Introduction

Logitek Digital Consoles represent a new concept for broadcast audio consoles.

Logitek consoles centralize all audio mixing, routing, and distribution functions

to one location in a facility. Once a Logitek system is in place, adding new inputs,

outputs, or even new studios is very easy.

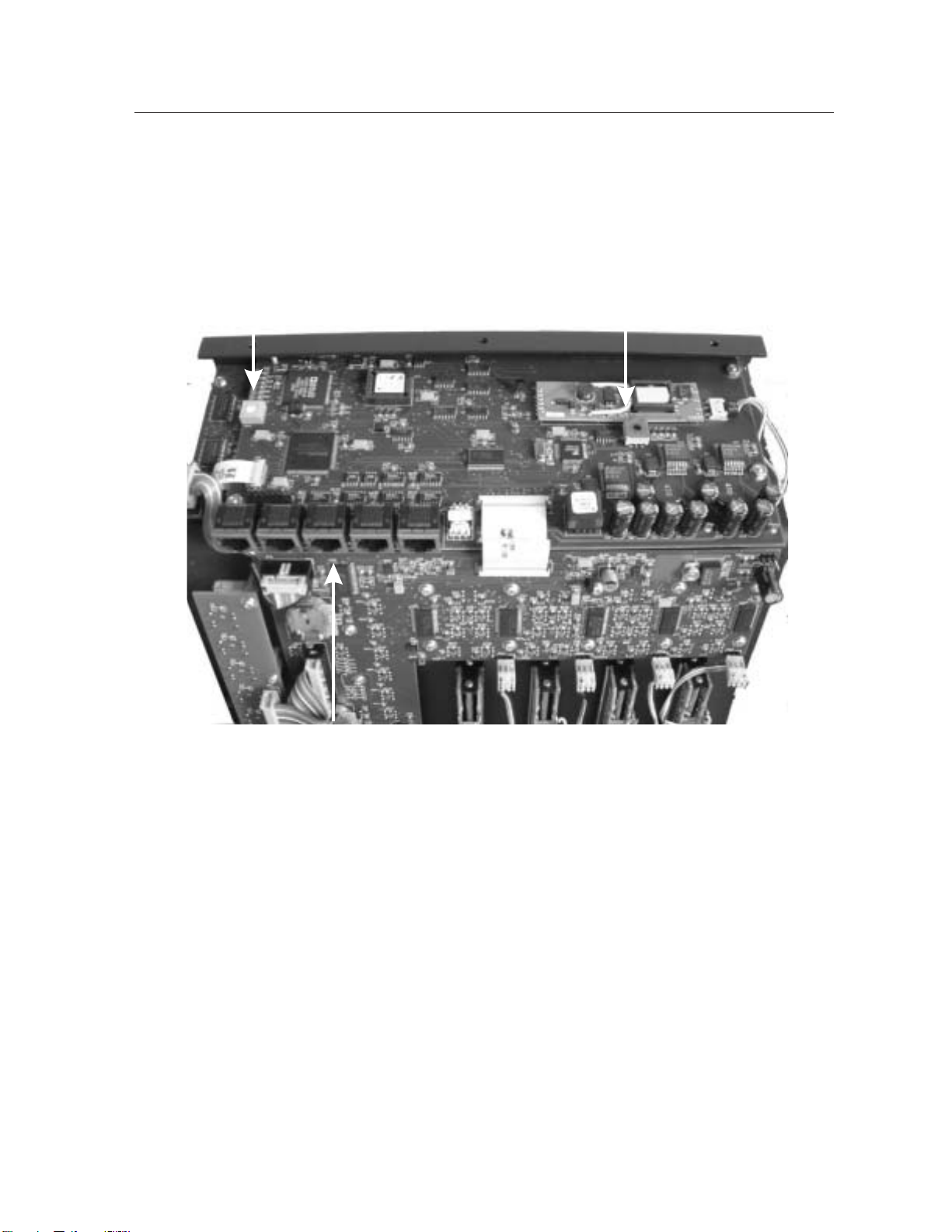

The heart of Logitek Digital Consoles is

the Audio Engine. This is a digital matrix

with equal numbers of input and output

channels ranging from 8x8 to 128x128 in

one engine. This matrix is capable of

mixing, routing, creating mix-minuses

and all other traditional functions of

consoles. The Audio Engine erases the

differences to the user between digital and

analog sources or destinations. The Audio

Engine can accept digital and/or analog

sources and feed digital and/or analog

destinations.

The part of the system in the hands of the user, what looks like an audio console,

is a control surface for the Audio Engine. This can be a ROC 10 or a ROC-5, both

of which look and feel like a traditional console in many respects, the ergonomic

Numix Control Surface or the new compact yet flexible Remora. The Audio

Engine can also be directly controlled by a personal computer using vMix virtual

computer software. Each Audio Engine can accept commands from up to three

consoles or two computers.

4