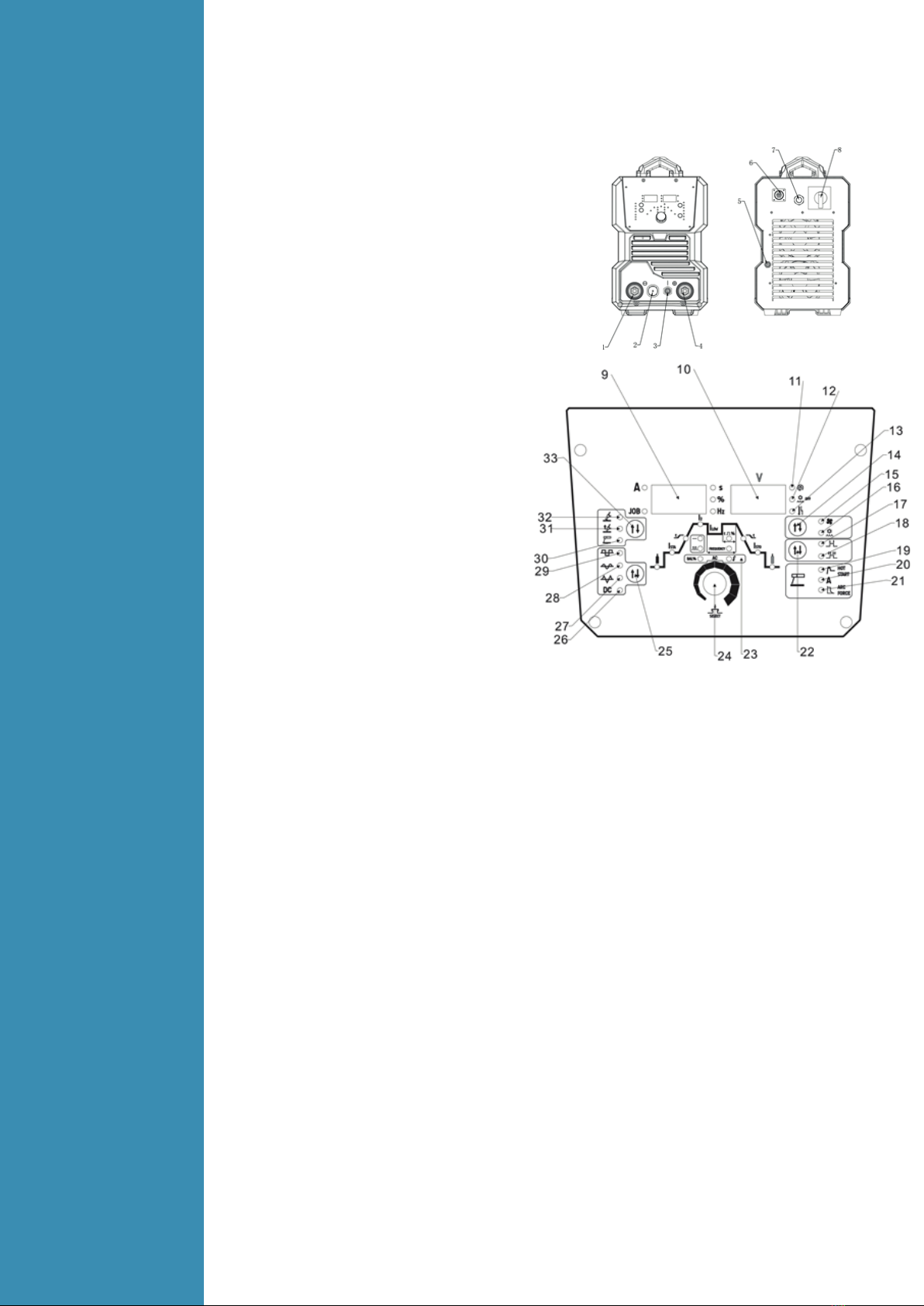

TIG welding current setting indicator (4)

Sets the main welding current. Unit(A) and setting range (10-320A/400A/500A).

Base current setting indicator (5)

Only available when pulse mode (12) is selected. Sets the current of the low/ base pulse. Unit(A)

and setting range (10-320A/400A/500A).

Down slope setting indicator (6)

When the trigger is released, the welding current will reduce gradually over the time selected down

to 0. This allows the operator to complete the weld without leaving a ‘crater’ at the end of the weld

pool. Unit(S) and setting range (0-10.0S).

End current setting indicator (7)

Available in 4T trigger mode only, sets a welding current 10-100% of the main welding current

activated when the trigger is held on to ‘unlatch’ the trigger before the weld is finished. If

downslope (6) is set, the current will go through the downslope period before going to the end

current set. When the trigger is released, the arc will stop.

Post gasflow setting indicator (8)

Controls the period of time the shielding gas continues to flow for after the arc is stopped. This

protects the weld area and torch tungsten from contamination while it is still hot enough to react with

atmospheric gases, after the weld is finished. Unit(S) and setting range (0-10.0S).

Pulse width setting indicator (9)

Only available when pulse mode (12) is selected. Sets the time proportion as a percentage between

the peak current and base current when using pulse mode. Neutral setting is 50%, the time period of

the peak current and base current pulse is equal. Higher pulse duty setting will give greater heat

input, while lower pulse duty will have the opposite effect. Unit(%) and setting range (5-95%).

Pulse frequency setting indicator (10)

Only available when pulse mode (12) is selected. Sets the rate that the welding output alternates

between the peak and base current settings. Unit(Hz) and setting range (0.5-999Hz).

Pulse mode ‘off’ indicator (11)

Pulse mode ‘On’ indicator (12)

Clean Width Area/ AC Balance Adjustment (13)

Only available in AC welding mode (27,28,29). Adjusts the balance as a percentage between the

forward and reverse current cycles when welding in AC output mode. The reverse part of the AC

cycle gives the ‘cleaning’ effect on the weld material, while the forward cycle melts the weld

material. Neutral setting is 0. Increased reverse cycle bias will give greater cleaning effect, less weld

penetration and more heat in the torch tungsten, which gives the disadvantage of reducing the

output current that can be used for a given tungsten size, to prevent the tungsten overheating.

Increased forward cycle bias will give the opposite effect, less cleaning effect, greater weld

penetration and less heat in the tungsten.

For maximum effectiveness, ideally the clean width/ AC balance should be set with as much forward

cycle bias as possible, while still maintaining a sufficient level of oxidisation removal for a

contamination free weld pool. The cleaner non-ferrous metal is before welding, the more effective it

is to weld. This effect can also be used to reduce heat in the tungsten, allowing use of a pointed

tungsten tip shape for a more defined arc. setting range (-5-+5).

AC Frequency Adjustment (14)

Only available in AC welding mode (27,28,29). Increasing AC frequency will focus the shape of the

arc, resulting in a tighter, more controlled arc causing increased penetration and less heated

affected area for the same current setting. Slower frequency will result in a wider, softer arc shape.

Unit(Hz) and setting range (50-250Hz).

AC/DC Output Modes

DC (Direct Current) Welding Output (26)

Suitable for TIG welding ferrous (iron based) metals such as mild steel and stainless steel, copper and

titanium. TIG welding reactive metals such as Aluminium, Magnesium and Zinc requires AC

(alternating current) output. When reactive metals are exposed to air they form an oxide layer that

insulates the base metal and prevents welding current flowing, it also contaminates the weld pool.

Reverse current flow is required to break through/ clean off this oxide layer so that welding can take

place, while the current flow during the positive cycle does the majority of the heating of the

weld pool area.