-3-

1. GENERAL INFORMATION

1.1 FOREWORD

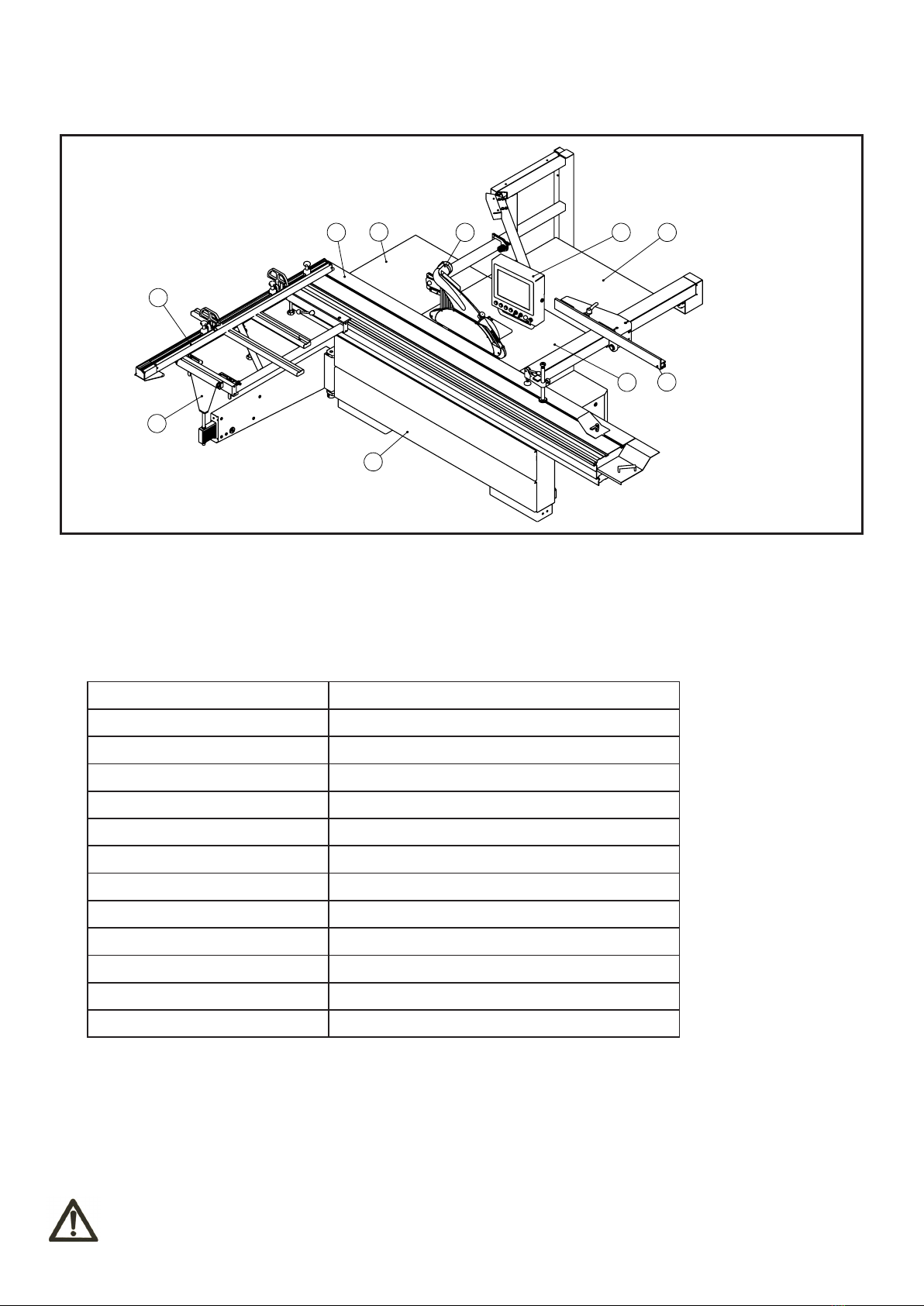

This machine is desinged to make straight and mitre cut for wood material, especially for wood board cutting. CAM

software which can automatically calculate the best layout plan is built in the machine. Also rip fence is controlled by

CNC computer.

Some information and illustrations in this manual may difer from the machine in your possession, since all the

configurations inherent in the machine complete with all the optionals are described and illustrated. Therefore, refer only

to that information strictly connected with the machine configuration you have purchased.

With this manual we would like to provide the necessary information for maintenance and proper use of the machine.

The distribution network is at your service for any technical problem, spare parts or any new requirement you may have

for the development of your activity.

This manual must be read and understood before operating the machine. This will provde a better working knowledge of

the machine, for increased safety and to obtain the best results.

To facilitate its reading, the manual has been divided into sections pointing out the most important operations. For a

quick research of the topics, it is recommended to consult the index. To better stress the importance of some basic

passages, they have been marked by some preceding symbols:

1.2 MACHINE IDENTIFICATION

There is a identification plate fixed to the machine, containing the manufacturer’s data, year of construction, serial

number and technical specifications.

1.3 CUSTOMER SERVICE RECOMMENDATIONS

Apply the machine to skilled and authorized technical staff to carry out any operation dealing with parts disassembly.

Keep to the instructions contained in this manual for the correct use of the machine.

Only skilled and authorized staff shall use and service the machine after reading this manual.

Respect the accident prevention regulations and the general safety and industrial medicine rules.

Indicates imminent risks which may cause serious injury to the operator or other persons. Be

careful and scrupulously follow the instructions.

A statement advising of the need to take care lest serious consequences result in harm to

material items such as the asset or the product.

CAUTION

WARNING

CAUTION

WARNING

2. SAFETY PRECAUTIONS

2.1 SAFETY REGULATIONS

Read carefully the operation and maintenance manual before starting, using, servicing and

carrying out any other operation on the machine.

The manufacturer disclaims all responsibilities for damages to persons or things, which might be caused by any failure

to comply with the safety regulations.

- The machine operator shall have all necessary prerequisites in oder to operate a complex machiery.

- It is prohibited to use the machine when under the influence of alcohol, drugs or medication.

- All the operators must be suitably trained for use, adjustment and operation of the machine.

- The operators must carefully read the manual paying particular attention to the warning and safety notes. Furthermore,

they must be informed on the dangers associated with use of the machine and the precautions to be taken, and must be

instructed to periodically inspect the guards and safety devices.