontothemountingpostsandsecurebyinsertingasnap pin(D)

(bothsides).

6.Press theairsupplyinlet/regulatorassembly(E)ontothequick disconnectmalefitting

on topof the unit.

Figure1-2Handle&RegulatorInstallation

Page1-3

E186Rev1

CORNERCADET

7.Using the(2)screws(F)providedinstall themagazine asshowninphotono.3(DO

NOTOVERTIGHTEN).

Figure1-3Installing CornerMagazine

8.The armsaremountedforTDCcornerinstallationasshipped. Whenusing TDF

cornersmoveeacharm totheoutermountingholesasshown.

Figure1-4DuctGuideInstallation

Page1-4

E186Rev1

CORNERCADET

9.Insert thepowercordintothemachinemountedreceptacle.

10.Graspthehandlefirmlyand placeonefootagainst awheelwhiletiltingbackward.

Transport tothedesiredoperatingsite. Slowlylowerwhileonceagainapplyingfoot

pressureagainstawheel.

CAUTION

Thismachineisfrontheavy.Usecarewhenlowering it inplace, especiallyifbystandersare

present.

11.Placetheshippingplatform infrontof themachine. Alignthetwomounting holes(TDC

orTDF)withtheholesintheend of theductguides.

CAUTION

When workingwithverylargeduct,it isrecommendedthataproportionallylargerplatform bebuilt

forgreaterstability.

12.For TDC cornersusetheholesthatare 26 inchesapart. For TDF cornerusethe holes

that are 26-1/8 inchesapart.

Figure1-5DeckMounting HoleLocations

13.Insert and firmlytightenthetwo5/16-18 x2”mounting screwsandwashersprovided.

Page1-5

E186Rev1

CORNERCADET

E.SAFETYREQUIREMENTS

Beforeoperating themachine, readthissection.Studyand followthesafetyprecautionslisted

herewhichisintendedtopreventinjurytoyouandyourfellowworkers.Theprecautionslisted

cannotcoverall possiblesituations. Therefore, considertheconsequencesof youractions

beforeexecuting anyprocedureoroperation.

(1)SafetyPrecautionsBeforeStarting TheMachine

1.Protect yourself.Wearsafetyglassesandleathergloveswhenhandlingmetal. Donot

wearlooseclothing,neckties,orjewelry. Iflongsleevesmust beworn,avoidcuffsand

buttons.

2.Keepyourworkarea clean. Removeall scrap, oil spills, rags, tools, andotherloose

itemsthatcouldcauseyoutoslip,trip,andfall.

3.Makesurethat theelectricalsupplyandairpressuresareatspecifiedlevelsbefore

operatingthemachine.

4.Besurethatall guardsareinplacewhenoperatingthe machine.Keepthe equipment

properlymaintained.

5.Bealertforloose, worn,orbrokenparts.Donot attempttooperatethemachinewith

suchpartspresent,orifthemachineismakingunusualnoisesoractions.

6.Besurethisoperation manualiskeptnearthe machinesotheoperatorcanrefertoit

whennecessary. Ifyouhavenotalreadydone so,studythe manualbeforeoperating

themachine.

7.Beawareof the locationof thepoweroff push-pullswitchanduseittostop the

machineincaseofemergencies.

NOTICE

DO NOTdryrun theCornerCadet, ordamagetothemachinewillresult.

(2)SafetyPrecautionsWhenOperating theMachine

1.Bealert wheneveroperatingthemachine.

2.Onlyonepersonshouldcontrolthemachine. Neverallowanyone tooperatethe

controlswhileyouareworking onthe machine.Use"WORK"tagsand warningsigns

toindicatethat someoneisworking onorrepairing the machine.

3.Keepyourarmsandhandsawayfromthe internalworkingsof the machine when

startingorstoppingthemachine.

4.Neverleavethe workarea whilethemachineisrunning.

5.Donottrytoprocess materialthatisbeyondthespecified thicknessorwidthforyour

machine. Usegood qualitymetalcoilsthat arefreefromcamber,burrs,andother

irregularities.

6.When cleaningthemachine,oranycomponentsof themachine,donotusetoxicor

flammablesubstances.Donot perform anycleaning operationswhilethemachineis

running.

7.Neveroverrideordisableanysafetyswitchorsafetyinterlock.

8.Usepropersizewrenchesand tools, mostofwhicharefurnishedwiththemachine.

Donotuseadjustablecrescent wrenchesorwornwrenches.Aslippingwrenchcan

causeinjury. Replacewornnuts,bolts,screws,etc., beingsuretheyareof equivalent

qualityof thosebeingreplaced.

Page1-6

E186Rev1

CORNERCADET

Table of contents