OM-ST-4E/6E 9

DRAIN CONNECTION

Model Drain ID Hose Size Required

ST-4E 1.5”

ST-6E 1.5”

Level the steamer left-to-right, and pitch it slightly to the front (maximum 1/4 inch) by

adjusting the optional legs or the bullet feet on the optional stand.

There must be a free air gap between the end of the drain hose and the building drain.

The free air gap should be as close as possible to the unit drain. There must also be

no other elbows or other restrictions between the unit drain and the free air gap.

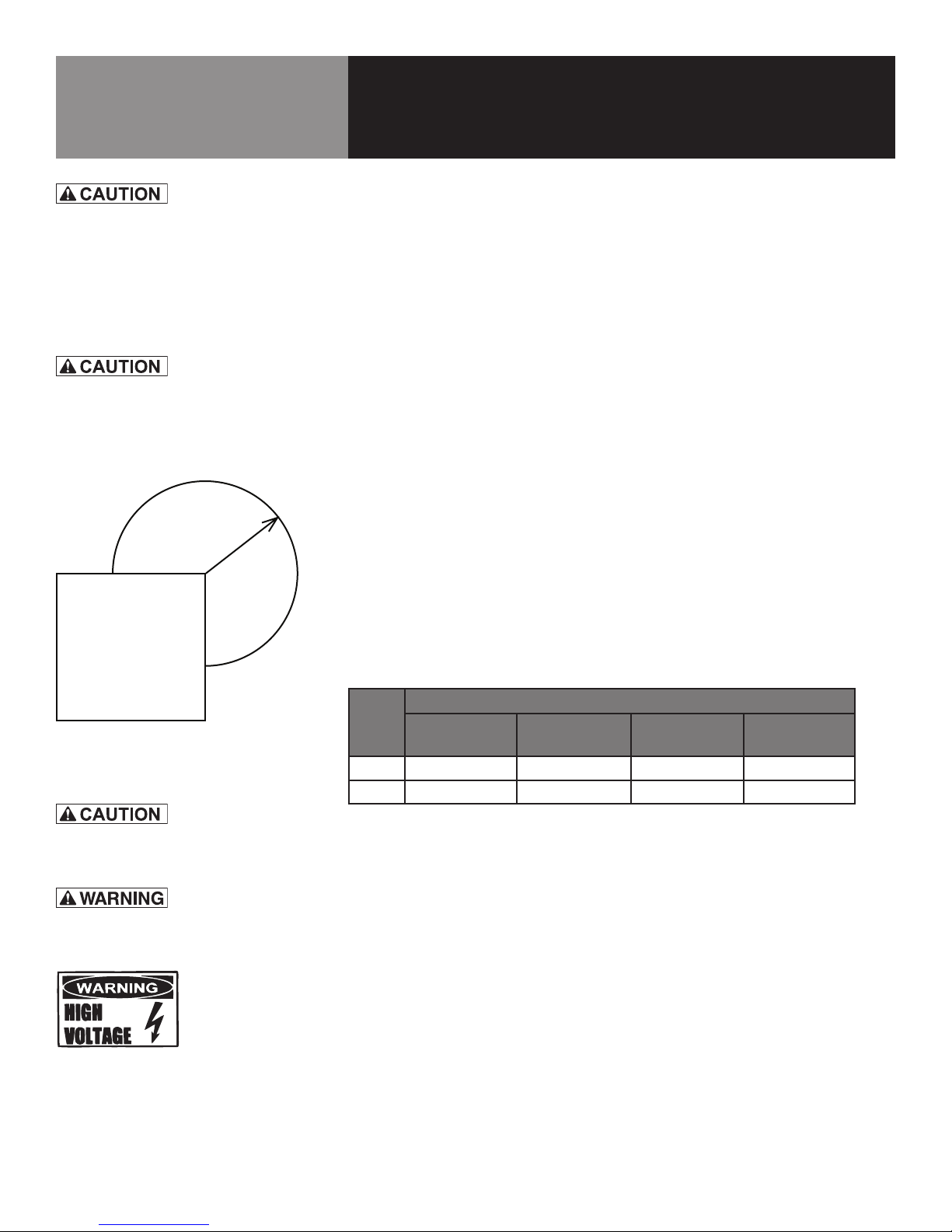

Install the drain line with a constant downward pitch (see Diagram 9-1 and 9-2 at

left). IMPORTANT: Do not allow water traps in the line. A trap can cause pressure

build-up in the cooking compartment, which may cause the door gasket to leak.

For a proper drain line connection, the drain line must have a constant downward

pitch of at least 1/4” per foot. Observe local code regarding air gap spacing and drain

connections.

COUNTER-MOUNTED UNITS

This section is applicable when the steamer will be flush-mounted to a counter. All

four edges of the bottom of the steamer must be sealed with RTV silicone sealant to

the counter if optional 4 inch legs are not used. Counter must be made of a non-

combustible material such as metal or tile.

STAND STACKED UNITS

This section is only applicable if you are installing two steamers on the optional sup-

port stand. The steamers are positioned on the top and bottom shelf that are standard

with LoLo Steamer Stands.

1. Water Connections

Separate water supply connections must be provided for each unit. At each wa-

ter inlet valve a ¾” NH connection (garden hose type) is used to supply water at

the pressure and delivery rate specified on page 5 and 8.

2. Electrical Supply Connections

Separate electrical connections are required for each steamer on the stand.

NOTE: Each steamer must have its own branch circuit protection.

3. Drain Connections

Both steamers must be leveled left-to-right; and pitched to the front (maximum

of ¼”) by adjusting the bullet feet or casters on the steamer stand. Make sure

both steamer drain connections are free-venting and slope continuously to the

floor drain.

REFRIGERATED STAND MOUNTED STEAMERS

IMPORTANT: Do not mount a LoLo Steamer on a conventional undercounter refrigera-

tor. Steamers must be placed on a refrigerated equipment stand, such as the LoLo

LRES Series, which are specifically designed to support the weight of heavy cooking

equipment; and heavily insulated to resist the heat generated by a working steamer.

Installation Instructions

DO NOT CONNECT THE DRAIN DIRECTLY

TO A BUILDING DRAIN. BLOCKING THE DRAIN

IS HAZARDOUS.

DO NOT USE PLASTIC PIPE. DRAIN MUST BE

RATED FOR BOILING WATER.

Diagram 9-1

Improper Drain Line Connection

Diagram 9-2

DO NOT PLACE A LOLO STEAMER ON

A CONVENTIONAL UNDERCOUNTER

REFRIGERATOR. THEY ARE NOT DESIGNED

TO SUPPORT THE WEIGHT OR INSULATED

AGAINST THE HEAT PRODUCED BY THE

STEAMER. FAILURE TO USE A PURPOSE-

BUILT REFRIGERATED EQUIPMENT STAND

COULD RESULT IN REFRIGERATOR FAILURE,

UNSAFE OR SPOILED FOOD AND EVEN

MELTED PLASTIC COMPONENTS IN THE

REFRIGERATOR.