Typical examples:

On a production line you get 1 pulse for

every item. You want to count number of

items.

P.in = 1

dISP = 1

P.Set = 0

In a paper mill, you want to measure

length. You have a wheel sensor which

gives 433 pulses per metre of material.

You want to count metres to 1 decimal

place (tenths of a metre)

P.in = 433

dISP = 1.0

P.Set = 0.0

7

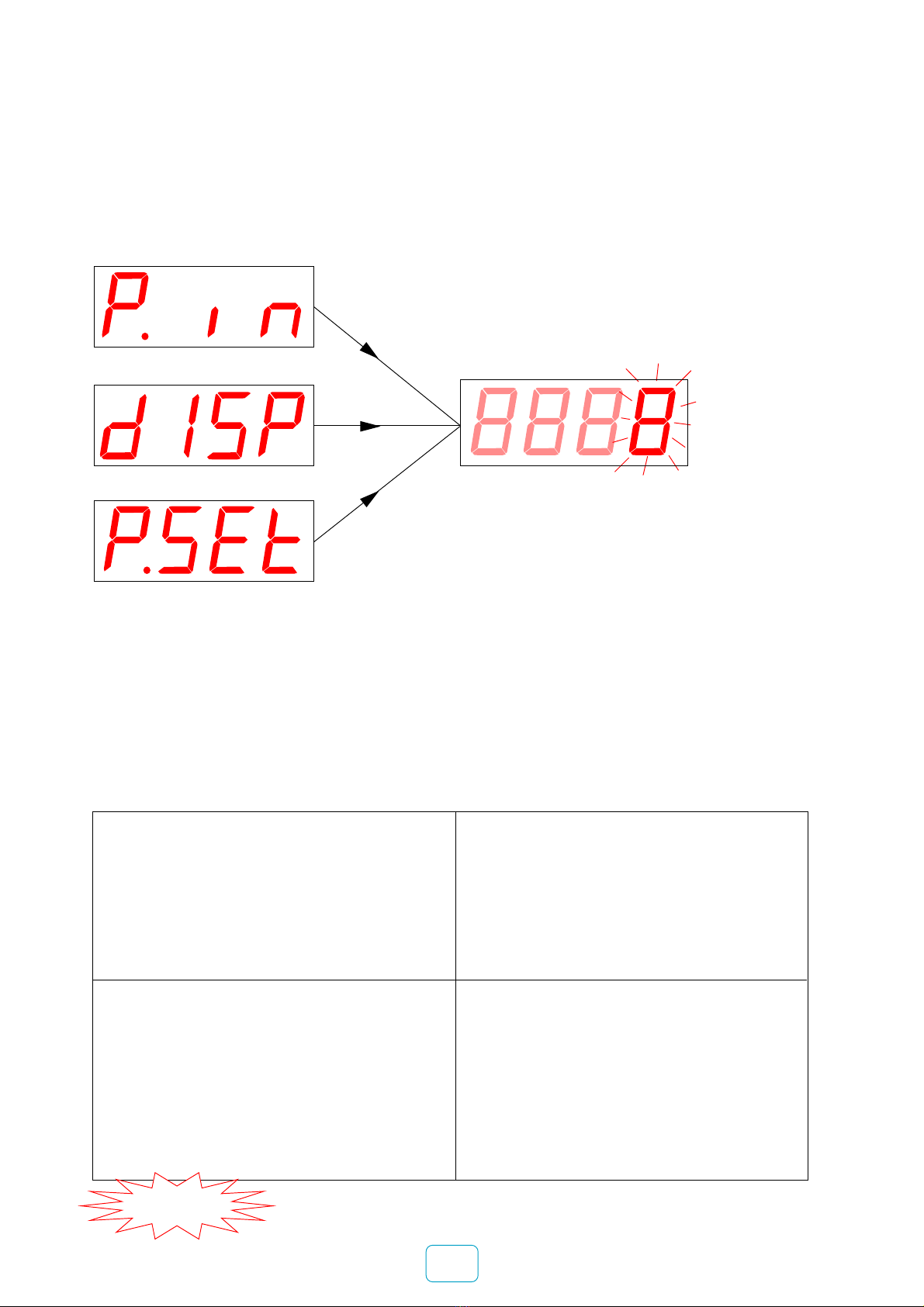

Scaling for the Counter modes 1 to 6

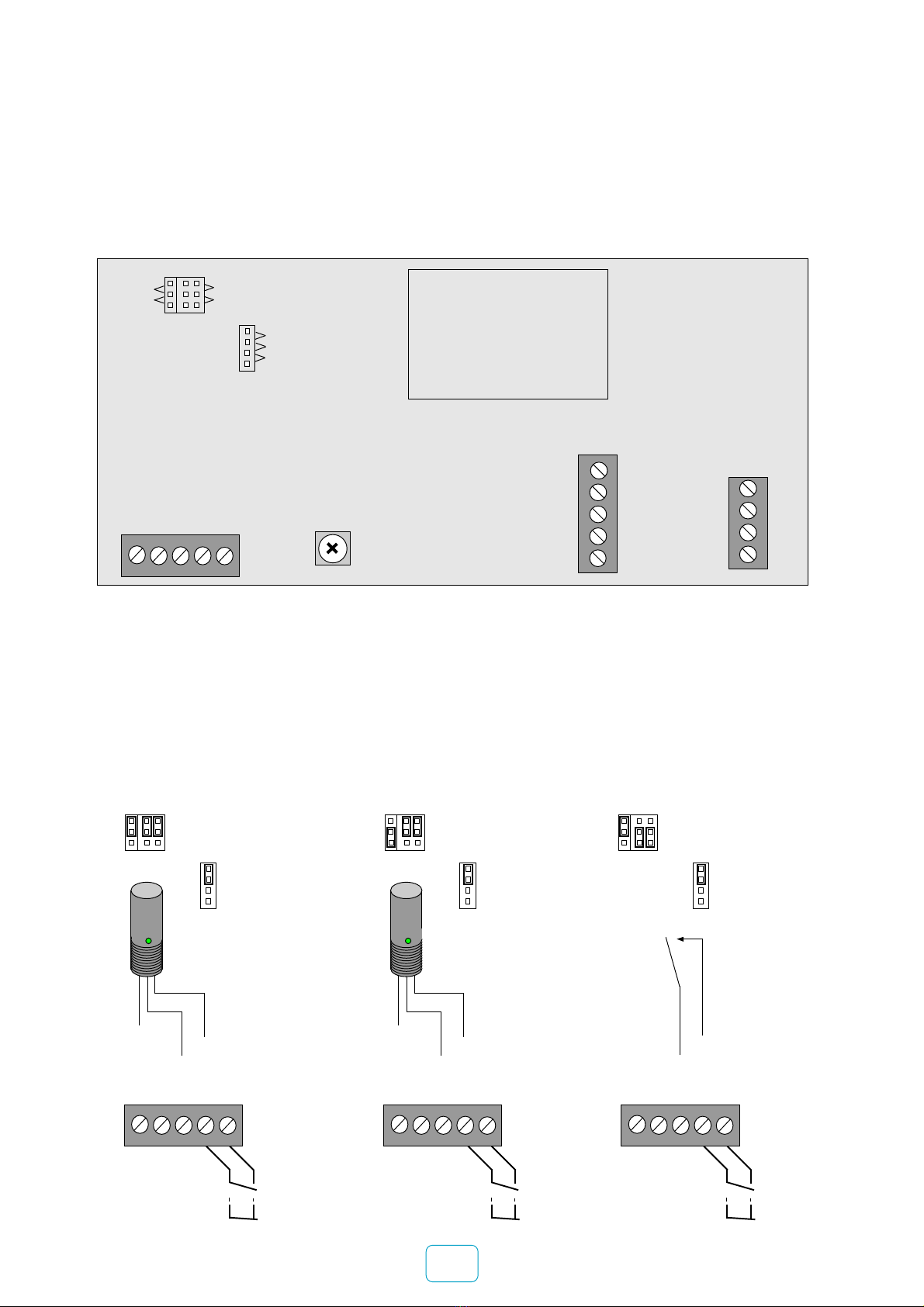

On the previous page, you saw how to select from one of 7 different modes. The first 6 modes are

all counter functions, which all have the same method of scaling.

To select a mode, you pressed OK. If you selected one of the first 6 counter modes, your display

should now show:-

You’ll see one digit brighter than

the others - this means you can

change its value with the UP or

DOWN button.

Use DIGIT button to select other

digits.

Select decimal-point with the

DIGIT button if you want to change

the decimal-point position. Move

the decimal-point with UP/DOWN

buttons.

Press OK when you have set the

whole number, to move on to the

next variable

Pulses In

Display

Preset (pre-load)

The value you can set for

each of these 3 variables

You have a rotary encoder which gives

5000 pulses per rotation (360 degrees).

You want to display degrees rotation

P.in = 5000

dISP = 360

P.Set = 0

A flow sensor gives 2345 pulses per litre

You want to count milli-litres (cc). You

want the display to start from 450 ml

P.in = 2345

disp = 1000

P.Set = 450

P.Set lets you start the counter from

some value other than 0.

For example if you wanted to fit a new

counter into a system which has

already passed 1367 litres, you

would set P.Set to 1367 and the

counter would start counting from

this value.

IMPORTANT To protect your settings, disconnect the

LOCKOUT link on the input connector.